mud pump parts support brands

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

At BOPM, we constantly maintain 5 million worth of mud pump parts on the shelf at our Houston warehouse location. It includes modules, liners, extension rods, piston rods, pistons , threaded rings, caps, valve covers, valve guides, valves, seats etc. for all major brands of pumps: Gardner Denver®, Ideco®, Emsco®, National®, Oilwell®, Skytop Brewster®, Lanshi(3NB1300C) ®, Bomco ®, HH ®.

BOPM offers a complete line of interchangeable fluid end modules and accessories for triplex mud pumps, such as National, Emsco, Gardner Denver, Bomco, Ideco and Oilwell. We offer both standard OEM style replacement parts and Two piece “L” Shaped fluid ends.

BOPM piston rods are made with premium grade, heat treated alloy steel. The rods offer excellent resistance to fatigue, corrosion and heavy loads. A full line of piston rods are available for various pumps.

BOPM extension rods are made from high strength alloy steel, and are either heat treated or chrome plated. The rod offers excellent resistance to fatigue, corrosion and heavy loads. BOPM extension rods are machined and polished to ensure a perfect seal to protect the mud pump gear end.

All of our gear set adopt high-end carburization heat treatment and precise grinding machining to offer unparalleled durability; first we use high strength alloy steel, then adopt the Carburization heat treatment to enhance the hardness and wearability, finally adopt the grinding fine machining to ensure the smooth gear teeth surface; Resulting in consistent and rugged performance throughout pump operation.

BOPM bonded urethane pistonsare constructed of urethane, bonded to a steel hub. The double durometer urethane is designed to provide optimal performance in oil or water based mud and high drilling pressures.

BOPM Replaceable Rubber Pistonis made with tough and durable Buna N rubber for all pressures, and is ideally suited for water-base mud. A special processing of the fabric provides an unusually waterproof bond of fabric to piston which assures longer life.

BOPM Bonded Rubber Pistonis made with tough and durable Buna N rubber for all pressures, and is ideally suited for water-base mud. A special processing of the fabric provides an unusually waterproof bond of fabric to piston which assures longer life.

Humble Industries, Inc. is an independent manufacturer of replacement parts. Humble Ind. is neither a licensee, nor is it affiliated with any of the original equipment manufacturers named above. The manufacturers names or trademarks used herein are solely for identification purposes and are not intended by Humble Ind. to cause confusion as to the source, sponsorship, or quality of the parts manufactured by Humble Ind. The original manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Humble Ind. products.

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

We know that cost savings on identical spare parts is important for offshore rig Companies today. Therefore we provide our services and spare parts at considerable cost reductions compared to sourcing from the major OEMs. Tratec can guarantee identical parts with all required part certificates. We maintaing the highest quality, using state-of-the art service facilities and experienced, specialist mud pump engineers for service work.

Tratec has supplied more than 20 mud pump spare part, overhaul and recertification projects the last 5 years. References include rig companies Odfjell Drilling, Maersk Drilling, Archer, Saipem, KCA Deutag, and others.

Tratec is an experienced specialist supplier of overhaul, SPS, parts and service for rig and drilling equipment. We can provide Norwegian quality and decades of experience, while maintaning sensible prices and flexible solutions.

Tratec have delivered solid cost savings to our customers. This is due to our lower cost base, system with access to identical parts directly from manufacturer, and utilizing our experienced drilling equipment employees at very competitive rates.

Tratec can supply overhaul and parts compatible with the following Mud Pump makers and trademarks: National Oilwell Varco (NOV), MHWirth, Continental Emsco, Gardner Denver, Lewco, Drillmec, and others. Tratec is an independent supplier of drilling equipment parts. Tratec is neither a licensee, nor is affiliated with any of the named original equipment manufacturers (OEM). The manufacturer’s names, equipment names, or trademarks used herein are solely for identification purposes, and are not intended by Tratec to cause confusion as to the source, sponsorship, or quality of the parts supplied by Tratec. The original equipment manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Tratec’s supply of parts.

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzechiaCôte d"IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People"s Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People"s Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRomaniaRussian FederationRwandaRéunionSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyria Arab RepublicTaiwanTajikistanTanzania, the United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkmenistanTurks and Caicos IslandsTuvaluTürkiyeUS Minor Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuelaViet NamVirgin Islands, BritishVirgin Islands, U.S.Wallis and FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

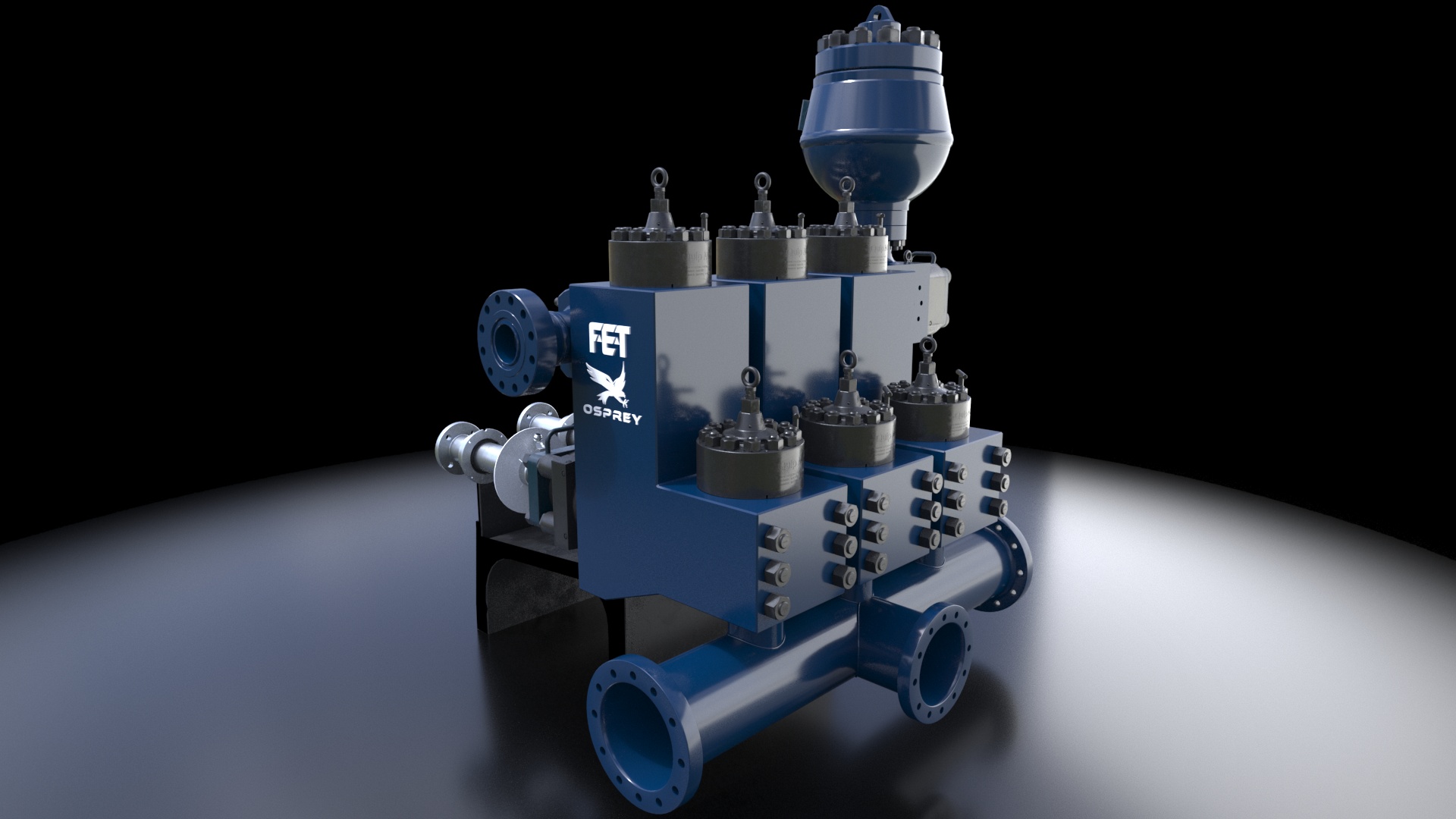

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

Exclusive distributor for TSC Workforce series pumps. From 450HP to 2200HP, these lightweight, high performance pumps are designed for todays drilling operations. Higher pressures, higher loads, these pumps deliver.

Full line offering of AC motors & VFD drives. Distributing and supporting WEG products ranging from 1/2HP to 2500HP, and variable frequency drives for control. From fan drives to pump drives, we provide both solutions and support for your needs.

Proudly carrying proven quality TSC fluid end consumables for all common model pumps, we also supply factory OEM power end and repair parts for many current brands/models including GD, HH, Bomco and others.

With over 60yrs of Bearing/Power Transmission experience, we deliver quality brand name products with knowledgeable service. From oilfield specific to supporting all other industries and equipment.

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

UDS International designs and manufactures heavy-duty centrifugal mud pump parts and equipment with innovative designs for optimum output and reliability.

Mud pumps are an important part of your drilling, tunneling and/or mining dynamics, helping to maintain drilling mud circulation through your drilling rig column, which improves the efficiency of drilling operations and reduces wear on your equipment.

UDS effective mud pump parts and equipment have the durability to meet the demands of high pressures, a range of ground conditions and are easy to maintain.

Using its experienced in-house technical team, UDS can manufacture all parts and equipment to suit your needs. UDS keeps a range of parts and equipment in stock, ensuring fast delivery if required.

UDS also offers ongoing technical support for all its products and solutions, and an upgrade service for increased fluid processing capability on its systems.

With our experience vast pool of resources and dedication to excellent customer service, we will go to the extra mile to confidently fulfill all of your pumping and equipment needs. One of our most important goals is to set the standard for great customer service. No matter if you need a seal, a gasket, or a complete new pump. We"ll treat you the same, with professional courtesy, throughout the sales process. Here"s a couple of testimonials from our customers.

Standard Industrial Manufacturing started in 1979. Our mission was to manufacture and supply pump parts to a few select pump retailers and OEMs. During the 1980s the company expanded its customer base to include all pump retailers and OEMs. Today, Standard has broadened its product lines to include most fluid-end expendables for all major pump brands.

Mud-Pump Gear Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Service and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Centerline Manufacturing is committed to the highest level of customer service quality. Every Centerline pump is comprehensively and repeatedly tested at diverse pressure levels to assure that it goes to our customer in perfect operational order. Centerline technicians work to ensure that our customers fully understand the operation of the model being delivered. If a customer"s pump is down, we understand the importance of timely response and parts availability. Centerline technicians will assess the problem and make repairs to bring the pump back into new specification. The Centerline mud pump technicians are well versed and qualified to operate and repair any product that is provided to the customer.

8613371530291

8613371530291