mud pump suction line strainer price

1-1/2 inch FNPT Suction Strainer with 1/2 inch round holes. 1.5" Irrigation or sprinkler pump strainer. Also comes in the 1/8" size holes SRHS-200-SM Zinc plated steel. Good for use with sprinkler pumps, irrigation pumps and other centrifugal and semi-trash pumps which can accept limited debris.

These zinc plated round hole strainers can be used with all popular makes of centrifugal pumps for use with hoses and pipes. Drop in to liquid to be suctioned. An "open" area of 50% allows filtering out large damaging debris, yet permits sufficient water passage to keep pumps functioning at full capacity.

For Top Hole skimmer strainers see SSKS-TH or SSKS-BH for Bottom Hole series or SRHS for barrel suction strainers. Image tab belows shows some of the various strainers available from PumpBiz. Please let us know if you do not see what you are looking for or for complete hose kits.

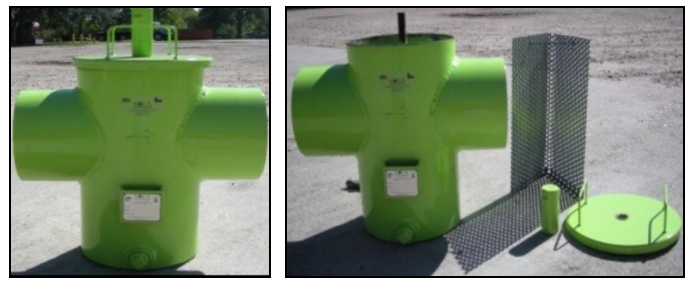

The HURRICANE suction line strainer protects mud pump fluid ends from unwanted debris entering the fluid stream. The strainer is easily cleaned and returned to service in minutes. A variety of end connections are available, including butt weld, flanged or threaded, to install in the suction line of any mud pump. HURRICANE strainers are built to withstand the rough service found on drilling rigs. Inlet / outlet diameters of 4”, 6”, 8”, 10” and 12” are standard. Provide the inlet / outlet size and height D as shown below with any price requests.

Explore a wide variety of mud pump discharge strainer on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These mud pump discharge strainer are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these mud pump discharge strainer is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right mud pump discharge strainer for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of mud pump discharge strainer to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

Looking for reliable wholesale oil pump suction strainer? We have you covered with various oil pump suction strainer, and to ensure the success of all your vehicles" repair and maintenance requirements. Alibaba.com is the ideal online marketplace for some of your automotive needs. With over a thousand products offered online. Shop today and take advantage of our convenient and pocket-friendly wide variety of items. We have a great number of wholesalers who are just waiting for you to make a deal.

With numerous wholesale oil pump suction strainer, our tools, mostly bought in bulk can help you make great savings. Automobile tools are a broad category that includes several separate tools such as car scanner tools, dent puller for car, car code scanner, car tester, fixed car diagnostic, car tool kit, and so much more. But whatever it is that you are looking for, it is worth checking it out here, you might be surprised and come across some hard-to-find items.

A great tip would be to enter a word on the search bar to filter your search and get the desired outcome which will make your online shopping experience enjoyable and efficient! Besides, this platform was conceived to make your experience pleasurable as possible. Therefore, grab the opportunity and get oil pump suction strainer now on Alibaba.com.

We are the manufacturer, supplier and exporter of Backwash Arrangement Duplex Strainer from Chennai-India to Globally offered by us are precision designed to meet the specific requirements of removing foreign particles in the flowing applications or services. It consists of two Basket strainers arrangement with backwash arrangement which is used for flawless functionality standards also help in increasing the overall service life of the pumps, valves and other flow control equipment. Our products are widely used in the low-pressure process applications, bulk drugs, pharma, Refinery, and other food grade industries.

Strainers are designed to remove large contaminants (defined as 40-microns or greater) from the material being processed. The ratio of mesh to microns changes depending on the number of gaps within one linear inch. For example, 60-mesh strainers typically catch particles around 240-microns, and 100-mesh strainers catch particles sized at 150-microns.

There are a number of different advantages to using this type of strainer. The easy-to-open design of the strainer provides for simple maintenance. Simplex strainers also have a large particle holding capacity with less pressure drop over the length of the filter element.

At Eaton, Simplex Industrial Basket Strainers are designed to be used where it is possible for the line to be shut down for short periods of time to allow for maintenance. Eaton’s standard cast pipeline strainers meet a number of high standards. These include ISO 9001-2008 quality management, reduced purge volumes due to their ultra-low discharge strainer technology, and appropriately sized parts to meet any flow rate and retention requirement. To learn more, check out our website.

The advantages of this type of strainer lie in the price, as Y strainers are commonly low cost. Maintenance for this type of strainer can be a little tricky, and particle retention capacity is low.

One of the biggest advantages of duplex strainers is their ease of maintenance. Not only do duplex strainers have an easy-open design, they are also able to be cleaned individually while one strainer stays on standby. In addition to an easier maintenance, duplex strainers have high particle holding capacity, which provides less pressure drop through the strainer. To get more specifications, peruse our selection of duplex strainers here.

Eaton’s Duplex Industrial Basket Strainer is able to operate on a continuous basis, never requiring the line to stop for maintenance tasks to be performed. This is due to the two baskets being used, which operate independently of one another. Once one of the baskets becomes full, the flow is channeled to the other basket, allowing the full basket to be removed and cleaned out. The design of Duplex Industrial Basket Strainer makes it a great option for applications where lines cannot be shut down for maintenance to take place. Visit our site to learn more.

The main advantage of using an automatic strainer is their self-cleaning capabilities. Because of the automatic nature of the strainer, the cleaning process is never interrupted. Instead, self-cleaning is controlled in a number of different ways, most commonly timers, pressure drop settings, or manually. Contact us today to find out your options.

Gas and oil strainers can be utilized in a number of different areas. Most commonly, strainers are used either in upstream or downstream applications.

Upstream applications include those for drilling oil. Strainers are used in the derrick/mast, drawworks and top drive. They are also used in mud/fuel tanks and within power/pump stations and within the shaker unit.

Strainers are designed to capture solid particles and other solid contaminants within a liquid and stop them from continuing through the system. When functioning properly, strainers help prevent potential damage to other parts of the system, including engines, pumps, nozzles, and heat exchangers. With better performing strainers, cost of ownership decreases while lifecycle of the equipment being used is extended, benefitting producers in the long run.

Pump inlet strainers are common parts for all airless sprayers. Many inlet strainers are compatible with sprayers that are not listed above. Consult your parts manual to ensure the correct strainer is purchased.

It’s no secret that a pump that runs at peak efficiency uses less fuel, experiences less downtime and costs less to operate. The time you spend maintaining your pump is actually an investment in its lifetime performance and value. In fact, there are many ways that a diligently maintained pump can reduce your costs, while increasing efficiency. For instance, by ensuring your pump investment brings an ease-of-service design, the time you spend on maintenance can be significantly minimized.

Using the information below, see if you can identify some of your own trouble spots, and uncover potential solutions to get you back on the road to good pump health – boosting profits along the way.

Take notice of the discharge flow. Has it visibly decreased? Is it taking your pump longer to do the same job than it used to? The slowed flow may be caused by a collapsed suction hose lining, a leaking gasket, a plugged suction line or a damaged or worn impeller or wear plate.

To determine the cause of any decrease in flow, the discharge pressure and the suction vacuum should be measured while the pump is operating. If the pump discharge pressure and suction vacuum were measured at start up, the latest readings should be compared to the originally recorded readings. When troubleshooting any pump and system, follow the high abnormal reading taken earlier. A higher than normal discharge pressure reading will indicate a decrease in suction vacuum, and could be a sign of a clogged or partially clogged discharge line, a closed valve, air unable to evacuate or any obstruction outboard of the point the gauge was installed into the discharge line. It is common practice to install gauges approximately two to four pipe diameters from the pump.

Both gauges can also decrease. If they do, the problem is located between the installed locations of the gauges. In this case, the problem is within the pump. A clog at the eye of the impeller, wear, wide clearances and air induced into the suction line could all cause both gauge readings to decrease. Note that gauge readings almost always teeter back and forth. But again, follow the problem to the highest abnormal gauge reading.

The pump isn’t re-priming as rapidly as it once did. Most commonly, slower re-prime can be attributed to excessive face clearance. If this is not the cause of your slowdown, check the following:

A maximum vacuum check can be performed to determine the location of the problem. Fill the pump with the minimum amount of water than what the volute casing normally retains for re-priming. To do so, simply remove the suction flap valve, priming the volute casing and energizing the pump. After the pump achieves dynamic operation, turn the pump off and allow the liquid in the pump to return to the sump.

Whatever product remains in the volute casing is the minimum left for a re-prime cycle. Install a vacuum gauge on the suction side of the pump and close a valve in the suction line outboard of the gauge. If there are no valves in the suction line, a solid gasket without an inside diameter hole may be installed in a pipe joint to create a “valve” effect. Energize the pump and inspect the vacuum gauge. The pump will pull a vacuum against the closed valve or solid gasket. This reading is the equivalent to the pump’s lift capabilities. If a vacuum gauge calibrated in inches of mercury (Hg) is used, multiply that reading by 1.13 to convert to feet of water.

If your pump sounds like a bunch of marbles rattling in a can, this may be an indication of cavitation – and could be caused by a suction lift that’s too high, a suction hose that’s too long, plugged or has a collapsed lining, a clogged strainer, a combination of any of these, or perhaps a problem on the discharge side of the pump. Failing bearings can also cause excessive noise. Noise should be qualified as mechanical or hydraulic noise. Run the pump briefly without water. If the noise is no longer present, the noise is one of a hydraulic nature. If the noise is present after removing the product, the noise is mechanical. Again, a quality set of gauge readings will direct your attention to the problem side of the system if the noise is deemed to be a hydraulic noise.

If a pump’s suction check valve is clogged, the strainer may be too large or too small, or face clearance could be too wide. Alternatively, the strainer may be stuck in mud, plugging the suction side.

In this case, very likely, the flow of liquid into or out of the pump is being restricted. Improper impeller clearance could be slowing re-priming, the suction strainer or recirculation port in the volute casing may be clogged or the pump’s ability to handle air through an air release line, air release valve or open ended discharge line may be obstructed. Never open a hot pump. Allow the pump to cool to the touch prior to opening. Even after cooling, there may be lingering pressure inside the volute casing.

Using a vacuum gauge, make sure that the suction line, fittings and pipe plugs are airtight. Pumps, such as Gorman-Rupp pumps typically have a tapped hole for easy connection of a vacuum gauge. Use pipe dope to seal gauge threads and pipe plugs. A vacuum gauge will fluctuate or give erratic readings while handling air during operation. At shut down, the suction gauge reading will display the vertical distance from the gauge tap to the product level. If this vacuum falls off after shut down, atmospheric pressure is entering the suction pipe causing the pump to lose its static lift. Replace the suction flap valve if worn and check for air leaks if the product returns to the sump. Replace leaky seals and badly worn hoses, if necessary.

The rubber lining in a suction hose can pull away from the fabric, causing partial blockage of the line. If the pump develops a high vacuum but low discharge pressure, the hose lining may be blocking suction flow. Gauge readings during operation will be higher than normal with the lining collapsed. To rectify this problem, simply replace the hose. Check the suction strainer. Frequent inspection and cleaning of the suction strainer is particularly important when pumping liquids containing solids. Gauge readings during operation will be higher than normal if debris obstructs the flow through the strainer. Always use the proper size strainer to prevent the pump from clogging.

Check the volute casing, impeller vanes, wear plate or wear rings and attaching hardware. A removable cover plate on the pump allows for quick, easy access when inspection of the impeller and wear plate is needed. These components should be inspected every six months or sooner, depending on pump application because they are subject to faster wear when pumping abrasive liquids and slurries. Gorman-Rupp wear plates and wear rings, for instance, can be replaced without replacing expensive castings. A shut off test can be performed to measure the internal wear. Start the pump and allow it to achieve full flow. Slowly close a discharge valve and record suction and discharge gauge readings. Those reading should equal the maximum pressure noted on the pump performance curve at zero flow.

Pumping efficiency will be reduced if the clearance between impeller and wear plate or wear rings is beyond the recommended limits. If the clearance is less than recommended, components will wear by rubbing, causing excess work for the engine or motor. Check the impeller clearance against the pump manual specifications and adjust it if necessary. A shut off test can be performed to verify not only wear but face clearance as well.

Better pumps are equipped with a double seal, which is lubricated under pressure by a spring-loaded grease cup, or an oil-lubricated seal for long, trouble-free service. Some pumps are equipped with a single seal that is lubricated by the liquid being pumped. Sand or other solids can cause rapid wear of the seal faces. Check and replace the seal if worn. The maximum vacuum test will qualify the integrity of the pump’s seal. Replace the seal liner or shaft sleeve if they have scratches.

Worn bearings can cause the shaft to wobble. Eventually the pump will become noisy and overheat. Worn bearings will reflect higher amperage readings due to the increased wear. Sooner or later it will freeze up and stop. Replace bearings at the first sign of wear to alleviate destructive damaged caused when bearings fail catastrophically.

The pump may not be getting the power it needs to operate efficiently. The engine may need a tune-up, or the motor may need service. Refer to the owner’s manual often for optimum efficiency.

Check air release devices, valves, check valves and shock control devices for proper operation. Old discharge lines are subject to internal rusting and pitting, which cause friction loss and reduce flow by as much as 15%. A discharge gauge reading will increase with the additional losses. Replace badly deteriorated lines.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The discharge line is the output end of pump, its end is provided with a discharge strainer assembly will mud pump generated pressure directly transported to underground; another end of the pipe with air out package assembly and safety valve and pressure gauge.

With over 10 years developing, we were developed from the beginning drilling service to manufacture factory who produce Mud pump and its spare parts, DST tools and Solid control products.

Kingwell oilfield are able to supply the mud pump and other OEM interchangeable spare parts, kindly contact with us if there has some enquiries, we will quote you a competitive price and fine delivery soon.

8613371530291

8613371530291