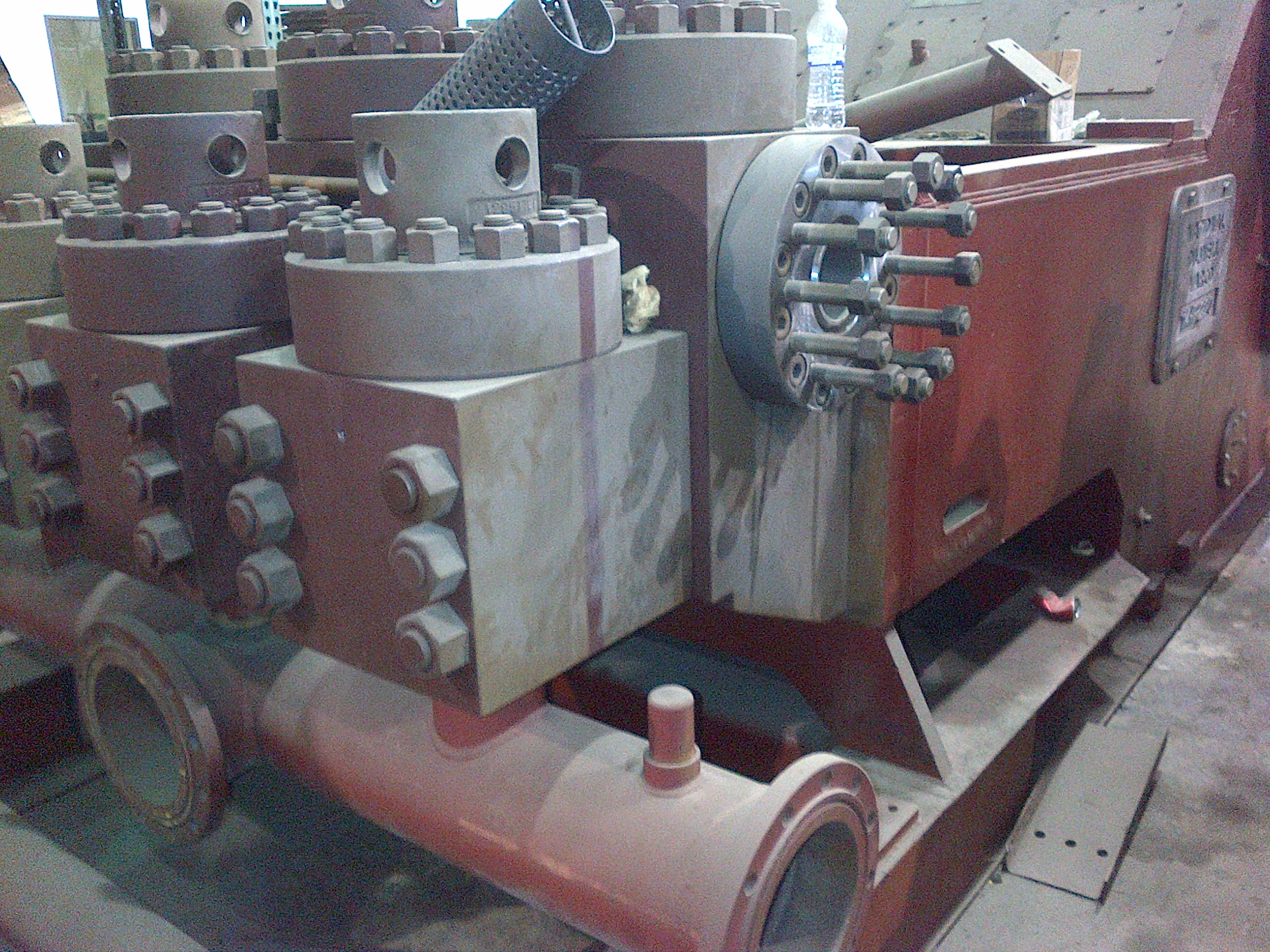

national 14 p 220 mud pump factory

This website uses cookies to improve your experience while you navigate through the website. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are as essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may have an effect on your browsing experience.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

FAB Marine Spares is the one of the leading suppliers in Bhavnagar (India). We buy all the machinery and spares direct from Alang which is Asia’s one of the largest ships breaking yard. We do stock and supply all types of Ship’s New, Used and Reconditioned Genuine Machineries and Spares across the world as per client"s requirement. We also recondition used machineries in workshop to use efficiently.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Complete with Southwest fluid end modules which have been reworked and pressure tested by Southwest and P-QUIP liner retention systems. Can be provided with AC or DC traction motors. Currently configured for top mounted motor arragement.

During the production cycle, theseFluid Ends have strict non-destructive testing, as ultrasound inspections and penetrant tests to ensure the ultimate suitability.

We know that cost savings on identical spare parts is important for offshore rig Companies today. Therefore we provide our services and spare parts at considerable cost reductions compared to sourcing from the major OEMs. Tratec can guarantee identical parts with all required part certificates. We maintaing the highest quality, using state-of-the art service facilities and experienced, specialist mud pump engineers for service work.

Tratec has supplied more than 20 mud pump spare part, overhaul and recertification projects the last 5 years. References include rig companies Odfjell Drilling, Maersk Drilling, Archer, Saipem, KCA Deutag, and others.

Tratec is an experienced specialist supplier of overhaul, SPS, parts and service for rig and drilling equipment. We can provide Norwegian quality and decades of experience, while maintaning sensible prices and flexible solutions.

Tratec have delivered solid cost savings to our customers. This is due to our lower cost base, system with access to identical parts directly from manufacturer, and utilizing our experienced drilling equipment employees at very competitive rates.

Tratec can supply overhaul and parts compatible with the following Mud Pump makers and trademarks: National Oilwell Varco (NOV), MHWirth, Continental Emsco, Gardner Denver, Lewco, Drillmec, and others. Tratec is an independent supplier of drilling equipment parts. Tratec is neither a licensee, nor is affiliated with any of the named original equipment manufacturers (OEM). The manufacturer’s names, equipment names, or trademarks used herein are solely for identification purposes, and are not intended by Tratec to cause confusion as to the source, sponsorship, or quality of the parts supplied by Tratec. The original equipment manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Tratec’s supply of parts.

The mud pump is the "heart" of the oilfield drilling system, and the mud pump cylinder liner is an important wearable part of the hydraulic end of the mud pump, so the life of the mud pump cylinder liner directly affects the life of the mud pump. Because the working surface of the cylinder liner is in contact with high-temperature and high-pressure gas, there is a piston ring that reciprocates at high speed on its surface, which determines that the cylinder liner must not only have sufficient strength and rigidity, but also must be resistant to high temperature, corrosion and wear damage.

Halliburton / National Oilwell Varco / 2500 HP / 2250 HP / 2000 HP / 600 HP / 400 HP / 350 HP / 300 HP / Cummins / CAT / DDC / Detroit Diesel / Allison /

8613371530291

8613371530291