mud pump module repair factory

We specialize in providing products, service and support for triplex mud pumps. Our experience in triplex mud pump applications means the right solution at the right price.

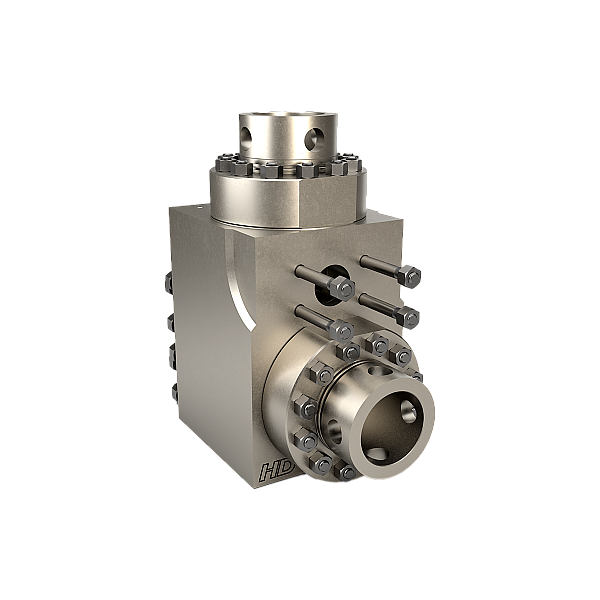

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

Premium Oilfield Technologies takes the responsibility of listening to our clients’ concerns very seriously. Acting on those needs enables Premium to offer robust solutions to customer issues at the rig. The Caliber® DS-7500 Fluid Ends bring together our years of field experience and unmatched client interface to represent the NEW standard for your Gardner Denver pumps.

An expendable needs to be dependable until its replacement. This is the very essence of the approach at ShalePumps towards all components, classified as expendables in Oil Exploration and Production. Mud Pump Fluid End Modules are absolutely vital to the operations of a Mud Pump. Machined from the highest quality of forged material, the fluid end modules have a very high threshold for cracking. This lends the fluid end modules longer life which in turn has a positive effect on overall operations.

All fluid end modules that leave the plant at ShalePumps got through a battery of tests that include hydrostatic testing. With assured integrity of the materials that go into all fluid end modules, the mud pumps can be operated with greater confidence.

The residual stress testing procedures are rigorous and translate into steady performance under exerted pressure in operations. All fluid end modules that go into the mud pumps are tested through scientifically proven fabrication techniques. Part of the reason why our expendables are always dependable till the extended duty cycle comes to the end of its operational life.

The NOV Fluid End Expendables and accessories add value to your drilling rig by increasing the operating range of existing mud pumps while reducing their maintenance and downtime. Fluid End Expendables are in-stock and ready for delivery at World Petroleum Supply, Inc.

National Oilwell Varco develops the highest quality, field-proven fluid end expendables and accessories for all pump manufacturers to provide extended run times and longer service life.

Mud pump liners The ceramic, chrome iron sleeved, and hardened steel liners are manufactured using only the highest-grade materials and offer extended run times with excellent resistance to abrasion, erosion, and corrosion.

Mud pump piston rods We manufacture crosshead extension rods, quick connect rods, self-aligning rod assemblies, and piston rods for all types of mud pump manufacturers. All rods are manufactured from high-quality materials and machined to exact tolerances to provide long life and superior service

Mud pump pistons We offer pistons of all styles and compositions designed for various types of drilling applications. All pistons are designed to provide consistent run times, minimize downtime, and reduce maintenance.

TSM Modules are forged using superior materials with characteristics that exceed the typical 4130 forged products in the industry. Characteristics include: through hardness, fatigue/crack resistant properties and low temperature ratings. These features combined with smooth inside surfaces/radii result in a high quality product.

NexGen Manufacturing & Supply keeps a wide variety of replacement parts in stock for mud pumps, plunger pumps, swivels, top drives, handling tools, and much more! Additionally, we have more than 3,000 prints and drawings of oilfield equipment and

GPM International is a supplier of durable oilfield replacement parts for a wide variety of drilling mud pumps. Inventory products including mud pump fluid end parts, handling tool, etc. All of our products are fully exchangeable with O.E.M. standards.

GPM warrants its products to be free from defects in material and/or workmanship under normal use and service for a period of one (1) year from the date of shipment. The liability for any defects shall be limited to the repair or replacement of such products, or at the option of GPMthe refunding of the purchase price. This warranty is expressly in lieu of all other warranties and representations, expressed or implied, and all other obligations or liabilities on the part of GPM, which shall not be liable for consequential damages for any breach of warranty. Any controversy or dispute arising out of the sale of GPMproducts shall be determined in accordance with the laws of the State of Texas

TSC"s high-strength, triple reduction, forged steel triplex fluid end modules are made from 4135 alloy steel and heat treated for long working life. These modules are machined to perfection and packaged for delivery.

8613371530291

8613371530291