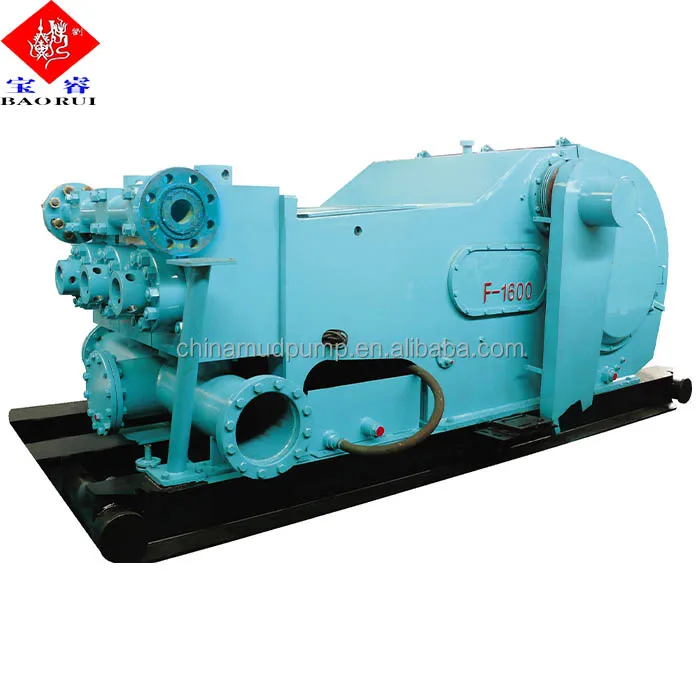

onshore mud pump made in china

Macro Technology is the onshore office of Qingzhou Petroleum Machinery, a professional company to provide mud pump for oil and gas well drilling system. Located at the sea port of Qingdao. QZPM was established in 1966. Now 1181 staffs, 193 technicians, 98 million RMB fixed assets. More than 5000 sets of oil and gas well drilling pumps have been installed all over the world. Now the enterprise has formed the ability with annual product more than 400 sets drilling pumps, parts and assemblies.

DUBAI, U.A.E,/PRNewswire/ -- The global mud pumps market is projected to surpass US$ 1.1 Bn by 2031, in comparison to the valuation of US$ 872.2 million estimated in 2021, as per FMI"s analysis. Owing to the increasing application across mining and oil & gas industries, the market for mud pumps is anticipated to expand at a CAGR of 3.4% over the assessment period, from 2021 to 2031.

Increasing exploration activities undertaken to meet the growing demand for energy across various the world is spurring the sales of mud pumps. Governments of several countries are adopting initiatives for expanding the mining operations.

For instance, in March 2021, Coal India Ltd. (CIL) announced approving 32 new coal mining projects, as per a report by the India Brand Equity Foundation. As mud pumps assist in reaching greater depths every hour and save rig operator time and money, they are increasingly being utilized in mining activities.

Onshore drilling application accounts for the lion"s share, contributing nearly 80% of the revenue in the market. In response to the increasing demand for 7500 psi mud pumps for onshore oil well drilling activities in the countries such as Saudi Arabia, China, the U.S., Oman, and India among others, the segment is projected to grow by 1.4X over the next ten years.

"Manufacturers are emphasizing on developing advanced configuration mud pumps with compact structure to make them suitable for high-pressure drilling operations. Launch of such novel mud pumps will facilitate the market growth in the coming year," says the FMI analyst.

Key Takeaways from FMI"sMud PumpsMarket AnalysisFavored by the increasing demand from the oil & gas industry in the U.S., the North America market is forecast to expand by 1.2X over the assessment period 2021-31.

China is projected to emerge as a remunerative market for mud pumps in the coming year, owing to the discovery of new oil reservoirs in Western China.

Based on driven system, electric pumps are gaining immense traction among end use industries due to stringent regulatory norms concerning environment friendliness.

Leading players operating in the global mud pumps market are currently emphasizing introducing novel products to meet the changing consumer preferences. Other market players are aiming at adopting strategies such as collaboration, mergers & acquisitions, and partnership in order to strengthen their market position. For instance,In 2019, Xylem, a large American water technology provider, announced introducing its new product named, Flygt N3069. It is a stainless steel submersible pump specially designed to address the rigid pumping obstacles. The product launch will assist the company to expand in consumer base in acquaculture and industrial foods applications.

FMI, in its new report, offers an unbiased analysis of the global mud pumps market, analyzing forecast statistics through 2021 and beyond. The survey reveals growth projections on in mud pumps market with detailed segmentation:

Mud pumps market survey identifies key growth drivers, restraints, and other forces impacting prevailing trends and evaluation of current market size and forecast and technological advancements within the industry

Mud pumps market share analysis, covering key companies within the industry and coverage of strategies such as mergers & acquisitions, joint ventures, collaborations or partnerships, and others

Mud pumps are the pumps deployed in the oil and gas industry, mainly to circulate drilling fluids and other kinds of fluids in and out of the drilled wells for exploration. The mud pumps transfer the fluids at a very high pressure inside the well using the piston arrangement. The number of pistons decides the displacement and efficiency of working of the mud pumps, originally only dual piston pumps and three-piston pumps were used, but the technological advancements have seen pumps with five and six pistons to come up. Currently the triplex pumps which have three pistons are used, but the duplex pumps having two pumps are still deployed in the developing countries.

Based on its types, global mud pump market can be segmented into duplex, triplex, and others. The triplex mud pumps will dominate the mud pump marking in the given forecast period owing to its advantages and ongoing replacement of duplex pumps with triplex pumps. Based on operation, the global mud pumps market can be segmented into electric and fuel engine.

The electric mud pumps will dominate the market during the given forecast period due to the advantage of eliminating the harmful carbon emission which is done in the case of fuel engine pumps. Based on its application, the global mud pumps market can be segmented into oil & gas, mining, construction, and others.

The major market driver for the global mud pumps market is the increasing exploration activities taking place in various regions of the world to satisfy the increased energy demand. The number of drilled wells has increased in recent years, which has certainly impacted the growth of the mud pumps market in both oil & gas and mining sectors.

Key market restraint for the global mud pumps market is the drift towards the cleaner sources of energy to reduce the carbon emissions, which will certainly decrease the demand for oil & gas and therefore will have a negative impact on the growth of the global mud pumps market.

Some of the notable companies in the global mud pump market are Mud King Products, Inc. Gardner Denver Pumps, Weatherford, Schlumberger, National Oilwell Varco, China National Petroleum Corporation, Flowserve Corporation, MHWirth, American Block, Herrenknecht Vertical Gmbh, Bentec GmbH Drilling & Oilfield Systems, Drillmec Inc, Sun Machinery Company, Shale Pumps, and Dhiraj Rigs.

The global mud pump market has been segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Owing to the well-established production sector and stable exploration industry North America holds the largest market for the mud pumps. The onshore exploration activities of oil & gas have increased at a good rate in the North America region, which has certainly boosted the growth of the mud pumps market in the region.

The demand from Europe and Asia Pacific has also increased due to exploration activities in both the regions owing to the increased energy demand. The energy demand specifically in the Asia Pacific has increased due to the increased population and urbanization. The Middle East and Africa also hold significant opportunities for the mud pumps market with increased exploration activities in the given forecast period.

In August 2018, Henderson which is a leading company in sales and service of drilling rigs, and capital drilling equipment in Texas signed a contract with Energy Drilling Company for the purchase and upgrade of oil field equipment’s which included three 1600hp × 7500psi mud pumps. This will be the first refurbishment completed at Henderson’s new service center and rig yard.

In January 2018, Koltek Energy Services launched the 99-acre facility for the testing of the oil field equipment in Oklahoma. This will allow the oil field equipment manufacturers to test their equipment at any given time. The company has deployed the MZ-9 pump which has a power rating of 1000Hp.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

We, Qingdao Hongbo Petroleum Machinery Co., Ltd. are a manufacturer of mud pump and expendables of mud pump in oil drilling fields. We hope we can have a sincere cooperation with your good company as a supplier of your good company. We are sure that our products with high quality & competitive prices will lead your company to having a large margin in future bids & lowering your costs very much. Please read our company profile as following:

Qingdao Hongbo Petroleum Machinery Co., Ltd. (HB) specializes in manufacturing and developingmud pump fluid end expendables for customers worldwide. HB’s products have equivalent qualitywith those of OEM and are produced for direct replacement for brand mud pumps including but not limited to Emsco, Gardner-Denver, National,Oilwell, Ideco, Skytop/Brewster, OPI, Wirth, Wilson, and Gaso. With a large range of specifications, HB’s high quality products have successfully proven themselves under various drilling conditions such as extreme pressure, high temperature and corrosive environments, andhave been accepted domestically and internationally.

As one of HB’s business principals, we treat product quality as our first priority. Our employees are well trained and have more than ten years of experience in manufacturing fluid-end fittings for mud pumps. We control the product quality by strictly follow the standard of API-7K. HB’s established Quality Control System and experienced expertise ensurethe best product quality and service.

Hy-chrome Mud Pump Liner (Double-metal liner); Chrome-plated Liner (Single-metal liner); Hardened Steel Liner (Single-metal liner); 3/4-web Valve and Seat; Full-open Valve and Seat (KQ/G2/FO); Valve Spring; Long-life Bonded Piston with Rubbers and Fabric;Long-life Bonded Piston with Urethane; Replacement Piston; Piston Hub; Piston Rod; Plate; Snap Ring; Crosshead; Upper and Lower Crosshead; Guide; Extension Rod; Piston Rod Clamp; Threaded Ring; Liner End Cover; Valve Pot Cover; Valve Guide; Cylinder Head; Cylinder Head Plug; Cap; Liner Seal; Valve Cover Gasket; Cylinder Head Gasket; Module (Fluid ends); Ceramic Liner, Rotary Table, Swivel, Hook, Well Head Equipment, drill pipe, drill casing, traveling blooks,F-500/800/1000/1300, PZ-9, 3NB-500/8001000/1300, 12-P-160, W-440 mud pump and 3/5 plunger pumps which are made in China, etc..

Qingdao Hongbo Petroleum Machinery Co., Ltd. (HB) specializes in manufacturing and developing mud pump fluid end expendables for customers worldwide. HB’s products have equivalent quality with those of OEM and are produced for direct replacement for brand mud pumps including but not limited to EMSCO, Gardner-Denver, National, Oilwell, IDECO, Skytop Brewster, OPI, Wirth and Wilson. With a large range of specifications, HB’s high quality products have been successfully proven themselves under various drilling conditions such as extreme pressure, high temperature and corrosive environments, and have been accepted domestically and internationally.

As one of HB’s business principals, we treat product quality as our first priority. Our employees are well trained and have more than ten years of experience in manufacturing fluid-end fittings for mud pumps. We control the product quality by strictly follow the standard of API-7K. HB’s established Quality Control System and experienced expertise ensure the best product quality and service.

Hy-chrome Mud Pump Liner (Bimetal liner); Chrome-plated Liner (Single-metal liner); Hardened Steel Liner (Single-metal liner); 3-web or 4-web Valve and Seat; Full-open Valve and Seat (KQ/G2/FO); Valve Spring; Long-life Bonded Piston with Rubbers and

This is Isacc of China Qingdao HNA Oilfield Machinery Co., Ltd. We are a large drilling tools, mud pump and Fluid End Expendables and mud pump spare parts manufacturer in China.

Our plants are specialized in producing wide range of replacement parts and liners, Pistons, Valve and seats for brand name mud pumps, including Emsco, National, Ideco, Gardner Denver, Oillwell, OPI Skytop, etc. and other brand liners. All items are manufactured to API 7K quality standards.etc.

And we make cranskshaft, pinion shaft, crosshead assy for EMSCO F series mud pumps, GARDNER DENVER PZ-9, NATIONAL OILWELL 9-P-100, 10-P130 and 12-P-160 mud pumps.

Our F1000 mud pumps have good market in Canada, Mexico, Thailand and Middle East. And our mud pumps have approved by mud pump and insurance industry in Canada.

We specialize in triplex mud pumps and triplex mud pump parts and accessories. If need a quality triplex mud pump or accessory at competitive prices, contact us.

Our plants are specialized in producing wide range of replacement parts and liners for brand name mud pumps, including Emsco, National, Ideco, Gardner Denver, etc. and other brand liners.

Our plants are specialized in producing wide range of replacement parts and liners for brand name mud pumps, including Emsco, National, Ideco, Gardner Denver, etc. and other brand liners.

We, Dezhou Jiatong Machinery Co., Ltd. are a manufacturer of mud pump and expendables of mud pump in oil drilling fields. We hope we can have a sincere cooperation with your good company as a supplier of your good company. We are sure that our products with high quality & competitive prices will lead your company to having a large margin in future bids & lowering your costs very much. Please read our company profile as following:

Dezhou Jiatong Machinery Co., Ltd. (JT) specializes in manufacturing and developing mud pump fluid end expendables for customers worldwide. JT’s products have equivalent qualitywith those of OEM and are produced for direct replacement for brand mud pumps including but not limited to Emsco, Gardner-Denver, National,Oilwell, Ideco, Skytop/Brewster, OPI, Wirth, Wilson, and Gaso. With a large range of specifications, JT’s high quality products have successfully proven themselves under various drilling conditions such as extreme pressure, high temperature and corrosive environments, and have been accepted domestically and internationally.

As one of JT’s business principals, we treat product quality as our first priority. Our employees are well trained and have more than ten years of experience in manufacturing fluid-end fittings for mud pumps. We control the product quality by strictly follow the standard of API-7K. JT’s established Quality Control System and experienced expertise ensure the best product quality and service.

Hy-chrome Mud Pump Liner (Double-metal liner); Chrome-plated Liner (Single-metal liner); Hardened Steel Liner (Single-metal liner); 3/4-web Valve and Seat; Full-open Valve and Seat (KQ/G2/FO); Valve Spring; Long-life Bonded Piston with Rubbers and Fabric;Long-life Bonded Piston with Urethane; Replacement Piston; Piston Hub; Piston Rod; Plate; Snap Ring; Crosshead; Upper and Lower Crosshead; Guide; Extension Rod; Piston Rod Clamp; Threaded Ring; Liner End Cover; Valve Pot Cover; Valve Guide; Cylinder Head; Cylinder Head Plug; Cap; Liner Seal; Valve Cover Gasket; Cylinder Head Gasket; Module (Fluid ends); Ceramic Liner, Rotary Table, Swivel, Hook, Well Head Equipment, drill pipe, drill casing, traveling blooks,F-500/800/1000/1300, PZ-9, 3NB-500/8001000/1300, 12-P-160, W-440 mud pump and 3/5 plunger pumps which are made in China, etc..

Our company is one of the leading designers and manufacturers of triplex mud pumps and fluid end expendables of oilfield drilling machinery, offering top quality and competitive products for our clients all over the world. We adopt ISO9001 quality system and our products meet the API standard.

We have been engaged in manufacturing series of quality mud pumps and spare parts for oilfield machinery since early 1990s. The main products are sold to USA, Mid-Asia, Canada, Mexico, Middle East and Russia. The mud pumps are used in oil drilling and mining. We can supply series of mud pumps( like f-500, f-800, f-1000, f-1300, f-1600 and PZ series )and a full line of fluid end expendables for popular mud pumps in the world, including continental Emsco, National, Gardener Denver,Oilwell,Ideco,Wheatly,Wilson,Wirth,OPI,EllisWillianms,Skytop/Brewster, etc.

We, Dezhou Jiatong Machinery Co., Ltd. are a manufacturer of mud pump and expendables of mud pump in oil drilling fields. We hope we can have a sincere cooperation with your good company as a supplier of your good company. We are sure that our products with high quality & competitive prices will lead your company to having a large margin in future bids & lowering your costs very much. Please read our company profile as following:

Dezhou Jiatong Machinery Co., Ltd. (JT) specializes in manufacturing and developing mud pump fluid end expendables for customers worldwide. JT’s products have equivalent qualitywith those of OEM and are produced for direct replacement for brand mud pumps including but not limited to Emsco, Gardner-Denver, National,Oilwell, Ideco, Skytop/Brewster, OPI, Wirth, Wilson, and Gaso. With a large range of specifications, JT’s high quality products have successfully proven themselves under various drilling conditions such as extreme pressure, high temperature and corrosive environments, and have been accepted domestically and internationally.

As one of JT’s business principals, we treat product quality as our first priority. Our employees are well trained and have more than ten years of experience in manufacturing fluid-end fittings for mud pumps. We control the product quality by strictly follow the standard of API-7K. JT’s established Quality Control System and experienced expertise ensure the best product quality and service.

Hy-chrome Mud Pump Liner (Double-metal liner); Chrome-plated Liner (Single-metal liner); Hardened Steel Liner (Single-metal liner); 3/4-web Valve and Seat; Full-open Valve and Seat (KQ/G2/FO); Valve Spring; Long-life Bonded Piston with Rubbers and Fabric;Long-life Bonded Piston with Urethane; Replacement Piston; Piston Hub; Piston Rod; Plate; Snap Ring; Crosshead; Upper and Lower Crosshead; Guide; Extension Rod; Piston Rod Clamp; Threaded Ring; Liner End Cover; Valve Pot Cover; Valve Guide; Cylinder Head; Cylinder Head Plug; Cap; Liner Seal; Valve Cover Gasket; Cylinder Head Gasket; Module (Fluid ends); Ceramic Liner, Rotary Table, Swivel, Hook, Well Head Equipment, drill pipe, drill casing, traveling blooks,F-500/800/1000/1300, PZ-9, 3NB-500/8001000/1300, 12-P-160, W-440 mud pump and 3/5 plunger pumps which are made in China, etc..

We,Dezhou Jiatong Machinery Co., Ltd have been engaged in manufacturing and dealing in mud pump and related fittings in oil drilling fields ---------High frequency quenching liners and modules and so on. Most of our products are exported, and we have the power of self-supporting import and export.Our company’ s products design is fit for worldwide brand mud pumps, such as: Emsco, Gardner-Denver, National, Oilwell, Ideco, Skytop/Brewster, OPI, Wirth, Wilson, Gaso and so on. Our company owns lots of large-scale advanced equipment. Both Liners’ quenching technique and heat treatment technique are in the leading place in China. Every year we produce and sell about 10000 liners of various kinds in different sizes . Products meet the criteria and rule of API totally. Part of our products are produced directly for mud pump producers who are famous worldwide. The product is widely approved by the user communities in American, Canadian, Mexican, the Middle East, the Australian market for its fine quality and the best service。Our company mainly produces and sells the following products:

Also, we produce custom-made valves, seats, liners and other mud pump parts. Customs can choose needed products by yourselves, and we can help you choose suitable products if you provide us with mud pump models and practical drilling conditions in detail. We have specialists of our products serve for the customer track. What’ more, we may defer to the blueprint or the sample customers provide and carry on processing. Jiatong’ s staff whole-heartedly welcome customers everywhere to exchange cooperation with us.

Zibo Huachuang Fine Ceramics Co., Ltd.- is a new & hi-tech ceramic enterprise that specializes in manufacturing of ceramic sleeves and pistons of mud/oil pump with the excellent performances, such as wearing-resistance, erosion-resistance, high-temperature-resistance, high-strength, high-hardness in the working conditions on which metal and polymer ones can not do. They are widely used in MUD PUMP in the fields of petroleum, such as NATIONAL, OILWELL, IDECO, EMSCO, GARDNER-DENVER,FMC etc.

HNA is specialized in producing mud pumps and wide range of replacement parts and liners for brand name mud pumps, including Emsco, National, Ideco, Gardner Denver, etc. and other brand liners. All items are manufactured to API 7K quality standards.

Our Products are designed to fit mud pumps of Emsco, Gardner- Denver, National, Oilwell, Ideco, Skytop/Brewester, as well as OPI, Wirth, Wilson and Gaso. Our products include Liners: Hy- chrome Mud Pump Liner, chrome-plated Liner, Hardened Steel Liner Valve and seat: Premium Cross Arms Valve and seat, Full open Valve and seat, Valve Spring Piston and piston rods; Long-life Bonded Piston with Rubber and Fabric, Long-Life bonded Piston with Urethane, Replacement Piston, Piston Hub, Piston Rod, Plate, Snap Ring Other parts: Crosshead, Upper and Lower Crosshead Guide, Extension Rod, Piston Rod Clamp, Threaded Ring, Linder End Cover, Valve Pot Cover, Valve Guide, Cylinder Head, Cylinder Head Plug, Cap, Linder Seal, Valve Cover Gasket, Cylinder Head Gasket and etc. Mud pumps: We can offer the F-650,F-800,F-1000,F-1300,F-1600 and PZ-9 mud pump.

We"re Dezhou Rundong Petroleum Machinery Co., Ltd., specializing in mud pump, fluid end. Our products mainly include valve seat and body, valve assembly, liners, piston, piston rod and other mud pump parts.

An innovative product policy and continuous advancement of essential design features make this pump a powerful, yet economical standard unit with a broad range of applications.

Professional China Mud Pump - BNS series Single Stage, End Suction Norm Centrifugal pumps – Beken, The product will supply to all over the world, such as: , , ,

Mud Pumps are available for the different purposes of drilling and extracting of oil. In fact, the Unitized Pumps are a work of the hydraulic mechanical transmission. Unitized pump parts include 4 types of packages such as the air clutch transmission takes in the diesel engine, transmission (including card and shaft, decelerator, clutch, belt and pulley) and the Mud pump. The Mud Pumps are also inclusive of the hydraulic coupling transmission that consists of the diesel engine, hydraulic coupling and the Mud pump. It also includes the electric drive Mud pump and the chain transmission for apt design and assembling.

The Unitized design Pumps are built as well as licensed according to the specifications of the American Petroleum Institute where the master skid is the standard oilfield 3 runner skid. Mud Pumps like the F 1000 are driven by the diesel engine with the help of the narrow V belts. Pumps are complete with a bulk wheel, a set of V belts, a screw assembly, a belt guard and the screw devices for tightening the belts. Mud pump like the triplex liner single action pumps has an input power of 1000 horse power. The maximum stroke is all of 10 inches or 254 mm.

Mud parts also contain a maximum working pressure of 5000 PSI or 35 MPA. The Mud Pumps have a gear type made of integral herring bone with API 6 valve pots. The intake of the F 1000 Pumps is 12 inches or 305 mm and they have a discharge space of 4 inches or 102 mm. Mud pump also contain a pulsation dampener model that has a capacity of 75.7 liters or 20 gallons. The relief valve and pressure gauge are also an important part of the Mud pump as they help in various ways.

Mud pump like the diesel engine has a rated speed of about 1200 revolutions per minute and the movement takes place in an anticlockwise direction with the face output shaft end. For the purpose of testing and commissioning, the Mud pump needs to be installed and secured with machinery and different kinds of equipment. Furnish the lube products for testing and the diesel is required to be run for testing the transmission devices. To give you an idea, the Mud pump that is being discussed in this category is available at competitive prices and can be obtained for pneumatic clutch transmission that can be adjusted according to customer’s requirements.

Excluding tubulars and camp facilities, the rig has 32-34 loads. However, the design of the rig was underpinned not just by a desire to have fewer loads but to manage the loads better, Mr Cromling said. For example, the BOSS rigs have been designed so that rig-up can begin with any part of the rig. “You could begin with the mud pits. You could begin with the substructure. You could begin with the engines. It can rig-up no matter which load arrives first. That facilitates a faster rig-up,” he said.

The new rig also features two 2,200-hp quintuplex mud pumps, which Unit Drilling opted over triplex versions for higher pump output. “This means we can truly drill most of the horizontal wells with one mud pump, with the second as a standby,” Mr Cromling said.

The company also chose to outfit the rigs with diesel engines with bi-fuel capability, rather than natural gas engines. “We felt like going all gas would limit us in places where field gas isn’t available. Another environmental feature is that the skids underneath the engines and pumps are enclosed and can trap any fluid that might spill. Any fluid is contained within the system to be pumped away to a disposal area,” he commented.

IADC recently established the Onshore Advisory Panel, which will address issues and initiatives specifically concerning the onshore drilling industry. In this video, Ed Jacob, a member of the IADC Executive Committee and Executive VP/COO at Independence Contract Drilling, speaks with Drilling Contractor at the 2014 IADC Drilling Onshore Conference about the group’s goal and efforts to engage onshore drilling contractors. Click here to watch the video.

Under a new corporate strategy focused on financial discipline, Chesapeake Energy expects to stay at an operational level of approximately 60 to 80 rigs per day, CEO Doug Lawler said at the 2014 IADC Drilling Onshore Conference in Houston in May. Although this is a significant change from previous years – when the operator was running as many as 175 rigs – Mr Lawler said he still expects to achieve a strong 9-12% production growth rate. “From 2012 to 2013, we reduced our operating expenses by about 15% and are expecting continued improvements there by about another 10%,” he added.

Under a growth plan called “2×3,” Concho Resources is expecting to ramp up its drilling activities in the Permian Basin in order to double its production by 2016. Further, most of this expected growth will come in the form of horizontal-drilling rigs, Ray Peterson, VP of Drilling for Concho, said at the 2014 IADC Drilling Onshore Conference in Houston in May.

Concho is using a variety of rig types, including older mechanical rigs, across its four major operating areas within the Permian, Mr Peterson said. In the New Mexico Shelf area, where the company is drilling shallow TVDs and 1-mile laterals, “a 750-hp mechanical kelly rig is taking care of us and doing a very good job.” In the Northern Delaware Basin, “we’re seeing 1,600-hp pumps on 1,000-hp rigs, and that is working for us. Some have top drives, and some don’t.”

Statoil, which has historically been an offshore operator, has invested significantly in the US onshore – the Marcellus, the Eagle Ford and the Bakken. “My view is that we can take a lot of good learnings from the offshore business to the onshore activities,” Torstein Hole, Senior VP, US Onshore for Statoil North America, said. While the technologies and challenges differ, he noted the same underlying factors in many of the incidents and near-misses onshore and offshore.

Mr Hole noted that Statoil has taken its systematic approach to safety from its offshore experience and applied it to its onshore business. “I’m seeing very good results of that so far and no reduction in efficiency.”

“On the reputational side, I can’t think of any major incident in deepwater that wouldn’t have a dramatic impact on what we do in the onshore, and I can think of a number of incidents we could have on the onshore that would have an impact on the acceptance of what we do offshore,” Mr Guidry commented.

The two segments do have different risk profiles, he continued, where onshore incidents typically have lower consequence but higher frequency. “A rancher cares about how you treat their land in a very particular way. There’s a much greater chance of upsetting that landowner than it is having a high-impact industry event.”

However, the principles associated with a company’s willingness to be transparent applies equally onshore or in deepwater. “There’s a substantial overlap on reputational or license to operate elements that we need to continue to mature and advance,” Mr Guidry said.

And the Chinese New Year is coming, if you need mud pumps or spare parts, please kindly prepare it in advance. Especially for Indian wholesalers, BW-600 and BW-800 mud pump"s spare parts will be a good choice for you,many of our end customers need them.

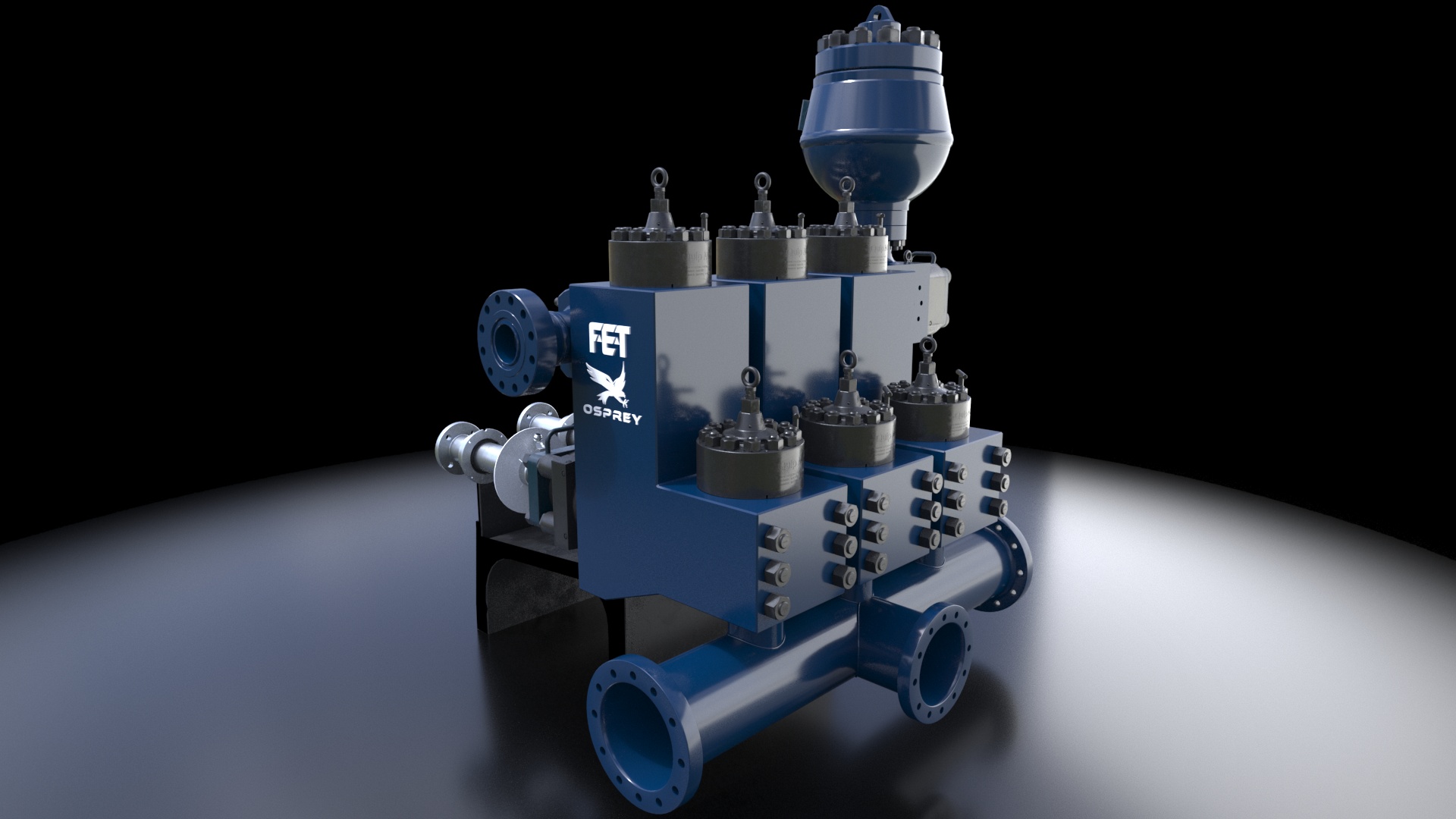

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

equipment in China, is the earliest established, largest and most powerful oil drilling rig and production equipment developer and manufacturer under CNPC, the largest research and production base of land rigs and series mud pumps in the world, and also the largest and most powerful base for R&D and production of wire ropes for special purposes in China.

The company owns five subsidiaries totally in home and abroad, with 3600 employees. Company headquarter is located in Deyang City, Sichuan, a heavy-duty equipment base in China, which covers an area of about 1,000 mus, and with more than 2,200 employees, annual output of 150 drilling rigs and 600 mud pumps etc. Its production capacity is up to 8 billion RMB production scale.

The company produces mainly various land drilling rigs for drilling 1000m to 9000m wells and offshore drilling modules– DC drive drilling rig, AC VF electric rig, mechanical drilling rig, composite drive rig, trailer mounted rig and independent RT electric drive drilling rig, as well as their matched equipments, i.e. drilling pumps, traveling block system, solid control system, electric control system etc.

Our company Shandong Kerui Holding Group is located in Shengli Oilfield the second largest oilfield in China. Our company arranges a wide range of businesses covering the scientific research and manufacture of the petroleum drilling equipment and oilfield engineering technical service. The main products manufactured and supplied include drilling equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China.

The main products manufactured and supplied include oil drilling rig equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China

8613371530291

8613371530291