mud pump suction line brands

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

Warranty: Manufacturer warrantees mud pump hoses to be free from manufacturing defects and shall replace or repair if found defective in workmanship within 1 year from the date of shipment.

Parker"s Series TKW160 Large Diameter Custom Made Heavy Duty Oilfield Mud Suction Hose provides excellent heavy duty service across multiple oilfield bulk transfer applications. The thick rubber tube provides additional resistance to abrasives, drilling mud and other typical oilfield materials going through the hose and the cover provides resistance to abrasion and weathering for maximum versatility and performance. The basic hose construction may be modified to customer-specified requirements, including brand, length pattern and built-in coupling configurations. Parker will quickly design and build a custom made product to satisfy specific application requirements and will drop-ship in protective packaging, eliminating the cost of additional handling and the need to compromise on hose performance.

• Reinforcement: Multiple textile plies for strength and durability, and a wire helix for full suction capability and a path to conduct a static charge to ground.

Trash pumps can be an integral part of a solids control system. These pumps are designed to pump large amounts of water that contain solids such as mud, leaves, sticks, sand and sludge. A trash pump is commonly a heavy-duty, portable centrifugal pump that features deeper impeller vanes and a larger discharge opening than other styles of pumps. Trash pumps are capable of moving hundreds or thousands of gallons per minute, all while processing materials with suspended particulates that would typically clog other styles of pumps.Mud Technology International, Inc. builds a line of trash pumps to accommodate projects of varying sizes and challenges.

Each pump is compatible with all of Mud Technology International"s Recycler Systems and can be adapted to work in conjunction with most other brands of solids control equipment.

The various models of Mud Technology International trash pumps can move from 500+ gpm to 800+ gpm and have a 4" fitting to transfer slurry to the recycling system. Each model has a completely submersible head and flooded suction (unit does not have to be primed.) All units run on 480V, 3-phase power, with a 100" weatherproof cord.

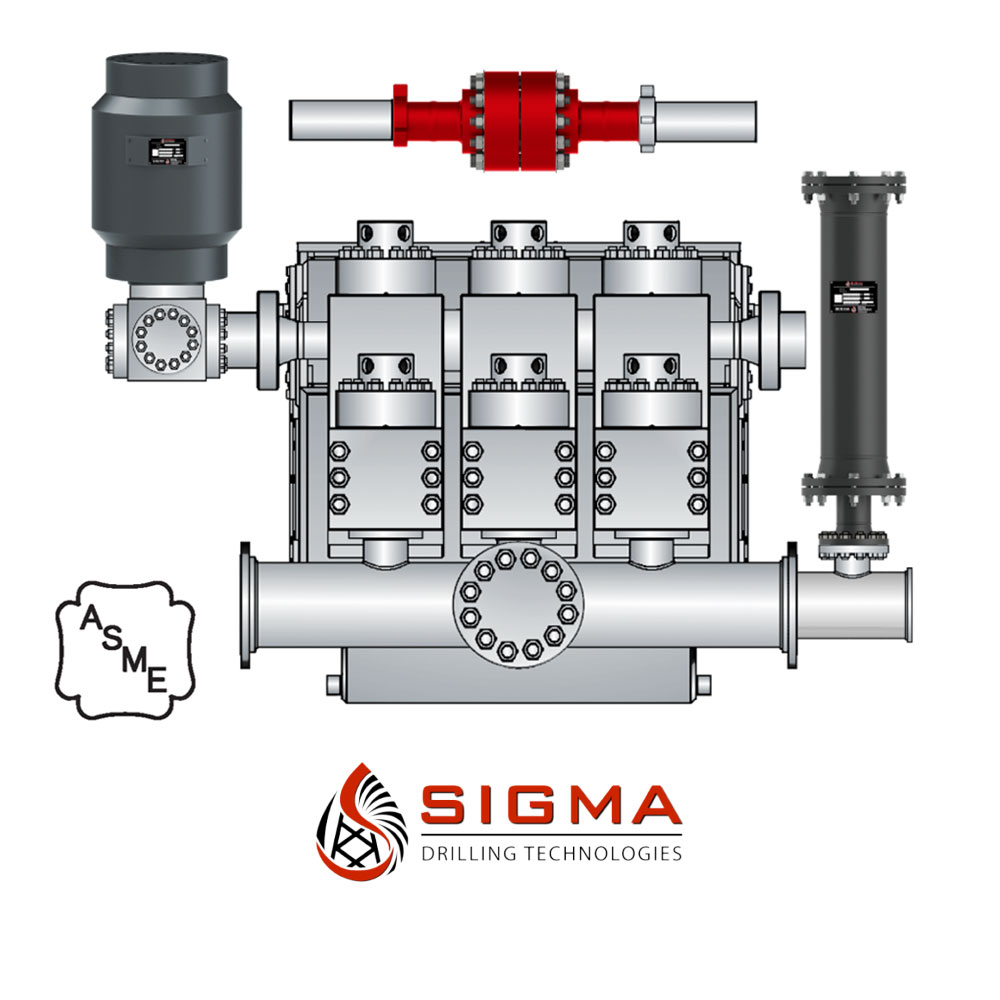

This multistage system utilizes several of Sigma’s advanced products that are proven to maximize efficiencies and upgrade operations of any reciprocating pumping system by themselves.

The Charge Free Dampening System™ is categorically the most sophisticated pulsation control available for your rigs’ pumping operations. With the introduction of the CFD System, Sigma Drilling Technologies proves to be the authority on state-of-the-art advancements in pulsation control technologies.

The OEM series PZ mud pump features a pleasing shape, advanced design, reasonable structure, and high efficiency. At power end, pinion shaft and bull gear are both hard teeth, wear-resistant, and transmission stable.

All parts at the power end except the lubrication oil pump and all parts of the fluid end are completely exchangeable with OEM pumps from the United States.

The pump frame is gang welding on casting and steel–plate construction. The bearing housings of the crankshaft, the transmission shaft, and guides seats are made of steel castings and are welded to the frame after rough–machined. They are stress–relieved through heat-treated aging after welded.

The cylinder is made of VD refined forged steel. And the three valves on each pump are exchangeable. The direct cylinder (the valve on the valve) design may reduce the volume and may improve the efficiency of it. As the customer required, we may nickel plating the surface, which may prevent the cylinder from erosion.

The taper of the valve seat is 1:6. The bottom of the seat is provided with a shoulder to be suitable for high pressure. The valve seat and the upper step of the valve seat conform to API 7K. The discharge valve and the suction valve are exchangeable.

There are two types of liners: high-grade liner and plain liner. The high – grade liner is made of carbon steel as a base metal, which is cast or inserted with high – chrome alloy – steel to ensure wearability, and the hardness has reached the HRC60-65. The plain liner is made of low–carbon steel which is carburized and quenched inside to enhance the surface hardness.

The liner can be inserted from the liner room in front of the cylinder. After the liner has been fixed, the liner and the liner room should be fixed in three holes in the front plate of the rack and should be connected with the cylinder with bolts.

The piston rod conforms to the spec API-7K. The piston is fixed with the 1-1/2"locking nuts. Without weariness of the piston and with the piston through the separated water tank, the piston spray pump may spray water or erosion-proof water to lubricate and to cool.

The discharge site of the pump involves a discharge pulsation dampener, relief valve, and discharge screen. The suction port is 12” flange. Three cylinders at the fluid end are of through-way stepwise structure, realize suction and discharge. The fluid end is composed of three fluid modules (cylinders), each of which is a sectional and communicating construction. The suction and discharge are accomplished by suction and discharge pipes. The suction and discharge valves are vertically aligned with each other to minimize the volumetric clearance.

Spray system includes a spray pump, cooling water box, and spray hose. It function involves cooling and washing cylinder liner and piston, which will extend liner and piston’s service life.

The spray system is a kind of eccentric pump, imported from the United States. The spray pump can be V-belt driven or electric driven. Use water as a cooling lubricant.

Spray hose is installed in the clamp connecting intermediate rod and piston rod, and can reciprocating run along with piston. The spray nozzle is very close to the piston face and can make cooling lubricant wash contact face of piston and liner. A fixed spray hose also can be used. Spray hose is durable.

The power end adopts force lubrication and splash lubrication. The gear oil pump in the reservoir transfers pressure oil to the crosshead, intermediate rod, guide, and each bearing through lubricating lines. The working status of the gear oil pump can be checked through the vacuum gauge aside from the frame.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Distributor of water pump systems including pumps, mixers, valves, pinch valves, and pump parts. Products such as grinder pump systems, agitation pump systems, tank systems, blend and feed systems, portable feeders, wet ends, rubber mold parts, and rubber linings are available. Available pump types include submersible, diaphragm, slurry, dewatering, engine driven, regenerative turbine, piston, sump, sewage, metering, progressive cavity, centrifugal, effluent, and suction pumps. Other pumps such as special purpose pumps, electronic and peristaltic pumps, anti-stalling and lubrication-free pumps, vertical single stage pumps, multistage pumps, liquid ring pumps, diaphragm pumps, stainless steel pumps, plastic pumps, bronze gear pumps, and nickel alloy pumps are available. Value-added services such as system engineering consulting, application assistance, system design, and installation can be provided.

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzechiaCôte d"IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People"s Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People"s Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRomaniaRussian FederationRwandaRéunionSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyria Arab RepublicTaiwanTajikistanTanzania, the United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkmenistanTurks and Caicos IslandsTuvaluTürkiyeUS Minor Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuelaViet NamVirgin Islands, BritishVirgin Islands, U.S.Wallis and FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

8613371530291

8613371530291