mud pump piston parts factory

Humble Industries, Inc. is an independent manufacturer of replacement parts. Humble Ind. is neither a licensee, nor is it affiliated with any of the original equipment manufacturers named above. The manufacturers names or trademarks used herein are solely for identification purposes and are not intended by Humble Ind. to cause confusion as to the source, sponsorship, or quality of the parts manufactured by Humble Ind. The original manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Humble Ind. products.

Humble Industries, Inc. is an independent manufacturer of replacement parts. Humble Ind. is neither a licensee, nor is it affiliated with any of the original equipment manufacturers named above. The manufacturers names or trademarks used herein are solely for identification purposes and are not intended by Humble Ind. to cause confusion as to the source, sponsorship, or quality of the parts manufactured by Humble Ind. The original manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Humble Ind. products.

These workhorses keep the mud flowing and your rig running. If theyʼre not working, youʼre not working. We make everything from the crankshaft to the liner seal to the skid. Each one is precision engineered for your rig so you can get back to turning.

At BOPM, we constantly maintain 5 million worth of mud pump parts on the shelf at our Houston warehouse location. It includes modules, liners, extension rods, piston rods, pistons , threaded rings, caps, valve covers, valve guides, valves, seats etc. for all major brands of pumps: Gardner Denver®, Ideco®, Emsco®, National®, Oilwell®, Skytop Brewster®, Lanshi(3NB1300C) ®, Bomco ®, HH ®.

BOPM offers a complete line of interchangeable fluid end modules and accessories for triplex mud pumps, such as National, Emsco, Gardner Denver, Bomco, Ideco and Oilwell. We offer both standard OEM style replacement parts and Two piece “L” Shaped fluid ends.

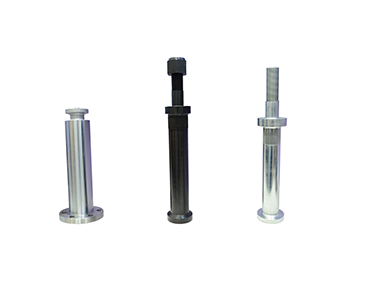

BOPM piston rods are made with premium grade, heat treated alloy steel. The rods offer excellent resistance to fatigue, corrosion and heavy loads. A full line of piston rods are available for various pumps.

BOPM extension rods are made from high strength alloy steel, and are either heat treated or chrome plated. The rod offers excellent resistance to fatigue, corrosion and heavy loads. BOPM extension rods are machined and polished to ensure a perfect seal to protect the mud pump gear end.

All of our gear set adopt high-end carburization heat treatment and precise grinding machining to offer unparalleled durability; first we use high strength alloy steel, then adopt the Carburization heat treatment to enhance the hardness and wearability, finally adopt the grinding fine machining to ensure the smooth gear teeth surface; Resulting in consistent and rugged performance throughout pump operation.

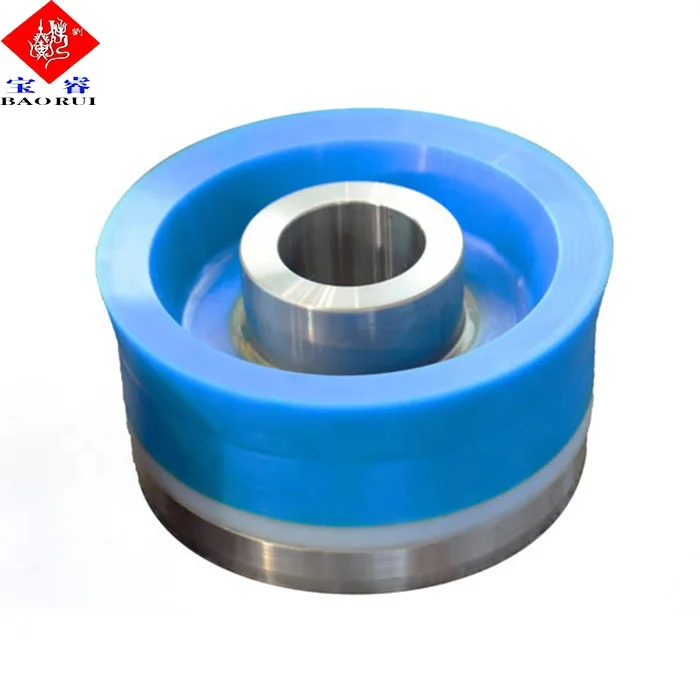

BOPM bonded urethane pistonsare constructed of urethane, bonded to a steel hub. The double durometer urethane is designed to provide optimal performance in oil or water based mud and high drilling pressures.

BOPM Replaceable Rubber Pistonis made with tough and durable Buna N rubber for all pressures, and is ideally suited for water-base mud. A special processing of the fabric provides an unusually waterproof bond of fabric to piston which assures longer life.

BOPM Bonded Rubber Pistonis made with tough and durable Buna N rubber for all pressures, and is ideally suited for water-base mud. A special processing of the fabric provides an unusually waterproof bond of fabric to piston which assures longer life.

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

A wide variety of mud pump rubber piston assembly options are available to you, such as 1 year, not available.You can also choose from new, mud pump rubber piston assembly,As well as from energy & mining, construction works , and machinery repair shops. and whether mud pump rubber piston assembly is 1.5 years, 6 months, or unavailable.

Dezhou Rundong Petroleum Machinery Co., Ltd is major in manufacturing oil drilling mud pump spare parts and drilling tools, in which liners, pistons and valves that developed new have got national patent certificate. Mud pump parts we manufactured can be totally exchangeable with spare parts from original manufacturer, and have excellent performance especially in drilling conditions of high temperature, high pressure, oil base mud, acid base mud and high sand content mud etc.

We have been committed to continuous optimization and upgrading of drilling mud pump products.We accumulate rich first-hand technical information through our service to drilling projects, for example different material products’ performance under different drilling conditions. Our aim is to make products manufactured can be more suitable for oilfield drilling needs, and our goal is where there is oil, there is Deshi Brand products.

Main advantages of the mud pump consumables that we manufacturedProducts are produced according to ISO9001 quality system,APISpec7K standard, and each process can be tracked, recorded and traceable

Years of production experience accumulation and continuous innovation, make parts manufacturing process more sophisticated, products service time more longer, cost performance more higher. Drilling cost can be effectively reduced by taking these products.

Import spare parts such as valve module, crankshaft, pinion shaft’s material are high quality alloy steel,The power end herringbone gear adopts the grinding process, the gear precision is high, the processing precision of the matching components is much more higher, which can make the whole mud pump can run more smoothly.

F500、F800 、F1000、F1300、 F1600、F-1600HL 、F-2200HLHydraulic end products and power end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, crosshead assy, air capsule, crankshaft, pinion shaft, connecting rod, manifold etc

HHF-1300、HHF-1600 、HH3NB-1600H、HH3NB-2200HLHydraulic end products and power end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, crosshead assy, air capsule, crankshaft, pinion shaft, connecting rod, manifold etc

7P-50、8P-80、9P-100、10P-130、12P-160、14P-220Hydraulic end products and power end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, air capsule, manifold etc

PZ-7、 PZ-8、 PZ-9 、PZ-10、PZ-11Hydraulic end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, air capsule, manifold etc

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

Titan Oil Tools offers high quality mud pump expendables and mud pump replacement parts for the wide variety of mud pumps, centrifugal pumps found on the world market today. These quality pump parts offer great performance and our pricing will save you money.

We are your oilfield supplier of choice for mud pump spares and mud pump parts: mud pump piston liners and pistons. All mud pump parts can be sourced for fast delivery; Come to us for mud pump liners, pistons, piston rods and parts, pony rods, threaded rings and caps,and more. Try us for duplex and triples pump spares and duplex and triplex mud pump parts, and also valve parts like valve seats. gland nut, and mud pump gaskets.

Mud pump liners may come in chrome, alumina ceramic and zirconia ceramic. Chrome liners and alumina ceramic liners are less costly, their cost of replacement over one year as the chart below shows, is much more than zirconia ceramic liners.

The table below shows a Mud Pump Liner Cost of Ownership which shows a reasonable cost comparison for a rig in continuous service for 36 months. This of course does not include the high cost of maintenance downtime and the cost of labor.

The prices below are based on cost/cylinder. Savings increase when you add up the number of pump cylinders on your rigs and extend the savings to understand the big difference it can make for your budget.

High quality 3NB-1600HL Triplex Mud Pump Module Discharge Suction Fliud End Module NB1602.01.01.00 from China, China"s leading Mud Pump Module product market, With strict qualit...

8613371530291

8613371530291