oil rig mud pump manufacturers in stock

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Welcome to Pickett Oilfield’s mud pumps web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used mud pumps and mud pump parts to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including mud pumps and parts to choose from at competitive prices. Browse our inventory of mud pumps and mud pump parts for sale at competitive rates.For more information or to request a quote, please Contact Us at 936-336-5154 or email to Sales@PickettOilfield.com.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Distributor of heavy duty submersible mud, sand, sludge & slurry pumps. Specifications of pumps include 5 hp to 30 hp motor, three phase, 208 V to 575 V, 6.8 A to 39 A, 3 in. to 6 in. NPT sizes, 38 ft. to 134 ft. head size & 475 gpm to 1,690 gpm flow rate. Features include impellers, wear plates & agitators made from abrasive resistant 28 percent chrome iron, process hardened ductile iron volutes casted with thick walls, class H motor insulation, double silicon carbide mechanical seals, heavy duty lip seal & stainless steel shaft & shaft sleeve. Sand, sludge & slurry pumps are used in mines, quarries, dredging, coal & ore slurries, sewage treatment plants & steel mills. UL listed. CSA approved. Meets OSHA standards.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

There are three types of mud pumps, depending on the type of client and the size they want. For general, mud pumps, there are three basic types of mud pumps, depending on the type of client and budget. The piston pump is another compressed mud pump, which is a pushed electric compressor mud pumps and by compressed air.@@@@@

Electric mud pumps are largely divided into three categories, among them the electric mud pumps and the semi-trash mud pumps. The piston inflated mud pumps are also classified in terms of the type of mud pumps, among them are electric mud pumps and semi-trash mud pumps. In addition, the piston inflates mud and mud pumps will be inflated by the piston, which is inflated mud pumps.

The Baoji/Bomco F1000 Triplex mud pump has a max. working pressure of 5,000PSI and a 6-3/4" liner size. This model is the first choice for the medium and deep dr... More Info

The Baoji/Bomco F1600HL Triplex mud pump has a max. working pressure of 7,5000PSI and a displacement of 46.5L/S with 6" liner size. This model is the f... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Emsco/Bomco 1600 Mud Pump, Unitized 1600 Mud Pump Powered by Two GE 752 Motors Charging Pump, Liner Flush Pump, Relief Valve, Mud Gauge, Etc. ....Call For Price More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - 1 - Rebuilt Gardner Denver PZ-9 Mud Pump Package, New Caterpillar C-27, 1050 HP diesel engine. Belt-driven. comes with pulsation dampener, discharge block, precharge, li... More Info

Mud Pumps - 1 of 3 used Gardner Denver PZ-8 triplex mud pumps. This would be a good rebuildable core. We also have new, rebuilt and good used pumps and packages available for sale ... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The NOV Fluid End Expendables and accessories add value to your drilling rig by increasing the operating range of existing mud pumps while reducing their maintenance and downtime. Fluid End Expendables are in-stock and ready for delivery at World Petroleum Supply, Inc.

National Oilwell Varco develops the highest quality, field-proven fluid end expendables and accessories for all pump manufacturers to provide extended run times and longer service life.

Mud pump liners The ceramic, chrome iron sleeved, and hardened steel liners are manufactured using only the highest-grade materials and offer extended run times with excellent resistance to abrasion, erosion, and corrosion.

Mud pump piston rods We manufacture crosshead extension rods, quick connect rods, self-aligning rod assemblies, and piston rods for all types of mud pump manufacturers. All rods are manufactured from high-quality materials and machined to exact tolerances to provide long life and superior service

Mud pump pistons We offer pistons of all styles and compositions designed for various types of drilling applications. All pistons are designed to provide consistent run times, minimize downtime, and reduce maintenance.

We carry stock of Fluid End Expendable and Power End Mud Pump parts for every drilling condition and different Mud Pumps from well known manufacturers.

Range of products we can supply is extremely large, Pipe Wipers, Roller Chain, Bearings, Float Valves, Centrifugal Pump, Sheaves, Subs, Kelly Valves, Dies & Inserts etc. is among many products we can supply. Please explore our website for more information or contact us.

You can find our high-performance mud pumps at some of the largest oil and natural gas drilling operations on the planet. Now, we’re ready to supply one of our mud pumps to you.

Looking for a mud pump for sale? Bridges Equipment has the biggest inventory of rebuilt duplex and triplex mud pumps and pump packages ready to ship. Unlike some suppliers, we completely rebuild our mud pumps to OEM standards and guarantee our work from 90 days up to six months against major failure.

Our fabrication facility customizes mud pumps, equipment, and pump packages to meet the needs of operations large and small, across the nation and around the world. Whether you need a custom-fabricated mud pit or a unitized pump package, we have the expertise to get it done.

Nothing wastes time and money like waiting on parts. With two supply stores stocked with the fluid ends and other mud pump parts you need to keep your operation running, and the field mechanics to install them, we can help keep your operation up and running.

Customizability. Functionality. Quality. Reliability. You’ll find these attributes and more in every mud pump, mud pump part or mud pump package we have available for sale or rental.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Mud pumps are the pumps deployed in the oil and gas industry, mainly to circulate drilling fluids and other kinds of fluids in and out of the drilled wells for exploration. The mud pumps transfer the fluids at a very high pressure inside the well using the piston arrangement. The number of pistons decides the displacement and efficiency of working of the mud pumps, originally only dual piston pumps and three-piston pumps were used, but the technological advancements have seen pumps with five and six pistons to come up. Currently the triplex pumps which have three pistons are used, but the duplex pumps having two pumps are still deployed in the developing countries.

Based on its types, global mud pump market can be segmented into duplex, triplex, and others. The triplex mud pumps will dominate the mud pump marking in the given forecast period owing to its advantages and ongoing replacement of duplex pumps with triplex pumps. Based on operation, the global mud pumps market can be segmented into electric and fuel engine.

The electric mud pumps will dominate the market during the given forecast period due to the advantage of eliminating the harmful carbon emission which is done in the case of fuel engine pumps. Based on its application, the global mud pumps market can be segmented into oil & gas, mining, construction, and others.

The major market driver for the global mud pumps market is the increasing exploration activities taking place in various regions of the world to satisfy the increased energy demand. The number of drilled wells has increased in recent years, which has certainly impacted the growth of the mud pumps market in both oil & gas and mining sectors.

Key market restraint for the global mud pumps market is the drift towards the cleaner sources of energy to reduce the carbon emissions, which will certainly decrease the demand for oil & gas and therefore will have a negative impact on the growth of the global mud pumps market.

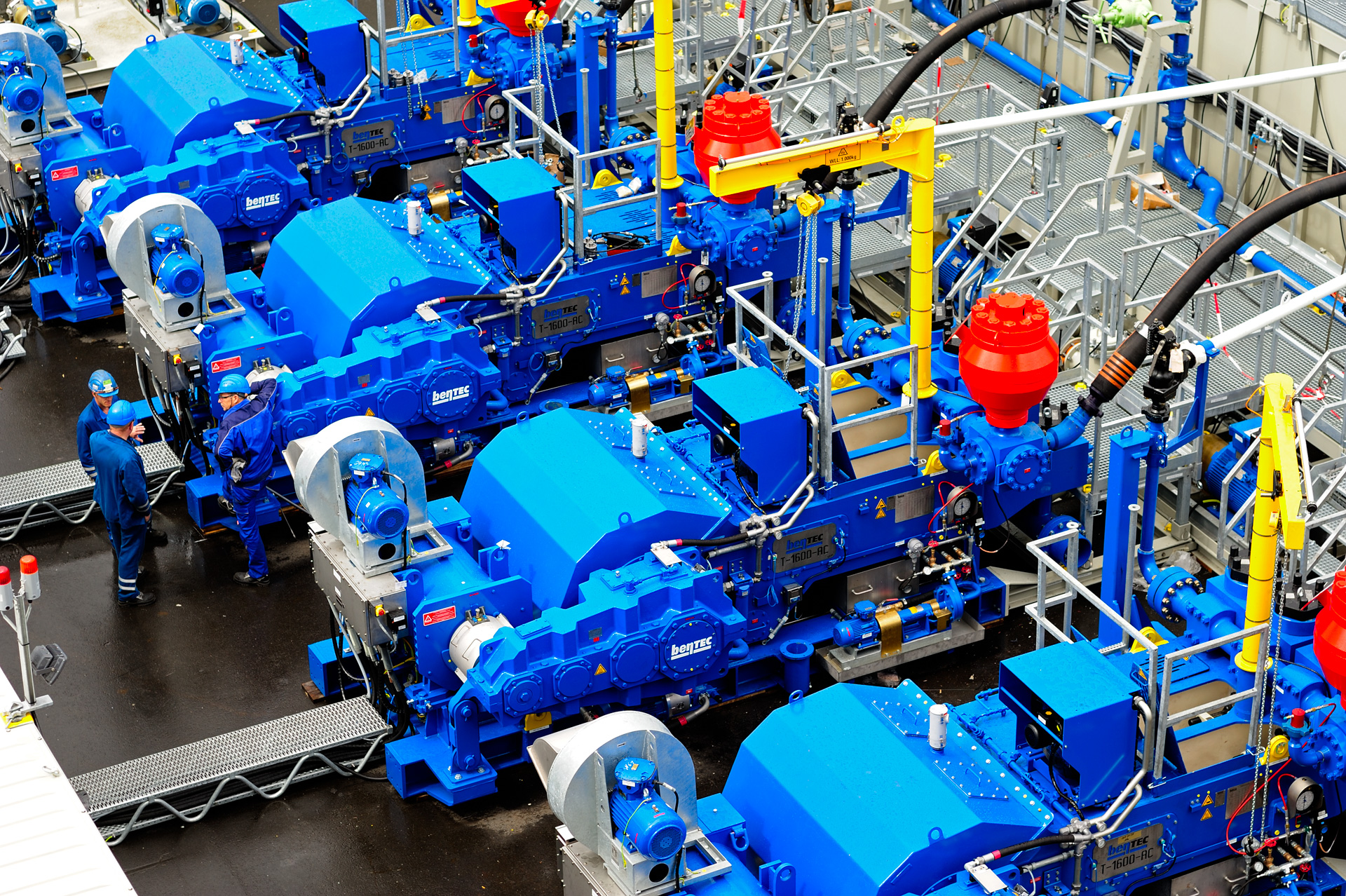

Some of the notable companies in the global mud pump market are Mud King Products, Inc. Gardner Denver Pumps, Weatherford, Schlumberger, National Oilwell Varco, China National Petroleum Corporation, Flowserve Corporation, MHWirth, American Block, Herrenknecht Vertical Gmbh, Bentec GmbH Drilling & Oilfield Systems, Drillmec Inc, Sun Machinery Company, Shale Pumps, and Dhiraj Rigs.

The global mud pump market has been segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Owing to the well-established production sector and stable exploration industry North America holds the largest market for the mud pumps. The onshore exploration activities of oil & gas have increased at a good rate in the North America region, which has certainly boosted the growth of the mud pumps market in the region.

The demand from Europe and Asia Pacific has also increased due to exploration activities in both the regions owing to the increased energy demand. The energy demand specifically in the Asia Pacific has increased due to the increased population and urbanization. The Middle East and Africa also hold significant opportunities for the mud pumps market with increased exploration activities in the given forecast period.

In August 2018, Henderson which is a leading company in sales and service of drilling rigs, and capital drilling equipment in Texas signed a contract with Energy Drilling Company for the purchase and upgrade of oil field equipment’s which included three 1600hp × 7500psi mud pumps. This will be the first refurbishment completed at Henderson’s new service center and rig yard.

In January 2018, Koltek Energy Services launched the 99-acre facility for the testing of the oil field equipment in Oklahoma. This will allow the oil field equipment manufacturers to test their equipment at any given time. The company has deployed the MZ-9 pump which has a power rating of 1000Hp.

The oilfield services sector has been battered for so long it is reasonable to favorably regard any company that has managed through the crucible. In the case of contract driller Patterson-UTI (NASDAQ:PTEN), that regard iswarranted. I recommend it as a buy.

By contrast, PTEN completed its acquisition of Pioneer Energy Services, has upgraded more of its equipment to producer-preferred Tier 1 super-spec rigs, and is operating in all major basins with a heavy emphasis on the favored Permian.

Day rates have been increasing and demand for drilling rigs and services is strong. Moreover, the forward curve for future oil (and gas) prices underpins a resumption of drilling activity and profitability.

Patterson-UTI has a small1.2% dividend; I don"t recommend it to dividend-hunters. I do recommend the company"s stock to those looking for capital appreciation in the oilfield services sector.

Because Russia is a big oil and gas exporter, the potential for conflict between Russia and Ukraine and further drop in its natural gas (and oil) exports has boosted world prices. Other factors include post-Covid demand increases that have not been matched by increases in production due to both deliberate restraint by OPEC+ and US producers-to meet investor preferences-and capex underinvestment reducing the ability of some countries to produce to their targets.

Daily rates are heating up. For example, even a few months ago in early November 2021, a private company executive at an oil conference said, "21K on a hot rig on Friday becomes 24K on a stacked rig on Monday." Translation: $21,000/day for a ready drilling rig became $24,000/day for a cold (non-operating) drilling rig three days later.

Indeed, in the company"s 4Q21 investor call, CEO Andy Hendricks said, For the base rig we are now in the mid-20s for day rates and that is where the discussions begin. And further to that, in some cases, our total revenue per day is at or above $30,000 a day when you include the revenue from technologies and ancillary services in our contract drilling business. In pressure pumping we see further pricing improvement for both dual fuel and conventional spreads due to the lack of readily available premium equipment in the market.

As the graph above shows, the number of PTEN rigs operating follows the oil price but with a lag and not proportionately. The number has increased but not yet recovered to the pre-2020 level. This reflects public company producers" caution as they prioritize return of capital to shareholders ahead of expanding drilling.

Of the company"s 192 rigs, about a third or 73, are in West Texas. Per the company"s rig locator only about a quarter of Permian rigs are available, the rest are contracted.

The 2022 capital expenditure forecast is $350 million. Most of the capex will be used for rig maintenance and reactivation. This includes upgrading more rigs to Tier 1 super-spec status with ESG and sustainability capabilities. Producers prefer, and PTEN has a competitive advantage in providing, Tier 1 super-spec rigs that have more clearance under the rig floor and a third mud pump for horsepower and redundancy. (The extra clearance allows the rig to "walk" to a new location.)

The primary driver of PTEN"s activity is the oil price, although it is clearly subject to the level of activity public and private producers choose to undertake at a given price.

The February 18, 2022, West Texas Intermediate (WTI) futures oil price (March 2022 delivery) was $91.07/barrel. On the same day, Henry Hub natural gas futures price, also for March 2022 delivery, was $4.43/MMBTU.

The Energy Information Administration (EIA) forecasts higher production of both oil and natural gas in 2023: 12.6 million BPD average for oil and 106.6 BCF/D average for natural gas.

The diagram accompanying the EIA article on the oil increase also gives a good picture of the rapid average decline rate from existing wells, a large portion of which are unconventional horizontal, hydraulically-fractured.

A Wall Street Journal article on drilling explained that while public companies such as Devon (DVN), Continental Resources (CLR), and Pioneer (PXD) were drilling only enough to keep production flat or up 5%, private companies were increasing drilling at a faster rate. Private oil producers were running 323 rigs in February 2022, up 127% from the beginning of 2021 while rigs run by large and mid-sized public companies were up only 28% to 215.

Be aware that due to a lack of takeaway (pipeline) capacity relative to the enormous size of Appalachian gas reserves, Marcellus prices usually lag those at Henry Hub, Louisiana. This is important because much gas drilling takes place in the Marcellus and PTEN has 33 rigs there. For example, on February 16, 2022, the Henry Hub price was $4.39/MMBTU while the Appalachian price (Tennessee Zone 4) was $3.70/MMBTU.

Patterson-UTI is headquartered in Houston, Texas. Its three service segments are: a) contract drilling, b) pressure pumping, and c) directional drilling.

US competitors include Baker Hughes (BKR), Halliburton (HAL), Helmerich and Payne (HP), Liberty Oilfield Services (LBRT), Nabors Industries (NBR), and ProPetro (PUMP). Schlumberger (SLB), which exchanged its US pressure pumping business for an ownership interest in Liberty, is a global competitor.

At February 1, 2022, Institutional Shareholder Services ranked Patterson-UTI"s overall governance as 1, with sub-scores of audit (4), board (2), shareholder rights (2), and compensation (1). In this ranking a 1 indicates lower governance risk and a 10 indicates higher governance risk, so the overall rating is excellent.

The company"s beta is 2.82, far more volatile than the overall market, representing a company on the front lines of the turbulent oil and gas drilling sector.

Its activity is a function of both oil and gas prices as well as the intensity of drilling at any given price level, both of which can fluctuate dramatically.

Patterson-UTI has good current and prospective adjusted EBITDA, an excellent governance score, positive analyst ratings, a slightly increased dividend due to good cash flow, a reasonable debt level, a solid oil price forward curve underpinning activity, producer-preferred rigs at rising day rates, moderate demand from public company customers and strong demand from private company customers.

While I do not recommend the company to dividend hunters, I do recommend Patterson-UTI to investors seeking capital appreciation in oilfield service stocks.

The drilling industry has roots dating back to the Han Dynasty in China. Improvements in rig power and equipment design have allowed for many advances in the way crude oil and natural gas are extracted from the ground. Diesel/electric oil drilling rigs can now drill wells more than 4 miles in depth. Drilling fluid, also called drilling mud, is used to help transfer the dirt or drill cuttings from the action of the drilling bit back to the surface for disposal. Drill cuttings can vary in shape and size depending on the formation or design of the drill bit used in the process.

Watch the video below to see how the EDDY Pump outperforms traditional pumps when it comes to high solids and high viscosity materials commonly found on oil rigs.

Solids control equipment including shakers, hydro-cyclones, and centrifuges are utilized to clean the drill cuttings from the drilling fluid, which then allows it to be reused and recirculated. The circuit includes the mixing of the drilling fluid in the rig tanks.

The fluid is charged into high-pressure mud pumps which pump the drilling mud down the drill string and out through the bit nozzles cleaning the hole and lubricating the drill bit so the bit can cut efficiently through the formation. The bit is cooled by the fluid and moves up the space between the pipe and the hole which is called the annulus. The fluid imparts a thin, tough layer on the inside of the hole to protect against fluid loss which can cause differential sticking.

The fluid rises through the blowout preventers and down the flowline to the shale shakers. Shale shakers are equipped with fine screens that separate drill cutting particles as fine as 50-74 microns. Table salt is around 100 microns, so these are fine cuttings that are deposited into the half-round or cuttings catch tank. The drilling fluid is further cleaned with the hydro-cyclones and centrifuges and is pumped back to the mixing area of the mud tanks where the process repeats.

The drill cuttings contain a layer of drilling fluid on the surface of the cuttings. As the size of the drill cuttings gets smaller the surface area expands exponentially which can cause rheological property problems with the fluid. The fluid will dehydrate and may become too thick or viscous to pump so solids control and dilution are important to the entire drilling process.

One of the most expensive and troubling issues with drilling operations is the handling, processing, and circulation of drilling mud along with disposing of the unwanted drill cuttings. The drilling cuttings deposited in the half round tank and are typically removed with an excavator that must move the contents of the waste bin or roll-off box. The excavators are usually rented for this duty and the equipment charges can range from $200-300/day. Add in the cost for the day and night manpower and the real cost for a single excavator can be as much as $1800/day.

One solids control company reported the idle time for the excavator can be more than 8 hours for a 24-hour period with 8 hours of operation and 8 hours of shut down time. Fuel and time lost can cause an economic drag on rig operations. And lastly, there have been several accidents on each rig causing a potential for injury, loss of production, and lost revenue as the excavator must be repaired.

Offshore drilling rigs follow a similar process in which the mud is loaded into empty drums and held on the oil platform. When a certain number of filled drums is met, the drums are then loaded onto barges or vessels which take the drilling mud to the shore to unload and dispose of.

Oil field drilling operations produce a tremendous volume of drill cuttings that need both removal and management. In most cases, the site managers also need to separate the cuttings from the drilling fluids so they can reuse the fluids. Storing the cuttings provides a free source of stable fill material for finished wells, while other companies choose to send them off to specialty landfills. Regardless of the final destination or use for the cuttings, drilling and dredging operations must have the right high solids slurry pumps to move them for transport, storage, or on-site processing. Exploring the differences in the various drilling fluids, cutting complications, and processing options will reveal why the EDDY Pump is the best fit for the job.

The Eddy Pump is designed to move slurry with solid content as high as 70-80 % depending on the material. This is an ideal application for pumping drill cuttings. Drill cuttings from the primary shakers are typically 50% solids and 50% liquids. The Eddy Pump moves these fluids efficiently and because of the large volute chamber and the design of the geometric rotor, there is very little wear on the pump, ensuring long life and greatly reduced maintenance cost for the lifetime of the pump.

plumbed to sweep the bottom of the collection tank and the pump is recessed into a sump allowing for a relatively clean tank when the solids are removed. The Eddy Pump is sized to load a roll-off box in 10-12 minutes. The benefit is cuttings handling is quicker, easier, safer, and allows for pre-planning loading where the labor of the solids control technician is not monopolized by loading cuttings. Here, in the below image, we’re loading 4 waste roll-off bins which will allow the safe removal of cuttings without fear of the half-round catch tank running over.

Mud cleaning systems such as mud shaker pumps and bentonite slurry pumps move the material over screens and through dryers and centrifuges to retrieve even the finest bits of stone and silt. However, the pump operators must still get the raw slurry to the drill cuttings treatment area with a power main pump. Slurry pumps designed around the power of an Eddy current offer the best performance for transferring cuttings throughout a treatment system.

Options vary depending on whether the company plans to handle drill cuttings treatment on-site or transport the materials to a remote landfill or processing facility. If the plan is to deposit the cuttings in a landfill or a long-term storage container, it’s best to invest in a pump capable of depositing the material directly into transport vehicles. Most dredging operations rely on multiple expensive vacuum trucks, secondary pumps, and extra pieces of equipment.

Using an EDDY Pump will allow a project to eliminate the need for excavators/operators to load drill cuttings, substantially lowering both labor and heavy equipment costs. The EDDY Pump also allows a company to eliminate vacuum trucks once used for cleaning the mud system for displacing fluids. Since the pump transfers muds of all types at constant pressure and velocity throughout a system of practically any size, there’s little need for extra equipment for manual transfer or clean up on the dredge site.

The EDDY Pump can fill up a truck in only 10 minutes (compared to an hour) by using a mechanical means such as an excavator. For this reason, most companies can afford one piece of equipment that can replace half a dozen other units.

This application for the Eddy Pump has the potential to revolutionize the drilling industry. Moving the excavator out of the “back yard” (the area behind the rig from the living quarters) will make cuttings handling a breeze. Trucking can be easier scheduled during daylight hours saving on overtime and incidences of fatigued driving. Rig-site forklifts can move the roll-off boxes out of the staging area and into the pump loading area. The operator can save money on excavators rental, damages, and keep the technician operating the solids control equipment.

The EDDY Pump is ideal for drilling mud pump applications and can be connected directly onto the drilling rigs to pump the drilling mud at distances over a mile for disposal. This eliminates the need for costly vacuum trucks and also the manpower needed to mechanically move the drilling mud. The reasons why the EDDY Pump is capable of moving the drilling mud is due to the hydrodynamic principle that the pump creates, which is similar to the EDDY current of a tornado. This tornado motion allows for the higher viscosity and specific gravity pumping ability. This along with the large tolerance between the volute and the rotor allows for large objects like rock cuttings to pass through the pump without obstruction. The large tolerance of the EDDY Pump also enables the pump to last many times longer than centrifugal pumps without the need for extended downtime or replacement parts. The EDDY Pump is the lowest total life cycle pump on the market.

8613371530291

8613371530291