mud pump valve seat failure supplier

Customers said they wanted long-lasting, easy-to-use valves and seats, and we delivered. Made from domestically sourced steel, GD Energy Products valves feature a two-piece friction-welded design, proprietary bonded inserts, and innovative geometry to deliver significantly longer life. GD Energy Products’ field proven Valves & Seats meet API Standard, and come with our “Ready Inventory” promise that we’ll have it in stock, when you need it.

Our full-open valves and seats are designed for use in GD Energy Products PZ, F-Series, and National 12P lines of triplex drilling pumps. This gives you options to use these parts across your whole fleet of pumps.

Mud Pump Valve & Seat are made of premium alloy steel through one-piece forging and carburizing treatment processes, thereby ensuring high intensity. In addition, the precise calculation is performed and CNC machining is conducted for the dimensional matching of the valve seat and valve body working angles to enhance the service life of the valve body and valve seat. Our valve products are able to work smoothly in normal mining and digging conditions for over 400 hours.

The Patriot Harsh Duty Valve is a bonded urethane valve that will hold up in the most extreme drilling environment. The Patriot HD offers the strongest urethane bond of any valve for increased service life and a stronger seal.

Superior Performance, Long Run Life, Excellent Abrasion Resistance and Sealing Surface coupled with the highest rated chemically resistant urethane make the Patriot HD Valve an excellent choice for any drilling application.

Design innovation has been the driving force for Weir Novatech and its rigid full open valve and seat. Novatech offers valves and seats for all major well service and mud pump applications including work-over, cementing, acidizing, fracturing and drilling. Weir Novatech valves and seats are manufactured by combining the advantages of forged steel to assure impact strength and precision casting to maximize flow and minimize fluid turbulence. All Weir Novatech valves and seats are manufactured to rigid quality control standards. Weir Novatech is the leader in full open valve and seat technology, providing the first drilling valve and seat in the industry rated for continuous service at 7500 PSI. Available in API 4, 5, 6, 7 and 8 sizes, plus seats for all OEM tapers. Weir Novatech manufacturers the strongest and most reliable valve and seat in the industry.

Mud pump valve body and mud pump valve seat were produced according to API Specs as well as ISO9001 quality system by our company, were used high quality alloy steel 40CrNiMo、20CrMnTi, processed with overall forging and carburizing, the surface hardness HRC≥60; They were produced under accurate calculation and numerical control lathe, which makes dimensions of valve body and seat perfectly match each other, also were used many times by land and offshore platforms. The service life of valve body and seat are 4-5 times more than ordinary ones, which improves the working efficiency and decrease the cost and working strength.

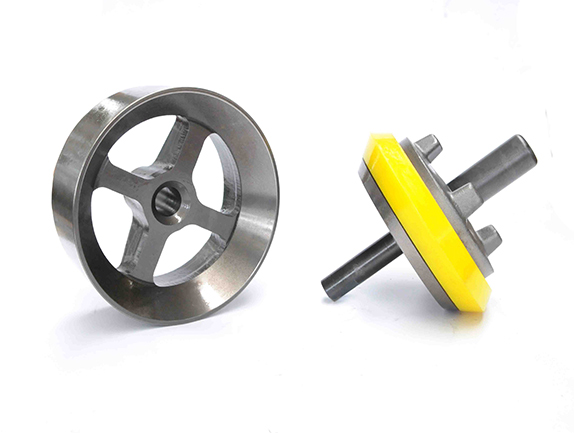

Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). As to valve insert (valve rubber) material, we can provide Nitrile rubber (NBR) valve insert, polyurethane (PU)valve insert, compound polyurethane and HNBR.

A wide variety of valve seat mud pump options are available to you, such as 1 year, not available.You can also choose from new, used valve seat mud pump,As well as from energy & mining, construction works , and machinery repair shops. and whether valve seat mud pump is 1.5 years, 6 months, or unavailable.

Mud pump valve seats are used in on-shore and offshore oil and gas drilling operations and in pumps used in land-based fracking operations. Valves used in these types of pumping equipment operate at a very high frequency – up to one hertz (one cycle per second) – and are prone to high wear and degradation from hysteresis. Parker’s premium grade valve seats feature our Resilon® Polyurethane which has a high modulus of elasticity to successfully withstand high frequency operation and resist hysteresis.

Where typical urethane valves may last up to 400 hours, our proven valve seat designs with Resilon Polyurethane have lasted up to 800 hours (400 hours longer) – greatly improving drilling productivity through longer life. Longer valve seat life means maintenance intervals can be extended and production jobs can be completed before service is required.

Mud pump valve seats are used in on-shore and offshore oil and gas drilling operations and in pumps used in land-based fracking operations. Valves used in these types of pumping equipment operate at a very high frequency – up to one hertz (one cycle per second) – and are prone to high wear and degradation from hysteresis. Parker’s premium grade valve seats feature our Resilon® Polyurethane which has a high modulus of elasticity to successfully withstand high frequency operation and resist hysteresis.

Where typical urethane valves may last up to 400 hours, our proven valve seat designs with Resilon Polyurethane have lasted up to 800 hours (400 hours longer) – greatly improving drilling productivity through longer life. Longer valve seat life means maintenance intervals can be extended and production jobs can be completed before service is required.

Also known as Nova Tech Valve or Roughneck Valve or High Pressure Valve. Full open Seat & wing guided Valve design features a large metal-to-metal bearing area for long life, directly casted urethane insert on valve body results in a perfect round shape that prevents premature failures of the insert. The insert is casted around the serrations, thus failure due to tears from the serrations are eliminated Most importantly the insert is not stretched over the valve during installation; there are no residual stresses left, to shorten insert life.

We can supply many kinds of mud pump spare parts to fit your drilling needs, suiting to almost all popular mud pumps in the world.. Such as valve, valve seats, liner, piston, fluid end parts, crankshaft Assembly, Pinionshaft assembly, valve cover, liner cage, liner nut, valve seat puller, extension rod and piston rod, bearing, cylinder etc.

4.The rubber sheet is made of polyurethane material which improves the service life of valve assembly, the operational use time is more than 300 hours.

According to the use of mud pumps in the jurisdiction, valve box puncture, bearing burnout, and abnormal noise are all frequent failures that affect the normal use of mud pumps. Therefore, carefully studying the causes of the above problems plays a key role in prolonging the service life of the mud pump.

The drilling mud pump valve box is an important component of the hydraulic end of the mud pump, because the working conditions of the mud pump valve box are harsh working environments such as high pressure, high sprint, and high abrasiveness.

The main reasons for the leakage of the valve box of the mud pump are: long-term high-pressure use, the material of the valve box is fatigued, and when penetrating cracks occur, the current conditions cannot be repaired.

Because the working conditions of the drilling pump valve are very bad, the valve disc and valve seat of the discharge and suction valves have an impact in each flush. The higher the pump speed, the greater the impact and scour wear.

Because of this, the working frequency of the drilling pump is not very high. Even so, the working life of the mud pump valve is still very short, and it is one of the weakest links in the drilling pump. The valve disc and valve seat need to be replaced frequently during work.

According to the valve box used and maintained, most of the puncture leakage occurs at the joint surface of the valve seat and the valve box. Therefore, it is necessary to replace the valve seat regularly.

At the same time, check the inner and outer walls of the valve box. When installing and replacing the valve disc and valve seat, the valve seat must be cleaned to ensure that the fitting surface of the mud pump valve box and the valve seat is clean and free of contamination, and there can be no anti-rust oil on the valve seat, and do not apply any oil stains.

Through correct installation and replacement of valve disc, valve seat and careful inspection of valve box, the fatigue limit of valve box can be reduced, thereby prolonging the service life of mud pump valve box.

When there is a puncture in the valve box, our current repair method is welding repair, but the effect is average. Generally, if the surface is punctured, or there are obvious cracks, it can be used through the car and then welded to the original size.

However, penetrating cracks cannot be seen with the naked eye. Now we basically rely on experience in repairs, and it is difficult to fundamentally solve the problem. Many valve boxes are dark wounds that cannot be determined penetrating during maintenance. Its use can be determined from the integrity of the surface of the valve box of the mud pump.

Some valve boxes with good appearance will be completely punctured as long as they are exposed to high pressure during the specific use process. Therefore, many repaired valve boxes will be seriously punctured within a few days after being put into the well, causing rework and making us overhaul. The service life of the latter pump head is significantly shortened.

Hydraulic Valve Seat Pullers and Kits is designed for safely and efficiently removing valve seats from mud pump. The components are made from premium forged steel with throughout heat treatment for center stem and nut in order to sustain high pulling force without mechanical yielding. Available in API and Non-API.

8613371530291

8613371530291