mud pump stroke counter sensor brands

The Two-pump Digital Stroke Rate Meter monitors and displays the Rate and Total Strokes of up to two individual pumps simultaneously. The unit continually displays, on large easy to read, low power LCD displays, RPM, TOTAL ACCUMULATED STROKES (0-9999 total strokes) and STROKE RATE (8-350 strokes per minute) for each pump. The unit is internally powered by a battery source having an operational life of 3 years.

At Matherne Instrumentation, we"re proud to provide both our two-pump and three-pump stroke counters to companies and oilfield operators across the states of Texas, Louisiana, North Dakota, and Pennsylvania. While our offices are based in Odessa, TX; Lafayette, LA; and Houma, LA, we"re proud to serve those across the cities of Midland, TX; Houston, TX; Williston, ND; and Pittsburgh, PA. To learn more or for a quote, please feel free to give us a call today!

Our pump stroke counter systems (CPS101 Series) measure the stroke rate and number of strokes on mud pumps. The oilfield pump stroke system is user-friendly and reliable and is configurable to measure up to three mud pumps at once. Our digital pump stroke counter systems are manufactured here in the U.S. by Crown Oilfield Instrumentation, and Crown’s Pump Stroke Counter provides easy monitoring of strokes per minute on multiple mud pumps. Each mud pumps’s stroke rate can be selected individually and the display is updated regularly for accurate monitoring. LCD displays indicate both pumps strokes per minute and the total number of strokes. Located at the bottom of the panel, push buttons provide easy operation and reseting of each pump. When you need to accurately monitor and maintain the amount of mud being pumped, you can trust Crown’s oilfield stroke counters.

Crown"s One Pump Stroke Counter System monitors and displays strokes per minute and total stokes and has everything you need to monitor one mud pump. Encased in a stainless steel box, the LCD screens are easy to view at a distance, and with buttons mounted on the face place, this system is easy to reset as needed. With a low power, low voltage lithium battery, this system is self-contained and intrinsically safe, with a operational life of 5 years. The Crown One Pump Stroke Counter system is designed to work in the harshest industry conditions and is waterproof and resistant to excessive rig vibrations. With everything ready-to-use right out of the box, this system will get you counting mud pump flow rate quickly and efficiently. Here"s what you"ll get in the one pump stroke counter system:

Made in the US, the Crown One Pump Stroke Counter system is powered by a 3.6 Type D lithium battery, with no external power supply needed. Because it is a self-contained system, the CPS101-2 is intrinsically safe. When the system is not in use it will go into a null state, saving battery power and the life of the LCD screens. Each Screen displays either strokes per minute (0-240 SPM) or total strokes (0-9999).

Crown"s limit switch assembly can be mounted near the mud pump piston with the easy-to-use c-clamp. The stainless steel rod can be bent to reach the piston easily, making the CPS101-2 one pump stroke counter system mountable in optimal proximity to the pump piston. The cable connecting the limit switch assembly to the stroke counter is made of the most durable materials to give you the best possible stroke counter on the market.

Need more information about our stroke counter systems? Check out our Stroke Counter Page or our Blog. And, if you only need one of the components in this system, give us a call. We"re more than happy to get you exactly what you need.

Monitors and displays the total accumulated mud pump strokes and the stroke rate of up to 4 individual mud pumps simultaneously. Constructed to operate in harsh environments and high vibration, conditions encountered in land and offshore drilling.

Monitors and displays the total accumulated mud pump strokes and the stroke rate of up to 4 individual mud pumps simultaneously. Constructed to operate ...

IRIS RMS is an on-board integrated riser instrumentation system for drilling risers. IRIS RMS integrates sensors with finite element software as well as providing measured data used to predict ...

Monitors and displays the total accumulated mud pump strokes and the stroke rate of up to 4 individual mud pumps simultaneously. Constructed to operate ...

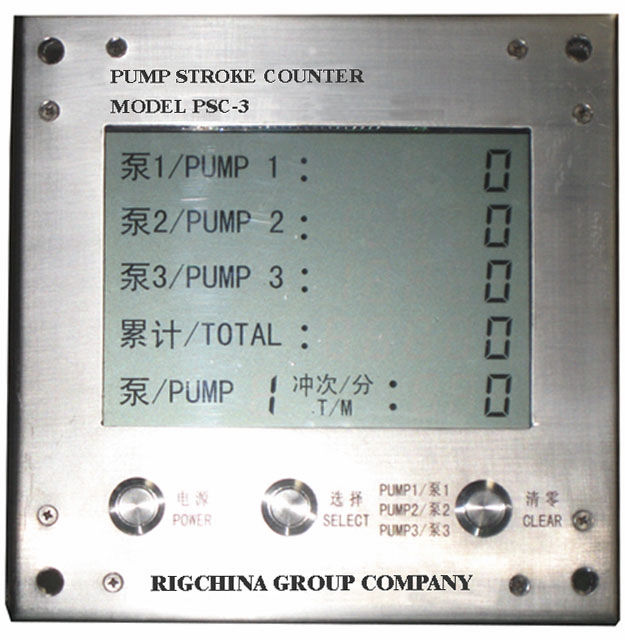

The RIGCHINA Pump Stroke Counter/Rate Meter displays both the total number of strokes and the strokes per minute for 3 mud pumps up to 1,024 strokes per minute for each pump. Push buttons conveniently located on the front of the instrument make it easy for the operator to reset each pump count

DRILLNG INSTRUMENTATION Pump Stroke Counter System PUMP STROKE COUNTER SYSTEM Model PSC-3 Instruction Manual …Quality is Everything... This manual describes the installation operation and maintenance of the Model PSC-3 Pump Strokes Counter System. This manual shall provide the user with information necessary to properly utilize the Pump Strokes Counter. Included in this manual are all the necessary procedures to install and maintain this Pump Strokes Counter Instrumentation properly. Email: service@rigchina.com SKYPE:RIGCHINA Website: http://www.rigchina.com Telephone: 0086-579-87537698 Fax: 0086-579-8753 696 Address: No.80-82, Qiude Road, West Cheng Industrial Estate, Yongkang city, Zhejiang P

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer 1. Introduction The Pump StrokeCounter (Model PSC-3) monitors and displays the total accumulated mud pump strokes and the stroke rate of up to 3 individual mud pumps simultaneously. The stroke rate for each mud pump can be individually display and is updated every second. The Battery Pack is designed to operate continuously for 2 years. No calibration is required. The quartz crystal oscillator provides high precision counts with no drift. The Pump StrokeCounter is designed to be intrinsically safe. The stainless steel case is...

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer 2. Systems Description: 2.1 Pump Stroke Counter With Mechanical Sensor Switch One (1) Pump Strokes Counter with three (3) pump input capability. The PSC-3 consists of a Pump Stroke Counter display and requires an inductive proximity sensor. The display shows (Pump1, Pump2, Pump3) the total strokes and strokes per minute. 1. Pump Stroke Counter 2. Connection Cable in Liquid Control Box (1.5m) 3. Junction Box of Pump Stroke Counter (on the liquid control box) 4. Main Cable (50 m) 8. Mechanical Sensor Switch

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer 2.2 Pump Stroke Counter With Passive Proximity Sensor Switch 1. Pump Stroke Counter 2. Connection Cable in Liquid Control Box (1.5m) 3. Junction Box of Pump Stroke Counter (on the liquid control box) 4. Main Cable (50 m) 8. Passive Proximity Sensor Switch The Inductive Proximity Sensor: The inductive proximity sensor used with the Pump Stroke Counter has a sensing range of 15mm. Care must be taken when mounting the sensor so it can safely detect the movement of the metal mass moving past th

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer Schematic Diagram of Installation of Magnetic Piece Note: When the magnetic piece is installed on the magnetic material, the material of the screw should be selected to use stainless steel. When a sensor is installed on non-magnetic material, the material of the screw should be of iron quality. The LCD has excellent daytime visibility and is backlight for night viewing as well. 3. Features and Specifications Stroke Rate Range: 0 to 999 strokes per minute (SPM) Total Accumulated Strokes: 0 to 99,999 strokes Front Panel...

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer Time Base: Quartz Crystal oscillator Pump Switch Micro-switch or passive proximity sensor Battery: ER26500 3.6V industrial lithium battery Intrinsically Safe sealed Power Pack Battery Life: 2 years continuous operation Maximum Cable Length: 250 ft (80 m) from pump switch to StrokeCounter Dimensions: 8"X8"X3.3" LXWXD (20.3X20.3X8.4 cm) Weight: 6.6 Lbs. (3 Kgs) Case Material: Stainless steel Operating & Storage Temperature: -40 to 100°C 4. Installation The Pump Stroke Counter is mounted in a driller’s or choke control panel in a...

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer Care should be taken not to over-tighten these bolts, as the clear panel behind the front panel can fracture if torque sufficient to distort the stainless front panel is applied. 5. Theory of Operation This system is comprised of a Control Head containing the necessary batteries, dis-plays, control and external connector. All power is supplied by a 3.6 Volt battery contained inside the instrument housing. Under normal use this battery should last approximately 2 years. The required input to the Pump Stroke Counter is either a...

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer Using the Pump Stroke Counter There are 3 push-buttons (switches) on the front panel, one for power(ONOFF), and one each for clearing the count on each pump(RESET),and one for Selecting Pump1,Pump2,Pump3 in the display. The power switch “ON-OFF” is an alternate action type; pressing it will turn the device on, and pressing it again will turn the device off. When the unit is on, there will be a Total Strokes displayed, and when the Mud Pump is operating, the rate will be displayed in the Strokes/Minute window. The “RESET”...

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer 6. Calibration No calibration is required for the Pump Stroke Counter. The device contains an internal crystal clock, which is used for determining the pump stroke rate. 7. Maintenance The internal battery will have to be replaced at the end of its life. This will normally be several years – a normal life is approximately 2 years with 24 hour Operation but the life can be short-ened with extremes of temperature. When the display segments appear to no longer have a high contrast, it is time to replace the battery. Turning the...

Measure and display the frequency of pump strokes of pump 1,and pump 2 and pump 3 by changing-over through the push- button of“select” on the panel.

material of the screw should be selected to use stainless steel. When a sensors installed on non-magnetic material, the material of the screw should be of iron quality.

DRILLNG INSTRUMENTATION Pump Stroke Counter System PUMP STROKE COUNTER SYSTEM Model PSC-3 Instruction Manual …Quality is Everything... This manual describes the installation operation and maintenance of the Model PSC-3 Pump Strokes Counter System. This manual shall provide the user with information necessary to properly utilize the Pump Strokes Counter. Included in this manual are all the necessary procedures to install and maintain this Pump Strokes Counter Instrumentation properly. Email: service@rigchina.com SKYPE:RIGCHINA Website: http://www.rigchina.com Telephone: 0086-579-87537698 Fax: 0086-579-8753 696 Address: No.80-82, Qiude Road, West Cheng Industrial Estate, Yongkang city, Zhejiang P

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer 1. Introduction The Pump StrokeCounter (Model PSC-3) monitors and displays the total accumulated mud pump strokes and the stroke rate of up to 3 individual mud pumps simultaneously. The stroke rate for each mud pump can be individually display and is updated every second. The Battery Pack is designed to operate continuously for 2 years. No calibration is required. The quartz crystal oscillator provides high precision counts with no drift. The Pump StrokeCounter is designed to be intrinsically safe. The stainless steel case is...

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer 2. Systems Description: 2.1 Pump Stroke Counter With Mechanical Sensor Switch One (1) Pump Strokes Counter with three (3) pump input capability. The PSC-3 consists of a Pump Stroke Counter display and requires an inductive proximity sensor. The display shows (Pump1, Pump2, Pump3) the total strokes and strokes per minute. 1. Pump Stroke Counter 2. Connection Cable in Liquid Control Box (1.5m) 3. Junction Box of Pump Stroke Counter (on the liquid control box) 4. Main Cable (50 m) 8. Mechanical Sensor Switch

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer 2.2 Pump Stroke Counter With Passive Proximity Sensor Switch 1. Pump Stroke Counter 2. Connection Cable in Liquid Control Box (1.5m) 3. Junction Box of Pump Stroke Counter (on the liquid control box) 4. Main Cable (50 m) 8. Passive Proximity Sensor Switch The Inductive Proximity Sensor: The inductive proximity sensor used with the Pump Stroke Counter has a sensing range of 15mm. Care must be taken when mounting the sensor so it can safely detect the movement of the metal mass moving past th

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer Schematic Diagram of Installation of Magnetic Piece Note: When the magnetic piece is installed on the magnetic material, the material of the screw should be selected to use stainless steel. When a sensor is installed on non-magnetic material, the material of the screw should be of iron quality. The LCD has excellent daytime visibility and is backlight for night viewing as well. 3. Features and Specifications Stroke Rate Range: 0 to 999 strokes per minute (SPM) Total Accumulated Strokes: 0 to 99,999 strokes Front Panel...

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer Time Base: Quartz Crystal oscillator Pump Switch Micro-switch or passive proximity sensor Battery: ER26500 3.6V industrial lithium battery Intrinsically Safe sealed Power Pack Battery Life: 2 years continuous operation Maximum Cable Length: 250 ft (80 m) from pump switch to StrokeCounter Dimensions: 8"X8"X3.3" LXWXD (20.3X20.3X8.4 cm) Weight: 6.6 Lbs. (3 Kgs) Case Material: Stainless steel Operating & Storage Temperature: -40 to 100°C 4. Installation The Pump Stroke Counter is mounted in a driller’s or choke control panel in a...

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer Care should be taken not to over-tighten these bolts, as the clear panel behind the front panel can fracture if torque sufficient to distort the stainless front panel is applied. 5. Theory of Operation This system is comprised of a Control Head containing the necessary batteries, dis-plays, control and external connector. All power is supplied by a 3.6 Volt battery contained inside the instrument housing. Under normal use this battery should last approximately 2 years. The required input to the Pump Stroke Counter is either a...

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer Using the Pump Stroke Counter There are 3 push-buttons (switches) on the front panel, one for power(ONOFF), and one each for clearing the count on each pump(RESET),and one for Selecting Pump1,Pump2,Pump3 in the display. The power switch “ON-OFF” is an alternate action type; pressing it will turn the device on, and pressing it again will turn the device off. When the unit is on, there will be a Total Strokes displayed, and when the Mud Pump is operating, the rate will be displayed in the Strokes/Minute window. The “RESET”...

DRILLNG FLUID TESTING INSTRUMENTATION RheoVADR™ Rheometer 6. Calibration No calibration is required for the Pump Stroke Counter. The device contains an internal crystal clock, which is used for determining the pump stroke rate. 7. Maintenance The internal battery will have to be replaced at the end of its life. This will normally be several years – a normal life is approximately 2 years with 24 hour Operation but the life can be short-ened with extremes of temperature. When the display segments appear to no longer have a high contrast, it is time to replace the battery. Turning the...

We support our purchasers with ideal premium quality products and substantial level company. Becoming the specialist manufacturer in this sector, we"ve acquired rich practical working experience in producing and managing for Mud Pump Stroke Counter Sensor, , , , We will supply high-quality solutions and fantastic companies at aggressive charges. Start benefiting from our comprehensive providers by contacting us today.

The pump stroke counter is used for measuring the number of pump strokes and per minute number of pump strokes (i.e. the frequency of pump strokes) of a reciprocation mud pump so to provide for the drill operators an accurate adding amount and speed of the mud to be grouted into a well shaft. It is a necessary meter in drilling process. Model BC-200A pump stroke counter comes out from improving the model BC 100 pump stroke counter, being a kind of updating and upgrading product of BC-100 pump stroke counter. Compared with BC-100, it increases a signal input channel and increases the functions of the count and accumulation of the pump strokes of a single channel, the total accumulation of the number of pump strokes, data memory when the machine is turned off, etc. Also its operation is even more convenient, simple and reliable. The totally enclosed structure, water-proof signal connectors and keys endow the BC-200A pump stroke counter with good moisture-proof and water-proof performance. After being subjected to a water-proof test for 12 hours under water with a depth of 1m, the BC-200A pump stroke counter shows so good water-proof performance that no water is found entering in. furthermore, with its overall power consumption being around 150uA, its sensor signal current around 5uA, the BC-200A pump stroke counter is actually explosion-proof, that is, it is intrinsically safe.

Forum Compound Pointer Pressure Gauge systems accurately measure and display pump pressures for downhole cementing, high-pressure hydraulic fracturing, or acidizing oil pay operations.

The HDI 2100 Pump Stroke Counter is an intrinsically safe, certified, solid-state electronic stroke counter primarily used for monitoring mud pumps. Found most commonly within the HDI 9000 Choke Console System, the HDI 2100 monitors and displays the total accumulated mud pump strokes and the stroke rate of up to 4 individual mud pumps simultaneously. The stroke rate for each mud pump can be individually selected for display and is updated every second. Once installed, there is virtually no maintenance or calibration required. The quartz crystal oscillator provides high precision counts with no drift. The stainless steel case is completely sealed and features stainless steel piezo switches for long life. The entire package is constructed to operate in harsh environments and high vibration conditions encountered in land and offshore drilling. All HDI Gauges provide safety, accuracy, reliability, and low maintenance for the user.

8613371530291

8613371530291