receprecating mud pump in portuguese supplier

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

We have designed affordable annual subscription plans which would help you get leads for your business. You can have a look at our pricing chart by clicking on this link: https://www.energydais.com/pricing/ . These plans are customized according to the specific needs and requirements of your business.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

Yes. We use third-party companies to provide best quotations for your shipment and inspection of manufactured goods. We make sure that you get quality products from the manufacturer at the best price.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A wide variety of reciprocating piston mud pump options are available to you, such as 1 year, not available and 2 years.You can also choose from new, reciprocating piston mud pump,As well as from energy & mining, construction works , and machinery repair shops. and whether reciprocating piston mud pump is 1.5 years, 6 months, or 3 months.

Triplex plunger-type mud pumps feature a reciprocating, positive displacement pump design utilizing three plungers to safely transfer high-viscosity fluids under high pressure over an extended depth. Although they have many industrial applications, these pumps have become an essential part of oil well drilling rigs where they’re used to provide smooth discharge of mud and debris from oil wells.

In addition to their use in drilling and well service operations, mud pumps are also frequently used to handle corrosive or abrasive fluids, as well as slurries containing relatively large particulates, in applications like commercial car washes, wastewater treatment, cementing, and desalination operations.

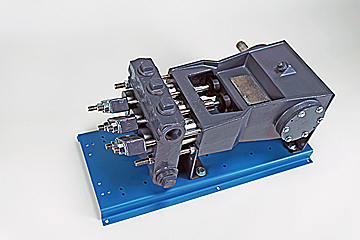

DAC Worldwide’s Representative Triplex, Plunger Mud Pump Dissectible (295-418) is an economical, conveniently-sized triplex plunger-type mud pump assembly that teaches learners hands-on maintenance activities commonly required on larger mud pump assemblies used in upstream oilfield production operations.

For example, mud pump assembly is used on well sites maintain downhole backpressure, to lubricate the rotating drill bit, and to help recycle and remove rock debris resulting from drilling activities. These heavy-duty, high-pressure pumps require regular refurbishment, inspection, and repair in the field.

DAC Worldwide’s dissectible mud pump assembly is a realistic sample that’s similar in geometry, design, and operating characteristics to the larger varieties learners will encounter on the job. DAC Worldwide chooses popular name-brand pumps for its dissectibles to ensure industrial and oil and gas training relevancy.

Using the dissectible mud pump, learners will gain hands-on experience with the operating principles, regular maintenance activities, and nomenclature/parts identification at a more convenient scale in the classroom or lab.

Technical training is most effective when learners can gain hands-on practice with industry-standard components they’ll encounter on the job. The Representative Triplex, Plunger Mud Pump Dissectible features a wide variety of common, industrial-quality components to provide learners with a realistic training experience that will build skills that translate easily to the workplace.

The Representative Triplex, Plunger Mud Pump Dissectible is a sturdy unit with a complete triplex, reciprocating, 20+ bhp plunger pump with .75" plunger, 1.5" stroke, and 3" cylinder sleeve. The unit allows for complete disassembly, assembly, and inspection, including removal of plungers, packing, and valves.

The dissectible mud pump comes with a formed-steel, powder-coated baseplate. It can also be mounted on a compatible DAC Worldwide Extended Electromechanical Workstation (903). Each unit comes with the manufacturer’s installation and maintenance manual.

BW400/10 mud pump is a horizontal three cylinder reciprocating single acting piston pump.Advanced product design, reasonable structure, high pressure, flow, multi-file variable, energy saving, light volume, efficiency, plant life, safe operation, easy maintenance.

BW series mud pump is widely used in mining, drilling, coal, railway, highway, water conservancy and hydropower, bridges, high-rise buildings, foundation reinforcement works.

They are also the main equipment of the geological survey,the main role in the process of core drilling boreholes is to supply fluid(mud or water),making it circulate during drilling and carry rock waste back to the ground,in order to achieve and maintain the bottom hole clean and lubricate drill bits and drilling tools with cooling.

In our after sales service system, We establish perfect control system strictly according to ISO-9000 series, in this system, technology date and problem solve solution and preventive measures will be provided in any maintain project, all the spare parts will be used in new OEM products with installation instructions, packing list, manufacturer"s instruction, qualification and Warranty certificate.

We provide "one equipment & one case, endless service, namely the after sales service begin from the order confirmation, last for the working life of the equipment.

BW400/10 mud pump is a horizontal three cylinder reciprocating single acting piston pump.Advanced product design, reasonable structure, high pressure, flow, multi-file variable, energy saving, light volume, efficiency, plant life, safe operation, easy maintenance.

BW series mud pump is widely used in mining, drilling, coal, railway, highway, water conservancy and hydropower, bridges, high-rise buildings, foundation reinforcement works.

They are also the main equipment of the geological survey,the main role in the process of core drilling boreholes is to supply fluid(mud or water),making it circulate during drilling and carry rock waste back to the ground,in order to achieve and maintain the bottom hole clean and lubricate drill bits and drilling tools with cooling.

In our after sales service system, We establish perfect control system strictly according to ISO-9000 series, in this system, technology date and problem solve solution and preventive measures will be provided in any maintain project, all the spare parts will be used in new OEM products with installation instructions, packing list, manufacturer"s instruction, qualification and Warranty certificate.

We provide "one equipment & one case, endless service, namely the after sales service begin from the order confirmation, last for the working life of the equipment.

Mud hog pump is used to circulate oil drilling mud on a drilling rig at high pressure. Drilling fluid or oil drilling mud is circulated down through the drill string, to help cool, lubricate and clean the drill head, and back through the annulus at high pressures. The drilling mud is also used to suspend and carry out drill cuttings from the drill head as it is brought in and out of the hole.

We can provide more types of mud pumps than other oil well drilling equipment suppliers, and the classification methods are different. There are roughly the following types:

According to the number of times a piston reciprocates in a cylinder to inhale or discharge liquid once, it is divided into sing-acting pump and double-acting pump.

According to different driven method, it is divided into diesel mud pump and electric mud pump.It depends on fuel or energy which is available on around area of drilling rigs.

“MALHAR” Barrel pumps works in reciprocating action. Barrel pump is useful for safe and efficient handling of highly corrosive chemicals, solvents, acids, petroleum products diesel oil, and fuel oils, plating solution, toxic chemicals etc. It eliminates danger of spillage explosion hazards. Construction of MALHAR Pump is such that operating compressed air never gets in contact with pumped liquid. The pump can be directly inserted in to the barrel threading provide on the pump adapter. It sucks the liquid from the bottom and hence less chances of leftover material. It does not have any type of motor and hence virtually zero maintenance.

One of the most popular applications of diaphragm hand pump is as barrel pump, for emptying drums, barrels and carboys. It can handle all types of liquids, such as clear liquids, liquids containing solids, latexes (shear sensitive liquids/ thyrotrophic liquids), slurries, corrosive liquids. It is ideal for handling of inflammable liquids, such as solvents, as its operation is without friction, and hence is suitable for flame-proof plant conditions. It is self-priming and requires no special mounting. Just dip suction tube in the barrel and apply handle. It can suck out the last drops of liquid from drum.

1" or 1.5" pump is recommended for this duty. It is a low cost substitute for motorized barrel pumps such as Lutz, Graco, etc. It can empty a 55 gallon (200 ltr) drum in 8 minutes (1" pump) or 4 minutes (1.5" pump). Depending on the application, these pumps are available in different materials of construction (MOC).

“MALHAR” Barrel pumps works in reciprocating action. Barrel pump is useful for safe and efficient handling of highly corrosive chemicals, solvents, acids, petroleum products diesel oil, and fuel oils, plating solution, toxic chemicals etc. It eliminates danger of spillage explosion hazards. Construction of MALHAR Pump is such that operating compressed air never gets in contact with pumped liquid. The pump can be directly inserted in to the barrel threading provide on the pump adapter. It sucks the liquid from the bottom and hence less chances of leftover material. It does not have any type of motor and hence virtually zero maintenance.

One of the most popular applications of diaphragm hand pump is as barrel pump, for emptying drums, barrels and carboys. It can handle all types of liquids, such as clear liquids, liquids containing solids, latexes (shear sensitive liquids/ thyrotrophic liquids), slurries, corrosive liquids. It is ideal for handling of inflammable liquids, such as solvents, as its operation is without friction, and hence is suitable for flame-proof plant conditions. It is self-priming and requires no special mounting. Just dip suction tube in the barrel and apply handle. It can suck out the last drops of liquid from drum.

1" or 1.5" pump is recommended for this duty. It is a low cost substitute for motorized barrel pumps such as Lutz, Graco, etc. It can empty a 55 gallon (200 ltr) drum in 8 minutes (1" pump) or 4 minutes (1.5" pump). Depending on the application, these pumps are available in different materials of construction (MOC).

BW-160/10 mud pump is a horizontal, triplex, single acting reciprocation piston pump. It"s function is to supply the drilling hole with flushing liquor in order to cool bit. It is used matching drill rigs. It is applied to geological and engineering prospecting such as the railway, the water conservancy, the met-al lurgy, the build and the geology etc industry whose hole deep is within 1000m. Also it can be used to deliver water to high mountains or in the execution domain of middle and low pressure grouting and non excavating matching.

Shandong XinWEI DRILLING EQUIPMENT Co., Ltd. is one of the most well-known manufacturers of trenchless equipment and oilfield equipment in China. After years of unremitting efforts, it has grown into a small but powerful enterprise. Our products cover the entire field, trenchless, from a very small spare part to a very large complete rig system. Our MAIN PRODUCTS are: pump SPARE parts, mud pumps and complete sets of equipment, DC/AC motor, solid control equipment, power plant, vehicle drilling rig, workover rig, land drilling rig, drill pipe and drilling tools, etc. Based on the needs of customers, to provide customers with the best products and services. We focus on providing the best solutions for the maintenance and supply of equipment and spare parts to our overseas oilfield customers.

We welcome the establishment of win-win cooperation with partners all over the world, every customer is our God and helper. Warmly welcome you to visit China!

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291