mud pump parts name pdf quotation

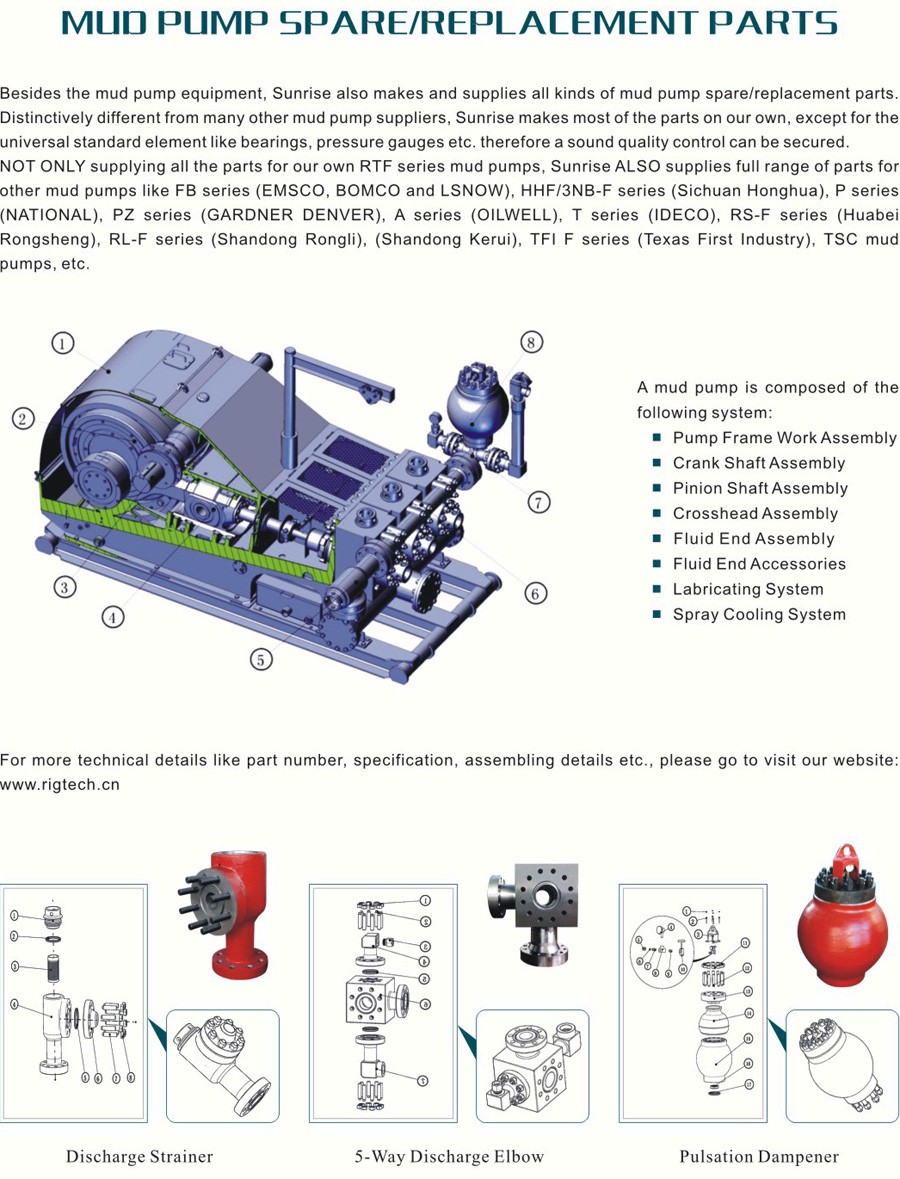

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

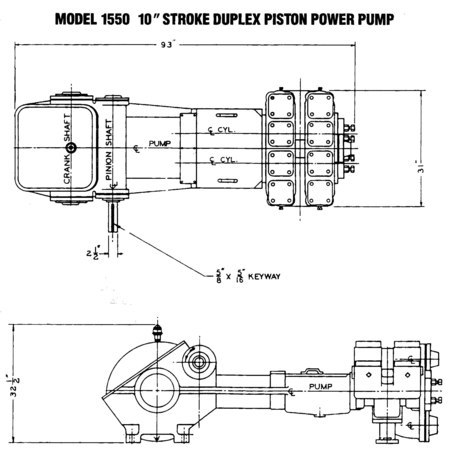

PAGE DRAWING NO. REV. DRAWING DESCRIPTION 1 PL 1292332 C FLUID END ASSEMBLY (STANDARD) 2 PL 1292613 -- FLUID END ASSEMBLY WITH PREMIUM MODULES 3 PL 1292737 -- FLUID END ASSEMBLY WITH H.P. MODULES 4 PL 1292000 U FLUID END ASSEMBLY (SHEET 1 OF 3) WITH TAPR-LOK VALVE COVERS 5 PL 1292000 U FLUID END ASSEMBLY (SHEET 2 OF 3) TOP VIEW OF ROD CHAMBERS 6 PL 1292000 U FLUID END ASSEMBLY (SHEET 3 OF 3) SECTION THRU ROD CHAMBERS 7 PL 1292120 D LINER SPRAY SYSTEM 8 PL 1292001 X POWER END ASSEMBLY (SHEET 1 OF 3) SECTION THRU POWER END 9 PL 1292001 X POWER END ASSEMBLY (SHEET 2 OF 3) SECTION THRU CRANKSHAFT 10 PL 1292001 X POWER END ASSEMBLY (SHEET 3 OF 3) SECTION THRU PINION AND CROSSHEADS 11 -- -- SUCTION STABILIZER ASSEMBLIES (OPTIONAL) 12 PL 1292312 G DAMPENER MANIFOLD, DOUBLE SIDE INLET (OPTIONAL) 13 -- -- DAMPENER MANIFOLD ASSEMBLIES (OPTIONAL) 14 -- -- LINER FLUSHING SYSTEM (OPTIONAL) 15 PL 1292316 -- LINER FLUSHING SYSTEM, RIGHT ANGLE DRIVE (OPTIONAL) 16 PL 1291157 B LINER FLUSHING PUMP, RIGHT ANGLE DRIVE (OPTIONAL) 17 -- -- STRAINER CROSS ASSEMBLIES (OPTIONAL) 18 -- -- TOOL AND ACCESSORIES 19 PL 1292004 E OUTLINE DRAWING

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

![]()

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

It’s the new Parts Lookup tool. Redesigned to give an enhanced, mobile-friendly customer experience, the Parts Lookup page offers an inventory of over 60 years of Ditch Witch equipment so you can place an order with your local dealer. Anywhere. Anytime.

Multiple search options, including integrated serial number lookup, allow you to search by part name, equipment model or keywords to find the part you need, faster.

After adding service parts to your pick list, you can request a quote from your dealer, download the list as a PDF, or save it to your account for future access to parts for recurring fulfillment.

Parts Lookup is part of the full suite of Ditch Witch customer productivity tools including Orange Intel™ and HDD Advisor® available through your MyDitchWitch account or at www.ditchwitchparts.com.

WheatleyGaso.com is your resource for Gaso pumps, Gaso pump parts and a supplier of ORIGINAL GASO PARTS and equipment, new used and remanufactured Wheatley, GASO and Wheatley/GASO plunger and piston pumps and pump parts and is not affiliated with Wheatley/GASO Inc. or its parent company, National Oilwell Varco,

WheatleyGaso.com is your resource for Gaso pumps, Gaso pump parts and a supplier of ORIGINAL GASO PARTS and equipment, new used and remanufactured Wheatley, GASO and Wheatley/GASO plunger and piston pumps and pump parts and is not affiliated with Wheatley/GASO Inc. or its parent company, National Oilwell Varco,

Humble Industries, Inc. is an independent manufacturer of replacement parts. Humble Ind. is neither a licensee, nor is it affiliated with any of the original equipment manufacturers named above. The manufacturers names or trademarks used herein are solely for identification purposes and are not intended by Humble Ind. to cause confusion as to the source, sponsorship, or quality of the parts manufactured by Humble Ind. The original manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Humble Ind. products.

This paper aims to develop a theoretical model in order to study the influence of the drilling fluid flow velocity on mud pumps valves wear. Mud pumps are operated at a high flow rate of the drilling fluid. The mud pumps valves come under the action of the abrasive drilling mud, which leads to their early wear. For the analysis of the velocity field in the flow area of the interspace between valve body and seat is used the finite element method. Research has shown that the maximum velocity…Expand

8613371530291

8613371530291