pressure relief valve mud pump supplier

A wide variety of pressure relief valve for mud pump options are available to you, You can also choose from new, pressure relief valve for mud pump,As well as from energy & mining, construction works , and machinery repair shops. And whether pressure relief valve for mud pump is 1.5 years, 3 months, or {3}.

Relief valve mud pump is also called the centrifugal pump, a compressor, and a compressor. It has a series of pistons, this is done in the form of a centrifugal pump, with a compressor. It is usually used by hydraulic maintenance. The rotating pumps have different cuffs and suction cuffs.@@@@@

Relief valve mud pumps are specially designed for the rotation of the vehicle. There are many types of relief valve mud pumps, suitable for a rotating purpose, such as electric relief valve mud pumps. In the case of the different, pumps are suitable for a rotating process. They are suitable for rotating, there are various sizes and varieties of the pumps depending on the rotation pattern, but with a lesser water flow. On the other hand, there are various types of relief valve mud pumps that are specially designed for use in rotating processes. If the pump is suitable for a rotary motion, these pumps are suitable for a rotary process, and can be used on both sides of the vehicle. On Alibaba.com, there are various types of relief valve mud pumps, such as electric relief valve mud.

Pressure relief valves are installed on mud pumps in order to prevent an overpressure which could result in a serious damage of the pump and serious or fatal injury to personnel.

The discharge pressure is routed to the closer mud tank, via a 3” XXS line clamped strongly on tank side . Mud is flowing into the mud tank until line bled off, bearing in mind that minimum slope is required to avoid mud settling in pipe ( around 1 inch/meter).

Pressure relief valves are set usually to 90% of the maximum working pressure of the liners in use. Read carefully manufacturer chart for pressure setting versus size of liners.

With a low pressure setting, ie, 1000psi, by adjusting the top nylon self lock nut to move on the vertical scale to get the same setting than the scale.

Discharge pressure losses close to the maximum preset pressure.The Pressure relief valves are usually installed on a upper point of the discharge side of the mud pumps.

The pressure relief valve can be reset, if not damaged during the release of pressure. Special care should be taken if no working platform available to access the PRV.

A relief valve is a Valve which is installed on a pump or pipework to relieve excessive pressure in a positive displacement pump which could cause damage to a pump or system. Relief valves (also known as bypass valve or safety valve) are known as an Internal Relief Valve if installed on the pump itself, and if installed on the system they are known as an External Relief Valve.

Such valves are used on positive displacement pumps as the pumps are designed to prevent recirculation of fluid back to the inlet, meaning the displacement is always forward. However if a valve is closed on the outlet of the pump, or a blockage occurs the pump will continue to build pressure in the outlet pipework and within itself. This can cause pressures to reach dangerously high levels, and the pressure will vent at the weakest part of the system, causing a leak, damage or pump failure.

Such valves work in different ways depending on where they are installed. If installed on a pump the fluid is recirculated within the pump head, preventing the buildup of pressure, however the fluid begins to heat up, and is something which should only be done temporarily as it can lead to pump failure. External relief valves should be used in conjunction with internal relief valves to relieve any excessive pressure in the pipework either back to a vented tank or to dump contents in an emergency to atmosphere.

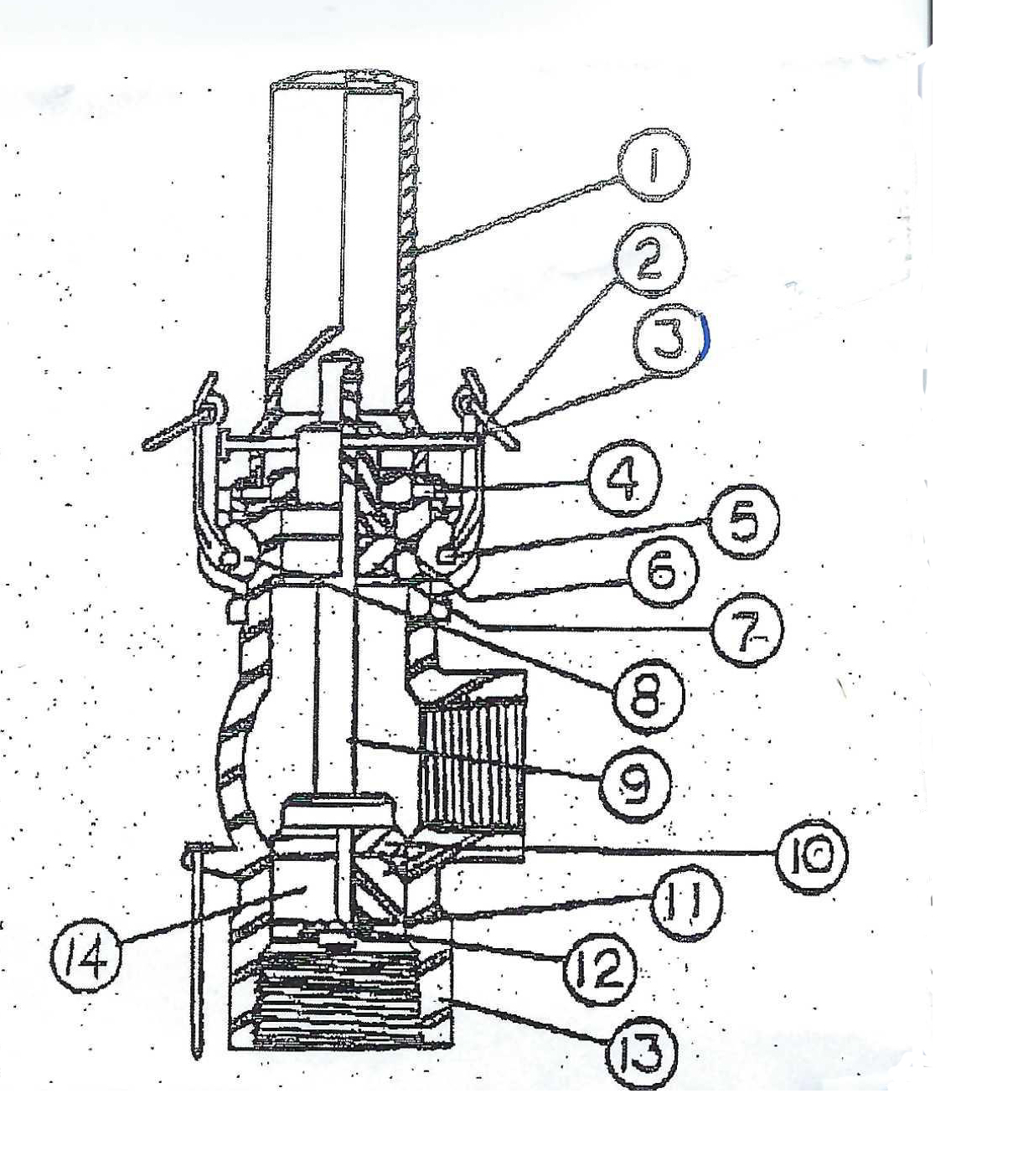

A relief valve design consists of a housing with inlet and outlet connections, a spring within a chamber which keeps a plate in place sealing the discharge. When the valve reaches the set relief pressure, the pressure plate causes the spring to compress revealing the discharge, causing the pressurised contents to vent through the discharge. A set screw or nut is used to set the relief pressure, at the top of the housing and when screwed clockwise, compresses the spring increasing the amount of pressure required to compress the spring and open the valve.

Internal relief valve set pressure is usually set at 10% above the operating pressure of the pump, and external relief valves should be set at 10% higher than the relief valve on the pump to prevent nuisance tripping. Valves are typically calibrated during manufacture and can be set on site with the use of pressure gauges during commissioning. Valves are rated in ranges such as from 0-10 bar, or 10-15 bar so should a valve pressure rating require recalibrating, checks should be made to ensure the setting is inline with the rating of the valve. Equipment should be checked at regular intervals to ensure succesful operation during an emergency.

Relief valves are not always required if the pressure capability of the pump is low, but also if used in conjunction with a product which can solidify when cooled if it enters the relief valve such as Chocolate or Bitumen. If fluid sets within a relief valve this will prevent it from operating as normal as any material which hardens will form a plug and can also cause contamination as it can be very difficult to clean thoroughly.

On some pumps a pressure relief valve is used in conjunction with a pressure regulator which regulates the pump to deliver the required pressure for the system. An analogy often used to describe a pressure regulator is akin to brakes in a car, with and the relief valve being the seat belt. A relief valve should only be relied on for use in emergencies to prevent damage to the pump or system and not as frequent protection for the system.

Our F series mud pump are designed and manufactured on the basis of American Emsco F series mud pump strictly according to America Petroleum Institution API 7K Standard. All of its expendable parts are interchangeable with any other spare parts produced according to API standard. Therefore it is easy to repair and maintain internationally .

All rig mud pump systems use pop-off valves to protect the pump from over pressurization. The best that can be achived with a pop or relief valve is approximately +/- 10% repeatability. On a high pressure system, this can be a significant variance. Although the valves are resettable, they generally go at a lover pressure once tripped and reset. Not WOM’s Pump Saver.

Available up to 10.000 psi, and is more accurate that pop/relief valves. WOM’s Pump Saver features +/- 3% above 3.500 psi. New rupture discs can be easily and quickly replaced.

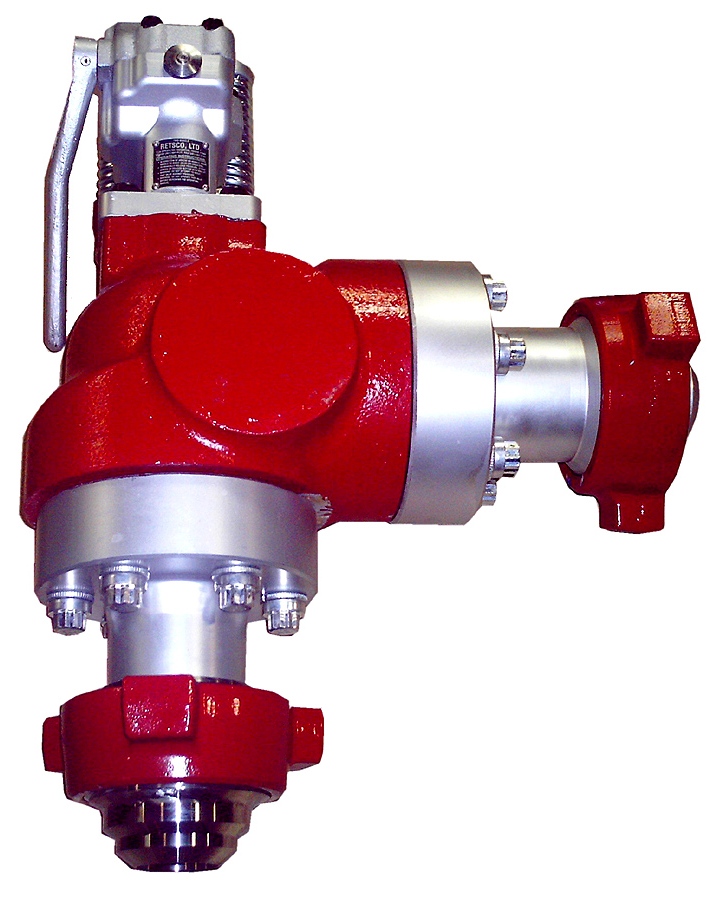

The CRV26 PRV is a product of the CORTEC Fluid Control division of CORTEC, which provides a complete line of high-end valves designed and manufactured according to specific project specifications. CRV26 PRV is engineered to protect drilling systems against the dangers of over pressurization and is the first of its kind to be rated to 10,000 PSI systems.

Stephen Corte, Vice President, CORTEC, said, “Automated PRVs provide the highest level of accuracy and reliability and are automatic or manually resettable for thousands of cycles. Our CRV26 PRV offers a competitively priced alternative to other remotely-operated PRV models, along with a degree of service life, precision and repeatability that conventional burst disks and manual spring reset valves cannot provide.”

The CRV26 PRV is suitable for frac system relief, mud pump relief and managed pressure drilling (MPD) and is compatible with API 6A and NACE MR0175 requirements.

These ASME-approved high pressure relief valves are decidedly better, safer, and more accurate than shear and spring valves. This makes them the product of choice for high pressure relief in mud and slurry, pulp and paper mills, oil and other applications. The Model IA offers mud and slurry pump relief to 10,000 PSI.

Oil Baron Supply provides a unique value to our customers by offering a one-stop shop solution for packaged systems. We work with customers to define the package, design the system, procure the materials and construct the complete package. We manage the entire process to minimize the design and project risks. Working with our suppliers to provide innovative components such as lightweight, high pressure pumps, efficient motors and auxiliary components.

Oil Baron Supply is also leader in supplying mud pump fluid-end and consumable parts trusted by drilling companies across the Asia Pacific Region. We provide a full-portfolio of parts to keep your mud system performing efficiently and reliably. We have a large warehouse of comprehensive stock where most of the interchangeable mud pump expendables and spares parts can be found which covers a wide range of brands, such as; Emsco, Bomco, Gardner Denver, Ideco, NOV, TSM, Weatherford and Wheatley.

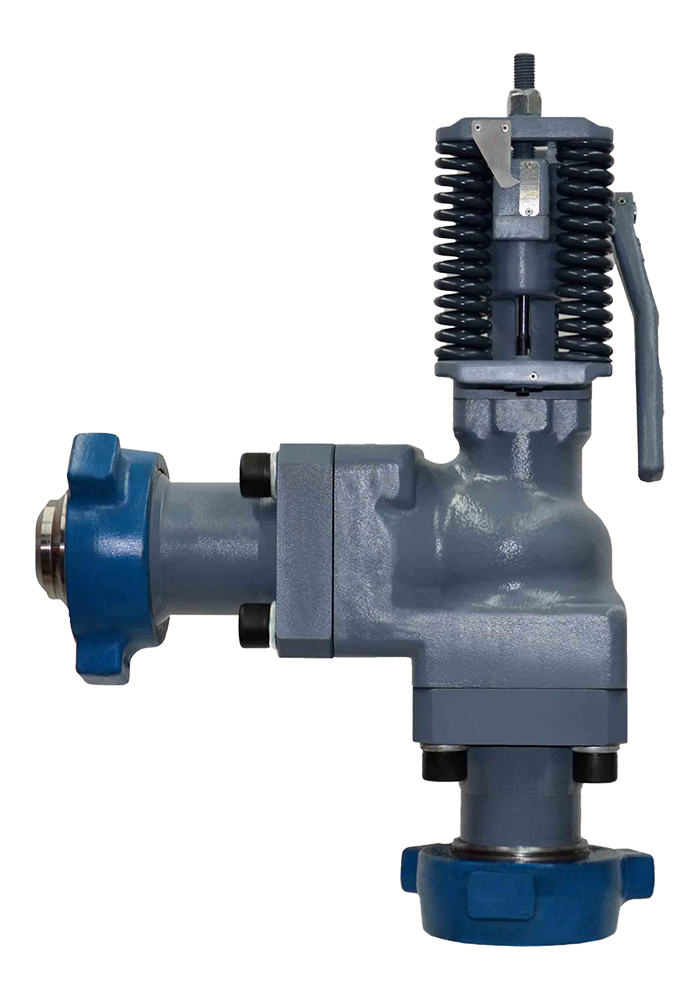

The Premium Oilfield Technologies Caliber® RV7500 Relief Valve was designed for today"s higher-pressure drilling conditions. The valve utilizes a pin buckling system to determine the relief pressure. Each pin is designed to deform when the pressure reaches a predetermined load. All pins go through a stringent quality control process and batch testing to ensure performance at the correct pressure rating.

8613371530291

8613371530291