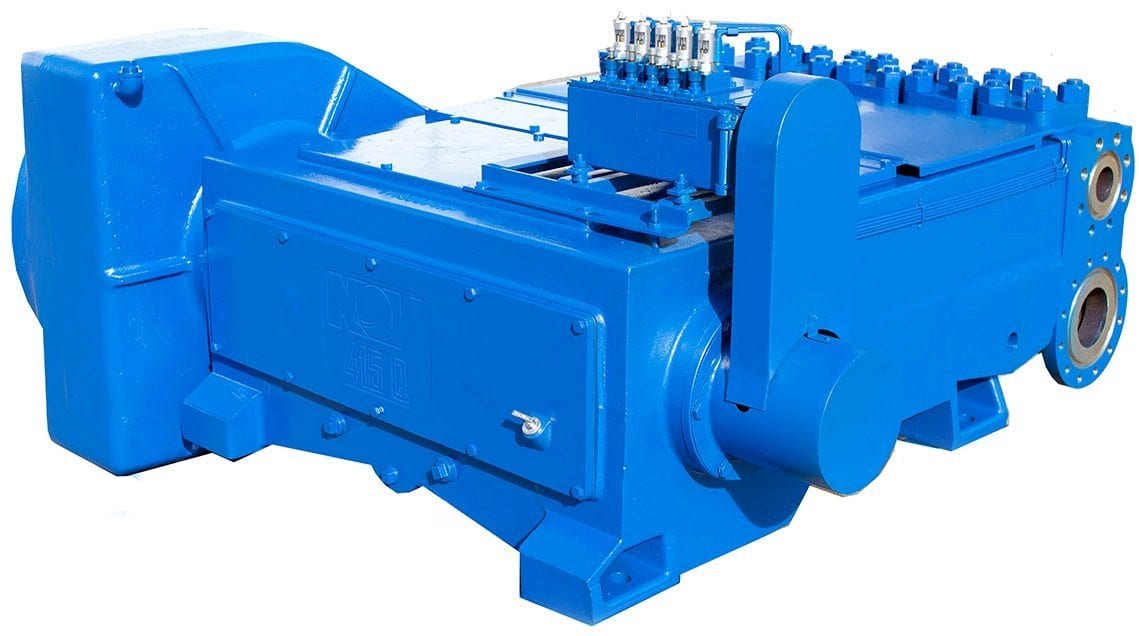

quintiplex mud pump manufacturers supplier

Black gold is truly the best description to sum up the value of oil. One of the most important contributors to change and industrialization, it drives the wheels of progress. ShalePumps is headquartered in Houston, the global oil capital. Headed by experts, it has a vision to support the industry with superior completion equipment. Frac operators, drilling contractors and well service companies source rely on ShalePumps for superior quality.

The key personnel of ShalePumps have a combined experience of more than a hundred years. This experience is reflected in the quality of our equipment. The fracking pumps, components and all services are much sought after for reliability and long life. This is because of the processes we follow. The design, materials, precision engineering and expertise contribute to an advanced assembly line.

After many years of thought and conscientious engineering, the team at ShalePumps is proud to add the Q5K™ 5000 HP Frac Pump to their list of many product offerings. Perfectly capable and suited for the next generation of hydraulic fracking market demands and technology. The Q5K is the only frac pump that has been designed and developed from the ground up to be capable of accepting true 5000 HP in a continuous duty frac application.

ShalePumps has consistently delivered high quality completion equipment to all stakeholders. The mission is to develop faster, rugged and efficient equipment to help the Oil and Exploration Industry. The vision is to continue leading the race with the best quality in completion equipment.

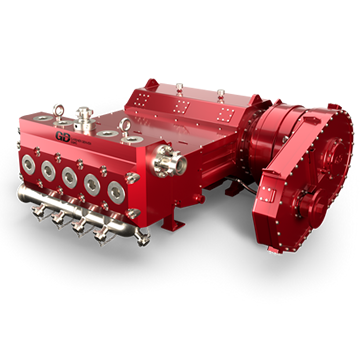

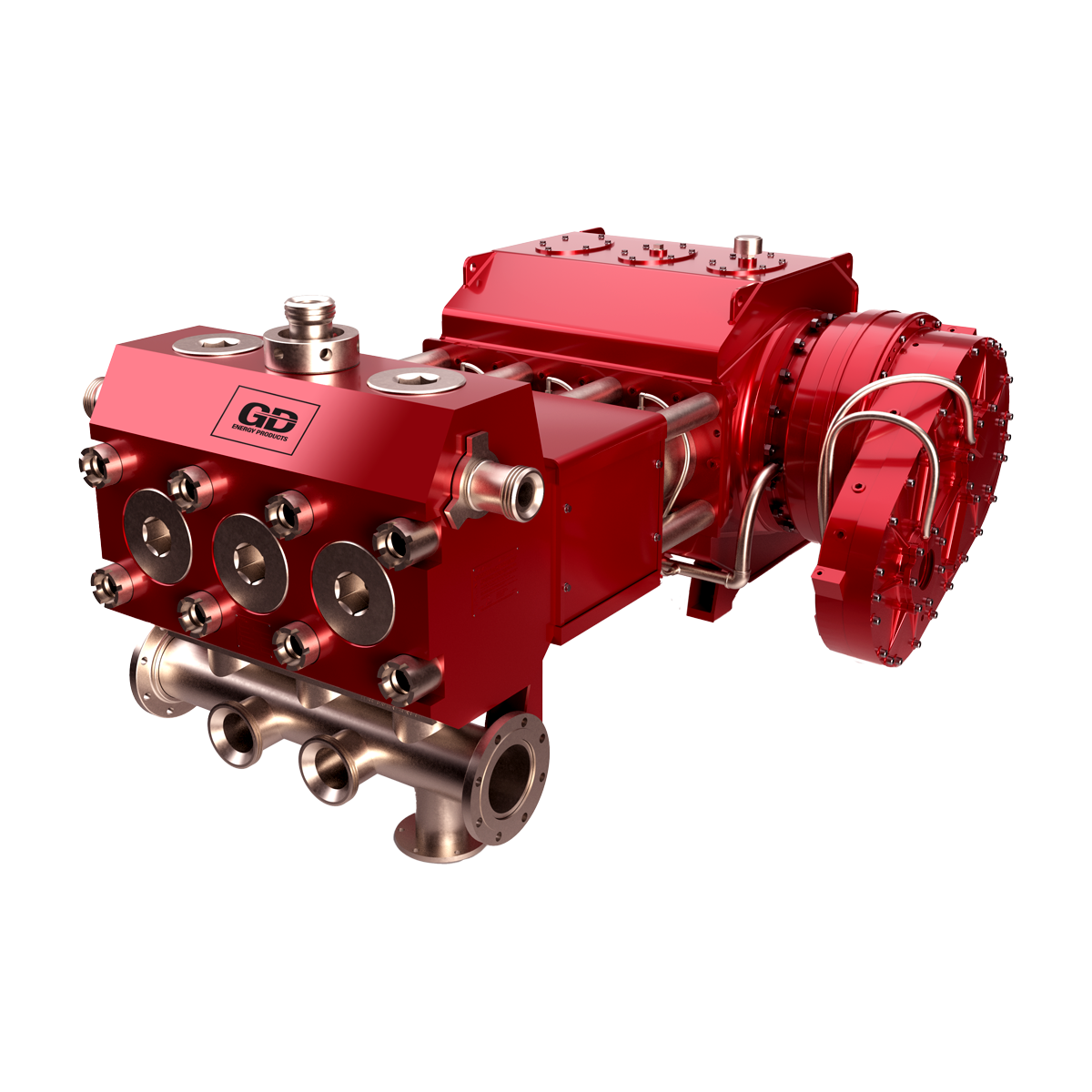

The GD 2500Q Heavy Duty Frame (HDF) quintuplex pump was designed to extend pump service life through an optimized power end frame design. Stable, robust, and durable, the GD 2500Q HDF ...

The HS is a horizontal triplex and quintuplex positive displacement reciprocating pump with very high efficiency and is offered in a wide range of hydraulic, mechanical, and material options.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

In the triplex pumps the crankshaft is supported by two roller bearings while in the case of the quintuplex or septuplex pumps intermediate bearings ...

The RDP range of Reciprocating Plunger Pumps by Ruhrpumpen comes in various sizes and in triplex and quintuplex formats. They are designed and manufactured in accordance to the lates edition of API 674 ...

JR2500Q pump is a widely used quintuplex plunger pump for high pressure and large displacement. It is suitable for continuous fracturing operation under harsh working condition such as ...

The plunger pump is an important device for the hydraulic system. It relies on the plunger to reciprocate in the cylinder to change the volume of the sealing working chamber to achieve oil absorption and oil pressure. The plunger pump has the advantages of high rated pressure, compact structure, high efficiency and convenient flow adjustment.

Piston pumps are widely used in applications where high pressures, high flow rates, and flow rates need to be adjusted, such as hydraulic presses, construction machinery, and ships.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

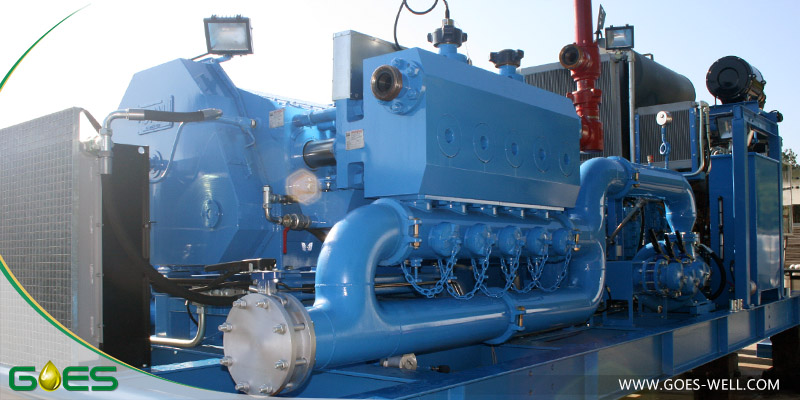

Our manufacturer Mud Pump skid is suitable for operations in rough, windy, damp and dusty oilfield conditions. Dependent upon customer horsepower requirements the engine sizes will vary.

Sticking to your belief of "Creating solutions of high quality and generating buddies with people from all around the world", we always put the fascination of customers to start with for Quintuplex Mud Pump, , , , Let"s cooperate hand in hand to jointly make a beautiful upcoming. We sincerely welcome you to pay a visit to our company or speak to us for cooperation!

▅ The max pressure for F500, F800, F1000 pump is 34.5MPa (5000PSI). These pumps are small, light and reliable. They are the best choices for shallow well and mid-deep well drilling rigs.

▅ The max pressure for F1300/1600, F22000 pump is 34.5MPa (5000PSI). These pumps are the best choices for mid-deep well and deep well drilling rigs due to its large displacement and high reliability.

▅ The max pump pressure for F1600HL and F22000HL pump is 34.5MPa (5000PSI), and the max displacement can reach 51.85L/S and 77.65L/S respectively. It is the best choice for deep well, super deep well, large displacements horizontal well, high pressure jetbit drilling, off-shore platform and other drilling rigs.

▅ The F1 series light weight pump is a new product. Under approximately equivalent power, displacement, pump pressure, and other basic conditions, the pump is 20% to 25% lighter than same model of F series. Meanwhile, all fluid end parts are forgings with outstanding quality. This pump is used when size and weight of drilling rigs are highly demanding, such as offshore platform drill rigs.

▅ QDP-3000 drilling mud pump is the largest power of quintuplex drilling mud pumps and pump package. The max pressure is 51.7MPa (7500PSI), and the largest displacement is 76.34L/S. The largest displacement under the max pump pressure reaches 55.08L/S, and the max pressure under the largest displacement is 27.0MPa, making it work better than similar products. Without pulsation dampener, the displacement and pressure fluctuation of this quintuplex pump is only about one third of triplex pump. The fluctuations are even less when pulsation dampener is installed. The pump package is inspired by ideas of modular and skid-mounted design, endowing it with reasonable layout, smooth operation, high transmission efficiency and reliability. This pump is particularly suitable for offshore platform purpose.

▅ Permanent magnet motor direct drive pump and pump package possess qualities of small volume, light weight, simple and reliable transmission, and high efficiency. It is a new energy-saving product, and also one of the developing trends for future drilling mud pump products.

Our pump manufacturing facility owns advanced paint coating production line, complete assembly production line and excellent mechanical processing equipment. There are 283 sets of various types of equipment altogether. Below are the high-lights:

The large-scale boring & milling machines group which includes XKA2840X160 CNC gantry moving milling machine, SKODA W250HD/W250G/W200G boring-milling machine, Speedram2000 CNC boring-milling machine, G60F CNC floor-type boring-milling machine and PAMA boring-milling machine. It is mainly responsible for boring and milling of drilling mud pump parts and large structural parts.

The drilling mud pump assembly line is equipped with advanced assembly tools, assembly facilities and skilled operators. There is a drilling mud pump test base. It is mainly responsible for the assembly, pressure test and factory test of the pumps.

To meet the needs of customers in a better way, our pump manufacturing facility take “customer satisfaction” as tenet and has been providing repair, test and on-site services of drilling mud pumps globally for a long time. Below are our commitments to the customers:

Piston pumps can be used for low viscosity and medium-flow media (in the range of 80 m³/h). Additionally, pumping solid particles is impossible with this type of equipment because the pump can ensure proper operation only if the seal between the cylinder and the piston is perfect.

For high-pressure uses, you can opt for a plunger pump, they differ from piston pumps in that the seal does not move with the piston, it is fixed and therefore able to withstand...

... heavy duty frac pump designed to operate at higher pressures for longer periods of time. Its compact design and 11” stroke results in less fatigue cycles and extended consumable life. With a legacy of ...

The HS is a horizontal triplex and quintuplex positive displacement reciprocating pump with very high efficiency and is offered in a wide range of hydraulic, mechanical, and material options.

Flojet Triplex Hi-Flow series pumps are designed for a wide range of applications and are constructed from a selection of materials suitable for handling a broad range of chemicals. ...

... alternative to our diaphragm pump series: The LEWA plunger pump is a high-performance and versatile plunger pump for high-pressure applications in various industries.

Three-es manufactures pumping sets with various flow and pressure characteristics, plug&play and optimised for any washing system. Each pumping unit is assembled using only high quality components.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

Triplex pump with connecting rod system. Pistons in ceramic-coated steel. Double gasket sealing system. Pump head in pressed brass. Automatic safety valve with pressure shut-off at pump ...

Drilling pump is also called mud pump, which transport high pressure, high specific gravity, high sand concentration drilling fluid to bottom of hole. Drilling fluid is used to cool bit, wash out bottom ...

Pumps of the WANGEN KL-R Triplex series impress with their consistent dosing option, as an intermittent input is compensated by the buffer volume in the collecting container. No bridge building. The small ...

... consists of 5 pump sizes in triplex execution. The 31.40 model is manufactured also in quintuplex (model 31.40/Q) and septuplex (model 31.40/S) execution, where the same components of the triplex ...

PressureJet pumps are triplex (three plungers), positive displacement, industrial high pressure triplex plunger pumps. We offer both the triplex piston ...

The RDP range of Reciprocating Plunger Pumps by Ruhrpumpen comes in various sizes and in triplex and quintuplex formats. They are designed and manufactured in accordance to the lates edition of API 674 ...

JR500W pump is a horizontal single-acting reciprocating triplex plunger pump. Power end is self-lubricated by oil pump built onto the worm gear. Driven by worm pair, ...

... 1600 mud pump is a single-acting reciprocating triplex mud pump that delivers increased reliability, improved maintainability, and reduced weight and footprint.

Weir provides the oil and gas industry with the best in full open valve and seat technology and manufactures a wide variety of valves and seats for workover pumps, high pressure well service fracturing pumps, cementing pumps and mud pumps through its Novatech™ pressure pumping equipment line.

Novatech leads the industry in full open valve and seat technology and manufactures valves and seats for workover pumps, high pressure well service fracturing pumps, cementing pumps and mud pumps. Novatech also manufactures caged assemblies for almost all well service pumps and applications, including workover, cementing, acidizing and fracking. Novatech developed the first valve and seat in the industry rated for continuous service at 7,500 psi. Products are 100% made in U.S.A.

Reasontek carry Weir/Novatech products for oilfield applications including valves, seats, inserts replacement of pump maintenance. Please check the catalogue below and let us know your request.

Used National Oilwell NOV J-250-H Quintuplex Injection Pump, (J-275-H, 300Q-5H), s/n 220, 1 3/4" Metal Plungers x 5" Stroke, Bronze Fluid End, c/w Reducer, 4.84:1 Ratio

NexGen Manufacturing & Supply keeps a wide variety of replacement parts in stock for mud pumps, plunger pumps, swivels, top drives, handling tools, and much more! Additionally, we have more than 3,000 prints and drawings of oilfield equipment and

8613371530291

8613371530291