mud pump lubrication supplier

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

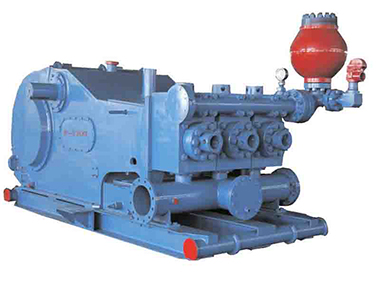

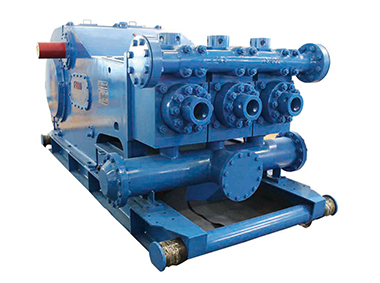

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

We also served as the acting shop and field repair representative for the Western Gear Company and as a manufacturing facility for Wilson Manufacturing Company based in Wichita Falls, Texas. Wilson was a manufacturer of well service rigs and mud pumps. SMC Inc. has served and currently serves as a manufacturing and repair center for Oil Well Supply, Cabot-Franks, National, Halliburton, The Western Company, B.J. Hughes, Gardner Denver and many others. We manufacture a triplex pump of 165 H.P. with parts interchangeable to the Gardner Denver model TEE and are currently developing a 500 H.P. pump with parts interchangeable to Oilwell"s SA-644-5 pump. SMC has a large warehouse full of quality replacement parts for various types of equipment such as Triplex Plunger Pumps, Mud Pumps, Swivels, Drawworks and Rotaries.

We manufacture positive displacement pumps and replacement parts vital to the oil industry worldwide. We have customers that include both domestic and foreign oil companies. We also manufacture and repair a variety of products used in routine maintenance by customers with rock crushers, aggregate and commercial cement manufacturing plants.

Titan Oil Tools offers high quality mud pump expendables and mud pump replacement parts for the wide variety of mud pumps, centrifugal pumps found on the world market today. These quality pump parts offer great performance and our pricing will save you money.

We are your oilfield supplier of choice for mud pump spares and mud pump parts: mud pump piston liners and pistons. All mud pump parts can be sourced for fast delivery; Come to us for mud pump liners, pistons, piston rods and parts, pony rods, threaded rings and caps,and more. Try us for duplex and triples pump spares and duplex and triplex mud pump parts, and also valve parts like valve seats. gland nut, and mud pump gaskets.

Mud pump liners may come in chrome, alumina ceramic and zirconia ceramic. Chrome liners and alumina ceramic liners are less costly, their cost of replacement over one year as the chart below shows, is much more than zirconia ceramic liners.

The table below shows a Mud Pump Liner Cost of Ownership which shows a reasonable cost comparison for a rig in continuous service for 36 months. This of course does not include the high cost of maintenance downtime and the cost of labor.

The prices below are based on cost/cylinder. Savings increase when you add up the number of pump cylinders on your rigs and extend the savings to understand the big difference it can make for your budget.

Bentec completely redeveloped the concept of Mud Pumps. Being equipped with a direct-driven gearbox, an own developed motor, and a state-of-the-art pump housing, there is no need for an internal gear coming with many disadvantages and no more belt tensioning.

Bentec Mud Pumps are light weight and have a small footprint. The AC-powered motor is top or rear mounted – suitable for any drilling rig arrangement. The pump is available with 5 000 or 7 500 psi fluid ends, and all its parts that are subject to wear and tear meet API standards and are available worldwide.

A handling crane makes it easy to handle the fluid end components. Furthermore, Bentec uses a patented liner and valve clamping technology to reduce the maintenance time significantly. A quick-change liner and piston system serves for easy maintenance. A special feature of the Bentec MUD PUMP is the side-mounted gear drive.

Liner cooling and gear oiler systems are included; a supercharge pump and a noise reduction package can be installed upon request. The Bentec MUD PUMP is the right choice especially when it comes to noise-sensitive environments such offshore or densely populated environments.

Beyond the supply of Mud Pumps, Bentec acts as system supplier. The pumps can be delivered together with a Bentec Power Control System and a Bentec Soft Pump System.

A wide variety of oil drilling mud pumps options are available to you, such as 1 year, not available and 2 years.You can also choose from new, used oil drilling mud pumps,As well as from energy & mining, construction works , and machinery repair shops. and whether oil drilling mud pumps is 1.5 years, 6 months, or unavailable.

A wide variety of oil drilling mud pump parts options are available to you, such as 1 year, not available and 2 years.You can also choose from new, oil drilling mud pump parts,As well as from energy & mining, construction works , and machinery repair shops. and whether oil drilling mud pump parts is 1.5 years, 6 months, or unavailable.

Payment Terms: L/C,D/A,D/P,T/T,Western Union,MoneyGram,Paypal; Pressure: 0-25Mpa; Warranty: 1 year; Application: Mud; Dimension(L*W*H): Requirement; After-sales Service Provided: Overseas third-party support available; Warranty: 1 Year; Head: 10~130m; Supply Ability: 10 Set/Sets per Day;...

Working pressure: 0.20~0.45Mpa; Production Capacity: 200-260 M3/h; Warranty: 1 Year; Dimension(L*W*H): according to different model type; Certification: API ISO CE; Place of Origin: Henan China; Application: Slurry Mud; Application: Mud and sand purification system; Model Number: ZCQ; Supply...

Advantage: Competitive; Engine: electric, diesel; Usage: equipped with Drill rig; Local Service Location: Thailand,Colombia; Type: mud pump; Showroom Location: Peru,South Africa; Pump power: electric or diesel engine; mud pump model: BW160,BW150,BW250,BW200,BW450; Payment Terms:...

brand: Exceed Health status: new Core components: PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump place of origin; place of origin: Shandong China Motor Power: 2*2.2kW Video external inspection: if Core Components Warranty: 1 year Discharge capacity: 42 L/sec Warranty: 12 months...

application: Stainless Steel Casting and Machining Applicable industries: Mud Pump Spare Parts model: f800/1000 color: Require type: part Supply capacity: 100,000 sets per month After-sales service provided: Online support Marketing Type: New Products 2021 standard: international standard Serve:...

maximum. flow: 250L/min Marketing Type: Hot Products of 2019 Packaging Details: Plywood case or sell as your request BW250 Powerful Small Triplex Mud Pump Drilling Mud Pump theory: reciprocating pump Core Components Warranty: 1 year Suction pipe diameter: 76mm Supply capacity: Annual output of 500..

Mud Balance: YM-2 Packaging Details: carton brand: Haitongda Supply capacity: 1000 sets per year Sand Content Kit: ZNH-1 Material: Stainless steel Certification: other model: F port: Qingdao place of origin; place of origin: Shandong China payment terms: wire transfer, cash Marsh Funnel Viscometer:.

Marketing Type: Hot Products of 2022 weight: 100 kg payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram brand: Canon Major equipment: Jet mixer, agitator, centrifugal pump, mud mixing system Bottom gun: DN80-1 Core components: tank Mechanical test report: if Origin: China Health status: new.

Supply Ability: 1000 Set/Sets per Month; Model Number: BW150; Packaging Detail: Exporting package; Port: QingDao; Payment Terms: T/T,Western Union; Introduction of BW150 Horizontal Triplex Piston Drilling Mud PumpBW150 Horizontal Triplex Piston Drilling Mud Pump is a reciprocating single-acting...

Place of Origin: Shandong China; Certification: API ISO; Port: Qingdao/Shanghai; Model Number: F/3NB; Brand: BEYOND; MOQ: 1 set; Core Components: Engine,Motor,Pressure vessel,Pump; Local Service Location: Egypt,India,Argentina,Kazakhstan,Uzbekistan; Warranty of core components: 1 Year; Video...

port: Qingdao, Ningbo, China Supply capacity: 100 sets per day Water absorption height (m): 2.5 Core component warranty: 1 year Product number: 250 type Required power (Kw): 15 Pump speed (min-1): 200 Showroom location: United Kingdom, Chile, Australia Applicable industries: Manufacturing plants,...

Port: QingDao; Type: Drilling mud Pump; Supply Ability: 1000 Set/Sets per Month; Model Number: BW160; Packaging Detail: Exporting package; Payment Terms: T/T,Western Union; Product Name: Drilling mud Pump; Introduction of BW160 Hydraulic Triplex Plunger Drill Rig Mud PumpBW160 Hydraulic Triplex...

Supply Ability: 500 Piece/Pieces per Month; Warranty: 6 Months; Condition: New; Payment Terms: L/C,D/A,D/P,T/T,Western Union; Model: F series; Model Number: mud pump parts&accessories; Certification: API; Color: Customer Specifications; Place of Origin: Shandong; Packaging Detail: packed in...

Port: Xingang; Dimension(L*W*H): 2419x2113x2147 (MM); Screen Qty: 3; Payment Terms: L/C,D/A,D/P,T/T,Western Union,MoneyGram; Model Number: GNZJ703F-3S16NF; Vibrating Mode: Linear Motion; Brand Name: GN Solids Control; Name: Mud Cleaning System; Production Capacity: 100%; Desander Cone: 10";...

Type: screw pump; Applicable Industries: Energy & Mining,oil,drilling,mud; size: 3270*370*665mm; Supply Ability: 30 Set/Sets per Month; MOQ: 1 SETS; Port: Tianjin; color: green,blue; Model Number: 21; Payment Terms: T/T; Name: Screw pump; Model Flow (m³/h) Pressure (Mpa) Max speed (RPM) Motor Po

Supply Ability: 500 Set/Sets per Year; Payment Terms: L/C,D/A,D/P,T/T,Western Union; Model Number: Size Mud Tank; Dimension(L*W*H): Model; Place of Origin: Shaanxi China; Power(W): 500; Name: Desander Cyclone; Usage: Mud Cycling; Weight: 1200 KG; Port: Tianjin/Qingdao/Shanghai; Production Capacity:.

Many things go into getting the most life out of your mud pump and its components — all important to extend the usage of this vital piece of equipment on an HDD jobsite. Some of the most important key points are covered below.

The most important thing you can do is service your pump, per the manufacturer’s requirements. We get plenty of pumps in the shop for service work that look like they have been abused for years without having basic maintenance, such as regular oil changes. You wouldn’t dream of treating your personal vehicle like that, so why would you treat your pump like that.

Check the oil daily and change the oil regularly. If you find water or drilling mud contamination in the oil, change the oil as soon as possible. Failure to do so will most likely leave you a substantial bill to rebuild the gear end, which could have been avoided if proper maintenance procedures would have been followed. Water in the oil does not allow the oil to perform correctly, which will burn up your gear end. Drilling mud in your gear end will act as a lapping compound and will wear out all of the bearing surfaces in your pump. Either way it will be costly. The main reasons for having water or drilling mud in the gear end of your pump is because your pony rod packing is failing and/or you have let your liners and pistons get severely worn. Indication of this is fluid that should be contained inside the fluid end of your pump is now moving past your piston and spraying into the cradle of the pump, which forces its way past the pony rod packing. Pony rod packing is meant to keep the oil in the gear end and the liner wash fluid out of the gear end. Even with brand new packing, you can have water or drilling fluid enter the gear end if it is sprayed with sufficient force, because a piston or liner is worn out.

There is also usually a valve on the inlet of the spray bar. This valve should be closed enough so that liner wash fluid does not spray all over the top of the pump and other components.

Liner wash fluid can be comprised of different fluids, but we recommend just using clean water. In extremely cold conditions, you can use RV antifreeze. The liner wash or rod wash system is usually a closed loop type of system, consisting of a tank, a small pump and a spray bar. The pump will move fluid from the tank through the spray bar, and onto the inside of the liner to cool the liner, preventing scorching. The fluid will then collect in the bottom of the cradle of the pump and drain back down into the collection tank below the cradle and repeat the cycle. It is important to have clean fluid no matter what fluid you use. If your liners are leaking and the tank is full of drilling fluid, you will not cool the liners properly — which will just make the situation worse. There is also usually a valve on the inlet of the spray bar. This valve should be closed enough so that liner wash fluid does not spray all over the top of the pump and other components. Ensure that the water is spraying inside the liner and that any overspray is not traveling out of the pump onto the ground or onto the pony rod packing where it could be pulled into the gear end. If the fluid is spraying out of the cradle area and falling onto the ground, it won’t be long before your liner wash tank is empty. It only takes a minute without the cooling fluid being sprayed before the liners become scorched. You will then need to replace the pistons and liners, which is an avoidable costly repair. Make a point to check the liner wash fluid level several times a day.

Drilling fluid — whether pumping drilling mud, straight water or some combination of fluid — needs to be clean. Clean meaning free of solids. If you are recycling your fluid, make sure you are using a quality mud recycling system and check the solids content often throughout the day to make sure the system is doing its job. A quality mud system being run correctly should be able to keep your solids content down to one quarter of 1 percent or lower. When filling your mud recycling system, be sure to screen the fluid coming into the tanks. If it is a mud recycling system, simply make sure the fluid is going over the scalping shaker with screens in the shaker. If using some other type of tank, use an inline filter or some other method of filtering. Pumping out of creeks, rivers, lakes and ponds can introduce plenty of solids into your tanks if you are not filtering this fluid. When obtaining water out of a fire hydrant, there can be a lot of sand in the line, so don’t assume it’s clean and ensure it’s filtered before use.

Cavitation is a whole other detailed discussion, but all triplex pumps have a minimum amount of suction pressure that is required to run properly. Make sure this suction pressure is maintained at all times or your pump may cavitate. If you run a pump that is cavitating, it will shorten the life of all fluid end expendables and, in severe cases, can lead to gear end and fluid end destruction. If the pump is experiencing cavitation issues, the problem must be identified and corrected immediately.

The long and the short of it is to use clean drilling fluid and you will extend the life of your pumps expendables and downhole tooling, and keep up with your maintenance on the gear end of your pump. Avoid pump cavitation at all times. Taking a few minutes a day to inspect and maintain your pump can save you downtime and costly repair bills.

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

Our manufacturer Mud Pump skid is suitable for operations in rough, windy, damp and dusty oilfield conditions. Dependent upon customer horsepower requirements the engine sizes will vary.

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

8613371530291

8613371530291