mud pump valves factory

Customers said they wanted long-lasting, easy-to-use valves and seats, and we delivered. Made from domestically sourced steel, GD Energy Products valves feature a two-piece friction-welded design, proprietary bonded inserts, and innovative geometry to deliver significantly longer life. GD Energy Products’ field proven Valves & Seats meet API Standard, and come with our “Ready Inventory” promise that we’ll have it in stock, when you need it.

Our full-open valves and seats are designed for use in GD Energy Products PZ, F-Series, and National 12P lines of triplex drilling pumps. This gives you options to use these parts across your whole fleet of pumps.

Mud Pump Valve & Seat are made of premium alloy steel through one-piece forging and carburizing treatment processes, thereby ensuring high intensity. In addition, the precise calculation is performed and CNC machining is conducted for the dimensional matching of the valve seat and valve body working angles to enhance the service life of the valve body and valve seat. Our valve products are able to work smoothly in normal mining and digging conditions for over 400 hours.

Mud pump valve body and mud pump valve seat were produced according to API Specs as well as ISO9001 quality system by our company, were used high quality alloy steel 40CrNiMo、20CrMnTi, processed with overall forging and carburizing, the surface hardness HRC≥60; They were produced under accurate calculation and numerical control lathe, which makes dimensions of valve body and seat perfectly match each other, also were used many times by land and offshore platforms. The service life of valve body and seat are 4-5 times more than ordinary ones, which improves the working efficiency and decrease the cost and working strength.

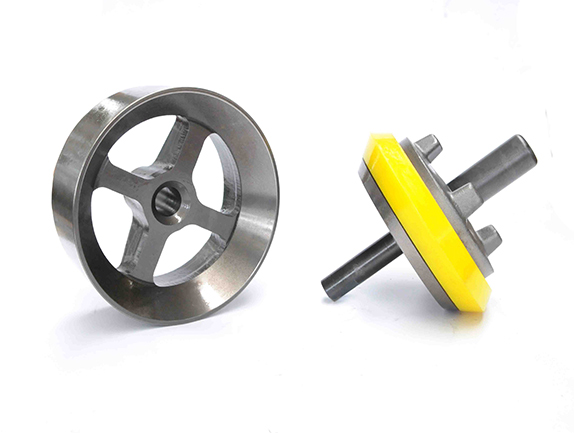

Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). As to valve insert (valve rubber) material, we can provide Nitrile rubber (NBR) valve insert, polyurethane (PU)valve insert, compound polyurethane and HNBR.

A wide variety of mud pumps valve options are available to you, such as 1 year, not available and 2 years.You can also choose from new, used mud pumps valve,As well as from energy & mining, construction works , and machinery repair shops. and whether mud pumps valve is 1.5 years, 6 months, or unavailable.

Since 1983, Centerline Manufacturing has been involved in the design, manufacture, and production of drilling equipment, support equipment, and tooling for the water well industry. When you need a mud pump built with a “get the job done attitude”, consider Centerline Manufacturing’s line of hydraulic mud pumps.Through expert design and acute attention to detail, Centerline Manufacturing’s aim is to maintain top of the line mud pumps, which perform beyond the highest expectation of the customer.

The pump bodies on our production models are made of a heat treated, high alloy, cast aluminum, with strength greater than cast iron. All of our machining is done in-house by CNC machines. The machined castings are hard anodized inside and out, to a hardness near that of a diamond. This protection creates an abrasion and corrosion resistant pump, that will provide for many years of service and reliability. The hydraulic drive cylinders are engineered for a continuous, high pressure, reciprocating duty, in any harsh environment. Our hydraulic shifting valves are cast of a material that has four times the wear resistance of standard hydraulic valve castings. We manufacture, distribute, and support this line of pumps, in such a manner as to make our pump the standard installation piston mud pump of our industry.

What makes our mud pumps different? All of our weight and size savings mean nothing if our pumps don"t deliver long term, day in and day out, trouble-free drilling service. We are committed to manufacturing a pump that drill rig manufacturers and drilling contractors recognize as top quality in every way. We are constantly designing new products, in order to provide the the drilling industry with innovative, high performing standards and products.

We make Mud Pump Valves, which are used extensively in compressors. These are made with qualitative raw material such stainless and aluminum. Our valve heads are the disk part of a poppet valve that gives a tight closure on the valve seat. The valve head is usually larger in diameter than the exhaust valve.

By keeping our connotation with the present market advancement, we are affianced in providing a supreme consignment of Bucket SealMud Pumps.Commended for their perfect finish, these are highly valued amid our customers owing to their uses. Along with this, these are well inspected in order to provide a flawless collection at the end of our patrons.

WOM’s Model 600 Mud Valve features a seat assembly engineered with a lock shell design to ensure accurate seat alignment every time the valve is cycled. WOM’s Model 600 Mud Valve body cavity area is designed to allow continuous flushing by the fluid flow. This action prevents the valve from sanding up, even in standpipe installations.

WOM’s Model 600 Mud Valve is in-line field repairable and has several features which make maintaining the valve easy and efficient such as a rising stem design, a visual position indicator lens and replaceable stem packing.

WOM’s Model 600 Mud Valves are offered with threaded, weld and flanged end connections. End connections vary by size and pressure rating depending on customer requirements.Available in sizes ranging from 1 13/16-in. to 5 1/8-in.

WOM’s Model 600 Mud Valve is designed for rigorous heavy-duty service in abrasive conditions and specifically engineered for the tough requirements of oilfield services. Model 600 Mud Valves are commonly used for a number of oilfield applications such as high pressure mixing lines, standpipe manifolds, wellheads, production manifolds and production gathering systems.

8613371530291

8613371530291