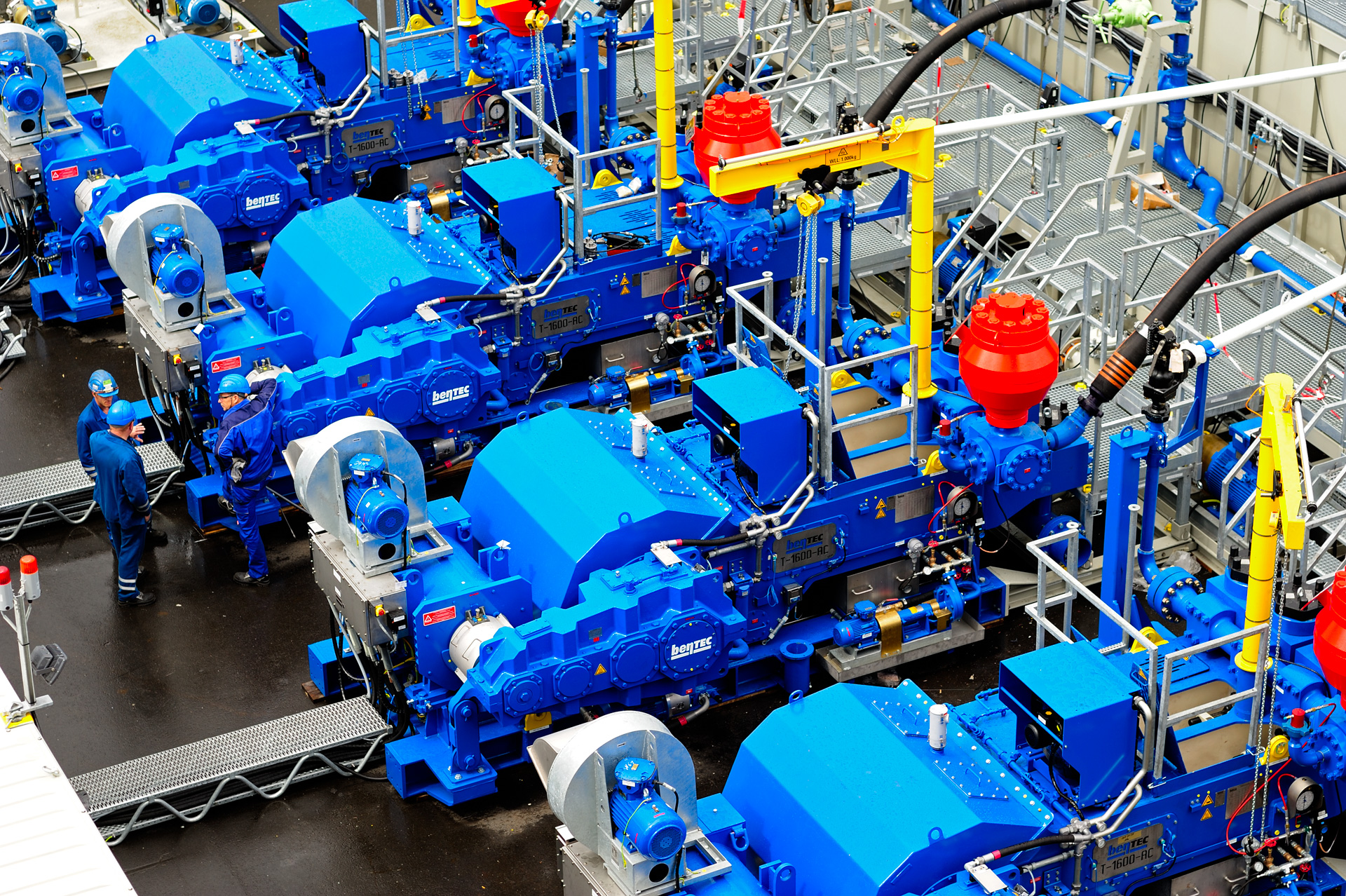

mud pump lubrication system factory

Central lubrication manifold system with Stainless Steel tubing for feeding all main, eccentric, and pinion bearings. Pressurized lubrication is also provided to the upper and lower crosshead slide for longer crosshead life

Our manufacturer Mud Pump skid is suitable for operations in rough, windy, damp and dusty oilfield conditions. Dependent upon customer horsepower requirements the engine sizes will vary.

All equipment is rated for operating at ambient temperatures up to +120 Deg F at 1200 ft altitude. The unit is built on heavy duty oilfield skid with lift frame. The control system is mounted in a stainless steel box on the side of the unit. The digital display provides all important engine and transmission data. Unit is also equipped with emergency kill function.

Mud pumps are the heart of a drilling operation. TSM designs and manufactures extremely reliable and easy-to-maintain mud pumps, eliminating unnecessary maintenance and downtime.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

◆F series mud pump has a longer stroke and can be operated at a lowerstroke,thusimproved the water supplyingperformanceeffectively and extended the lifetime of expendable parts in the fluid end greatly.◆The power end uses combined lubricating system of forced lubrication and splashlubrication.reliableto lubricate and promote the service life of power end.◆This series mud pump are strictly manufactured according to API7K,andare tested accordingly when leave factory.

● The power end of F series mud pump adapts combined lubricating system of forced and splash lubrication, Reliable to lubricate and increased the service life of power end.

Whether onshore or offshore, well-drilling sites rely on a multitude of systems to successfully perform the drilling operation. The mud pump is a key component tasked with circulating drilling fluid under high pressure downhole. The mud pump can be divided into two key sections: the power end and the fluid end. The alignment of the power end to fluid end on mud pumps is key to achieving suitable life and performance of the piston and liner system.

Misalignment contributes to accelerated wear on both the piston and the liner, and replacing these components requires downtime of the pump. The traditional method of inspecting alignment is to remove the piston from the piston rod, stroke the pump forward and check the vertical and horizontal alignment of the piston rod OD to the piston liner ID with micrometers. This is a time consuming and cumbersome technique that was ultimately not well suited to troubleshoot and solve alignment issues.

“I’m a firm believer in Pinpoint’s Mud Pump Alignment Kit, having used it as well as the old manual methods and even Faro arms in troubleshooting pumps on offshore rigs. In the hands of someone who understands pump alignment it is a powerful yet portable tool.”

“We routinely utilize Pinpoint Laser Systems’ Mud Pump Alignment Kit. We have one service technician dedicated to pump alignments and have seen continued success correcting issues on pumps after numerous rebuild attempts by others proved unsuccessful.”

Pinpoint products are not only easy to use but are easy to customize and even easier to upgrade down the road. The Microgage laser alignment system is the last measurement tool you will ever need.

The pump is designed to circulate mud or drilling fluid under great pressure down the drill hole and back up. The pump is a reciprocating model that features five pistons, hence the name quintuplex mud pump. The right degree of pressure and precision is crucial for efficient well operations. At Shale Pumps, we understand the value of a well designed and manufactured quintuplex pump, lending great focus on robust build and superior engineering quality.

Despite the fact that all mud pumps have pulsation dampeners, noise levels are likely to be high and require modifications to keep noise pollution levels low. This is important, considering the long-running hours of equipment and the need to protect personnel from constant and high noise levels. With a quintuplex mud pump, the pulsation noise and the mud telemetry noise come down by as much as half, making operations less noisy.

At Shale Pumps the designs of quintuplex mud pumps incorporate smaller footprints making the pumps more compact. Despite the smaller size of the pumps, the quintuplex pumps are rated for continuous duty with greater efficiency. The pressurized lubrication system with lubrication pumps mounted on the outside makes it easy for maintenance, reducing downtime of the equipment.

The build quality of the quintuplex mud pumps, much like the other equipment we manufacture and assemble at Shale pumps are superior, as a result of the materials, the design, and the processes employed in the assembly line. For detailed information about the service call at 713.248.3999 or mail at sales@shalepumps.com.

8613371530291

8613371530291