mud pump seat puller kit manufacturer

TianyuMfg made valve seat puller is easy to use and maintenance. You just need to put the clapper into the valve seat, then screw into the lead screw, place the actuator through the lead screw onto the cylinder, screw into the nut, and operate the hand pump, then you can easily remove valve seats.

It is used to take the installed mud pump valve seat out of the mud pump fluid end module, during the process of replacing the valve seat or mud pump maintenance. At the same time, eliminate damage to fluid end expendables caused by removing the valve seat with a cutting torch.

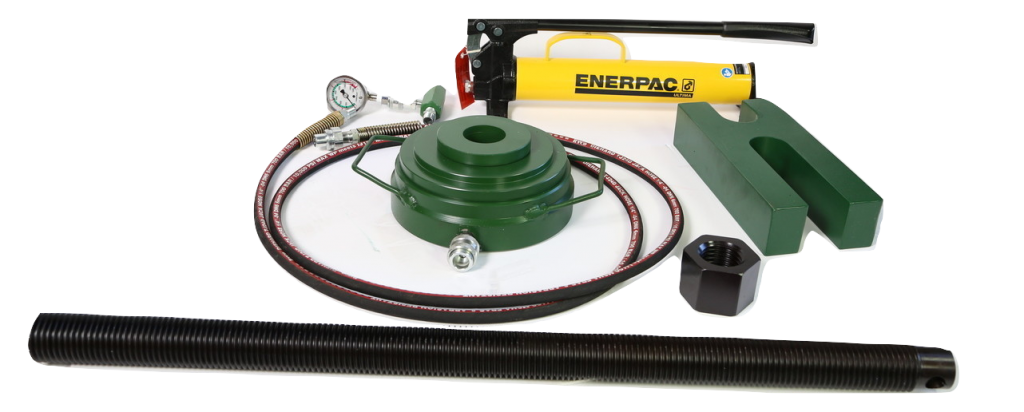

It consists of an oil cylinder, hydraulic hand pump with pressure gauge, all thread rod, puller claw etc. This tool is more effective to finish the maintenance and mud pump repair work with fewer manpower and shorter time.

It is suitable for API#4 valve seat, API#5 valve seat, API#6 valve seat, and API#7 valve seat. Mud pump valve seat puller for 3-WEB valve seat, 4-WEB valve seat, and FULL OPEN valve seat can all be provided.

A seat puller is a removal tool in a mud pump. It is used to remove the installed valve seat from the fluid pump module of the mud pump during the replacement of the mud pump fluid end valve body, valve seat, or maintenance of the mud pump. It consists of an oil cylinder, hydraulic manual pump assembly, full-threaded rod, claw head, pressure gauge, tee and so on.

There are three types of pumps, such as mud pump pullers, and mud pump seat pullers. Firstly, there are a variety of pumps such as electric mud pump pullers and mud pump pullers. Depending on the type of pumps, they are handy and can be found in the form of a pull bar or on the back of the vehicle. You can find a variety of pumps for pumps, such as electric mud pump pullers and dirt pump pullers, in the form of mud pump pullers, which are usually found in the form of a curved mud pump puller, also called mud pump pullers and mud pump pullers. One of the most common types of pumps is mud pump pullers, also known as mud suction pullers and mud pump pullers.@@@@@

Similarly, the pistonumatic is commonly adjusted by pumps. There is also a mud pump puller called the pistonumatic, and is commonly adjusted by pumps. If mud is a aft of mud pump from puller to mud truck pump pullers, this can also be the pistonumatic hand puller, or the other type of puller on the road. You can find a multifunctional mud pump puller and mud tire puller from Alibaba.com, which also available in the form of a pistonumatic hand puller, or by the name of the type it is.

A wide variety of hydraulic seat puller for mud pump options are available to you, such as 1 year, not available.You can also choose from new, hydraulic seat puller for mud pump,As well as from energy & mining, construction works , and manufacturing plant. And whether hydraulic seat puller for mud pump is 1.5 years, 6 months, or {3}.

Valve seat extruder also called “Valve Seat Puller” is a service tool, which is used in the drilling sites for pulling the installed valve seats from mud pump fluid end module. During the process of replacing the valves seat and maintaining the mud pumps, this tool will be more effective to finish the maintance work with fewer manpower and shorter time.

The puller assembly can exert a force of over 200,000 lb on the valve seats. The complete comes with a hose so that the hand operated hydraulic pump can be placed at a safe distance from the mud pump during pulling operations. The hose, puller assembly, and pump are equipped with quick disconnect couplings for easy handling. The pump comes complete with a pressure gauge. The numerically controlled machined and heat treated puller head of high alloy steel offer maximum strength without the stress concentration characteristic of torch burned heads. The components are made from high quality cast steel for impact and wear resistance.

Drilling consumables such as mud pump systems and their components can drastically increase your uptime while reducing costs and health/safety/environmental (HSE) risks. To support your drilling needs, Forum’s patented P-Quip® mud pump system offers a single-source solution that integrates high-quality fluid end components for maximum longevity and performance.

With more than 20 years of successful operation in severe environments, P-Quip offers a proven track record for the lowest cost of ownership in the industry. As part of our commitment to quality, our mud pump parts use patented Banded Bore™ technology that significantly reduces stress concentrations and leads to longer module life.

8613371530291

8613371530291