mud pump replacement motors repair brands

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

The NOV Fluid End Expendables and accessories add value to your drilling rig by increasing the operating range of existing mud pumps while reducing their maintenance and downtime. Fluid End Expendables are in-stock and ready for delivery at World Petroleum Supply, Inc.

National Oilwell Varco develops the highest quality, field-proven fluid end expendables and accessories for all pump manufacturers to provide extended run times and longer service life.

Mud pump liners The ceramic, chrome iron sleeved, and hardened steel liners are manufactured using only the highest-grade materials and offer extended run times with excellent resistance to abrasion, erosion, and corrosion.

Mud pump piston rods We manufacture crosshead extension rods, quick connect rods, self-aligning rod assemblies, and piston rods for all types of mud pump manufacturers. All rods are manufactured from high-quality materials and machined to exact tolerances to provide long life and superior service

Mud pump pistons We offer pistons of all styles and compositions designed for various types of drilling applications. All pistons are designed to provide consistent run times, minimize downtime, and reduce maintenance.

Rhino Pumps provides all types of centrifugal pumps. No matter how difficult the application, we have the optimal pump for your operation. We sell and service pumps of any size. Our full service repair shop provides the highest quality service and repair, and we are a preferred distributor for leading brand pumps. Rhino Pumps serves the Mountain West region with fast lead times and quality products from all leading manufacturers. See More…

We sell, service, remove and install vertical turbine pumps of any size. We have a turbine shop, with a highly skilled team dedicated just to vertical turbines. When it comes to vertical turbine pumps, it is vital to be meticulous in installation and repair. If you need a pump, we can help size, install, troubleshoot, or rebuild your pumps. We also offer a complete line of high quality new pumps for any application. See More…

Rhino Pumps sells, pulls, installs, provides diagnostics, and repairs deep well pumps. We specialize in deep well pumps for municipal, mining, industrial, agriculture, and commercial applications. We provide our own installations, making this easier for the customer to work with one company that provides and guarantees all aspects of your project, from sizing or new pump sales, to repairs and installation. See more…

Our complete product line of booster pumps gives our customer many different options when choosing a pump for their application. We have high efficiency pumps from leading brand manufacturers, as well as cost efficient options for every budget. We sell, repair and install in-line booster pumps. See more…

Rhino Pumps sells and services pumps and pump parts for all split case pumps. We work hard to guarantee fast lead times, expert service, on-site service, repair, and high quality sales for all of your split case pumps and other pumping projects. See more…

Sewage and Sump pumps are some of the many options that Rhino Pumps has to offer. Do you need a new sewage pump? If so, we can help! Our team can help with sizing, diagnostics and troubleshooting, or repairing your existing equipment. See more…

We are a preferred supplier for fire pumps in the Mountain West region. We sell, service, repair and install fire pumps. Rhino Pumps works hard to provide high quality pumps and fast lead times. Call today for pricing.

When you are dealing with abbrasives and corrosives, a durable slurry pump is essential to keep your pumps operational. We boast a complete line of slurry pumps made with the most durable materials and heavy duty coatings to withstand harsh environments. Rhino Pumps sells, services, repairs and installs slurry pumps for all applications. See more…

We have many different sizes and configurations of rotary lobe pumps. We sell, service and repair rotary lobe pumps with the highest quality and fastest lead times in the Mountain West region. See more…

With our experience vast pool of resources and dedication to excellent customer service, we will go to the extra mile to confidently fulfill all of your pumping and equipment needs. One of our most important goals is to set the standard for great customer service. No matter if you need a seal, a gasket, or a complete new pump. We"ll treat you the same, with professional courtesy, throughout the sales process. Here"s a couple of testimonials from our customers.

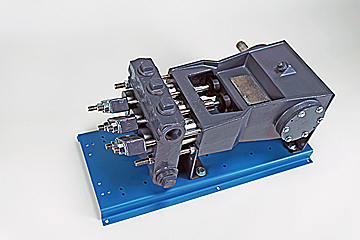

The AMT line of diaphragm pumps features a 2-stage, heavy duty forged gear driven transmission. Often referred to as mud or sludge Pumps, diaphragm pumps are designed to pump mud, slurry, sewage and thick liquids that have the ability to flow. AMT Diaphragm pumps are available with a choice of drivers to meet your application requirements: gasoline, diesel or single or three phase electric motor. Built-in check valve assures self-priming to 20 feet after initial prime. Heavy duty forged gear driven transmission is designed to operate pump at 40 strokes per minute for electric motor models and 60 strokes per minute for engine driven models. Each unit includes a 2 or 3 inch NPT steel suction strainer, two NPT nipples and a wheel kit for portability.

Exclusive distributor for TSC Workforce series pumps. From 450HP to 2200HP, these lightweight, high performance pumps are designed for todays drilling operations. Higher pressures, higher loads, these pumps deliver.

Full line offering of AC motors & VFD drives. Distributing and supporting WEG products ranging from 1/2HP to 2500HP, and variable frequency drives for control. From fan drives to pump drives, we provide both solutions and support for your needs.

Proudly carrying proven quality TSC fluid end consumables for all common model pumps, we also supply factory OEM power end and repair parts for many current brands/models including GD, HH, Bomco and others.

We know that cost savings on identical spare parts is important for offshore rig Companies today. Therefore we provide our services and spare parts at considerable cost reductions compared to sourcing from the major OEMs. Tratec can guarantee identical parts with all required part certificates. We maintaing the highest quality, using state-of-the art service facilities and experienced, specialist mud pump engineers for service work.

Tratec has supplied more than 20 mud pump spare part, overhaul and recertification projects the last 5 years. References include rig companies Odfjell Drilling, Maersk Drilling, Archer, Saipem, KCA Deutag, and others.

Tratec can supply overhaul and parts compatible with the following Mud Pump makers and trademarks: National Oilwell Varco (NOV), MHWirth, Continental Emsco, Gardner Denver, Lewco, Drillmec, and others. Tratec is an independent supplier of drilling equipment parts. Tratec is neither a licensee, nor is affiliated with any of the named original equipment manufacturers (OEM). The manufacturer’s names, equipment names, or trademarks used herein are solely for identification purposes, and are not intended by Tratec to cause confusion as to the source, sponsorship, or quality of the parts supplied by Tratec. The original equipment manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Tratec’s supply of parts.

Dreisilker is a family-owned business that has been providing pump repair services since 1955. We have experience with many different types of pumps, and our team is dedicated to providing quality repairs. We understand the importance of your pump, and we will work quickly to get it up and running again. Whether you need a simple tune-up or a major repair, we will be there to help. Call us today to schedule a consultation. We look forward to serving you.

Plus, the repaired unit has additional benefits from Dreisilker’s MotorSafe Repair which increases up time, improves efficiency and reduces operating costs.

We also served as the acting shop and field repair representative for the Western Gear Company and as a manufacturing facility for Wilson Manufacturing Company based in Wichita Falls, Texas. Wilson was a manufacturer of well service rigs and mud pumps. SMC Inc. has served and currently serves as a manufacturing and repair center for Oil Well Supply, Cabot-Franks, National, Halliburton, The Western Company, B.J. Hughes, Gardner Denver and many others. We manufacture a triplex pump of 165 H.P. with parts interchangeable to the Gardner Denver model TEE and are currently developing a 500 H.P. pump with parts interchangeable to Oilwell"s SA-644-5 pump. SMC has a large warehouse full of quality replacement parts for various types of equipment such as Triplex Plunger Pumps, Mud Pumps, Swivels, Drawworks and Rotaries.

We manufacture positive displacement pumps and replacement parts vital to the oil industry worldwide. We have customers that include both domestic and foreign oil companies. We also manufacture and repair a variety of products used in routine maintenance by customers with rock crushers, aggregate and commercial cement manufacturing plants.

Standard Industrial Manufacturing started in 1979. Our mission was to manufacture and supply pump parts to a few select pump retailers and OEMs. During the 1980s the company expanded its customer base to include all pump retailers and OEMs. Today, Standard has broadened its product lines to include most fluid-end expendables for all major pump brands.

American Oil Tools isan oilfield equipment supplier for valve parts, mud pump spares,blowout preventer parts, drilling equipment, downhole tools, blowout

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

TR provides high quality Mud Pump replacement parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve & Seat etc. We are dedicated to assisting worldwide clients with most cost-effective and quality guaranteed mud pump liners, pistons and other mud pump replacement parts. Reducing the mud pump production cost is our priority so that significant saving can be achieved for our valuable clients and end users.

TR liners offer both ceramic mud pump liners and high-chrome mud pump liners (bimetal liner) with excellent resistance to abrasion, erosion and corrosion for most mud pumps in worldwide. Advanced anti-wear measures are adopted and highest-grade materials are selected in our mud pump liners production to increase their service life, which can reduce our clients’ investment cost of the project, and improve their production efficiency.Replacement Mud Pump Liners for Gardner Denver PZ 6/7/8/9/10/11

TR provides a wide series mud pump liners for all major brand mud pumps. We also offer custom design-built service per our clients’ drawings and specifications

TR also offers high quality replacement parts for all major brand mud pumps including valve module, piston/extension rods, pistons, valves and seats etc.

For over 25 years, Liberty Process Equipment has been the leader in the field of economically priced Progressive Cavity Pumps and Progressive Cavity Pump replacement parts in North America.

Liberty specializes in Progressive Cavity Pumps for industry. The progressive cavity pump is a positive displacement system that is extremely flexible in its usability in a variety of specialized fields with difficult pumping applications such as viscous and highly-abrasive media. The design offers a pulsation-free, self priming operation that allows solids contents up to 50% to be moved without shearing.

When it comes to moving fluids with suspended solids content such as sludge"s or biosolids or thickened abrasives such as grouts or slurries, the PC Pump is the best choice for your application. Liberty can supply both the multiphase progressive cavity pumps and replacement parts to keep your PC Pump operating optimally for a lower price than other suppliers and OEM"s and can even offer you full pump packages with motors and baseplates if your job requires it.

Industrial and commercial pumps and pump motors are built to last, so we’re prepared to service your equipment even if it’s a decade old or older. Our team boasts decades of experience, complemented by extensive and high-tech tools.

Pumps are critical in the continuous operations of your establishment. That’s why we’re available all day, all night, and all week to ensure you get your defective unit up and running again in no time.

The expert technicians on our team inspect and test your equipment to determine the cause of failure. You can trust our transparent assessment. We’ll tell you whether your unit can be repaired or if it needs to be replaced. Likewise, you’ll get a quote and we’ll wait for your approval before we commence work. You can rest assured there will be no hidden fees or surprise charges.

Every pump system has its own problems ranging from the usual wear and tear to overheating. We help you identify these issues before they get worse. Take advantage of our decades-long experience to keep your rotating equipment running smoothly, minimize downtime, and improve efficiency.

Our repair shop is equipped with overhead cranes of up to 7.5 tons lifting capacity and a low and medium voltage test set. Square One is a UL-certified repair facility for explosion-proof machinery as well.

We provide services for electric motors, pumps, blowers, gearboxes, and other rotating equipment. We also service air handlers, baghouse dust collectors, andcooling towers.

Square One boasts of field technicians and machinery mechanics on its team. When your equipment cannot be removed from your facility for repair, we will come to you. Our onsite services include the appropriate tools to carry out the job efficiently. And, if necessary, we can dismantle your machinery and take it to our well-equipped machine shop for a thorough assessment and complete repairs. Upon project completion, we will return it to the site, reinstall it, and even start it up for you.

When equipment vibration is not a direct result of aged or damaged parts, then it may be a sign of misaligned components. In such cases, we perform laser shaft alignment to various applications, including HVAC or air handler belts and sheaves, motor or gearbox couplings and bearings, compressor and drive shafts, gas and steam turbines, printing machines, rollers and chocks, diesel and gas engine generating sets, and pump couplings, bearings, and seals.

This is another service that our field technicians can perform onsite. They will evaluate your equipment to determine the source and severity of the imbalance. Upon pinpointing the cause, they will correct the problem by adding or reducing weight in the right places. The procedures we implement can extend the life of your machine, reduce operating costs, enhance safety in the workplace, diminish overall noise, decrease structural stress, improve product quality, and result in the fewer parts replacement and unscheduled repairs.

We take care of your pump repair from start to finish. We will extract your unit from the production line and reinstall it when the repair is done. We’ll even start it up for you. Our millwright services cover motors, pumps, air handlers, gearboxes, to name a few. Some examples of common equipment removal jobs we handle with excellent capability are rooftop units, facility pump systems, and pumps in a pit. Turnkey projects are our specialty!

Is the unit mounted securely? Are the couplings worn? Is there new or excessive leaking? These are factors that contribute to premature pump failure, so you need to constantly keep an eye on your equipment’s mechanicals.

Failure to put the right match in place will cause one pump to overpower another, resulting in lost efficiency, rough operation, excessive heat, and even pump failure.

8613371530291

8613371530291