pony rod seal mud pump brands

Plunger pumps are the workhorse of oil and gas fracking and drilling operations. They circulate high pressure fluid down the well and back up the annulus in both land and off-shore operations. When pumps are offline for planned or unplanned maintenance to replace leaking fluid, or worn seals, your operations stop.

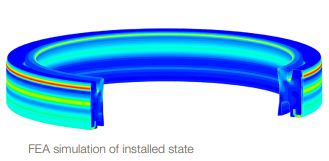

Parker’s patented pony rod seal extends continuous service with a longer lasting, reliable design that retains lubrication and prevents leakage of hydraulic fluid in the power end and also serves as a rod wiper to keep contaminants out.

•High contact force sealing lip design, coupled with compression-set resistant Resilon seal material, retains lubricating oil in the power end, eliminating necessity of shut down to add fluid

High-contact force sealing lip design coupled with compression set resistant Resilon seal material retains lubricating oil in the power end, eliminating necessity of shut down to add fluid

One of the challenges oil and gas companies face is sustaining seal life in challenging applications. Parker’s proprietary Resilon® material offers superior wear resistance and the highest operating temperature on the market to ensure performance and reduce downtime due to seal failure.

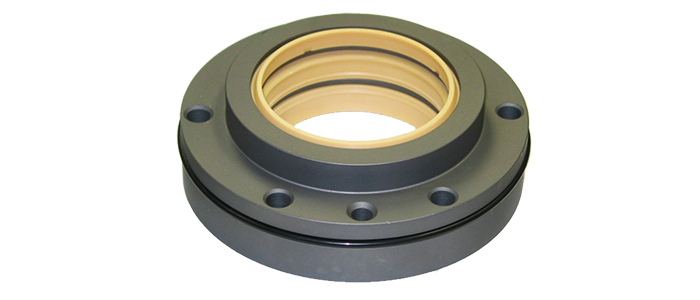

Forum Energy Technologies Pony Rod Enhanced Sealing System incorporates a patented polymer that has 4 sealing surfaces plus an excluder wiper to provide a superior dependable seal. It is dimensionally stable to 275F degrees, has excellent memory and elasticity and is highly abrasion resistant. Case studies have shown results of over 4X longer life than traditional pony rod seals which result in much lower operating costs.

Drilling fluid contamination into the power end of your mud pump can lead to costly repairs. Install the PRESS seal system on your pumps, lower your costs and prevent costly failures.

Pony rod also called the intermediate rod, is an important part of the connection between the crosshead and the piston rod. It is the key component that connects the power end and the hydraulic end of the mud pump. One end is connected to the crosshead and the other end is connected to the piston rod by a clamp. Its outer circumference is filled with a packing box assembly. In the reciprocating motion, the outer circle of the intermediate tie rod and the sealing member in the packing box rub against each other. To ensure it"s wear resistance, the outer surface of the intermediate rod is hard chrome-plated.

We can offer a wide range of extension (pony) rods for triplex mud pumps that are made of high quality alloy steel (40Cr). After strict heat treatment of quenching and high temperature, the rods have the features of high intensity on surface and high tough inside. The surface is treated with galvanization or nitrogen for high intensity and low abrasion.

The Sur-Lock Rod Link System was developed to provide a safer and faster way to unfasten the piston rod and remove the piston from the liner. The sub rod contains a proprietary “wedge lock” mechanism that allows the piston and pony rods to be connected by simply inserting pins and turning a bolt. No hydraulic fitting, seals, or pumps are necessary.

The system uses rods and rod extensions that are 100% compatible with the same parts from the P-Quip system. Additionally, our torque module can completely replace the P-Quip hydraulic module in plug-and-play fashion.

We developed the Sur-Line system to prevent mud and other fluids from passing into the power section from the fluid end section of the mud pump, and to prevent fluid from going from the power section into the fluid end section.

The Sur-Line system uses a unique floating seal system that bolts into the wall between the power section and the fluid end section. The seals inside this housing seal against the OD of the pony rod, thus preventing fluid from passing between the two sections of the mud pump.

We carry parts to fit pumps from most major manufacturers. Sur-Line® systems are simple enough to be installed by the rig crew, or can be installed by our technical service department at the rig site.

We are a large drilling tools, Drilling rig spares, Water well drilling and mining pump part, Drilling mud pumps and Fluid End Expendables and mud pump spare parts manufacturer in China.

We make all fluid end modules, Ceramic liners, Hy-chrome liners, rubber replaceable and bonded urethane pistons and all spares for popular brand mud pumps.

Designed and manufactured by HNA Plant, F-1300 and F-1600 mud pumps can meet the requirements of the same manufacturing technique and quality level...

We are a large drilling tools, Drilling rig spares, Water well drilling and mining pump part, Drilling mud pumps and Fluid End Expendables and mud ...

HNA offers four different type of liners for all popular mud pumps to suit any drilling condition, including Premium Chromium Liners, Ceramic Liner...

HNA offers four different type of liners for all popular mud pumps to suit any drilling condition, including Premium Chromium Liners, Ceramic Liner...

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

Polyurethane has been an industry standard for dynamic sealing in hydraulic applications for more than 30 years. But polyurethane materials are not all formulated from the same hard- and soft-segment chemistry. The specific diisocyanate and chain extenders used in the synthesis of a polyurethane affect its physical and mechanical properties. When looking to achieve the best performance with mud and frac pumps, Parker’s Resilon® polyurethane is recommended. Our proprietary PPDI (p-phenylene diisocyanate) TPU formulation is specifically suited for injection molding of both large and small articles while retaining superior high-temperature performance.

The characteristics common to Resilon formulations make this PPDI class of material a leading choice for high pressure, dynamic sealing applications. These characteristics include exceptional:

"Our sales team members receive inquiries from well completion operators who are frustrated when they are interrupted and have to shut down to replenish gallons of hydraulic fluid lost from leaking seals. These operators and their service technicians who are in the field doing the change-overs make it known they "want the the tan colored pony rod seal," referring to Parker"s recognizable tan-colored Resilon 4300 formulation. Some operators are so pleased with the performance of the Parker pony rod seal they are demanding that the mud pump manufacturers install it as a condition to deploy their pumps on the job site."

Suction and Discharge Cover Seals. Our HGP Profile suction and discharge cover seals provide four times the reliable service life compared to traditional elastomer D-rings. Owing to its combination of unique geometry and Resilon 4300 polyurethane material, the HGP Profile resists wear due to the abrasive fluid proppant, high pressure and vibrating motion generated by high frequency pulsating pressurization. The tough, rugged material improves sealing reliability and minimizes degradation of fluid end mating hardware.

With well conditions becoming increasingly challenging and taking a toll on equipment and expendables, you require sealing products that will enable you to achieve greater production efficiencies, improve performance and reduce down time. Whether you service frac pumps, run completion operations, or build frac pump equipment, Parker’s proprietary Resilon materials can improve your bottom line by:

8613371530291

8613371530291