mud pump repair singapore manufacturer

With more than 20 years of engineering experience, he is excellent in handling all site matters and is able to implement high standards of quality, innovation and technology in service and work practice. With immense interest in engineering, he started his own M&E company – Singapore Innovation Technology, which serves clientele from oil and gas, offshore marine, commercial and residential industries, in Southeast Asia and beyond.

He is a key figure in propelling Singapore Innovation Technology into the best and trusted one-stop engineering solutions partner that every client looks for.

MFF Oilfield is a worldwide brand providing the best oilfield tools and equipment. Holding stock in multiple locations worldwide including in USA, Singapore, UAE, Indonesia and in multiple other locations worldwide.

We know that cost savings on identical spare parts is important for offshore rig Companies today. Therefore we provide our services and spare parts at considerable cost reductions compared to sourcing from the major OEMs. Tratec can guarantee identical parts with all required part certificates. We maintaing the highest quality, using state-of-the art service facilities and experienced, specialist mud pump engineers for service work.

Tratec has supplied more than 20 mud pump spare part, overhaul and recertification projects the last 5 years. References include rig companies Odfjell Drilling, Maersk Drilling, Archer, Saipem, KCA Deutag, and others.

Tratec can supply overhaul and parts compatible with the following Mud Pump makers and trademarks: National Oilwell Varco (NOV), MHWirth, Continental Emsco, Gardner Denver, Lewco, Drillmec, and others. Tratec is an independent supplier of drilling equipment parts. Tratec is neither a licensee, nor is affiliated with any of the named original equipment manufacturers (OEM). The manufacturer’s names, equipment names, or trademarks used herein are solely for identification purposes, and are not intended by Tratec to cause confusion as to the source, sponsorship, or quality of the parts supplied by Tratec. The original equipment manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Tratec’s supply of parts.

Tang Seng was started in February 1980 as a pump repair specialist. Throughout the years, we consistently expanded our size and capabilities. With the move to our Loyang factory in 2004, we were able to design, manufacture and maintain complete units and provide end-to-end solutions for our clients.

We have since moved to our current location at 14 Tuas Avenue 5. Our 110,000 sq. ft. compound allows us to have extensive workshop facilities which include 30-ton lifting cranes, engine dynamometer and pump testing bay all under one roof. We also have provisions for full engine overhauls, steel fabrication and parts storage.

We are one of the reliable leading pump supplier in Singapore and trusted one stop solution provider, committed to satisfy most demand in the industry, supplying Quality and Reliable Pumps, we have been involved in this field with expertise built out since 2001.

We select pump and its system with great care. We work for our customers with empathy and help them to have right pump for their application. We can work as your In house Engineering consultant as well as supplier in very reliable and friendly manner.

We are the pump supplier in Singapore, supplying wide range of pumps We supply TUTHILL Internal Gear Pump in Singapore for Diesel fuel & all types of Viscous Oil transfer applications. We supply pumps for Industries, Marine, Construction, Oil and gas industries, Pharmaceutical, food and beverages applications, cleaning, mining and many more industries where there is a need to move the liquids.

We supply Sea Water Cooling Pumps, Water Transfer Pumps, HVAC water circulation pump, Oil transfer pumps, Well Pointing Pumps, Self Priming type Sewage transfer pumps and many more types. our range of pumps include End Suction Centrifugal pump, Self- Priming Centrifugal pump, Gear Pump, Lobe Pump, High pressure triplex plunger pump, vacuum assisting priming centrifugal pump, Rotary Blowers etc…

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

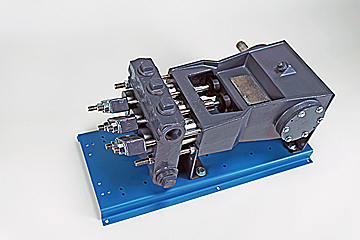

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

We supply and repair water displacement, vacuum and submersible pumps for sewage handling with experience in pumping station, hotel and railway facilities...

Since 1933, Gorman-Rupp has manufactured the high-performance, high-quality pumps and pumping systems required for lasting service in the municipal, water, wastewater, sewage, industrial, construction, petroleum, mining, fire, and OEM markets.

8613371530291

8613371530291