mud pump supplier in malaysia for sale

A wide variety of malaysia mud pump options are available to you, such as 1 year, 2 years and 3 years.You can also choose from new, used malaysia mud pump,As well as from energy & mining, construction works , and machinery repair shops. and whether malaysia mud pump is 1.5 years, 6 months, or unavailable.

Vikas Pumpis a growing Sludge Pump Manufacturers In Malaysiaengaged in offering a wide range of Industrial Pumps, Water Treatment Plant, Demineralisation Plant, Rain Water Harvesting Systems, Transfer Conveyors, Steel Tank, Industrial Chain, etc. to serve various purposes. By serving an excellent range at industry-leading prices, we have become a preferred choice of leading companies to get Sludge Pump In Malaysia. We stand behind our products with confidence, as all our products reflect the standard of quality we explain and we maintain.

As one of the leading Sludge Pump Manufacturers in Malaysia, we make sure to test all our products against several parameters before delivering it to our valuable clients. Our products are the best in the industry and are known for their smooth performance, innovation, excellence and affordability. Our efforts are always in the direction to meet and exceed client expectations. We offer the best Sludge Pump Manufacturers In Malaysia, Our pricing is not just competitive, but it matches the best in the industry. If you are looking for a reliable supplier and Manufacturers of Sludge Pump in Malaysia, you must contact us now.

Our company is managed to attain the position among the top Sludge Pump Exporters and Suppliers in Malaysia. If you want impeccable products, discuss your requirements with our experts. Call us or drop your enquiry to get our assistance today.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

We have designed affordable annual subscription plans which would help you get leads for your business. You can have a look at our pricing chart by clicking on this link: https://www.energydais.com/pricing/ . These plans are customized according to the specific needs and requirements of your business.

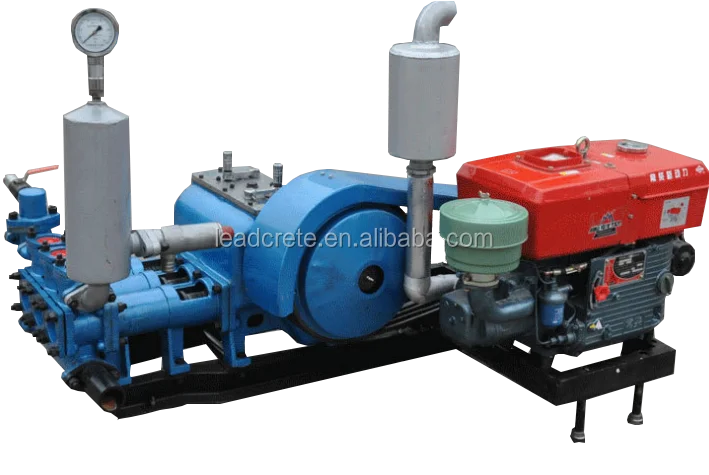

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

Yes. We use third-party companies to provide best quotations for your shipment and inspection of manufactured goods. We make sure that you get quality products from the manufacturer at the best price.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Since commencing its full scale pump business in 1952, Kubota has been developing and manufacturing pumps for water supply, sewerage, rainwater drainage, power generation and steel production. Kubota"s pumps play an important role within our lives, supporting people"s everyday life. They play an active role from upstream, such as water purification plant, to downstream, such as wastewater treatment plant. Not only developing pump as a product, but Kubota, certified as ISO9001, has also built pump plants by taking advantage of its general engineering capabilities. Kubota has developed its pump business inside and outside Japan, including Southeast Asia and Middle East. In Southeast Asia, it is fully utilizing its production centers in China to provide products stably and corresponding to rapidly growing demand for infrastructure. Meanwhile, in Middle East, Kubota offers a whole range of pumps for seawater desalination and sewerage plants, from seawater intake pumps to long-distance water transfer pumps and high-pressure pumps for reverse osmosis (RO). Today, Kubota intends to further enhance its after-sale services such as maintenance of pumps, in addition to the provision of products.

Regaline Pumps is a Water Pump Supplier in Malaysia providing a comprehensive range of centrifugal pumps in single and multiple stages, submersible pumps and other pumps for special services. Pumps are essential in our daily lives for transferring, boosting and handling large industrial liquids or water fluids. Trusted by many companies nationwide, our products are of high quality made by materials such as cast iron, ductile iron, stainless steel and more. As a Water Pump Supplier Malaysia with over 20 years of experience in the industry, our team of driven experts are skilled to create customized solutions for each of our customers. We have the product for every situation you need. Just talk to us and let us know what you need!

Ramnath Industrial Park, Rajkot Ramnath Industrial Park, Kothariya Ring Road, Beside Murlidhar Way Bridge Aaji dem, Near Ramvan, Ramnath Industrial Park, Rajkot - 360002, Dist. Rajkot, Gujarat

Amraiwadi, Ahmedabad No. 16, Bankar Estate, Near Anup Estate, Behind Bharat Party Plot National Highway No. 8, Amraiwadi, Amraiwadi, Ahmedabad - 380026, Dist. Ahmedabad, Gujarat

MTI is a full-service company providing equipment, parts, and service to the oilfield, HDD (Horizontal Directional Drilling), geothermal, mining and water well drilling industries.

We manufacture a complete line of solids control equipment including; mud reclaimers & mud recyclers, shale shakers, de-silters, de-sanders, and pump packages, all for sale or for rent, allowing us to achieve a higher standard of excellence.

A large inventory of parts and accessories , and knowledgeable staff makes Mud Technology the smart choice for operators needing fast-turnaround times and competitive pricing.

Our staff is available to assist you with complete line of parts, including pump parts, shaker screens and drilling mud all available at competitive prices. As we are just a phone call away, we are available to answer questions and assist you with troubleshooting while you are in the field.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Since 1995, we have been a leading professional pump & system solutions provider, engaged in R&D, manufacturing, marketing, sales and service of a full range of pumps, systems and machineries.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291