mud pump pulsation dampener function manufacturer

Mud Pump Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump.

Mud Pump Pulsation Dampener is a pneumatic device built into the outflow line of each UUD pump to dampen the pressure fluctuations resulting from the action of the pump. Although presented as a surge tank, this device is really a device that can be tuned to greatly diminish the output pulsations transmitted downstream from the mud pump. Unfortunately, the effectiveness of the pulsation dampener is a function of both output pump pressure and frequency of the pump pulsations.

All pulsation dampeners utilize one of two methods for mitigating energy produced by reciprocating pumps; compression or exchange. The traditional gas-charged dampeners use a compressible gas cushion, either by a gas over liquid or gas-filled diaphragms, bladders, or cartridge. As the reciprocating pump produces pressure spikes, the gas compresses, thus absorbing the pressure difference and smoothing the pumped media flow. For maintenance free pulsation dampeners, rely on energy exchange. There is a common misconception regarding maintenance free pulsation control devices that the pumped media is compressible enough to absorb the reciprocating pumps’ pressure spikes. This is not true. However, the maintenance free pulsation dampeners work by utilizing the kinetic energy exchange. This kinetic energy exchange can only happen if the pulsation dampener’s volume is large enough to dissipate enough energy to reduce the adverse effects caused by the reciprocating pump. This is why maintenance free pulsation devices require massive volumes to be effective. Sigma Drilling Technologies has developed a pulsation dampening system that utilizes both methods for reducing the harmful effects of positive displacement pumps, both compression and exchange.

In order to reduce the fluctuation of pressure and displacement of the drilling mud pump, air bag are usually installed on the discharge line. The air bag manufactured by our company has advanced structure and reliable performance, which can make the mud pump achieve the best inhalation effect and is widely used in petroleum, high-pressure pipeline of chemical transportation. This product can also be used as a stabilizer and shock absorber for air extractors.

The pulsation dampener can be divided into discharge pulsation dampener and Suction Dampener.Discharge pulsation dampener- reduces displacement of pump and fluctuation of pressure.

In order to reduce the pressure and displacement of drilling mud pumps, air bags are usually installed on the discharge pipeline. The suction air bags produced by our company have advanced structure and reliable performance, which can make the mud pump achieve the best suction. The effect is widely used in high-pressure pipelines for petroleum and chemical transportation. It can balance the peak pressure of high-pressure fluid in mud pumps, stabilize the pressure, and reduce losses. This product can also be used as a stabilizer and shock absorber for air extractors.

The mud pump is installed on the discharge line, which can balance the peak pressure of the high pressure fluid of the mud pump, play a role in stabilizing the pressure, reducing losses and ensuring safety, so that the mud pump can achieve the best suction effect.

Drain buffer: Installed at the drain end of pumps and compressors, it can avoid fatigue damage of cylinder pistons, valves, bases and pipelines due to pressure fluctuations, thereby extending the service life of the equipment.

Reverse Oscillation: When the head of the water pump reaches a certain height, the reverse oscillation caused by the impact of the fluid into the pump valve will cause the pump to suddenly shut down. A suction air bag is installed to absorb part of the vibration.

BW Series Mud Pumps are mainly used for supplying flushing fluid to the borehole in core, geothermal, water resource, shallow oil, CBM and other drilling process. The fluid can be divided into mud, water, etc. They also can be used as transfer pumps of the above-mentioned medium. This series of mud pumps are with simple structure and easy to maintain and operate. Piston, lip-shaped and self-sealing type, is made of rubber or PTFE and nylon pads, equipped with shock-resistant pressure gauge, necessary spare parts and special tools. Bi-metal liner can be used to extend service life of pump greatly.

NBB Series Mud pumps are mainly used for the core, coal geology, metallurgy geology, hydrogeology engineering hole drilling fluid is supplied, flushing fluid can be divided into mud, water, etc., may be used as the above medium pump.

The mud pump is crank structure, horizontal triplex single acting piston pump, the piston is self-sealing lip, made of rubber or PTFE and nylon protective pads pressed, the pump adopts auto gearbox, variable five kinds of flow, the pump is compact, high efficiency, durable, safe, reliable, easy maintenance, low maintenance costs.

ZB Series grouting pumps are mainly used for kinds of weak corrosivity viscous and nonviscous liquid grouting(such as water, mud), especially for vertical shaft working face grouting, goaf filling, coal mine water inrush governance and so on.

The pump is triplex single-acting plunger high pressure pump, fitted with international first-class gearbox, which is of features like compact structure, multistage speed regulation, realizing different flow rate and pressure, meeting the grouting requirements of different formation. Electric motor drives triplex pump through transmission system. It has many advantages, like convenient adjustment for pressure and flow rate, long service life and so on.

3NB & 5NB Series Mud Pumps are mainly used for oil, water well, geothermy, CBM, shale gas, coalfield exploration, freezing well as well as well other drilling ,well cementation, work-over and other operations in industrial and mining enterprises. It is used for transferring mud, clay gum, mortar and other medium to the borehole. The pump adopts international advanced technology. It is characterized by advanced structure, reliable operation, good suction performance, long service life of wearing parts, easy for maintenance and repairing and so on.

F Series Mud Pumps are mainly used in oil field and geological prospecting for well drilling, well work-over, cementing, water shut off, water flooding and sending mud, clay, grout and so on.

This equipment plays an important role as an accessory to Yamada air-operated double diaphragm pumps. The pulsation dampener serves to reduce pulsation produced in operation and to assure stable discharge flow and pressure.

When pulsations occur with pump operation, it will result in the pressure in Chamber Bbeing greater than that in Chamber A. The diaphragm will act as an air cushion and automatically adjust to this pressure change and absorb the pulsations.

This operation will shift the center rod position upwards and allow more air in Chamber Athrough the air inlet, returning the diaphragm to a neutral position. If liquid pressure decreases, air pressure in Chamber Acauses the diaphragm to move downward, shifting shaft location and changing valve position, releasing excess air pressure in Chamber Awhich returns diaphragm to a neutral position. This action causes a reduction in surges and pulsation caused by a air operated double diaphragm pumps

Pulsation dampeners (also called pulsation dampers) are used for stabilizing the flow and the pressure in circuits with volumetric or dosing pumps. They are used in a wide range of applications.

In every pulsation dampener there is a separator element between the gas it is charged with and the liquid of the circuit; its basic function being to avoid the leaking of the gas into the circuit. This separator element is basically made of two kinds of materials: Rubber (NBR, EPDM, FPM, butyl, silicone, etc…) or a thermoplastic material (normally PTFE); although it can also be made in stainless steel.

When a rubber separator element is used, the dampener is called bladder type. If the material is PTFE, we refer to membrane type and bellows type dampeners, depending on the shape of the separator element.

Choosing between different types of dampener depends on characteristics of the circuit like working pressure, temperature and chemical compatibility between the liquid and the material of the separator.

All our pulsation dampenersare made according to the European PED97/23/CE pressure vessels regulations, and their design meets the AD-2000 and ASME VIII Div.1 & 8 codes requirements (“U” stamp pending).

We can supply all of our dampeners with different circuit connection gauges as well as fitted with whatever flange, either screwed on, welded or integrated, to suit the customer’s needs.

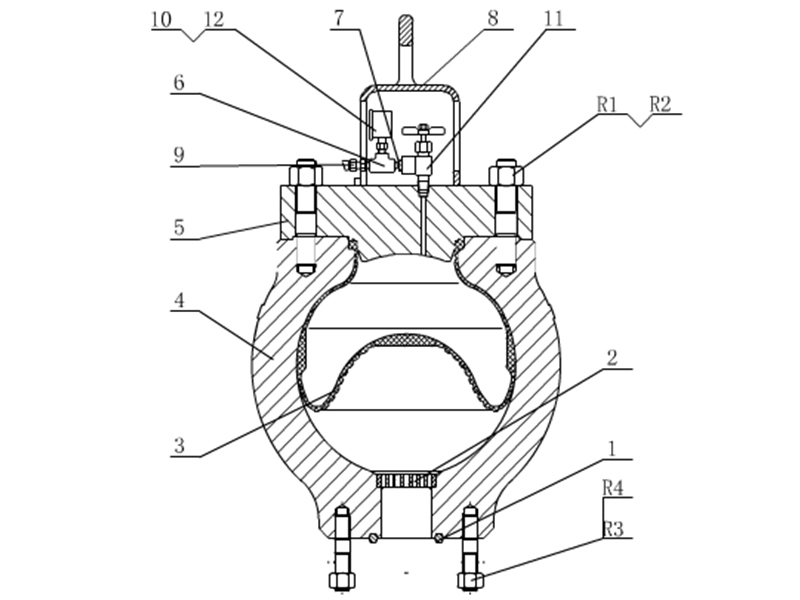

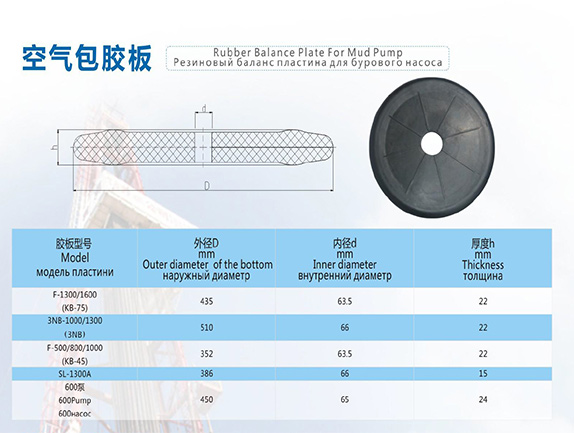

Mud pump pulsation dampeneris the mud pump discharge end main component, installs in the hydraulic end discharge pipe one end, plays the stable pressure and the pressure compensation function, the air bag work pressure is the mud pump work pressure 80%.Attention should be paid to the use of air bag, must be the first pressure relief.The mud pump of F500/F800 USES kb-45 air bag, and the mud pump of F1000/F1300/F1600 USES kb-75 air bag.The middle tie rod produced by our company is made of 35CrMo material, which has a smooth surface after chrome plating and fine grinding, greatly improving the wear resistance and corrosion resistance.

Proper installation and use of pulsation dampener can effectively reduce pressure fluctuations in the discharge system, thus achieving a more uniform fluid flow.In order to achieve a high service life of the air bag, always maintain the recommended ratio between the pump pressure and the air bag precharge pressure (generally not more than 2/3 of the pump discharge pressure, the maximum should not exceed 4.5mpa).

2. In the maintenance of air bag, air bag pressure must be zero, the pump pressure must be zero.Cannot rely on the pressure gauge to judge, because the residual pressure is small, the pressure gauge can not be displayed, but this low pressure will also lead to accidents!

For more information about pulsation dampeners, we sat down with Brandon Dalrymple and Nathan Ackeret fromBlacoh Fluid Control(manufacturer of pulsation dampeners, surge suppressors, and inlet stabilizers), and asked them to answer a few of our customers’ most common questions about pulsation dampeners.

Pulsation dampeners absorb the energy from the pulse wave created by a positive displacement pump, much like a shock absorber on a vehicle. Absorbing those pulse waves protects pipe welds and supports, and system components from damage due to pressure or excess movement.

A pulsation dampener creates an area of low pressure in the system with enough volume to absorb the pulsation. The pulsation dampener has a membrane with a "cushion" of compressible gas/air behind it that flexes to absorb the pulse, allowing a laminar flow downstream of the dampener.

Pulsation dampeners are commonly used wherever a positive displacement pump discharges flow in an unsteady manner, and where the pulse is not desired for the piping system. Air operated double diaphragm, metering and hose/peristaltic pumps typically benefit from a pulsation dampener.

The type of pulsation dampener used is typically defined by where they are placed in the system, and what they need to do. For example, "pulsation dampeners" are on the downstream side of the pump, "inlet stabilizers" are on the inlet side of the pump, and an accumulator or "surge suppressor" is used next to a valve or other device that restricts the flow in a system.

This video shows where you would place an inlet stabilizer, and how it is used to reduce the pulsation with an air operated diaphragm pump in suction lift conditions.

If you"re experiencing problems with rattling pipes, intermittent flow, water hammer, or pulsations in your system, don"t ignore it. Take the steps necessary to control these symptoms to prevent system deterioration down the road.

Need help with pulsations or water hammer problems? Ask us about it! We gladly provide technical assistance to businesses in Wisconsin and Upper Michigan.

Mud pump pulsation dampener is the mud pump discharge end main component, installs in the hydraulic end discharge pipe one end, plays the stable pressure and the pressure compensation function, the air bag work pressure is the mud pump work pressure 80%.Attention should be paid to the use of air bag, must be the first pressure relief.The mud pump of F500/F800 USES kb-45 air bag, and the mud pump of F1000/F1300/F1600 USES kb-75 air bag.The middle tie rod produced by our company is made of 35CrMo material, which has a smooth surface after chrome plating and fine grinding, greatly improving the wear resistance and corrosion resistance.

Proper installation and use of pulsation dampener can effectively reduce pressure fluctuations in the discharge system, thus achieving a more uniform fluid flow.In order to achieve a high service life of the air bag, always maintain the recommended ratio between the pump pressure and the air bag precharge pressure (generally not more than 2/3 of the pump discharge pressure, the maximum should not exceed 4.5mpa).

Warning: 1. Only compressed nitrogen or compressed air can be used when charging -- flammable and explosive gases such as oxygen or hydrogen cannot be used.2. In the maintenance of air bag, air bag pressure must be zero, the pump pressure must be zero.Cannot rely on the pressure gauge to judge, because the residual pressure is small, the pressure gauge can not be displayed, but this low pressure will also lead to accidents!

Pulsation Dampener (Surge damper) is installed on the discharge pipeline of the mud pump to balance the peak value of the high-pressure fluid pressure of the mud pump, so as to stabilize the pressure and reduce losses.

8613371530291

8613371530291