piston mud pump fluid end components made in china

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

Dezhou Rundong Petroleum Machinery Co., Ltd is major in manufacturing oil drilling mud pump spare parts and drilling tools, in which liners, pistons and valves that developed new have got national patent certificate. Mud pump parts we manufactured can be totally exchangeable with spare parts from original manufacturer, and have excellent performance especially in drilling conditions of high temperature, high pressure, oil base mud, acid base mud and high sand content mud etc.

We have been committed to continuous optimization and upgrading of drilling mud pump products.We accumulate rich first-hand technical information through our service to drilling projects, for example different material products’ performance under different drilling conditions. Our aim is to make products manufactured can be more suitable for oilfield drilling needs, and our goal is where there is oil, there is Deshi Brand products.

Main advantages of the mud pump consumables that we manufacturedProducts are produced according to ISO9001 quality system,APISpec7K standard, and each process can be tracked, recorded and traceable

Import spare parts such as valve module, crankshaft, pinion shaft’s material are high quality alloy steel,The power end herringbone gear adopts the grinding process, the gear precision is high, the processing precision of the matching components is much more higher, which can make the whole mud pump can run more smoothly.

Production and quality inspection are separated, different process have different people to responsible, inspection methods are advanced, and have high-end inspection laboratories and detectors.

F500、F800 、F1000、F1300、 F1600、F-1600HL 、F-2200HLHydraulic end products and power end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, crosshead assy, air capsule, crankshaft, pinion shaft, connecting rod, manifold etc

HHF-1300、HHF-1600 、HH3NB-1600H、HH3NB-2200HLHydraulic end products and power end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, crosshead assy, air capsule, crankshaft, pinion shaft, connecting rod, manifold etc

7P-50、8P-80、9P-100、10P-130、12P-160、14P-220Hydraulic end products and power end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, air capsule, manifold etc

PZ-7、 PZ-8、 PZ-9 、PZ-10、PZ-11Hydraulic end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, air capsule, manifold etc

Fluid End Spare Parts produced by our company is mainly used in oil drilling and geological exploration, especially in deep oil reservoirs, poor surface structure and soil production environment, as well as offshore oil and gas development。

Valve assembly is the critical component of mud pump fluid end , with high operation frequency and great impact subjected. The quality of valve assembly will have a direct effect on the life of hydraulic cylinder.

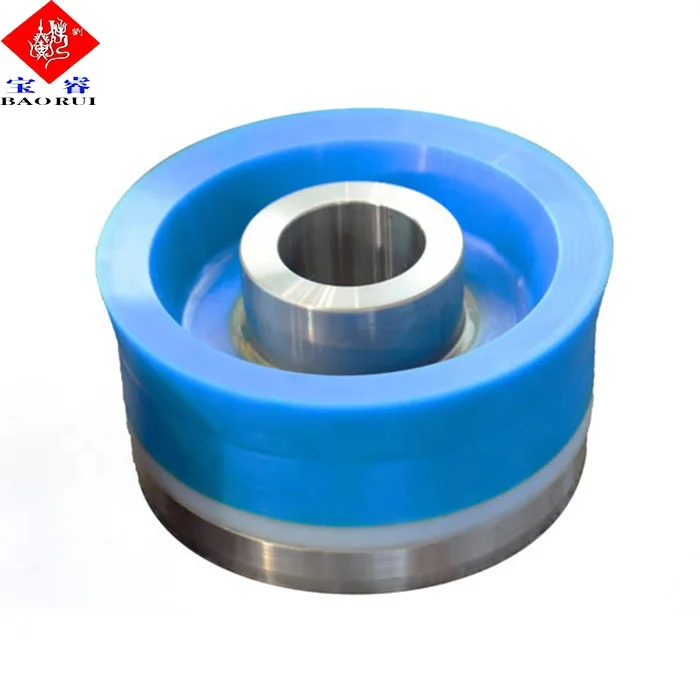

Piston assembly is the major part of the mud pump fluid end. The discharge pressure of mud pump is generated by the up-and-down motion of the piston in the cylinder. Small piston—high pressure and low flow rate; Big piston—low pressure and high flow rate. Metric pump and inch pump adopts metric piston and inch piston respectively.

The structural features and properties of F series mud pumps are more advanced. Wearing parts of fluid end can be universally used with those of API standards.

F series mud pumps are firm and compact in structure and small in size, with good functional performances, which can adapt to drilling technological requirements such as oilfield high pump pressure and large displacement etc. The F series mud pumps can be maintained at lower stroke rate for their long stroke, which effectively improves the feeding water performance of mud pumps and prolongs the service life of the fluid end. The suction stabilizer, with advanced structure and reliable service, can achieve the best buffering effect. Power ends of the F series mud pumps adopt the reliable combination of forced lubrication and splash lubrication to increase the service life of power ends.

This series of pumps is manufactured strictly in accordance with API Spec 7K Drilling and Workover Equipment Specifications and carried out delivery test in accordance with the standard.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

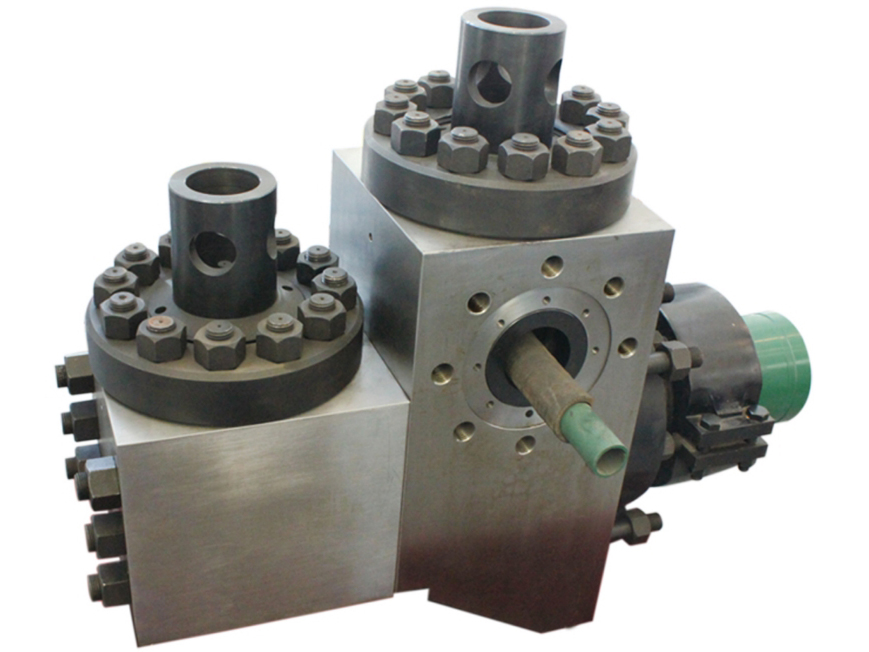

The fluid end includes cylinders (module), valve assembly, cylinder liners, piston assembly, suction manifold, discharge manifold, piston rod, pulsation dampener assembly, etc.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

At this time the intake valves are closed and the exhaust valves open, allowing the piston to force the fluid out of the cylinder under pressure. Once the piston reaches its maximum depth into the cylinder, the exhaust valves close and the process repeats.

For Fluid End: piston rod clamp, piston rod, piston assembly, cylinder cover, liner, liner flange, wear plate, cylinder, valve assembly, valve cover, valve guide, flashboard assy., cylinder cover flange, cylinder head, gaskets, studs, nuts, seal rings, pulsation dampener, bladder, discharge manifold, suction manifold, etc.

The purpose of this utility model is: a kind of crank-linkage type mud pump with plunger is provided, and the pressure height of this pump, discharge capacity are evenly, stable working, volume be little, in light weight, it is reliable to use, the life-span is long, easy to maintenance.

The technical solution of the utility model is: the crank-linkage type mud pump with plunger is made of power end and fluid end, and its power end is provided with casing, bent axle and five cover crank linkage mechanisms.Be provided with the valve piece at fluid end, equally distributed five plunger cases of the level that is provided with in the valve piece, five cover suction valve and drain valves; Suction flange and drainage flange and valve piece are made one.Five connecting rods 4 are housed on the bent axle 3 of described power end 1, and an end of connecting rod 4 is equipped with crosshead 5; Described fluid end 2 is provided with a valve piece 6, levels is provided with five plunger cases 7 in the valve piece 6, plunger 8 in the plunger case 7 is connected with the crosshead 5 of power end, with corresponding with each plunger case 7 five suction valves 9, five drain valves 10 of being provided with, the top of all suction valves 9 and drain valve 10 all places the top, the vertical placement, downside at suction valve 9, be provided with a suction sleeve 11, be provided with a waste pipe 12 at the upside of drain valve 10, suction sleeve 11 and waste pipe 12 are made as one with valve piece 6.

The main advantage of the utility model is that discharge capacity is even, working stability, and the reliability height, volume is little, and is in light weight.Owing to adopt five cover crank linkage mechanisms to do running stably, make that mutual overlapping coefficient of suction cycle of five plunger cases is higher, thereby make this slurry pump discharge capacity evenly, pressure stability, the vibration of the whole pump housing is less, has reduced spoilage; Their arrangement mode also is beneficial to the minimizing fault simultaneously, and convenient for maintaining improves working life.

Fluid End Module As an important component on the fluid end of mud pump, our Rundong value module is made premium 8620 or 4135 alloy steel with forging, normalizing, rough machining and then quenching and tempering processes. In this way, the interior of the fluid end module will have hardness in the range of HB285 to HB330.

Pump Liner Rundong’s mono-metal liner has its inner bore quenched with the carburized layer thickness as 1.5 to 1.8mm to achieve hardness of 58 to 60 HRC. The liner features high hardness, great corrosion resistance, no deformation and high surface finish.

Piston Assembly Piston is one of the wear parts consumed the most in mud pump for drilling system. Rundong manufactures pistons of various specifications, which can be applied on different drilling pumps, such as F series, 3NB series, P series, PZ series and UNB series.

Piston Rod Our company provides piston rods and extension rods for different mud pumps including F series, 3NB series, QZ series, PZ series, P series, etc.

Pulsation Dampener Rundong provides discharge pulsation dampener assembly, discharge pulsation dampener capsule and suction pulsation dampener capsule and related accessories, which all could be applied on different types of mud pumps such as F series, PZ series and P series, etc.

Safety Valve Our shear safety valve is able to ensure normal operation of the mud pump in conditions with working pressure less than rated value. It comes in flange type and thread type. It features great flexibility in toggling on and off, small pressure-bearing area of the piston attached, easy resetting, good compatibility with most types of mud pumps.

Flanges and Cylinder Parts Rundong provides different flanges and cylinder parts, which include cylinder head, cylinder liner, valve cover, cylinder head flange and cylinder liner flange, etc. Those parts could be applied on various mud pumps, such as F series, 3NB series, PZ series and P series.

Rubber Pump Parts Rundong provides varieties of rubber pump parts including piston rubber cup, valve rubber, seal ring, O-ring, gasket, etc. These rubber parts could be applied on different mud pumps, such as F series, 3NB series, PZ series and P series.

Crosshead and Parts Rundong manufactures crossheads, crosshead pins and crosshead slides for different mud pumps including F series, 3NB series, PZ series and P series. Our crosshead pins are made of premium structural alloy steel through one-piece forging process, while crossheads and crosshead slides are made...

Other Mud Pump Parts Rundong offers drilling rig mud pumps and pump components. There are wide ranges of mud pump parts like bearings, manifolds, cross fittings, pump housings, clamps and others.

8613371530291

8613371530291