mud pump piston assembly manufacturer

A wide variety of mud pump rubber piston assembly options are available to you, such as 1 year, not available.You can also choose from new, mud pump rubber piston assembly,As well as from energy & mining, construction works , and machinery repair shops. and whether mud pump rubber piston assembly is 1.5 years, 6 months, or unavailable.

The RRP PINNACLE ASSEMBLED PISTON also known as Replaceable Rubber Piston or Supreme Piston is designed for use in the most demanding applications. The replaceable seal element is manufactured from a specially formulated elastomeric compound designed to be resistant to most chemical fluid found in the drilling industry today. These pistons can also be used in conditions where elevated temperatures can be problematic to other types of pistons in the market. The fabric anti-extrusion device on the piston is constructed from proprietary materials utilizing well researched process to reduce the extrusion of the rubber even at the pump’s maximum pressure rating.

Piston is one of the wear parts consumed the most in mud pump for drilling system. Rundong manufactures pistons of various specifications, which can be applied on different drilling pumps, such as F series, 3NB series, P series, PZ series and UNB series.

Our replaceable rubber pistons and inserts are based off of the industry standard “Mission-Supreme” style; our inserts will ft all competitors’ piston hubs that are interchangeable with the OEM.

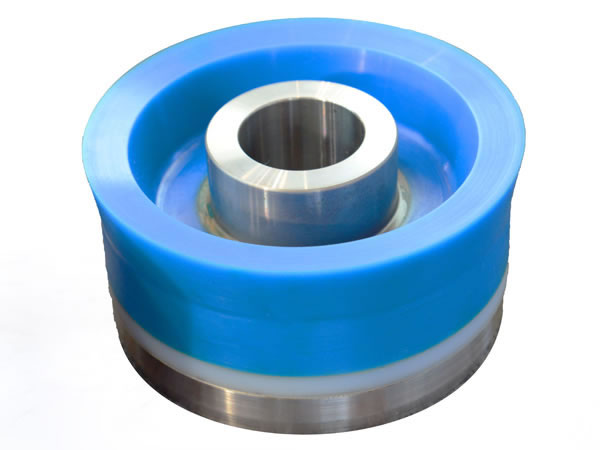

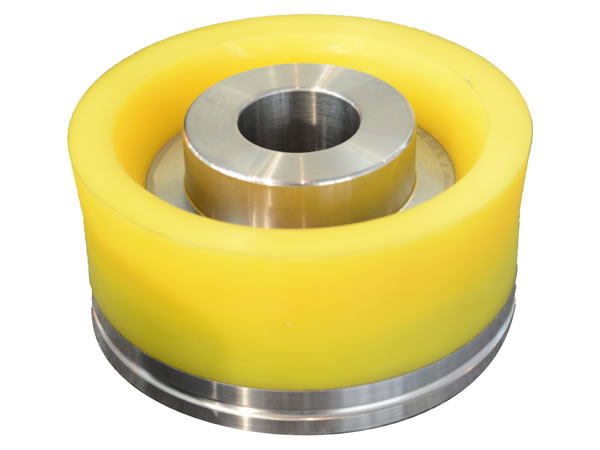

Material: The piston assembly is constituted by the piston core, rubber, spring, clamp, etc. Pistoncore is made of 42CrMo and the piston rubber is made of nitrile rubber or polyurethane rubber.

Application: Piston assembly is one of the main parts of mud pump hydraulic system, but also th e vulnerable part of drilling work. Mud pump discharge pressure is through the piston assembly by the piston reciprocating linear motion.

Our replaceable rubber pistons and inserts are based off of the industry standard “Mission-Supreme” style; our inserts will ft all competitors’ piston hubs that are interchangeable with the OEM.

Material: The piston assembly is constituted by the piston core, rubber, spring, clamp, etc. Pistoncore is made of 42CrMo and the piston rubber is made of nitrile rubber or polyurethane rubber.

Application: Piston assembly is one of the main parts of mud pump hydraulic system, but also th e vulnerable part of drilling work. Mud pump discharge pressure is through the piston assembly by the piston reciprocating linear motion.

American Mud Pumps LLC: warrants its products to be free from defects in material and/or workmanship under normal use and service for a period of one(1)year from the date of shipment. The liability for any defects shall be limited to the repair or replacement of such products, or at the option of American Mud Pumps LLC the refunding of purchase price. This warranty is expressly in lieu of all other warranties and representations, expressed or implied, and all other obligations or liabilities on the part of American Mud Pumps LLC, which shall not be liable for consequential damages for any breach of warranty."

American Mud Pumps LLC is a quality independent company. We are neither a licensee, nor affiliated with any other original equipment manufacturer (OEM) which may be named throughout. The manufacturers" names or trademarks used herein are solely for identification purposes and are not intended by American Mud Pumps LLC to cause confusion as to the source, sponsorship or quality of the parts provided by American Mud Pumps LLC. The OEMs named throughout this catalog do not sponsor, promote, warranty or endorse American Mud Pumps LLC products. Part number usage is for identification purposes only."

Mud Pump Pistons are made of high hardness alloy steel, and they are wear-resistant, anti-corrosive and anti-distortion after heat treatment. The seal of the piston can be made of polyurethane, polyether material and it can be also made of thiakol rubber.

G.D. TEE-BJA / TEE BFB : Valve assembly (PT. No. 200 PEE 482B) 5” stroke 3.1/2” triplex plunger mud pump spares : Valve body, valve, PU insert, washer, spring, spacer lantern, 3.1/2” Hardchrome plunger & packing set (60bu73)

Triplex plunger mud pump spares : Valve assembly complete (B-73991), fluid valve body, seat, polyurethane insert, self lock nut, spring are ready stock. 4” & 4.1/2” plunger (Hardchrome)

Providing you the best range of Rod And Clamps, Valves And Seats, Piston Assembly, Liners and Rubberized Spares Parts with effective & timely delivery.

EMCON” screens are designed to maximize solids removal capabilities while significantly reducing costs associated with drilling fluid and disposal. The use of EMCON screens lowers the percentage of drilled solids in the mud system. Less dilution is required, decreasing total drilling fluid requirements and disposal costs. Cleaner drilling fluid will decrease down hole problems which can adversely affect drilling time. All the benefits of clean drilling fluid lead to one end result.

EMCON” Piston Rubber Assemblies are available as a kit comprising Piston Rubber, End Plate & Snap Ring for field replacement.We manufacture replacement screen for following - Derrick, Kemtron, Brandt, MI-Swaco etc

EMCON” offers very high quality and precision machined sleeved bi-metallic liners finished to relevant API dimensions. They are available for various pumps, manufactured by Oil Well, National, Gardner Denver, Omega, Ellis Williums, Bournedrill and others. They are available in different sizes ranging from 5" to 7.1/2" diameter. Accurate mirror finish at inside diameter of the liner ensures very high lives for the Pistons.

The mud pump piston is one of the main parts of the fluid end system of the mud pump, and also one of the vulnerable parts in drilling work. The discharge pressure of mud pump is produced through the reciprocating rectilinear motion of the piston assembly in the piston. The piston assembly is composed of a piston core, rubber, spring, pressing plate, etc..

Mud pump piston and cylinder liner constitute a pair of dynamic sealing and sealing components are assembled on the piston (some mud pump pistons don"t have cylinder liner and are directly linked to the inner wall of the cylinder body). The reciprocating motion of the piston alternately changes the volume of the working chamber and the pump suck and discharge the liquid through the valve.

SHANDONG SAIGAO GROUP CORPORATION is specialized in producing mud pump pistons, and our product, the F1300 triplex piston mud pump, has advanced structure, small volume, reliable operation and is easy to maintain. The cylinders are made of alloy steel forgings and the three cylinders of each pump are interchangeable. The suction and exhaust valves of the F1300 and the F1600 can be used interchangeably, too. In order to improve their corrosion resistance, the cylinder surface is treated with chemical nickel-plating, and the straight-through cylinder valve structure is designed to reduce the volume of the hydraulic cylinder and improve the volume efficiency.

The present invention relates generally to mud pump pistons, and more particularly to a single acting mud pump piston having a multi-component flange and hub assembly.

Mud pumps are used in the oil and gas drilling industry for circulating drilling fluids, which are commonly and collectively referred to as mud. Mud pumps are positive displacement type pumps that include pistons mounted on reciprocating rods within cylindrical sleeves or liners.

Historically, the first mud pumps were of the duplex type. Duplex pumps include a double sided piston and cylinder arrangement which is adapted to pump in both directions of reciprocation. Duplex pump pistons include a unitary forged piston body which includes a central flange with hubs extending axially from both sides of the flange. Piston rubbers are mounted on the hubs in contact with the flange. The piston rubbers are held on to the piston body by a retainer plate and a snap ring.

More recently, there have been developed single acting multiplex mud pumps, which pump in a single direction of reciproction. Single acting multiplex mud pump pistons are, in effect, duplex mud pump pistons cut axially in half. Indeed, certain manufacturers refer to multiplex mud pump pistons as "half-pistons." More specifically, single acting multiplex mud pump pistons include a unitary forged piston body, which includes a unitary flange with the hub extending axially from one side thereof, and a piston rubber which is retained on the hub in contact with the flange by a retainer plate and snap ring.

There are numerous disadvantages inherent in the construction of presently available mud pump pistons. There are a number of sites that are subject to wear, but at differential rates. The rubbers are most subject to wear and therefore have the shortest expected life of the components of the piston. It would be advantageous to be able simply to replace the rubber periodically. However, the metal parts of the piston are also subject to wear.

A primary wear site is the periphery of the piston body flange, which over time becomes worn down. As the periphery of the piston body flange wears, the rubber has an increased tendency to flow or extrude between the piston body flange and the cylinder wall, thereby leading to failure of the rubber. Another wear site in the piston body assembly is in the snap ring and retaining groove. As the piston reciprocates, the snap ring works back and forth in the groove causing wear to both. As the snap ring and groove wear, the movement therebetween increases and thereby increases the wear. Also, increased movement of the snap ring with respect to the groove causes increased movement and wear of the rubber. When rubbers are replaced, it is common also to replace the retainer plate and snap ring. However, because of the wear to the snap ring groove, replacement of the snap ring does not return the piston to its original tolerances. Thus, replaced snap rings and rubbers have shorter lifes than originals.

A further site of wear or failure is in the piston body itself, primarily at the connection between the flange and the hub. Stresses due to bending of the flange are concentrated at the connection with the hub, which stresses in some cases lead to cracks in the piston body. Additionally, fluid sometimes is able to flow between the rubber and the hub, thereby leading to washout of the hub. Since the piston body is a unitary forging, if any part thereof, i.e. flange, hub, or snap ring groove, is worn, damaged, or out of tolerance, the entire piston body must be replaced.

It is an object of the present invention to provide a single acting mud pump piston that overcomes the shortcomings of the prior art. It is a further object of the present invention to provide a single acting mud pump piston that maximizes the operating life of the various components thereof. It is a further object of the present invention to provide a single acting mud pump piston that is economical to produce and maintain. It is a further object of the present invention to provide a single acting mud pump piston that may be repaired or reconditioned by replacing only the worn parts.

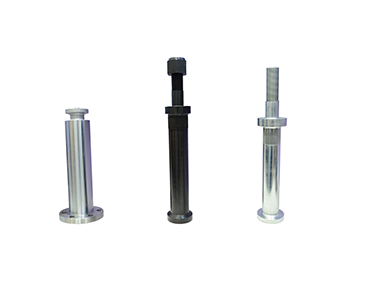

The foregoing and other objects are accomplished by the piston assembly of the present invention. The piston assembly is adapted for use in a single acting mud pump which includes a cylinder and a piston rod. The piston rod includes a reduced diameter cylindrical end portion with at least the end of the end portion being threaded.

The piston assembly includes a flat circular flange having an outside diameter less than the inside diameter of the cylinder and a bore through its center. The bore has a diameter substantially equal to the diameter of the end portion of the piston rod. The flange is adapted to be carried on the end portion of the piston rod. Means are provided for forming a seal between the flange and the piston rod.

The piston assembly includes a circular planar hub having an outside diameter less than the outside diameter of the flange and a bore through its center. The bore has a diameter substantially equal to the diameter of the end portion of the piston rod. The hub is adapted to be carried by the end portion of the piston rod in abutting relationship with the flange.

A circular piston cup is carried about the hub in removable abutting relationship with the flange. The piston cup has a body with an outside diameter substantially equal to the outside diameter of the flange and an outwardly flaring annular lip having an outside diameter greater than the inside diameter of the cylinder. The piston cup has a bore through its center with a diameter substantially equal to the outside diameter of the hub. The piston cup has a central portion surrounding the bore with an axial thickness greater than the axial thickness of the hub.

A circular planar washer is provided having an outside diameter greater than the outside diameter of the hub and an inside diameter substantially equal to the diameter of the end portion of the piston rod. The washer is adapted to be carried by the end portion of the piston rod in removable abutting relationship with the hub and the central portion of the piston cup. A retaining nut is adapted to threadedly engage the threaded portion of the piston rod to axially compress the central portion of the piston cup and urge the washer into abuttment with the hub.

The drawing is a sectional view of the single acting mud pump piston assembly of the present invention mounted on a fragment of a mud pump piston rod within a fragment of a mud pump cylinder.

Referring now to the drawing, the piston assembly of the present invention is designated generally by the numeral 11. Piston assembly 11 is adapted for mounting on a mud pump piston rod 13 a reduced diameter end portion 17 of in abuttment with a shoulder 19 for reciprocating movement within a mud pump cylinder 15. End portion 17 includes a threaded portion 21.

Piston assembly 11 includes a circular planar flange 23. Flange 23 has an outside diameter less than the inside diameter of cylinder 15 so as to be reciprocable therein. Flange 23 has a bore 25 through its center having a diameter substantially equal to the diameter of end portion 17 of piston rod 13. Flange 23 is removably carried by end portion 17 in abuttment with shoulder 19. A generally "L" shaped recess 27 is formed in flange 23 about bore 25 and carries therein an O-ring 29 for providing a seal between piston rod 13 and flange 23. Flange 23 is preferably made from steel barstock.

A circular planar hub 31 is carried by end portion 17 of piston rod 13 in removable abutting relationship with flange 23. Hub 31 has an outside diameter that is smaller than the outside diameter of flange 23. Hub 31 has a bore 33 through its center having a diameter substantially equal to the diameter of end portion 17. Hub 31 is also preferably formed from steel barstock.

A circular piston cup 35 is carried about hub 33 in removable abutting relationship with flange 23. Piston cup 35 includes a circular body portion 37 having an outside diameter substantially equal to the outside diameter of flange 23. Piston cup 35 also includes an outwardly flaring annular lip portion 39 having an outside diameter greater than the inside diameter of cylinder 15 so as to sealingly interfit therewith.

Piston cup 35 includes a central bore 41 having a diameter substantially equal to the diameter of hub 31. A flat central portion 43 is defined in piston cup 35 about central bore 41. The axial thickness of piston cup 35 in central portion 43 is at least as great as and preferably greater than the axial thickness of hub 31.

Piston cup 35 is preferably a compound structure that includes a reinforced section 45 and an unreinforced section 47. Reinforced section 45 is made with a plurality of fabric sheets embedded in an elastomeric rubber-like material. Reinforced section 45 is resistant to extrusion or flow between flange 23 and cylinder 15 during operation. Unreinforced section 47 is formed of the elastomeric material.

A circular planar washer 49 is carried about end portion 17 in removable abutting relationship with hub 31 and central portion 43 of piston cup 35. Washer 49 has an outside diameter greater than the outside diameter of hub 31 and an inside diameter substantially equal to the diameter of end portion 17. A self-locking nut 51 is provided for threadably engaging threaded portion 21 of end portion 17 of piston rod 13 for urging washer 49 axially into abuttment with hub 31 and to compress axially central portion 43 of piston cup 35. As central portion 43 of piston cup 35 is compressed, piston cup 35 seals about hub 31 and over flange 23, thereby to prevent fluid from flowing between piston cup 35 and hub 31 or flange 23.

Piston assembly 11 is assembled by first mounting flange 23 and O-ring 29 on end portion 17 of piston rod 13 in abuttment with shoulder 19. Hub 31 is then abutted with flange 23 with piston cup 35 thereabout. Washer 49 is then mounted over end portion 17 and nut 51 is threaded down to urge washer 49 into abuttment with flange 31 and central portion 43 of piston cup 35.

From the foregoing it is seen that the assembly of the present invention is well adapted to overcome the shortcomings of the prior art. If any part of the assembly becomes worn or damaged, that part may be replaced to fully recondition the entire assembly.

8613371530291

8613371530291