quad mud pump brands

Bruce Suggs, vice president of marketing and sales for White Star, speaks with DC editorial coordinator Katherine Scott about White Star’s quadraplex mud pump at its headquarters in Waller, Texas, on 17 February.

Drilling Contractor visited the manufacturing facility of White Star Pump Company in Waller, Texas, on 17 February to view a demonstration of the company’s quadraplex mud pump, which was designed to address the challenges of the conventional triplex pump.

“After working on all the different brands of (triplex) pumps, it became evident that they all had the same common issues,” said Bruce Suggs, vice president of marketing and sales for White Star. “(We) tried to build a triplex and ended up with the Quatro.”

Instead of taking an existing triplex pump and trying to make it better, White Star approached the project with a clean-sheet design. The Quatro pump features a width of only 82 in. and easily fits on a standard-width trailer, a potential advantage in areas with limited space, such as on offshore rigs and in shale plays like the Marcellus. With the fluid modules sitting inside the frame, change-out time can be reduced to 23 minutes versus up to 10 hours for conventional triplex pumps. The quadraplex pump also uses a fully assembled crankshaft that requires no castings or welding. Using a crankshaft that is fully assembled and supported by modern bearing placement dramatically reduces crankshaft bending and cracking.

Additionally, the Quatro is equipped with two pulsation dampeners, one for each pair of pistons, unlike the triplex, which carries only one. This allows mud to be dampened before it gets to the strain across, creating a quieter, smoother fluid flow and reducing vibrations.

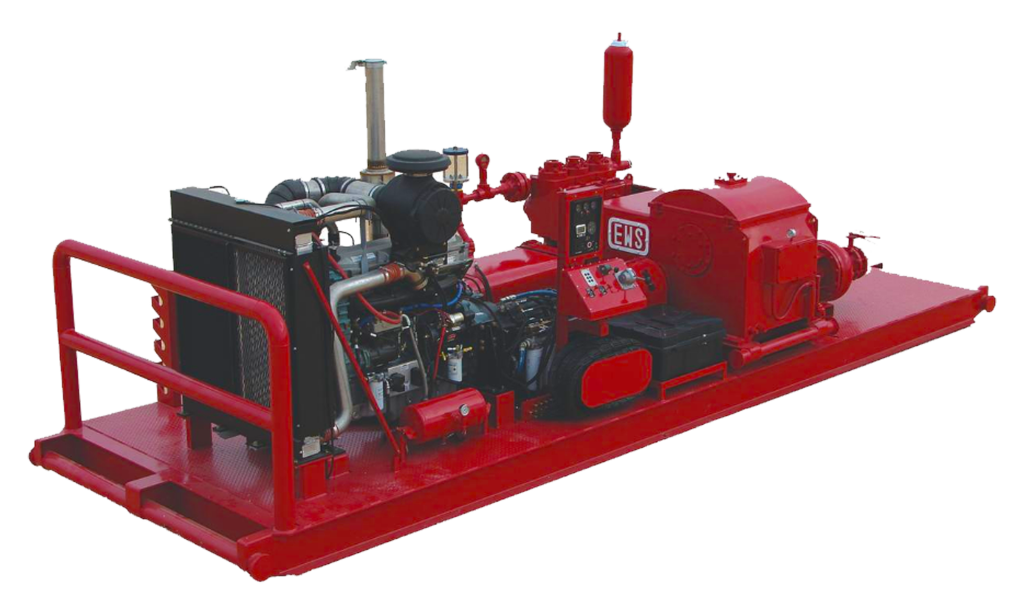

White Star Pump designs, manufactures, and services high-performance mud pumps for oil and gas-drilling operations worldwide. From Ideco-interchangeable parts to ready-to-ship, fully unitized mud pumps, White Star has the solution you need to increase operational efficiency and maximize profits — offshore or on land. For more information, call 281.357.4999 | About us

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Mud Sucker Pro Series engine driven diaphragm pumps use check ball technology in the suction and discharge valve chambers to pump slurries, abrasive fluids, solids and general wastewater. Access to both the suction and discharge areas is available within seconds.

The Mud Sucker 4B-M includes a standard emergency pressure relief valve. Since a diaphragm pump is also a positive displacement pump, a pressure relief valve reduces the chances of damage in an over pressurization event.

The only diaphragm pump in the industry with an exclusive pump body designed to enhance the flow of slurries and debris laden liquids to prevent clogs.

Ships complete with safety guards. Pump operator does not come into contact with moving components when guards are in place (removed in illustration above for clarity).

Mud Sucker Pro Series air driven diaphragm pumps use check ball technology in the suction and discharge valve chambers to pump slurries, abrasive fluids, solids and general wastewater. Access to both the suction and discharge areas is available within seconds.

The Mud Sucker 4B-EC includes a standard emergency pressure relief valve. Since a diaphragm pump is also a positive displacement pump, a pressure relief valve reduces the chances of damage in an over pressurization event.

The only diaphragm pump in the industry with an exclusive pump body designed to enhance the flow of slurries and debris laden liquids to prevent clogs.

Ships complete with safety guards. Pump operator does not come into contact with moving components when guards are in place (removed in illustration above for clarity).

The P series mud pumps are featured by its compact structure, small weight, and land use and high efficiency and can be equipped with drilling rigs according to the requirements and site conditions.

The P series mud pumps are durable and compact and can ensure stable operation. During shallow and middle to deep drilling, the P series mud pumps can meet the special requirements of users.

The durable fluid end of P series mud pumps significantly increases the performance of three-cylinder mud pumps. In addition, the independent structure is easy to inspect and maintain.

The base of the machine frame adopts one-piece welded structure and the seats of the main bearing and transmission bearing are made of one-piece cast steel. The whole pump has good stiffness and strength.

The extension rods are connected to the crossheads by pinholes, so as to ensure the concentricity of the pump. The packing adopts quad-layer sealing structure, which realizes good seal performance.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Product Features Power End The power pump shell is the structure of steel plate welding and has been tested with its intensity by authority. The crankshaft is a composed structure of straight shaft and eccentric wheel. Its airproof part of elastic ripple tube has been awarded a patent certificate by the state. The...

Product Features Power End The power pump shell is the structure of steel plate welding and has been tested with its intensity by authority. The crankshaft is a composed structure of straight shaft and eccentric wheel. Its airproof part of elastic ripple tube has been awarded a patent certificate by the state. The...

Product Features Power End The power pump shell is the structure of steel plate welding and has been tested with its intensity by authority. The crankshaft is a composed structure of straight shaft and eccentric wheel. Its airproof part of elastic ripple tube has been awarded a patent certificate by the state. The...

Product Features Power End The power pump shell is the structure of steel plate welding and has been tested with its intensity by authority. The crankshaft is a composed structure of straight shaft and eccentric wheel. Its airproof part of elastic ripple tube has been awarded a patent certificate by the state. The...

Product Features Power End The power pump shell is the structure of steel plate welding and has been tested with its intensity by authority. The crankshaft is a composed structure of straight shaft and eccentric wheel. Its airproof part of elastic ripple tube has been awarded a patent certificate by the state. The...

Product Features Power End The power pump shell is the structure of steel plate welding and has been tested with its intensity by authority. The crankshaft is a composed structure of straight shaft and eccentric wheel. Its airproof part of elastic ripple tube has been awarded a patent certificate by the state. The...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

We sincerely welcome you come to visit us. Hope we have good cooperation in the future. for Quad Mud Pump , Quadruplex Mud Pump , Mud Pump , we can meet up with different inquiries from different clientele. Be sure to obtain our web page to check much more information and facts from our products.

We strive for excellence, services the customers", hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for Quad Mud Pump , Quadruplex Mud Pump , Mud Pump , Establish long term and win-win business relationships with all our customers share the success and enjoy the happiness of spreading our products to the world together. Trust us and you will gain more. Please feel free to contact us for more information we assure you of our best attention at all times.

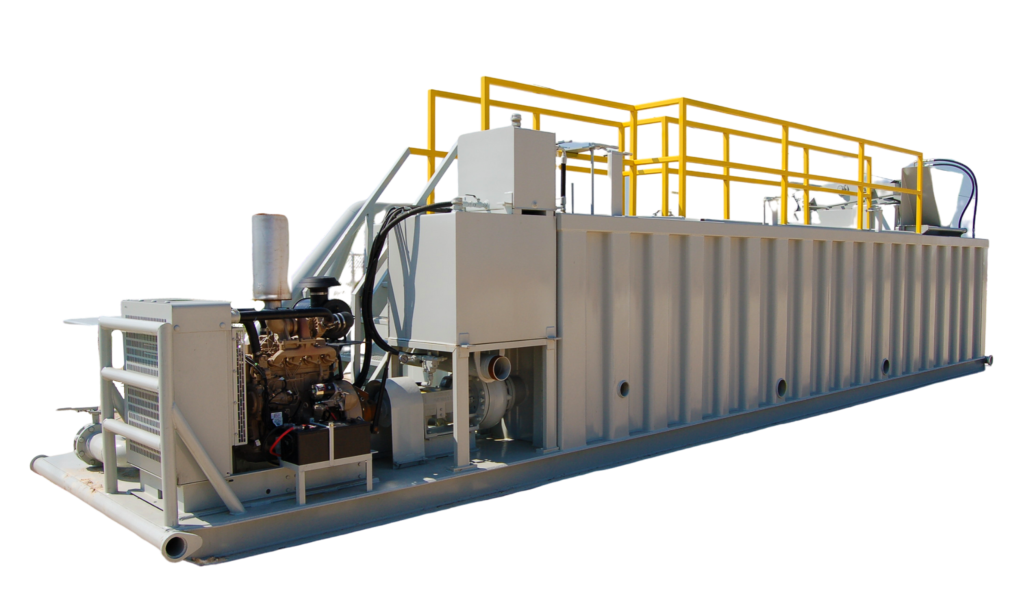

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

8613371530291

8613371530291