quintiplex mud pump manufacturers for sale

Quintuplex Pumps - Used Bethlehem TP-6 triplex pump. 6" stroke, aluminum bronze fluid end, 4 1/2" plungers, gear reducer. 279 max gpm, 629 max psi, 225 max rpm. More Info

Quintuplex Pumps - 350 HP, 5" Stroke Quintuplex Pump, Forged Carbon Steel Fluid End With 2 1/4" plungers, 4" 300 # Suction, 2" 2500 # Discharge.155 GPM MAX, 3483 PSI MAX, 360 rpm max. More Info

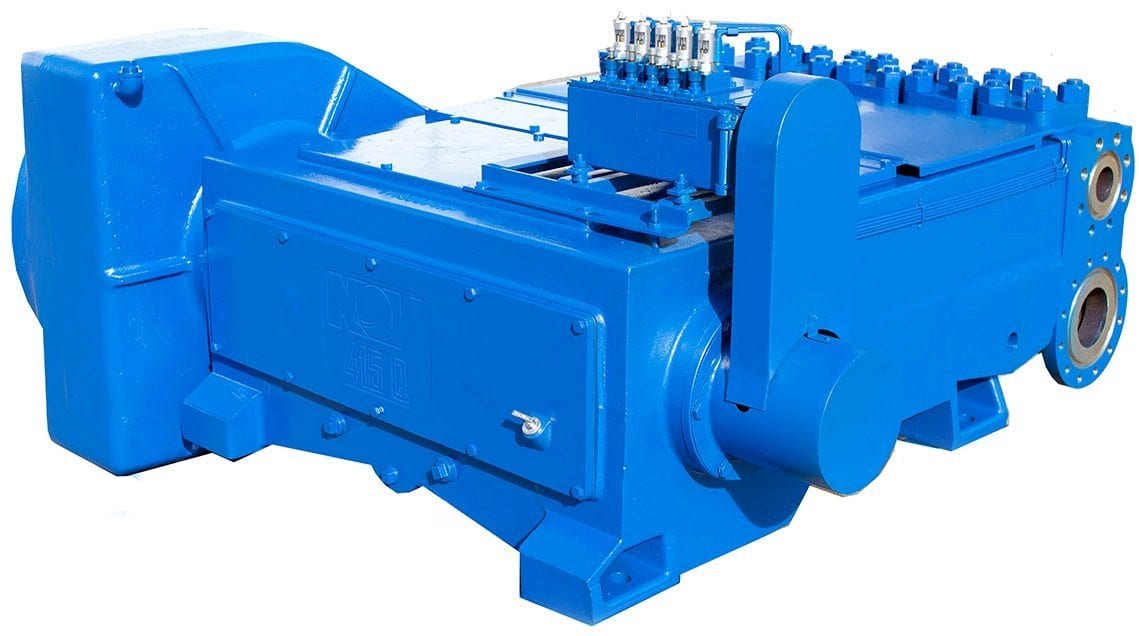

Quintuplex Pumps - Used Oilwell B-558 quintuplex plunger pump, same as NOV 630Q-8L, steel billet fluid end, with 4.5" plungers, 619 gpm max, 1575 psi max, 225 rpm max. More Info

Quintuplex Pumps - Used Wheatly 5p-323 quintuplex, aluminum bronze head, 2.5"" steel plungers, power end in excellent condition, mounted on skid, bull wheel and 40 hp electric motor. More Info

A quintuplex pump has a crankshaft supported in the pump by external main bearings. The crankshaft has five eccentric sheaves, two internal main bearing sheaves, and two bull gears.

A quintuplex pump is central to oil drilling and exploration due to the nature of operations. This pump circulates the mud to and from the surface, supporting the process for oil well operations.

The quintuplex pump is designed to circulate mud or drilling fluid under great pressure down the drill hole and back up. The pump is a reciprocating model that features five pistons, hence the name quintuplex mud pump. The right degree of pressure and precision is crucial for efficient well operations.

Despite the fact that all mud pumps have pulsation dampeners, noise levels are likely to be high and require modifications to keep noise pollution levels low. This is important, considering the long-running hours of equipment and the need to protect personnel from constant and high noise levels. With a quintuplex mud pump, the pulsation noise and the mud telemetry noise come down by as much as half, making operations less noisy.

Quintuplex pumps can be used in various applications including salt water disposal, descaling, high pressure pumping, Frac pumping, pipeline transfers in the Oil & Gas, Agriculture, Mining, Municipal and Manufacturing sectors.

Mud pumps comes in a variety of sizes and configurations but for the typical petroleum drilling rig, the triplex (three piston/plunger) mud pumps are the pump of choice. Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers.

Duplex, triplex and quintuplex pumps all have an enviable history of sound engineering, designed to exceed the rigorous requirements of API 674 and customer satisfaction.

The plunger pump is an important device for the hydraulic system. It relies on the plunger to reciprocate in the cylinder to change the volume of the sealing working chamber to achieve oil absorption and oil pressure. The plunger pump has the advantages of high rated pressure, compact structure, high efficiency and convenient flow adjustment.

Piston pumps are widely used in applications where high pressures, high flow rates, and flow rates need to be adjusted, such as hydraulic presses, construction machinery, and ships.

Black gold is truly the best description to sum up the value of oil. One of the most important contributors to change and industrialization, it drives the wheels of progress. ShalePumps is headquartered in Houston, the global oil capital. Headed by experts, it has a vision to support the industry with superior completion equipment. Frac operators, drilling contractors and well service companies source rely on ShalePumps for superior quality.

The key personnel of ShalePumps have a combined experience of more than a hundred years. This experience is reflected in the quality of our equipment. The fracking pumps, components and all services are much sought after for reliability and long life. This is because of the processes we follow. The design, materials, precision engineering and expertise contribute to an advanced assembly line.

After many years of thought and conscientious engineering, the team at ShalePumps is proud to add the Q5K™ 5000 HP Frac Pump to their list of many product offerings. Perfectly capable and suited for the next generation of hydraulic fracking market demands and technology. The Q5K is the only frac pump that has been designed and developed from the ground up to be capable of accepting true 5000 HP in a continuous duty frac application.

ShalePumps has consistently delivered high quality completion equipment to all stakeholders. The mission is to develop faster, rugged and efficient equipment to help the Oil and Exploration Industry. The vision is to continue leading the race with the best quality in completion equipment.

Used National Oilwell NOV J-250-H Quintuplex Injection Pump, (J-275-H, 300Q-5H), s/n 220, 1 3/4" Metal Plungers x 5" Stroke, Bronze Fluid End, c/w Reducer, 4.84:1 Ratio

With our experience vast pool of resources and dedication to excellent customer service, we will go to the extra mile to confidently fulfill all of your pumping and equipment needs. One of our most important goals is to set the standard for great customer service. No matter if you need a seal, a gasket, or a complete new pump. We"ll treat you the same, with professional courtesy, throughout the sales process. Here"s a couple of testimonials from our customers.

Mud pumps are used on drilling rigs. They are reciprocating pumps for circulating mud, making them ideal in the process of drilling oil wells. If you are looking for a mud pump for sale, a great place to get started is online, and HENDERSON is here to help educate and find the ideal mud pump for your drilling operation.

We are based in Houston, Texas, USA, and we are a leading supplier of re-manufactured and used drilling equipment to international and domestic drilling contractors. Mud pumps are among the types of drilling equipment we carry, and we offer them in different types, so you can be sure to find the right mud pump for sale that suits your needs and budget.

Triplex mud pump – We recommend the triplex mud pump for drilling applications that require a high pump pressure. One of the most common applications for a triplex mud pump is oil drilling, and it works by decreasing the volume of the working fluid being discharged to generate enough pressure to produce the flow.

A triplex mud pump comes with three pistons, where the middle piston is the one that generates more pressure to a crankshaft. However, be careful of high piston load, which can cause the excessive application of pressure that can lead to crankshaft failing or cracking. Be sure to explore our range of triplex mud pumps for sale here.

Quintuplex mud pump – These mud pumps are used to pump fluid during drilling operations, and they work as a continuous duty return piston. Their external bearings aid in the crankshaft’s support to ensure the proper function of the five eccentric sheaves.

Duplex mud pump – Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

Adjust or replace these bearings at first sign of wear. The bearings in the crank end are babbitt lined steel shells, adjustable for wear by removing shims and easily replaced when completely worn. These bearings should be watched closely and adjusted at first signs of looseness.. You will note on series 3400, 3800, 3500, and 3900 pumps, that the shims do not completely fill the outer gap between rod and cap casting, although the connecting rod bolts are tight. This is because the faces of the shell bearings project slightly beyond the faces of the rod and cap castings, and the shims are gripped only between the faces of the bearing halves. Do not try to close this outer gap by tightening the connecting rod bolt as it will put an excessive strain on the bolts.

To check for wear, place a wrench on the top connecting rod bolt and shake the rod parallel to the crankshaft. (The pressure must be relieved from the liquid end of the pump, so that the pump"s mechanism is free to move.) If the rod bearing moves without resistance, the bearing may be too loose and need adjusting. If the bearing does need adjusting, remove shims until you cannot shake the rod, then add .005" shims one at a time until there is little side movement. Be sure to torque rod bolt nuts to proper value for each adjustment. Oil clearance should be checked with Plastigage (available in most parts stores). Wipe crankshaft journal clean of any oil, place a strip of Plastigage on the crankshaft journal and tighten rod cap to the proper torque value. Once tightened, remove rod cap and measure oil clearance with scale on Plastigage package. See oil clearance chart. (NOTE: If you are making this adjustment after having had the crossheads out, be sure that the oil holes in the rod are pointing up. The "up" side is indicated by matching numbers stamped on the cap and rod at the split between them. These numbers should be the same on each rod and should be on the top side of the crankshaft.) Rotate the shaft by hand and if there is any hard drag or tight spots in the bearing, add another 0.005" shim. After this bearing is properly adjusted, loosen bolts a few turns and repeat the above operation on the other bearings. After all bearings have been adjusted.

Torque all connecting rod bolt nuts back to proper value. Again rotate the pump by hand to check for excessive drag and tight spots. If none, the pump should be ready for operation.

If the pump cannot be rotated by hand due to the drive being enclosed, care must-be taken: not to over-tighten the bearings, since they cannot be checked by rotating the pump. When bearings are adjusted by this method, watch carefully for overheating when the pump is put into operation.

It is usually better to have a bearing a little too loose than too tight. A slightly loose bearing will cause very little trouble because of the slow operating speeds of the pump, but a tight bearing will overheat and the babbitt may melt or pull. Normal precautions must be taken to insure cleanliness of parts upon their assembly.

To check for wear, place a wrench on the top connecting rod bolt and shake the rod parallel to the crankshaft. (The pressure must be relieved from the liquid end of the pump so that the pump"s mechanism is free to move.) If the rod bearing moves without resistance, the bearing may be too loose and need adjusting. If the bearing does need adjusting, remove shims until you cannot shake the rod, then add .005" shims one at a time until there is a little side movement. Be sure to torque rod bolt nuts to proper value for each adjustment. (NOTE: If you are making this adjustment after having had the crossheads out, be sure that the oil holes in the rod are pointing up. The "up" side is indicated by matching numbers stamped on the cap and rod at the split between them. These numbers should be the same on each rod and should be on the top side of the crankshaft.) Turn the shaft by hand and if there is any hard drag or tight spots in the bearing, add another .005"" shim. After this bearing is properly adjusted, loosen bolts a few turns and repeat the above operation on the other bearings. After all bearings have been adjusted, torque all connecting rod bolt nuts back to proper amount. Again turn the pump by hand to check for excessive drag and tight spots. If none, the pump should then be ready for operation.

If the pump cannot be rotated by hand due to the drive being enclosed, the bearings may be completely adjusted by shaking the bearing on the shaft as stated above. Care must be taken not to over-tighten the bearings since they cannot be checked by rotating the pump by hand. When bearings are adjusted by this method, they must be watched carefully for overheating when the pump is put into operation.

Alternatively, plastic gauge strips, found in most parts stores may be used to adjust these bearings. It is usually better to have a bearing a little too loose than too tight. A slightly loose bearing will cause very little trouble because of the slow operating speeds of the pump, but a tight bearing will overheat and the babbitt may melt or pull. with experience, an operator can tell by feel when the bearings are properly adjusted. Normal precautions must be taken to insure cleanliness of parts upon their assembly. All wrenches used in adjusting these bearings are standard wrenches.

▅ The max pressure for F500, F800, F1000 pump is 34.5MPa (5000PSI). These pumps are small, light and reliable. They are the best choices for shallow well and mid-deep well drilling rigs.

▅ The max pressure for F1300/1600, F22000 pump is 34.5MPa (5000PSI). These pumps are the best choices for mid-deep well and deep well drilling rigs due to its large displacement and high reliability.

▅ The max pump pressure for F1600HL and F22000HL pump is 34.5MPa (5000PSI), and the max displacement can reach 51.85L/S and 77.65L/S respectively. It is the best choice for deep well, super deep well, large displacements horizontal well, high pressure jetbit drilling, off-shore platform and other drilling rigs.

▅ The F1 series light weight pump is a new product. Under approximately equivalent power, displacement, pump pressure, and other basic conditions, the pump is 20% to 25% lighter than same model of F series. Meanwhile, all fluid end parts are forgings with outstanding quality. This pump is used when size and weight of drilling rigs are highly demanding, such as offshore platform drill rigs.

▅ QDP-3000 drilling mud pump is the largest power of quintuplex drilling mud pumps and pump package. The max pressure is 51.7MPa (7500PSI), and the largest displacement is 76.34L/S. The largest displacement under the max pump pressure reaches 55.08L/S, and the max pressure under the largest displacement is 27.0MPa, making it work better than similar products. Without pulsation dampener, the displacement and pressure fluctuation of this quintuplex pump is only about one third of triplex pump. The fluctuations are even less when pulsation dampener is installed. The pump package is inspired by ideas of modular and skid-mounted design, endowing it with reasonable layout, smooth operation, high transmission efficiency and reliability. This pump is particularly suitable for offshore platform purpose.

▅ Permanent magnet motor direct drive pump and pump package possess qualities of small volume, light weight, simple and reliable transmission, and high efficiency. It is a new energy-saving product, and also one of the developing trends for future drilling mud pump products.

Our pump manufacturing facility owns advanced paint coating production line, complete assembly production line and excellent mechanical processing equipment. There are 283 sets of various types of equipment altogether. Below are the high-lights:

The large-scale boring & milling machines group which includes XKA2840X160 CNC gantry moving milling machine, SKODA W250HD/W250G/W200G boring-milling machine, Speedram2000 CNC boring-milling machine, G60F CNC floor-type boring-milling machine and PAMA boring-milling machine. It is mainly responsible for boring and milling of drilling mud pump parts and large structural parts.

The drilling mud pump assembly line is equipped with advanced assembly tools, assembly facilities and skilled operators. There is a drilling mud pump test base. It is mainly responsible for the assembly, pressure test and factory test of the pumps.

To meet the needs of customers in a better way, our pump manufacturing facility take “customer satisfaction” as tenet and has been providing repair, test and on-site services of drilling mud pumps globally for a long time. Below are our commitments to the customers:

F04B15/02—Pumps adapted to handle specific fluids, e.g. by selection of specific materials for pumps or pump parts the fluids being viscous or non-homogeneous

"Triplex Mud Pump Parts and Accessories;" Product Information Brochure; copyright 2007 Sunnda LLC; downloaded from http://www.triplexmudpump.com/triplex-mud-pump-parts.php on Sep. 5, 2008.

"Triplex Mud Pumps Triplex Mud Pump Parts for Sale;" copyright 2007 Sunnda LLC; Product Information Brochure located at http://www.triplexmudpump.com/.

"Triplex Mud Pumps Triplex Mud Pump Parts;" copyright 2007 Sunnda LLC; downloaded from http://www.triplexmudpump.com/F-series-triplex-mud-pumps-power-end.php on Sep. 5, 2008.

China Petrochemical International Co., Ltd.; "Quintuplex Mud Pump;" Product Information Brochure downloaded from http://www.intl.sinopec.com.cn/emExp/upstream/Quituplex-Mud-Pump.htm downloaded on Oct. 2, 2008.

FMC Technologies; "Fluid Control: Well Service Pump;" Product Information Brochure; downloaded from http://www.fmctechnologies.com/-FluidControl-old/WellServicePump.aspx on Sep. 5, 2008.

National Oilwell; "Triplex Mud Pumps;" Product Information Brochure; downloaded from http://nql.com/Archives/2000%20Composite%20Catalog/pg-32.html downloaded on Sep. 5, 2008.

All CategoriesBuildings (4)Drilling Equipment (168)Additional Drilling Equipment (1)Block (3)Centrifugal Pumps (2)Drilling Equipment - Misc. (1)Duplex Pumps (13)Power Swivels (15)Pump Parts (1)Pumps (57)Pumps - Misc. (11)Rotary Tables (7)Rotating Equipment (22)Sheaves (1)Traveling Equipment (4)Triplex Pumps (30)Drilling Equipment - Misc. (3)ENGINE (1)Fluid End Modules (2)Hoisting Equipment (5)Oilfield - Misc. (3)Additional Oilfield Equipment (1)Catwalks (2)Power Equipment (10)Air Compressors - Industrial (2)Engine Accessories (2)Engines - Other (3)Gear Boxes | Drives (1)Generators | Electric Power (2)Production Equipment (26)Compression Equipment (3)Gas Compressors (3)Tanks (6)Tanks - Misc. (4)Vessels - Horizontal | Vertical (2)Well Service Equipment (4)Well Service - Misc. (4)Pumps (69)Centrifugal Pumps (4)Duplex Pumps (12)Pump Packages (2)Pump Parts (3)Pumps - Misc. (18)Quintuplex Pumps (4)Triplex Pumps (24)Water Injection Pumps (1)Rig Structures (1)Rotating Equipment (28)Power Swivels (16)Rotary Tables (12)Support Equipment (36)Air Compressors - Industrial (4)Buildings (1)Catwalks (3)Doghouses (1)Engines - Other (8)Generators | Electric Power (2)Oilfield - Misc. (3)Power Equipment (14)Tanks & Vessels (15)Tanks - Horizontal | Vertical (1)Tanks - Misc. (12)Trailers (15)Traveling Equipment (16)Block & Hook Combos (4)Blocks (5)Sheaves (7)Triplex Pumps (4)Saltwater pumps (1)Trucks (2)Flatbed Trucks (1)Water Trucks (1)Well Service Equipment (9)Power swivels (1)Swabbing Unit (1)Triplex Pumps (1)

SINCE 1997, HNA has been an integrated engineering & manufacturing specialist recognized worldwide for its unique World Leading HIGH PRESSURE Technology and high quality products in the O&G industry, by designing and fabricating HNA Duplex, Triplex and Quintuplex pumps, which are 100% interchangeable to most of the global famous brands: Bomco, Honghua, TSC, Weatherford, Ellis Williams, Gardner Denver, Emsco , National, Oilwell, Ideco, Drillmec & other major types of models, and customized design and production available.

8613371530291

8613371530291