mud pump in well quotation

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

Q:i have a water leak near the water pump in my 1990 cadillac deville i replaced the water pump but it was remanufactured and a pipe on the back of the water pump can it be a heater core or should i buy a brand new one p.s. water leaks after it passes the radiator

it would,nt be the heater core because it,s a good ways from the water pump. it might be that the water pump gasket slipped when you were putting it on or the by-pass hose is bad or loose. check all the hoses like both radiator hoses and where the heater hoses hook up to the block.Q:The truck has 89k on it and i"m having the timing belt done this week; would it be wise to get the pump changed since it"s in the same area, even though it"s not leaking; for preventitive maintenance purposes, or is there life left in the pump? I don"t want to take it back soon after if the pump does go out

Water pump life is a direct function of proper maintenance, therefore there is no real answer to your question. At 89k you could certainly elect to replace the WP as long as the T-Belt is also being done, but it is purely a preventive maintenance item. Might save you a lot of money later, or it might not. Impossible to say. It will give you more peace of mind though.Q:Does anyone know where to find small A/C powered submersible pumps, that operate at 20-25 psi? I can only find D/C pumps for ship use.I need one for running humidifiers and misters for large terrariums

My Husband purchased a 25 psi A/C water pump from Grangers Supply. Lift was no problem with it. Grangers is listed on the internet.Q:1997 Caravelle 1900BR3.0L HO Volvo PentaSX Cobra OutdriveI have a small leak coming from my raw water pump, it is not a continuous stream just a drop every now and then. The best I can tell it is coming from between the shaft and water pump housing. Is there just a small o-ring there? How can this be fixed?We"re going to the lake for Memorial Day Weekend. Will I be alright with the small drip for over the weekend? Then I"ll fix it when I can get the parts.

Well I don"t know what mavrick is smoking but obviously he hasn"t got a clue about a raw water pump on a volvo. He probably is on a sail boat. Here it is. There is a non replaceable seal on the shaft in the back of the pump.You have a 12 year old boat. Its time it went bad. The only way to repair it is to replace the pump. If you could get a seal from Volvo ( I will look it up in a minute) You would have to press the shaft out of the pump and this would more than likely end badly . You would end up replacing it anyway. So replace the pump , If it is just a small drip and the engine is not running hot you can run it but there is no telling when it will all of the sudden just disintegrate.Q:Is there a water pump with its own flow regulating function?

Pump with adjustable flow depends on your useThe ordinary displacement pump, which has a small flow rate, can set the flow rate per second into the system and is widely used in the laboratory.Large flow regulating flow pump is mainly variable frequency pump, through the electrical signal feedback regulation, change the pump water storage flow.The main thing is to see your flow, and then determine what you want to pump!Q:Here are specifications for two water pump sets. I would like to know which one will have more vertical suction.Pump 1:1.5 hp, 98cc Engine, 4 - Strokes RPM 3600 (Engine RPM), Petrol Fuel, Fuel Consumption 700 ml/hour, Delivery (horizontal) 50m, Inlet / Outlet Port (Dia) 1.5x1.5 inches, Output Capacity 48000 Litres / Hour.Pump 2:3.3hp, 163 cc Engine, 4 - Strokes RPM 3600 (Engine RPM), Petrol Start amp; Kerosene Run, Fuel Consumption 700 ml/hour, Delivery (horizontal) 26m, Inlet / Outlet Port (Dia) 2x2 inches Output Capacity 36000 Litres / Hour.which one should I go for.

The first one appears to have a higher flow rating but neither gives a head figure, which is the maximum height it can work to above the pump. Lift from below a pump is limited to 32ft on any form of water pump; that is the limit water will rise to with a total vacuum above it. A normal pump cannot pull a perfect vacuum so working lift will be somewhat less. The practical limit depends on the pump head in use and it"s actual head limit; the total height from the pickup point to the delivery point count as working head. Any kind of centrifugal pump or one which cannot also pump air perfectly will need a foot valve at the base of the inlet pipe and a priming system to fill the pipe and pump body with water before the pump is started. If you expect the water level to be more than 10 - 15ft down, you would be better off with a submersible pump; the only limit then is the head rating which can be just about anything. Get a suitably rated petrol or diesel generator as well (3x the pump power rating) if it must operate independently of mains power.Q:Hi -- could someone please give me information on how much I should expect to pay for a water pump and to cleanse my coolant system (or something like that) or if it"s something I really need to do. Or if I can get the water pump without the coolant system...My car is running fine, just started making kind of a rough running sound a few weeks ago when it"s idling. ANY advice is greatly appreciated!

Right..the water pump doesn"t sound like your problem. However, it would not hurt to get the cooling system totally flushed out and replaced with new fluid, if this has not been done in a long time. Might run you about...$75, just a guess. You also should really consider replacing the fuel filter, air filter, and spark plugs. This could really make a difference for you if they are old. Wouldn"t cost you but $30 for all of those parts and maybe 45 minutes labor.Q:How would you set the pressure on the tank that has the bladder in it? This is another question to the question that Peter W. answer about the private water. Well water. My water will be running and juststopped for about 2 to 3 minutes and then started back. It"s seem like it loosing pressure. I just need to know how to fix it.Q:I"m not too familiar with computerized cars, just wondering if the water pump going out would cause the car not to start?

Drain coolant, would would desire to eliminate coolant reservoir,next pull belt tensoner back and eliminate belt remembering the way its routed. next eliminate the bolts on w-pump pulley eliminate outer ring of bolts on pump. sparkling gasket setting up new one ,.bleed air from equipment to pevent overheat.desire that"s stable.Q:I think my water pump has crapped out on my 1997 Jeep Cherokee. I have been leaking coolant for a few days now and there is a puddle under my Jeep after I turn it off and my reserve tank keeps emptying out on me. I replaced the lower radiator hose and still the same problem. It is not over heating so I am wondering if it IS a water pump problem? If it is, could I do the work myself?

i doubt that your motor vehicle has 2 gas pumps yet until now you replace the pump have it examined first ! besides the pump it ought to be something else like the pump relay or the fuse ! not commencing ought to additionally be a clogged gas clear out ! getting back to the thermostat and water pump ! specific you are able to replace them in case you have the appropriate kit and your quickly vulnerable !

Ramnath Industrial Park, Rajkot Ramnath Industrial Park, Kothariya Ring Road, Beside Murlidhar Way Bridge Aaji dem, Near Ramvan, Ramnath Industrial Park, Rajkot - 360002, Dist. Rajkot, Gujarat

Amraiwadi, Ahmedabad No. 16, Bankar Estate, Near Anup Estate, Behind Bharat Party Plot National Highway No. 8, Amraiwadi, Amraiwadi, Ahmedabad - 380026, Dist. Ahmedabad, Gujarat

Shapar Veraval N.H.27, Rajkot R. S. 252, Plot No.1,2,3, Opp. Field Marshal School, Near Galaxy Bearing Ltd Shapar Kotda Sangani, Shapar Veraval N.H.27, Rajkot - 360024, Dist. Rajkot, Gujarat

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

The synchronous reciprocating motion of drilling mud pumps operating at optimized speed, symbolize the steady but continuous operations of oil exploration and production. ShalePumps, as a recognized quality producer of high quality drilling mud pumps constantly strives to pull out an improvised and operation enhancing equipment from the assembly lines. SP-2200L drilling mud pumps are an instance of enhanced engineering and precision.

Firing optimized pump speeds, and comprising of superior materials, the drilling mud pumps are designed to operate effortlessly. To enable easy replacement of high wear components, the design incorporates a fast access mechanism, to reduce downtime.

The drilling mud pumps have been developed and manufactured by factoring in the structural demands as a result of long runs. The components are manufactured from superior materials like high strength steel frames, forged steel crankshaft, metal liners and high capacity bearings.

The combination of tested materials and engineering excellence has helped ShalePumps to consistently deliver the needs of the industry in advance. The drilling mud pumps perform in mechanical harmony to standards that overrun industry performance parameters such as displacement and pressure. At ShalePumps, the desired parameters of performance of pumps are by default, pegged higher than industry requirements.

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

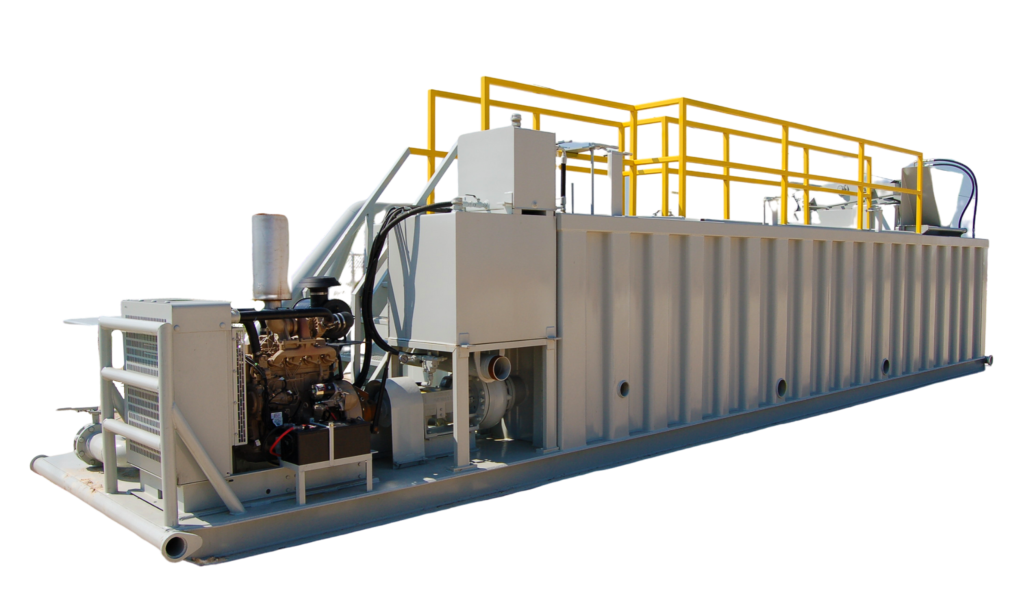

Having a quality mud pump is a critical part of keeping your oil well drilling system running as smoothly as possible. Dragon carries a wide range of mud pumps for systems of all kinds and jobs of all sizes. We also carry a 50 BPM mud mixing table to make drilling fluid mixing more efficient and accurate so you can always get the job done safely and correctly. View our full well service pump and mud pump selection to find the right system for your job site, or check out the rest of our drilling rigs for even more options.

The policy set forth below outlines the personal data that Power Zone Equipment may collect, how Power Zone Equipment uses and safeguards that data, and with whom we may share it. This policy is intended to provide notice to individuals regarding personal data in an effort to be compliant with the data privacy laws and regulations of the jurisdictions in which Power Zone Equipment operates.

Power Zone Equipment encourages our employees, independent contractors, customers, suppliers, commercial visitors, business associates, and other interested parties to read this policy. By using our website or submitting personal data to Power Zone Equipment by any other means, you acknowledge that you understand and agree to be bound by this policy, and agree that Power Zone Equipment may collect, process, transfer, use and disclose your personal data as described in this policy.

Power Zone Equipment is committed to maintaining all reasonable precautions to ensure the privacy and security of personal data gathered by Power Zone Equipment. During your use of our website or through other communications with Power Zone Equipment, personal data may be collected and processed by Power Zone Equipment. In general, Power Zone Equipment collects personal contact information (e.g. name, company, address, telephone number and e-mail address), which you knowingly provide either by registration, requesting quotes, answering questions or otherwise for use in our commercial relationship. At times we may collect additional personal data that you voluntarily provide, including, but not limited to, job title, additional contact information, date of birth, hobbies, areas of interest, and professional affiliations.

Power Zone Equipment’s website is intended to be used by Power Zone Equipment customers, commercial visitors, business associates, and other interested parties for business purposes. Personal data collected by Power Zone Equipment through its website or by other means is used in support of our commercial relationship with you, including, but not limited to, the processing of customer orders, orders from vendors, managing accounts, learning about customers’ needs, responding to inquiries, and providing access to information. Also, in compliance with the laws and regulations of the relevant jurisdiction to support our relationship with you:

we may use third party service providers to assist us in collecting, assembling or processing personal data in connection with services related to our business relationship;

we (or a third party on our behalf) may use personal data to contact you about a Power Zone Equipment offer in support of your business needs or to conduct online surveys to understand better our customers’ needs; and

If you choose not to have your personal data used to support our customer relationship (especially direct marketing or market research), we will respect your choice. We do not sell your personal data to third parties, nor share it with third parties except as set forth in this policy. Power Zone Equipment will retain your personal data as long as you maintain a customer relationship with Power Zone Equipment and/or if you have registered to receive marketing or other communication from Power Zone Equipment, until such time as you request that we delete such personal data.

Power Zone Equipment is the commercial operator of its website and uses service providers to assist in hosting or otherwise acting as data processors, to provide software and content for our sites and to provide other services. Power Zone Equipment may disclose personal data supplied by you to these third parties who provide such services under contract to protect your personal data. In addition, where consistent with the laws and regulations of the relevant jurisdiction, Power Zone Equipment may disclose personal data if such disclosure:

For our customers in Switzerland and the European Union (EU), please note that Power Zone Equipment is a US based company. If you use our websites or web portals or, all information, including personal information, may be transferred to Power Zone Equipment (including subcontractors that may be maintaining and/or operating our website) in the United States and elsewhere and may be transferred to third parties that may be located anywhere in the world. Although this may include recipients of information located in countries where there may be a lower level of legal protection for your personal information than in your location country, we will protect your information in accordance with requirements applicable to your information and/or location. Specifically, for data transfers out of the EU, Power Zone Equipment will utilize data transfer agreements containing the Standard Contractual Clauses. By using our websites or web portals, you unambiguously consent to the transfer of your personal information and other information to the United States and elsewhere for the purposes and uses described herein.

When you access Power Zone Equipment’s websites or web portals, we may automatically (i.e., not by registration) collect non-personal data (e.g. type of Internet browser and operating system used, domain name of the website from which you came, number of visits, average time spent on the site, pages viewed). We may use this data and share it with our worldwide affiliates and related service providers to monitor the attractiveness of our websites and improve their performance or content. In this case, processing is performed on an anonymous basis and at Power Zone Equipment’s discretion.

In addition, certain online technical applications or other interactions you have with Power Zone Equipment may require the entry of business and technical data. By providing the requested information, you are consenting to the processing and storage of such information by Power Zone Equipment. Unless Power Zone Equipment is advised that you want this information removed from Power Zone Equipment’s server, such information may be retained by Power Zone Equipment and used for future commercial communications. A request for removal of this information can be made at the contact information provided below. Power Zone Equipment will take all reasonable precautions to assure that no such information will be provided or divulged to other third parties, except, if applicable, those third parties performing site hosting, maintenance, and related site service activities.

Cookies are information stored automatically on a website user’s computer. When a user views Power Zone Equipment’s website(s), Power Zone Equipment may store some data on the user’s computer in the form of a “cookie” to automatically recognize the user upon future visits to Power Zone Equipment’s website(s). Power Zone Equipment will make reasonable efforts to ensure compliance with the laws and regulations of relevant jurisdictions with regard to cookies.

Power Zone Equipment will not knowingly collect personal data from children under the age of 18. Power Zone Equipment’s website(s) is not intended for individuals under 18 years of age

Power Zone Equipment will take reasonable precautions to protect personal data in its possession secure against the risk of loss, misuse, unauthorized access, disclosure, alteration and destruction. Power Zone Equipment periodically reviews its security measures in an effort to ensure the privacy of personal data.

Power Zone Equipment will use personal data only in ways that are compatible with the purposes for which it was collected or subsequently authorized by you. While Power Zone Equipment will take reasonable steps to ensure that personal data is relevant to its intended use, accurate, complete, and current, Power Zone Equipment is also relying upon each individual to assist in providing accurate updates of his or her personal data.

Power Zone Equipment website(s) may contain “links” to websites owned and operated by third parties. By accessing these links, which are provided for your convenience, you will leave our site and will be subject to the privacy practices of the other website. This policy does not apply to any personal information you provide to unrelated third parties.

In general, Power Zone Equipment will only retain personal data for as long as needed for the specific purpose of processing and in accordance with Power Zone Equipment’s records management policy, or as otherwise required by the laws and regulations of a particular jurisdiction. For example, data will be retained during the time period that you are authorized to use Power Zone Equipment website(s), including any Power Zone Equipment tools accessible through our website(s). Upon termination of such authorization, your personal data related to use of Power Zone Equipment website(s) will be removed.

Upon request, Power Zone Equipment will grant individuals reasonable access to personal data that it holds about them. In addition, Power Zone Equipment will take reasonable steps to permit individuals to correct, amend, or delete information that is demonstrated to be inaccurate or incomplete. Power Zone Equipment also relies upon each individual to assist in providing accurate updates of his or her personal data. In order to access, correct, amend, or delete the personal data Power Zone Equipment holds about an individual, the individual should contact the following:

If your personal data is processed in the EU or you are a resident of the EU, the EU General data Protection Regulation grants you certain rights under the law. In particular, the right to access, correct, or delete the personal data Power Zone Equipment holds about you.

To the extent required by applicable law, Power Zone Equipment will grant individuals reasonable access to personal data that Power Zone Equipment holds about them and will take reasonable steps to permit such individuals to correct, amend, or delete information that Power Zone Equipment holds about them. Power Zone Equipment also relies upon each individual to assist in providing accurate updates of his or her personal data. In order to access, correct, amend, or delete the personal data Power Zone Equipment holds about an individual, the individual should contact his or her Power Zone Equipment commercial contact or contact us at the following email address:sales@powerzone.com.

If you have a comment, question, or complaint about how Power Zone Equipment is handling your personal data, we invite you to contact us in order to allow us to resolve the matter. In addition, individuals located in the EU may submit a complaint regarding the processing of their personal data to the EU data protection authorities (DPAs). The following link may assist you in finding the appropriate DPA:http://ec.europa.eu/justice/data-protection/bodies/authorities/index_en.htm.

Power Zone Equipment reserves the right to modify this policy from time to time in order that it accurately reflects the legal and regulatory environment and our data collection principles. When material changes are made to this policy, Power Zone Equipment will post the revised policy on our website.

Humble Industries, Inc. is an independent manufacturer of replacement parts. Humble Ind. is neither a licensee, nor is it affiliated with any of the original equipment manufacturers named above. The manufacturers names or trademarks used herein are solely for identification purposes and are not intended by Humble Ind. to cause confusion as to the source, sponsorship, or quality of the parts manufactured by Humble Ind. The original manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Humble Ind. products.

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

We have designed affordable annual subscription plans which would help you get leads for your business. You can have a look at our pricing chart by clicking on this link: https://www.energydais.com/pricing/ . These plans are customized according to the specific needs and requirements of your business.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

Yes. We use third-party companies to provide best quotations for your shipment and inspection of manufactured goods. We make sure that you get quality products from the manufacturer at the best price.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

8613371530291

8613371530291