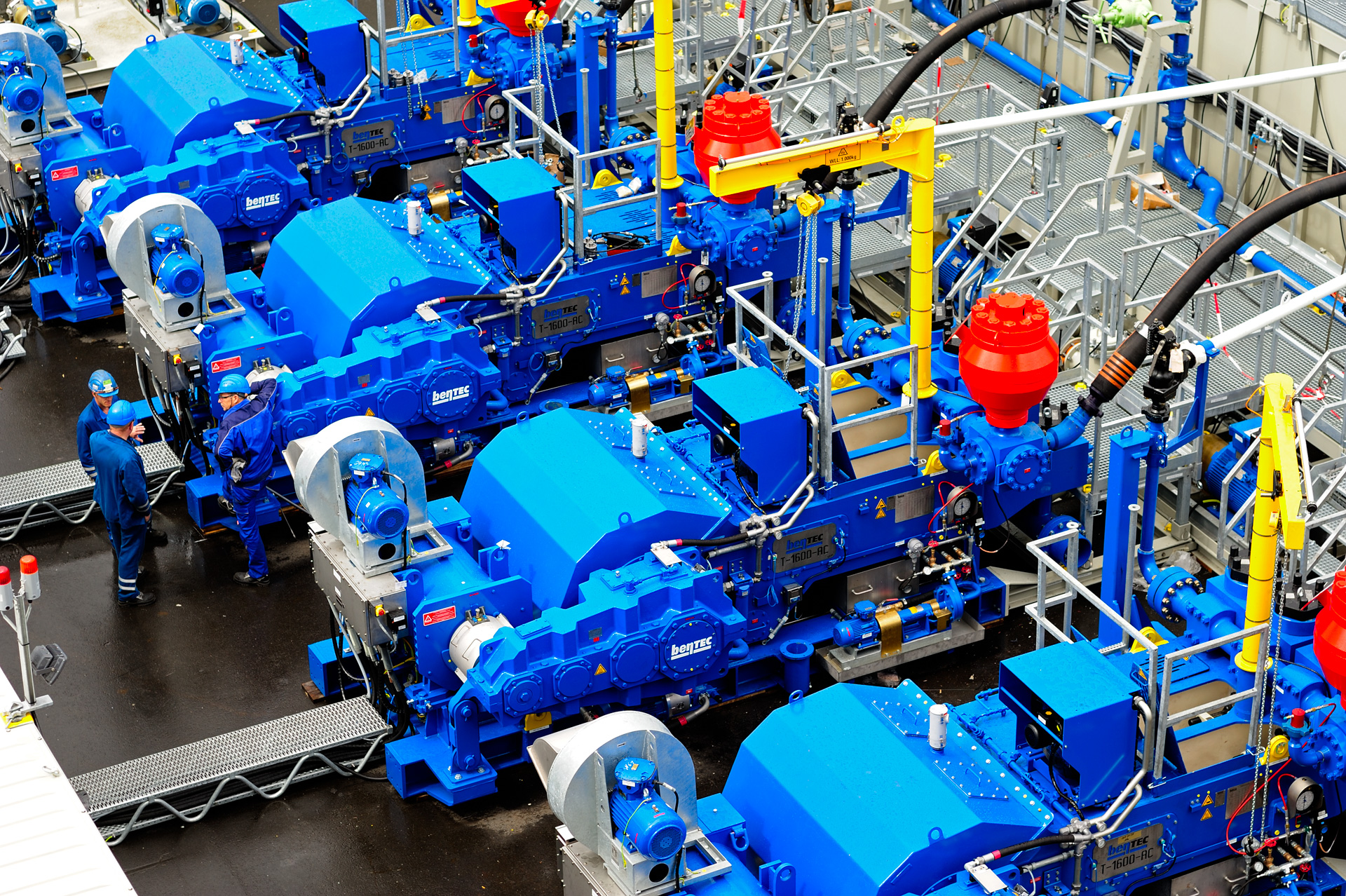

mud pump inspection factory

Our Inspection team is formed of professionals from the OEM environment: Quality Experts with solid experience in OEM & API Standards to ensure the inspection is meeting requirements and your expectations.

Our core team is formed of Field service, Assembly, Manufacturing Technicians, Engineering & Quality Assurance that have previously worked for mud pumps manufacturing product line.

American Mud pump services provides an outstanding on-site inspection of your mud pumps. Our Field service Technicians in conjunction with our Quality Engineering team determine the current condition of internal components from inspection for wear, cracks and damage to critical components such as bearings, bull gear, pinion, conrods and crossheads, assuring maximum performance of your mud pumps.

Instead of using paper checklists when out in the field, drilling contractors and rig inspection services can generate a new inspection form from anywhere and the results are saved electronically.

Specifically designed for drilling companies and others in the oil and gas industry, the easy to use drilling rig inspections app makes it easy to log information about the drill rigs, including details about the drill rigs operators, miles logged and well numbers. The inspection form app covers everything from the mud pump areas and mud mixing area to the mud tanks and pits, making it easy to identify areas where preventative maintenance is needed. The drilling rig equipment checklist also covers health and safety issues, including the availability of PPE equipment, emergency response and preparedness processes, and other critical elements of the drilling process and drill press equipment.

Since 2001, TSC Manufacturing and Supply, LLC has been a leading global manufacturer and supplier of fluid end expendables, as well as mud pump spare parts for oilfield applications. Today, we continue to keep our proud tradition of excellence going, as we strive to better ourselves in order to better our customers" experience. Our global network of inventory locations provides unrivaled quality, customer service, on-time delivery, and unmatched technical integrity.

When it comes to mud pump fluid end expendable parts, TSC Manufacturing and Supply, LLC, has it all. TSC can, and will, match your needs, so that you won’t be lacking in anything. TSC mud pump liners are designed and manufactured to meet or exceed original equipment specification and API standards for almost all types of mud pumps in use today. With advanced technology, metallurgical control, and rigid inspection, we offer unmatched performance and durability, according to customer testimonies, in the most severe drilling conditions; both triplex and duplex liners are available in a wide range of sizes.

What sets us apart? Superior customer service. Laser-focused expertise. And, of course, our comprehensive line of pumps—from the industry-standard E-447

ShalePumps, LLC adheres to its reliability promise, ensuring testing standards are in compliance with the most current industry regulations. The ShalePumps, LLC team puts our products through the highest degree of scrutiny – we stand by our work.

During our manufacturing and assembly process, we maintain a strict format that has been critical to ensuring product quality. If any material defects or assembly situations arise because of this process, we correct the matter immediately and record the occurrence for future planning. After complete pump assembly and final inspections, the pumps are cycle tested to assure quality of design and materials.

ShalePumps, LLC is committed to protecting the health and safety of all individuals affected by our activities, including our workforce and the public. We will not compromise the health and safety of any individual in conducting our projects. We will provide a safe and healthy working environment and will expect our workforce to comply with the health and safety practices established for their protection. We will safeguard the environment and will operate in a manner consistent with recognized American industry standards regarding the environment, health and safety.

Mud pumps are the heart of a drilling operation. TSM designs and manufactures extremely reliable and easy-to-maintain mud pumps, eliminating unnecessary maintenance and downtime.

Mud pumps are the heart of a drilling operation. TSM designs and manufactures extremely reliable and easy-to-maintain mud pumps, eliminating unnecessary maintenance and downtime.

Created specifically for drilling equipment inspectors and others in the oil and gas industry, the Oil Rig Mud Pump Inspection app allows you to easily document the status and safety of your oil rigs using just a mobile device. Quickly resolve any damage or needed maintenance with photos and GPS locations and sync to the cloud for easy access. The app is completely customizable to fit your inspection needs and works even without an internet signal.Try Template

Fulcrum helps us improve our processes and make our work environment safer by streamlining inspections, surfacing inspection-related insights, and managing follow-up actions. Once you close the loop from action to insight to further action, the possibilities are limitless.

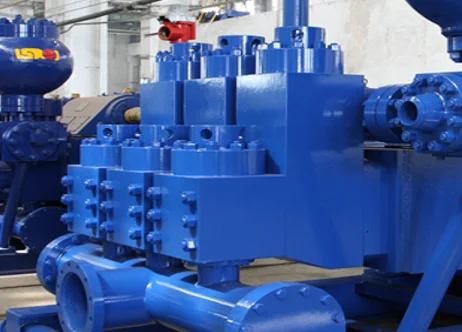

Whether onshore or offshore, well drilling sites rely on a multitude of systems to successfully perform the drilling operation. The mud pump is a key component tasked with circulating drilling fluid under high pressure downhole. The mud pump can be divided into two key sections: the power end or crosshead and the fluid end. Proper alignment of the pump’s crosshead to the fluid end liner is necessary to maximizing piston and liner life. Misalignment contributes to

accelerated wear on both the piston and the liner, and replacing these components requires downtime of the pump. Traditional methods of inspecting alignment range from using uncalibrated wooden rods, Faro Arms and micrometers to check the vertical and horizontal alignment of the piston rod OD to the piston liner ID. These are time consuming and cumbersome techniques that are ultimately not well suited to troubleshoot and solve alignment issues.

A “Mud Pump Laser Alignment Kit” enables you to measure where the piston will run through the liner at various positions along the pump’s stroke. It will also project a laser centerline from the fluid end back towards the rear power end of the pump that can be used to determine how much shimming is required to correct any alignment issues. The kit can include either a 2-Axis receiver or a 4-Axis which accepts the laser beam and documents where it falls on the active surface of the receiver. The 4-Axis receiver can decrease alignment time by as much as 50% as it will measure angularity as well as X and Y while the 2-Axis does not and will need multiple measurement locations to get the same information. In addition, the alignment system is a non-intrusive service requiring the removal of only the piston rod which allows for much quicker service and less down time on the pump. As the mud pumps in question are located globally both on and offshore, having a small, portable system is another great advantage. Our recommendation would be Pinpoint laser System’s “Mud Pump Alignment Kit”. They are being used by many of the leading repair service companies and have been their main alignment tool for over 15 years. Manufacturers are also utilizing these for new pump set-up.

Mud King Products offers a full line of Triplex Mud Pumps from 165HP to 1600HP. All of our P Series as well as F Series are fully interchangeable with the OEM. All MKP pumps are manufactured under API License. Our pumps are thoroughly inspected at the plant and a second quality inspection is performed in the USA.

The X-series mud pump type PD X-3.004 SG HDD manufactured by PRIME DRILLING impresses with its robust and low-wear design. The 7-fold bearing mounted drive shaft, which is equipped with 3 eccentric wheels, replaces the conventional crankshaft. Due to the revolution of these shafts and their maximum 230 rotations per minute operational wear of rubbers and liners are reduced to a minimum.

The pump is driven by a 470 kW CAT engine. This type of mud pump is exclusively manufactured in our Wenden plant, i.e. „made in Germany“. Its electronic gearshift in combination with eccentric wheels used instead of a crankshaft make it a high- power but low- maintenance product. All valves and plungers also comply with API standards.

8613371530291

8613371530291