mud pump foundation manufacturer

The HMI HM-1 hydraulic mudjacking pump was the first concrete raising product engineered and manufactured by HMI, just over 40 years ago. It’s reliability and superior engineering maintains its place in the market, but has also acted as the springboard for other, more advanced models / options which offer various options of engine horsepower, hopper size, pumping pressure, and so much more.

Our largest, self-propelled, multi-functional pump. This rugged and durable pump is the top-of-the-line mudjacking unit. With the highest available pumping pressure, largest material hopper, most horsepower and versatility.

Our most popular model, the self-propelled, hydraulic mudjacking pump drives circles around the competition. Affordable and durable, the Power Pump is a great way to start-up or add to a concrete raising business.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Black-Jack Grout Pumps, Inc. offers more than 50 years of combined experience in Slabjacking, Mudjacking, Foundation Pier Repair, grout mixing, and grout pumping.

Through our experience and technical expertise within the grout pump and mortar pump industry, we offer the latest solutions in Grout Pumping, Mud Pumping, and Concrete Pumping across a large variety of applications.

From the most versatile grout pumping system on the world-wide market, “The Black-Jack Grout Pump,” to all the necessary training and advice to make your company successful in the industry, Black-Jack Grout Pumps, Inc. has the equipment, supplies, and training you need.

Centerline Manufacturing is committed to the highest level of customer service quality. Every Centerline pump is comprehensively and repeatedly tested at diverse pressure levels to assure that it goes to our customer in perfect operational order. Centerline technicians work to ensure that our customers fully understand the operation of the model being delivered. If a customer"s pump is down, we understand the importance of timely response and parts availability. Centerline technicians will assess the problem and make repairs to bring the pump back into new specification. The Centerline mud pump technicians are well versed and qualified to operate and repair any product that is provided to the customer.

And the Chinese New Year is coming, if you need mud pumps or spare parts, please kindly prepare it in advance. Especially for Indian wholesalers, BW-600 and BW-800 mud pump"s spare parts will be a good choice for you,many of our end customers need them.

A slurry of mud and cement is pumped under the slab (depending on the amount of lift) to fill the voids created by raising the slab. During this time, all water faucets inside the house must be turned on to keep sewer lines open in case a sewer line has broken during the jacking process. All pier areas are then backfilled with sand and top soil and plants are replaced. Any concrete break-outs are patched smooth with new concrete and the entire area is given final clean-up.

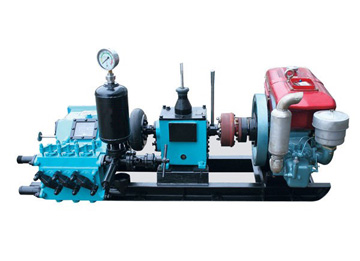

BW320 mud pump are mainly used for irrigation agricultural machinery.the main characteristic is the high pressure, lift much, less energy consumption, easy operation, high quality and durable, easy to move, especially for mountain terraces of irrigation.

BW320 type mud pump is a horizontal triplex single acting reciprocating piston pump, which has two bore and fourth gear speed. Displacement and hole depth can be adjusted according to the application, the deepest can be adjusted to the application, the deepest can be used with 1800meters drilling rig, it also can be used cement perfusion.

They are also the main equipment of the geological survey, the main role in the process of core drilling boreholes is to supply fluid(mud or water), making it circulate during drilling and carry rock waste back to the ground, in order to achieve and maintain the bottom hole clean and lubricate drill bits and drilling tools with cooling.

BW320 Mud Pumps is equipped with drilling rigs to drill holes with mud. During drilling mud pump pumps slurry to the hole to provide coat to the wall, to lubricate the drilling tools and to carry the rock debris up to the ground. It is applied to geological core drilling and prospecting drilling with depth less than 1500 meter.

Are you seeing signs of foundation problems around your home?Common structural problems include crack in brick veneer, door and window separation, expansion joint separation, cracks in walls, doors and windows that stick and cracked or uneven floors.

Over time, untreated foundation damage often gets worse, resulting in more costly repairs. If you think you have a foundation problem, it’s important to act fast.

We offer a variety of solutions for foundation repair and drainage systems.Fixing your foundation with Premier Foundation repair is easy! Simply give us a call or contact us online to schedule your free, no-obligation Structural Assessment.

To meet our rigorous specifications, each Premier Foundation repair service line has been tested in the field and represents the latest technology, developed by the finest people, using only the best available materials.

You’re researching foundation repair options and have come across the term “mud-pumping” and you want to know what it means. Or maybe you are thinking about when a foundation is lifted, what happens with the space underneath your home? There’s a void there now and does it get filled in or what?

Mud-pumping is a finishing step of foundation repair, but not every foundation repair contractor adds this final step. It’s not automatically done so you might be wondering why some companies would use this technique or what its advantages and disadvantages are.

At Anchor Foundation Repair, we have been repairing foundations since 1985 and began adding mud-pumping to all slab-on-grade foundation repairs in 1998. We decided to take every reasonable step to provide the most security and stability in foundation repairs to Brazos Valley homeowners and bought our first hydraulic mud pump at that time.

We know mud-pumping has great value and importance in a foundation repair project, it’s a standard part of our slab foundation repairs. But we can tell you about it in an objective way so that you can decide if it’s as important to you as it is to us.

We know that not everyone is trying to meet the same goals in selecting a foundation repair method or provider. We just want to give you all the information and options so that you can choose what works best for you and your home.

In a nutshell, foundation settlement coupled with foundation repair creates voids. Here’s why: a home with a slab foundation is built on the ground. Homes are heavy. Over time, the weight of the home will compress and compact the soil below it.

This initial compression causes the home to sink into the ground a bit. This is called settlement, and it’s not a bad thing unless it causesfoundation problemsfor your home.

Settlement can also occur because of the expansive clay soil we have in this area. Expansive clay expands when wet and contracts when dry. The drier the soil gets, the more it can contract, also causing a home to sink. It might not all sink evenly. This is how slab foundations can crack and possibly need repair.

Now, you could just scream into the void underneath your home. But more productively, you can consider filling it with mud-pumping material so that there is not a bunch of empty space between the bottom of your home and the earth. Mud-pumping helps lessen the opportunity for more foundation settlement or problems to arise.

Mud-pumping is not typically needed for pier and beam foundations, but for slab-on-grade foundation repair, it is an option. While mud-pumping is not *required* in foundation repair, it has many benefits for the homeowner.

So no, mud-pumping is not necessary to complete a foundation repair project, and manyfoundation repair companiesdon’t do it. Even though foundation repair contractors often skip this final step, you may want to seriously consider it. All the “whys” are in the next section.

Nature doesn’t like empty things, nature wants to fill them up. This is that “nature abhors a vacuum” thing. If the void under your home doesn’t get filled with mud-pumping material. It will very likely get filled with something else, like:

PRO #1: So one of the pros of filling voids with mud-pumping is that it takes up that empty space and prevents those areas from getting filled with something less desirable. The slurry material flows and fills every little space, permeating even the smallest pockets of air. But there are a couple more compelling reasons for you too . . .

PRO #2: Empty space creates weaker points and added stress to the foundation where it is not directly supported. Mud-pumping provides extra stability and holding power to your foundation without empty spaces under it. Having something solid underneath your whole slab is more supportive than drilled piers or pressed piles alone.

PRO #3: Mud-pumping the voids under your foundation also minimizes the risk of further movement and settling. When things are all snug and surrounded by other material, it’s less likely for them to wiggle and move around. It’s kinda like tucking your kid in at night. You burrito that little one in good with the hopes that they will stop moving and fall asleep, right?

Side Effect Bonus PRO #4: The step before mud-pumping is testing your under-slab plumbing to make sure there are no leaks. If leaks are found, they need to be fixed first. So if mud-pumping is used on your foundation repair, you will have the added comfort of knowing that there are no leaks or that they have been repaired. This is another way to make sure that further problems don’t come up later for your foundation or underneath it.

Like anything else, there are a few cons to mud-pumping as part of your foundation repair. Even though we are a fan of mud-pumping, it does have some risks and downsides that we want you to be aware of.

CON #1: Mud-pumping costs more. This is an additional step that takes added time and more materials, SO there will be extra cost to you. Mud-pumping adds between $2,000 and $4,000 to the price of your average-sized foundation repair.

CON #2 (minor): There is a small risk of over-pumping the mud and adding too much material under the home. This can cause a hump in your floor. But with an experienced team working on your foundation repair project, this has a low chance of happening. Just want you to know this is a potential problem that could happen with an inexperienced or less careful contractor.

CON #3: Just like that kid that you tucked into bed with a burrito blanket, there’s no guarantee that no more movement will take place. Mud-pumping is a safeguard, an insurance policy, a risk minimizer, but it’s not an absolute settlement solution with no potential for failure.

Like many forms of insurance or safeguards, you don’t really know if you’re going to need it or not. You might only know the value of mud-pumping afterward in hindsight since we can’t predict what will happen later with your home.

As mentioned, mud-pumping is a final step in a foundation repair project, but it has a few steps of its own to complete the process. Here’s a breakdown of how it works:Raise the foundation and secure it in place with shims

The mud-pumping process takes about half a day or small projects and several delays for larger jobs at the end of a foundation repair project. So it doesn’t add a lot of time to the job but it can add some peace of mind.

What’s the worst-case scenario if you don’t do mud-pumping? Well, you could spend thousands of dollars on a foundation repair only to have it settle all over again due to missing that final step and leaving voids under your foundation.

On the flip side, your home can still settle no matter what you do (or it might not, there’s no way to know for sure) but the risk is minimized as much as humanly possible if you add mud-pumping to the repair. This seems like a tricky decision, so let’s try and make it a little easier with some “if-then” statements.If you love your home and plan to be in it for the long haul and want the very best, get the mud-pumping.

If you are selling your home and won’t be living in it any longer, then you’re not worried about the longevity of the repair and could skip the mud-pumping.

Here’s one more “if-then” statement for you: if you want to use Anchor Foundation Repair for your slab-on-grade foundation repair project, then mud-pumping is part of the deal. We don’t leave repair projects without the last step because we also have a lifetime warranty and service agreement.

At Anchor Foundation Repair, we have seen firsthand the consequences of not filling voids after repairs in our 35 years in business. We have inspected and repaired dozens of homes that had previous foundation repairs (by other companies) without mud-pumping. We have felt the hollow-sounding floors and seen homeowners having to go through the repair process again to get it right the second time.

To get it right the first time, Anchor employs more than one “risk-minimizing” tactic to provide the longest-lasting foundation repair possible. Check out our article highlighting4 service features that set us apartfrom other foundation repair contractors.

Ewing & Ray Foundation Services, Inc. has been recognized as the premier foundation repair company since 1968. We are a proven and experienced company with working knowledge of soils and the best method(s) to repair or construct your foundation. We are not a chain franchise moving through the area offering only one product. We are a second-generation company owned by Professional Engineers committed to solving your problems.

Ewing & Ray Foundation Services, Inc. is licensed by the State Board of Contractors of Mississippi, Alabama, Louisiana and Tennessee. With over half of the projects generated by referral, we are a highly respected company with extensive knowledge of site stabilization and the most effective method(s) to repair or construct new foundation for residential, commercial, and industrial projects.

Ewing & Ray Foundation Services, Inc. is owned and operated by professional engineers. Kip Ray, P.E. is the Operations Manager, Corey Ray, P.E. is the Engineering Manager, and John Ray, is remaining on staff as the Senior Project Manager.

Our staff of well-trained and committed individuals will go the extra mile to assist the customer with the best decisions in identifying the probable cause. We will recommend the best method(s) of repair or design an engineered foundation best suited for your home or commercial building.

Ewing & Ray Foundation Services, Inc. is unique in that the company will go on-site, inspect the residence, gather elevation data and determine the cause of the failure. After the site visit we return to the office to compile the data and determine the best method of foundation repair for the residence. Then we submit a report with a correction plan and quotation to perform the work. Since we offer both professional engineering and construction expertise, you can deal with one company. Our company’s philosophy has always been based on integrity and honesty.

Our Ridgeland, MS based company executes foundation repairs, special foundations, grout pumping, drainage systems, and site stabilization. Projects range from small residences to large multi-story buildings. Helping the customer determine the probable cause of the problem and the best solution is key to our company’s success. Our Professional Engineers and employees are certified by Chance Helical Foundation Systems. Ewing & Ray Foundation Services, Inc. is licensed by the Mississippi, Alabama, Louisiana, and Tennessee State Board of Contractors and is a second-generation family owned business.

Recognizing that there are two types of foundation repairs, shallow and deep, we offer 6 foundation options to best meet your needs. Shallow systems are the most common in residential repairs. Examples of shallow repairs are concrete segmented piles, grout/mud pumping, and concrete pads, none of which should be considered a permanent fix. These are considered “shallow” because they are still leaving the load of the structure in the active soils. Our Building Code Approved deep systems include helical piers, concrete piles, and deep steel push piles installed to the stable/unweathered soils.

After lifting, we pressure grout pump all voids to support the foundation. Omitting grout pumping to cut costs will ultimately cause future foundation problems. Your home was originally designed to be supported by the soils and not point loaded on lift points, so leaving it sitting in the air may lead to future breaking of the slab or grade beams if additional loading occurs. It also prevents water intrusion and ponding under the home, which may affect the longivity of the repair or leads to future problems outside the area of the current repair.

Gaodetec is a drilling rig high pressure mud pump equipment company located in central China. We have been in business for more than 6 years. Many of our employees have over 20 years of background and experience in the design and manufacture of piston mud pumps. We can create custom packaging and modify it, as well as provide specially designed reciprocating mud pumps. We provide our customers with pumps suitable for drilling projects.

As a world-renowned manufacturer of high pressure mud pumps, we offer a wide range of high-pressure mud pumps to meet different construction needs. BW series of high-pressure mud pump is an energy saving, special structural equipment, widely used in mining, drilling, coal, railways, roads, water and hydropower, bridges, high-rise buildings, foundation reinforcement projects.

They are also the main equipment for geological surveys, and their primary role in the drilling of boreholes in the heart is to supply fluids (mud or water) that circulate during drilling and transport rock waste back to the ground to achieve and maintain bottom cleanliness and to lubricate drill bits and drills by cooling them.

1. Electric high-pressure piston double mud pump using advanced product design, reasonable structure, pressure, large flow, multi-shift variable, energy saving, small size, high efficiency, long service life, safe operation, convenient maintenance.

Gaode Equipment now has BW series three-cylinder mud pump inventory. Different flows and pressures are available. And meet the flow and pressure requirements of different projects. High-value, high-performance drilling mud pumps are ready for your project. For more information about diesel engine three-cylinder drilling mud pumps, feel free to email us at info@gaodetec.com

Centerline Manufacturing, manufacturer of aluminum hydraulic-drive mud pumps, introduces its new line of ductile iron models. The new models incorporate all the features of the aluminum models but utilize a new ductile iron pump body. The weight of the ductile iron model is about 200 pounds per pump cyclinder more than the aluminum. These pumps are available in mono, duplex and triplex models rated for 150-, 300- and 450-gpm displacements, respectively, at pressures up to 800 psi. Both the aluminum and ductile iron models will be offered concurrently. Centerline Manufacturing

8613371530291

8613371530291