mud pump pressure gauge manufacturers brands

The m1 digital pressure gauge maintains 0.2% of reading accuracy from -10 to 50°C. Accuracy is not affected by dropping, over-pressure, vibration, temperature, or rapid pressure ...

... corporate partner, US Gauge, provides some of the world’s most popular analog pressure gauges for a variety of applications and markets. Included are process gauges, ...

The Digital Pressure Gauge DPG10 provides precise pressure measurement. The measurement pressure ranges start from -0.1 – 0 MPa and up to 0 – 250 MPa. The DPG10 is robust, ...

OILFIELD INSTRUMENTS PRESSURE INDICATING SYSTEM DRILLING INSTRUMENTATION ...Quality is Everything... Contact Rigchina Group Company for more information on our complete line of Oilfield Instruments, drilling fluids testing equipment and instrumentation for oil and gas industry. Call us today, or visit our website at www.rigchina.com © Copyright 1996-2016 Rigchina Group Company All rights reserved. Tel: 0086-579-87537698(switchboard) Fax: 0086-579-8753 696 Rev.2015 URL: http://www.rigchina.com Email: sales@rigchina.com SKYPE:RIGCHINA Add: No.80-82, Qiude Rd, West Cheng Industrial Estate, Yongkang city Zhejiang Province, China 321300

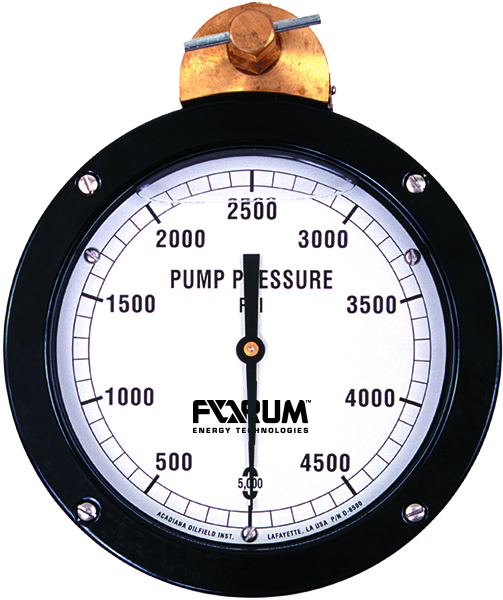

OILFIELD INSTRUMENTS PRESSURE INDICATING SYSTEM 1 MUD PUMP PRESSURE GAUGES Rugged standpipe-type gauges provide dependable, accurate pressure readings RIGCHINA Stand Pipe Gauges provide a quick, accurate display of pump pressure. Main applications are for standpipes and to be mounted on mud pumps. This style of gauge has been in service for many years and has proven to be a tough, dependable and reliable way to monitor pump pressure. Interchangeable with Cameron type gauges Temerature range -20 to 250(-29 to 121) 3 gauge models offering a multitude of sizes,pressure ranges and sub end...

OILFIELD INSTRUMENTS FEATURES: Diameter: 4-7/8"(124 mm), Height: 10-1/16" (256 mm) Pressure range: 7MPa, 14MPa, 21MPa, 25MPa, 35MPa, 40MPa, 60MPa, 80MPa, 100MPa, 120Mpa,160MPa 1,000 PSI, 1500PSI 3,000 PSI. 5,000 PSI, 6,000 PSI, 10,000 PSI, 15,000 PSI and 20,000PSI 70 Bar, 140 Bar, 210 Bar, 350Bar, 420 Bar, 700Bar, 1,040 Bar and 1,400 Bar Temperature range: -50°F to 180°F Liquid surrounding gauge mechanism minimizes wear from vibration and mechanical shock Heavy duty seals create watertight barrier around gauge mechanism Combination threaded male 2" line pipe and threaded female 1" line pipe...

OILFIELD INSTRUMENTS TYPE D PRESSURE GAUGE (MODEL 7) Model D Gauge for capacities up to 6,000 PSI FEATURES: Standard capacities of: 1,000 p.s.i., 3,000 p.s.i. 5,000 p.s.i and 6,000 p.s.i. 70 Bar, 210 Bar 350 and 420 Bar * 2" Nutted version available Tel: 0086-579-87537698(switchboard) Fax: 0086-579-8753 696 Rev.2015 URL: http://www.rigchina.com Email: sales@rigchina.com SKYPE:RIGCHINA Add: No.80-82, Qiude Rd, West Cheng Industrial Estate, Yongkang city Zhejiang Province, China 321300

OILFIELD INSTRUMENTS Temperature range: -50°F to 180°F Liquid surrounding gauge mechanism minimizes wear from vibration and mechanical shock Heavy duty seals create watertight barrier around gauge mechanism Impact resistant, clear polymer lens Connects with threaded female 2" line pipe TYPE E PRESSURE GAUGE (MODEL 8) Model 8 Gauge for capacities up to 20,000 PSI Tel: 0086-579-87537698(switchboard) Fax: 0086-579-8753 696 Rev.2015 URL: http://www.rigchina.com Email: sales@rigchina.com SKYPE:RIGCHINA Add: No.80-82, Qiude Rd, West Cheng Industrial Estate, Yongkang city Zhejiang Province, China...

OILFIELD INSTRUMENTS Liquid surrounding gauge mechanism minimizes wear from vibration and mechanical shock Heavy duty seals create watertight barrier around gauge mechanism Impact resistant, clear polymer lens Dial sizes: 8-1/8" (206 mm) dials Tel: 0086-579-87537698(switchboard) Fax: 0086-579-8753 696 Rev.2015 URL: http://www.rigchina.com Email: sales@rigchina.com SKYPE:RIGCHINA Add: No.80-82, Qiude Rd, West Cheng Industrial Estate, Yongkang city Zhejiang Province, China 321300

OILFIELD INSTRUMENTS FEATURES: Standard capacities of: 7MPa,14MPa,21MPa,25MPa,35MPa,40MPa,60MPa,80MPa,100MPa,120MPa and 160MPa 1,000 PSI, 1500PSI 3,000 PSI. 5,000 PSI, 6,000 PSI, 10,000 PSI,15,000 PSI and 20,000PSI 70 Bar, 140 Bar, 210 Bar, 350Bar, 420 Bar, 700Bar,1,040 Bar and 1,400 Bar Accuracy: ± 1.6% of full range Threaded:2” LPT male with 1” LPT female Temperature range: -50°F to 180°F TYPE RC-100 PRESSURE GAUGE Model RC-100 Gauge for capacities up to 20,000 PSI Tel: 0086-579-87537698(switchboard) Fax: 0086-579-8753 696 Rev.2015 URL: http://www.rigchina.com Email: sales@rigchina.com...

OILFIELD INSTRUMENTS FEATURES: Standard capacities of: 7MPa,14MPa,21MPa,25MPa,35MPa,40MPa,60MPa,80MPa,100MPa,120MPa and 160MPa 1,000 PSI, 1500PSI 3,000 PSI. 5,000 PSI, 6,000 PSI, 10,000 PSI,15,000 PSI and 20,000PSI 70 Bar, 140 Bar, 210 Bar, 350Bar, 420 Bar, 700Bar,1,040 Bar and 1,400 Bar Dial sizes: 124 mm dials Accuracy: ± 1.6% of full range Threaded:2” LPT male with 1” LPT female or 2” LPT female Temperature range: -50°F to 180°F Liquid surrounding gauge mechanism minimizes wear from vibration and mechanical shock Heavy duty seals create watertight barrier around gauge mechanism Impact...

OILFIELD INSTRUMENTS Liquid surrounding gauge mechanism minimizes wear from vibration and mechanical shock Heavy duty seals create watertight barrier around gauge mechanism Impact resistant, clear polymer lens Main Technical Specification Part-No. Description &Technical Parameters Dial sizes: 4-7/8" (123 mm) dials Accuracy: ± 1.6% of full range Pressure Range: 7MPa,14MPa,21MPa,25MPa,35MPa,40MPa,60MPa,80MPa, 100MPa,120MPa and 160MPa 1,000 PSI,1500PSI 3,000 PSI. 5,000 PSI, 6,000 PSI, 10,000 PSI,15,000 PSI and 20,000PSI 70 Bar, 140 Bar, 210 Bar, 350Bar, 420 Bar, 700Bar, 1,040 Bar and 1,400 Bar...

OILFIELD INSTRUMENTS Dial sizes: 8-1/8" (206 mm) dials Accuracy: ± 1.6% of full range Threaded:FLANGE,1.81,RJ,BX-151 FLANGE,2.06,RJ,R-24 FLANGE,2.06,RJ,BX-152 FLANGE,3.12,RJ,R-35 Pressure Range: 7MPa,14MPa,21MPa,25MPa,35MPa,40MPa,60MPa,80MPa, 100MPa,120MPa and 160MPa 1,000 PSI, 1500PSI 3,000 PSI. 5,000 PSI, 6,000 PSI, 10,000 PSI,15,000 PSI and 20,000PSI 70 Bar, 140 Bar, 210 Bar, 350Bar, 420 Bar, 700Bar, 1,040 Bar and 1,400 Bar Size: 6.5" × 6" × 10.2" (16.5 × 15 × 26 cm) ,Weight: 35lb (16 kg) Dial sizes:3.94" (100 mm) dials Accuracy: ± 1.6% of full range Pressure Range:...

OILFIELD INSTRUMENTS 2 PRESSURE INDICATING SYSTEM RIGCHINA’s PRESSURE gauges provide quick, accurate readings of your rigs. 2.1 E-17 DIAPHRAGM PROTECTOR 1:1 Piston Protects measuring or recording device from working fluid while transmitting no-lag, linear pressure signal. Rugged workhorse sensor found in every corner of the world doing every conceivable pressure sensing job. Robust, time proven design allows easy field repair and maintenance. Available in flanged, threaded, and weld on female sub configurations. Certified models available E-17 Diaphragm Protector. The Debooster is a stepped...

Crown Oilfield Instrumentation’s mud pressure gauges are extremely accurate and widely used in the harshest drilling environments. Each of our mud pressure systems are designed to meet or exceed API specifications, and you can count on a Crown mud pump pressure gauges to stand up to whatever the oil and gas industry can throw at them. Our mud pressure systems monitor the pump pressure for a variety of pumps and applications to ensure that you are getting the most out of your drilling fluids. Our single pointer systems use a 6" aluminum cast gauge to detect the slightest pressure changes and come with three different sensors: diaphragm gauge protector, 1:1 piston separator and 4:1 debooster gauge protector. The Crown compound pointer system uses unique pointer design that affords the reader to see the smallest pressure changes at a glance. Crown"s unitized pressure gauges are gauge and protector in one and can be mounted on a standpipe and seen up to 60 ft. away. Crown’s pressure gauges are designed, developed and tested to be durable, reliable and dependable, and all systems can stand up to the rigors of the oilfield. Manufactured in the US, you can depend on our pressure gauge systems to provide years of service.

All manufacturers names, numbers, symbols, and descriptions are used for reference purposes only, and it is not implied that any part listed is the product of these manufacturers. All trademarks are property of their respective owners. The terms NOV and VARCO are registered trademarks owned by Varco I/P, Inc. or National Oilwell Varco, L.P., and Magic Industries is not endorsed, sponsored, or affiliated with Varco I/P, Inc. or National Oilwell Varco, L.P.

The OTECO Pressure Gauge offers high accuracy and dependability for your standpipe, mud pump, and other drilling and production applications where precision pressure measurements are required.

Forum Compound Pointer Pressure Gauge systems accurately measure and display pump pressures for downhole cementing, high-pressure hydraulic fracturing, or acidizing oil pay operations.

A standard pointer provides a full 360° sweep of the dial, and a vernier pointer offers 4 to 1 resolution for indicating even small pressure changes. The system consists of a 6-inch Pressure Gauge, a Gauge Protector, and a high-pressure Hose.

We put forth for our clients a comprehensive range of CNG Pressure Gauges. All the products offered by us are manufactured using qualitative raw material which is sourced from the famed vendors of the market. Our professionals use latest technology and tools to manufacture this range as par the industry set quality parameters. These are used as a indicators for refilling of CNG from empty to full in a clockwise direction, available in varied custom-design models.

To meet the demand of oil exploration and refineries ‘ANI’ has developed a gauge for the pressure measurement of ‘Crude Oil’ completely on the basis of their in-house development department know-how.The gauge is designed as rugged and dependable keeping in view of applicationread more...

To meet the demand of oil exploration and refineries ‘ANI’ has developed a gauge for the pressure measurement of ‘Crude Oil’ completely on the basis of their in-house development department know-how. The gauge is designed as rugged and dependable keeping in view of application requirement of oil industries. To take careread more...

Backed with the professional workforce, we offer a wide range of Mud Pump Pressure Gauge. These products are specially designed using current techniques. The range of our product is made-up using finest quality materials, which are procured from expert and reputed sources of the industry. We offer our exclusive range afterread more...

Timer Travel Gauges find suitability for Bosch VE / Distributor Pumps of up to 6 cylinders. Made available in precision designed and constructed finish, these are developed using advanced technology support which makes these deliver optimum functionality support in checking movement of auto advance piston as well as for meetingread more...

We make available for our valued clients SI 3000/4000 series Test Gauges/Master GAUGES. These are made from high qualityberyllium copper bourdon tube, and provide precision movement and knife edge pointer with anti parallax. further, the range for SI 4000 series test gauges is ±0.5% FSD, whileread more...

Backed with the professional workforce, we offer a wide range of Mud Pump Pressure Gauge. These products are specially designed using current techniques. The range of our product is made-up using finest quality materials, which are procured from expert and reputed sources of the industry. We offer our exclusive range afterread more...

RIGCHINA Stand Pipe Gauges provide a quick, accurate display of pump pressure. Main applications are for standpipes and to be mounted on mud pumps. This style of gauge has been in service for many years and has proven to be a tough, dependable and reliable way to monitor pump pressure.

Afghanistan, Albania, Algeria, Andorra, Angola, Anguilla, Antigua and Barbuda, Argentina, Armenia, Aruba, Australia, Austria, Azerbaijan Republic, Bahamas, Bahrain, Bangladesh, Belgium, Belize, Benin, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, Botswana, Brazil, British Virgin Islands, Brunei Darussalam, Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Cape Verde Islands, Cayman Islands, Central African Republic, Chad, Chile, China, Colombia, Costa Rica, Cyprus, Czech Republic, Côte d"Ivoire (Ivory Coast), Democratic Republic of the Congo, Denmark, Djibouti, Dominican Republic, Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Ethiopia, Fiji, Finland, France, Gabon Republic, Gambia, Georgia, Germany, Ghana, Gibraltar, Greece, Greenland, Grenada, Guatemala, Guinea, Guinea-Bissau, Guyana, Haiti, Honduras, Hong Kong, Hungary, Iceland, India, Indonesia, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Liechtenstein, Lithuania, Luxembourg, Macau, Macedonia, Madagascar, Malawi, Malaysia, Maldives, Mali, Malta, Mauritania, Mauritius, Mexico, Moldova, Monaco, Mongolia, Montenegro, Montserrat, Morocco, Mozambique, Namibia, Nauru, Nepal, Netherlands, New Zealand, Nicaragua, Niger, Nigeria, Niue, Norway, Oman, Pakistan, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Poland, Portugal, Qatar, Republic of Croatia, Republic of the Congo, Romania, Rwanda, Saint Helena, Saint Kitts-Nevis, Saint Lucia, Saint Pierre and Miquelon, Saint Vincent and the Grenadines, San Marino, Saudi Arabia, Senegal, Serbia, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, South Africa, South Korea, Spain, Sri Lanka, Suriname, Swaziland, Sweden, Switzerland, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tonga, Trinidad and Tobago, Tunisia, Turkey, Turkmenistan, Turks and Caicos Islands, Tuvalu, Uganda, United Arab Emirates, United Kingdom, United States, Uzbekistan, Vanuatu, Vatican City State, Vietnam, Wallis and Futuna, Western Sahara, Western Samoa, Yemen, Zambia, Zimbabwe

Many types of pressure measurement devices convert their readings into electric signals that can be displayed by a data acquisition device (or DAQ). Although pressure gauges are able to display their readings digitally, they are notable for being able to directly measure and display pressure readings without necessarily converting such information electronically. Pressure gauges are valued in the industrial world for their simplicity, accuracy, cost-effectiveness, and low maintenance.

In a certain sense, the origin of pressure gauges can be traced back to the early modern era and the scientific discoveries of Evangelista Torricelli, a mathematician and physicist from Italy. In 1644, Torricelli discovered the existence of vacuums in nature as well as the fact that air carries weight. Other scientists like the Frenchman Blaise Pascal continued to build on Torricelli’s discoveries. Pressure gauges as we know them today, however, did not truly come in to being until the Industrial Revolution. During the 1840s, Frenchman Eugene Bourdon began searching for a solution to the disturbing rate of fatalities involving highly-pressurized locomotive engines. The result of his efforts was the invention of the Bourdon gauge in 1849. Although initially designed for railroad application, Bourdon inadvertently made a much larger contribution to the field of industry as a whole. The Bourdon gauge enabled industrialists of all types to measure much higher-pressure levels than had previously been possible and opened the way for further gauge development. Today, the Bourdon gauge (discussed further below) continues to be the most commonly used type of pressure gauge.

The measurement of pressure is crucial to the safe and proper functioning of many types of industrial systems (e.g. water-based systems, oil-based systems, gas-based systems), and corresponding industrial products (e.g. water heaters, fire extinguishers, medical gas cylinders, etc.) Entire fluid power systems would be unpredictable and unreliable (and thus, useless) without an accurate way to measure and adjust pressure. Measuring pressure is important not only to maintain mechanisms that directly run on proper pressure control, but to properly operate mechanisms that depend on values tied to pressure control (e.g. flowmeters where pressure levels affect flow rates). In fact, pressure is so important to modern industry that it is one of the most commonly measured phenomena in commerce as a whole. Only temperature is more commonly sampled.

Pressure gauges may be fabricated with a number of materials, depending on the demands of the specific application. A couple of examples follow below.

• Many gauges are exposed to harsh substances or chemicals including those that operate in the chemical, petrochemical, refining, power, and pharmaceutical processing industries. Such gauges must be corrosion-resistant; most likely, they be made of stainless steel. On the other hand, for pressure gauges that will encounter only non-corrosive fluids or gases, brass or bronze construction will probably be adequate.

• The specific pressure conditions a gauge will operate in constitute another factor in material selection. High pressure scenarios generally require gauges made of very durable material, such as steel. In contrast, low pressure scenarios may be well served by gauges made of bronze, or similar material.

The internal mechanisms of gauges are usually made of materials such as Beryllium copper, phosphor bronze, various steel alloys, etc. Typically, the internal tubes inside pressure gauges (discussed in the following section) receive a specific form of heat treatment know as spring tempering. Such treatment increases the tube’s elasticity while (more or less) retaining its original shape.

With regard to actual size, pressure gauges display a marked degree of variability. Regardless of their specific material makeup, standard and custom pressure gauges are designed to be able to fit into any number of tight spaces or (on the other hand) to sufficiently span an uncommonly large tank.

The (relative) simplicity of pressure gauges derives from the fact that the pressure measured by the gauge is the only energy source necessary for the gauge to work. At the end of the production process, pressure gauges are calibrated according to the pressure readings of a “master” gauge that already exists. Once this is accomplished, the gauge is ready for use. Gauges are typically able to be installed at various points on a fluid power system (e.g. near a hydraulic pump’s pressure port, at a stand-alone regulator in a pneumatic or compressed air system, etc.). Sometimes, pressure gauges are even able to measure “sub-circuits” within a fluid power system that operate at different pressures than the rest of the overall system (e.g. a circuit that occurs after a reducing valve).

Two major groups of pressure gauges exist: analog pressure gauges and digital pressure gauges. This division is important to take note of since these two types of gauges operate and display information somewhat differently. Analog gauges are “traditional” pressure gauges which display information with a needle that changes position on a meter’s clock-like face (in proportion to changes in pressure).

The key component of analog gauges is the “tube” alluded to in the previous section. These types of gauges contain some type of inner, elastic chamber that is somehow connected to the pressure being measured – and thus deforms, or otherwise moves, as the pressure acting on it changes. Through an intricate system of gears (known as the movement), the chamber within an analog gauge is able to translate pressure-induced motion into the movement of a needle across a scale.

• Bourdon tubes are the most common type of elastic analog chamber. A Bourdon tube is an elastic, C-shaped chamber consisting of one of the metals described in the previous section (e.g. copper, steel). When pressurized fluid enters this tube, it causes the tube to uncoil or straighten. This uncoiling of the Bourdon tube activates the gear and shaft assembly – which, in turn, moves the needle on the gauge’s clock-like display. Bourdon tubes may also come in the form of spirals or helices. Overall, this type of elastic chamber comprises a simple yet effective mechanical method for converting changes in pressure to quantitative readings on a scale.

• Bellows are elastic chambers that expand and contract rather than uncoiling in response to pressure changes. They consist of some type of thin-wall tubing and are almost always supplemented by a coil spring that strengthens its fatigue life.

• Diaphragms or stacks (single or multi) Elastic chambers consisting of thin metal sheets within a cup are known as diaphragms or stacks. This type of chamber moves as pressure is applied to its interior. Unlike bellows, diaphragms do not utilize supporting spring structures.

Although analog gauges are still very popular, they are increasingly being replaced by digital gauges, which are easier to read and more accurate. Unlike analog gauges, digital pressure gauges require another power source (e.g. batteries) to operate. They are attached to an additional measuring device, which measures pressure using sophisticated sensors and microprocessors. Once this additional measuring device feeds results back to the gauge, the gauge is able to display a numerical reading.

Digital gauges operate either using strain gauge technology or piezoelectric technology. Strain gauge sensors indirectly measure mechanical pressure by measuring changes in the electric resistivity of conducting materials. (Most often, this material is silicon, bonded metal foil, or some type of film – polysilicon film, thick film, sputtered thin film, etc.) When pressure mechanically deforms the chamber (usually a diaphragm) within the gauge, changes in resistivity also occur. These resistivity changes are then electronically converted and subsequently displayed. Piezoelectric type digital gauges work in a similar fashion. However, instead of measuring changes in resistivity, piezoelectric sensors measure electric charges that develop across them, proportional to mechanical changes in pressure.

To accommodate many different applications, manufacturers make many different types of pressure gauges. Examples of these include water pressure gauges, air pressure gauges, oil pressure gauges, temperature gauges, gas pressure gauges, fuel pressure gauges, differential pressure gauges, and vacuum pressure gauges. Some of the uses of these gauges are more obvious than others.

Water pressure gauges (naturally) monitor the pressure of any water-based system. Quite commonly, they are found attached to tanks, where they monitor the pressure of the water within.

Gas pressure gauges measure and display gas pressure. They are especially prevalent in factories and manufacturing facilities, where they keep track of the flow rate of both high and low pressure natural gas and propane-based systems. Fuel pressure gauges also check gas pressure levels, but they do so in the context of automobiles. They measure and display the fuel supply, or amount of gas, left in a vehicle tank.

Vacuum pressure gauges measure and display the pressure within vessels or systems that are immersed in a sub-atmospheric or vacuum environment. Vacuum environments are particularly used to create cold temperatures.

Seal gauges are made specifically to stop and avoid potential leaks. As such, they are designed with the addition of a diaphragm seal isolator. Most of their applications are found in the process, pharmaceutical, chemical, petrochemical, and sanitation industries.

Some pressure gauges may be designed to specifically measure substances flowing at either exceptionally high velocities or exceptionally low velocities. High pressure gauges are important to manufacturing and industrial applications, particularly those related to high pressure hydraulic technology (e.g. hydrodemolition, hydroblasting pumps, and water cutting machines). Low pressure gauges are extremely accurate and sensitive, generally measuring pressures between ten and fifteen PSI. They are especially important to applications that take place in environments with frequent pressure fluctuation.

Thus far, only pressure gauges that operate with reference to gauge pressure have been discussed. A pressure gauge that measures gauge pressure uses the surrounding atmospheric pressure as the standard by which it measures. However, this is not the only way for a pressure gauge to operate. The main exceptions follow below.

Absolute pressure gauges measure pressure with reference to a perfect vacuum. This means that absolute pressure gauges include surrounding atmospheric pressure within their overall pressure reading. Due to the name of the standard by which they operate, absolute pressure gauges are commonly misidentified as being identical to vacuum pressure gauges. Diaphragm type chambers are typically used in absolute pressure gauges.

Sealed pressure gauges operate in a manner more similar to normal gauge pressure mechanisms. However, instead of using the surrounding atmosphere as the standard by which to measure pressure, sealed pressure gauges simply use some fixed pressure quantity – that may not necessarily correspond to the surrounding atmosphere – in order to make measurements.

Differential pressure gauges are a bit different than other gauges. Instead of measuring pressure as a whole, they measure the difference in pressure between two points of contained liquid or gas. They are popular for filtration applications.

Yet another way to approach gauge classification is focusing on the specific application a gauge is used for. To provide just one example, magnehelic gauges are a special type of pressure test gauge that uses a diaphragm and measures static pressure within the HVAC industry. Many gauges are designed for use with a specific type of product. A single example is the use of dial gauges or weighted gauges for use with pressure canners.

More so than other industrial devices, pressure gauges are frequently used in conjunction with complementary instruments, like pressure sensors, pressure transmitters, pressure transducers, and switches. With the addition of these devices, gauges increase in accuracy and precision, displaying more specific readings with smaller margins of error. They may also be equipped with electric contacts that sound alarms, turn on signal lights, or control a valve or pump. Two specific examples of accessories used to increase the functionality of gauges are test point adapters and gauge isolators. Test point adapters fit to gauges and allow them to screw onto various points within the system, enabling a wide range of test pressure measurements without the purchase of multiple, separate gauges. Gauge isolators turn a pressure gauge into an “on/off” mechanism by mounting between a gauge and its circuit; unless a button is activated, the gauge will not be exposed to and will not read fluid pressure.

Many accessories for gauges have protective purposes. As sophisticated industrial instruments, gauges face a variety of threats such as pipe vibration, water condensation, etc. The aforementioned gauge isolator also serves a safety function by protecting a gauge’s internal mechanism from sudden pressure spikes. Snubbers provide a similar function by damping intense fluctuations in pressure. A variety of case protectors can be purchased to protect the exterior of a gauge from hard shocks, while chemical seals are available to protect gauges from being corroded or plugged up. While pressure gauges generally do not require a high level of maintenance, investing in protective accessories is one of the best things gauge users can do to protect and extend the life of a gauge.

When choosing a pressure gauge for a specific application, several factors should be taken into account. Some of the major considerations include the size of the dial, the size of the connection or port the gauge will be using, units of measurement that the gauge is capable of (e.g. PSI, mmHg, PA, etc.), compatibility of gauge material with the operating conditions (including temperature, corrosiveness, etc.). and whether the gauge should be dry or liquid filled (the latter tends to have longer life due to shock absorption).

One of the most important factors to consider is the pressure range of the gauge. Generally speaking, you should use a gauge that is able to read at least twice the amount of the expected working pressure. This provides a reasonable margin of safety for using the gauge. As a rule of thumb, operating pressure should never go above three-quarters of a gauge’s reading range.

A corollary of the rules of thumb involving pressure is the importance of choosing application-specific pressure gauges. Hydraulic systems, for example, should only utilize hydraulic gauges designed for operating under normal conditions in hydraulic environments.

It is important to note that the different types of chambers utilized by pressure gauges correspond to different ideals concerning pressure conditions. Bourdon type gauges are especially useful for medium to high pressure environments. However, they do not work well for low pressure scenarios. Gauges which utilize bellows and diaphragm chambers, on the other hand, are well suited to sensing low amounts of pressure and incremental changes within them.

For even greater accuracy – as well as greater speed, reliability, and durability – digital pressure gauges should be used in place of analog devices (despite their greater expense). Keep in mind, however, that the limitations of analog devices can often be overcome with the variety of accessories available for pressure gauges. (For example, some analog gauges possess temperature compensation equipment and multiple dial sizes to enhance the accuracy of their readings.)

Since so many factors constitute proper pressure gauge selection, investing in a quality pressure gauge provider is one of the best choices that pressure gauge consumers can make. You should focus on finding a reputable provider that offers a broad array of gauge products and/or services (e.g. recalibration services.) Working with a quality supplier will ensure that you are able to maximize the usefulness and effectiveness of your pressure gauges for your particular application.

By connecting with the best mud pressure gauge manufacturers and suppliers you can grow your business and satisfy your clients with top-notch products and services. At ExportHub you’ll find global mud pressure gauge suppliers and manufacturers ready to serve your demands. Regardless of where you are located, you can get your products manufactured easily without setting foot out of your national border. As a leading B2B platform, we highlight the following attributes of the listed manufacturers and suppliers.

8613371530291

8613371530291