run mud pump with one geneator and old scr house free sample

Zeefax has developed a program to mitigate against unscheduled stoppages and breakdowns. It is a complete and holistic approach which aims to avoid stoppages but if they do occur, ensure that the resources are on hand to minimise the damage caused. This is the Total Rig Audit (TRA) by Zeefax and is carried out by our very specialised and highly experienced Field Service Engineers.

The Zeefax Total Rig Auditavoids downtime and ensures rig systems remain operational and reliable. Many Drilling Companies will invest in a completeRig Auditin the knowledge that it offers a comprehensive overview of the state of their rig, which can also be submitted for compliance and due diligence purposes.SCR Training Simulator

Every Drilling Rig must have a Power Control Room – sometimes also known as an SCR (standing for Silicon Controlled Rectifier) System – which forms the functional heart of the power control of the drilling operations. Typically, SCR systems comprise a large steel room, inside of which will be a range of Motor Control Centres, Engine & Generator Controls, SCR Control cubicles, and other instruments and systems used for drilling purposes.

SCR Systems usually operate at 600V, and clearly, these systems can be extremely dangerous if not operated correctly and carefully by suitably trained operators. It is therefore vital that drilling engineers and operators are well trained using a combination of class room tuition and on-the-job training.

In response to this need, Zeefax have created the world’s first full size SCR Training Simulator, which accurately mimics the a real SCR; it looks and feels like the real thing, providing a realistic experience of live field operations – but without the dangerous high voltage. This system was created specifically for Naftogaz – for more details, click here.

A key feature of the simulator is the addition of the on-board computer system, which mimics all of the signals that would normally come into this SCR system from the live engines and generators, including the motors running the mud pumps, the rotary table or the Drawworks, etc. and can also simulate a wide range of known faults, allowing trainees to experience first hand problem solving in the safety of the simulator, before they experience the live system.GE Legacy Drive Systems

Used the same type SCR bridge as the Generation III, but rated at only 1200-1500 amp since the heat sink assembly is of a slightly different design. This system uses the GE generator GEM modules controls.

1980’s, 900amp. SCR bridges using the GE GEM Generator Control. As the bridges are small it requires two SCR bays to run a two-motor Mud Pump or Drawworks.

This module features digital circuitry providing enhanced control accuracy for speed and voltage, and also provides tools for system diagnostics, including “first fault” and multiple fault storage and annunciation. A fully featured internal diagnostic self-test on power up is provided, and available outputs include system KVA and kW limit protection.

The EGR is a direct replacement for the GEM Module and protects the engine through tachometer loss sensing, over speed detection, and reverse power protection with adjust-able time delay.Test and Calibration Engineer – IMP products

If you are interested in applying for this position, then please send us your latest CV and a covering letter toTest and Calibration Engineer – SCR products

Zeefax is the value source for parts and services for your legacy GE Drive and Generator Control Systems. We hold an inventory of critical spare parts and can provide comprehensive service solutions including Repair and Return of Modules and PCBs.

Zeefax operates a comprehensive repair and return service for all legacy GE Drive and Generator Control Systems. which includes cleaning, testing, repairing or replacement of defective components and a full system load test. This service includes a 6-month limited warranty.

Zeefax understands that replacement of a complete SCR Control System is often not viable due to the large cost and loss of production due to system downtime. At Zeefax we can offer a comprehensive service to support your legacy GE Drives and give it a renewed lease of life. That not only includes supply of spare parts and a repair/calibration service; qualified service engineers with years of experience with these Drives are available for regular Health Checks, fault-finding and general support purposes.Careers

Zeefax Limited has been made aware that unauthorised individuals have masqueraded as Zeefax Limited, promising job opportunities in our name and requesting payments to cover processing fees, visas, work permits or other formalities. The job offers are typically supported by forged documents, giving the appearance of an official communication, including the use of the Zeefax Limited logo and links to the Zeefax Limited website.

Zeefax Limited (nor any of the placement firms that recruit on our behalf) will NEVER require potential candidates to make any form of advance payment as part of the hiring process.

These communications are fraudulent (usually from @worker.com or @126.com) and do not originate from Zeefax Limited (@zeefax.com), nor are they associated with the Zeefax Limited recruiting process. The individuals who are sending these communications are doing so in an attempt to solicit money from potential job seekers. Be cautious of any unsolicited offers of employment particularly if you are requested to supply personal banking information or provide any form of advance payment.

If you suspect fraud, we would urge you NOT to respond to these unsolicited offers of employment, and to report such activity to your local law enforcement agency immediately!

Should you have any concerns over the validity of any correspondence received in respect of employment with Zeefax Limited, contact us directly atPLC Programming

We have expertise in many of the commonly used devices, including Siemens, Allen-Bradley, GE Fanuc and Mitsubishi, and we have the operational experience and knowledge to provide completely new applications or modify existing ones. We are also able to help and advise on strategy and implementation, as well as with start-up and commissioning.

Not only can we provide a comprehensive programming resource to help with your programming needs, we also can provide a series of PLC programming training courses. The comprehensive training experience is intended for those who wish to expand their skills and knowledge of PLC programming, fault finding and maintenance, and include modules for both novice and advanced users.

Course materials include information and techniques for a range of manufacturers including Siemens, Allen-Bradley, GE Fanucand Mitsubishi, and the curriculum may be tailored for specific requirements and needs, but will typically focus on the more practical aspects of Programmable Logic Controller applications.

All of Zeefax’s training courses are held in our design and manufacturing facility, located near London, England. To find out more about our training courses, pleaseDigital AutoSync Module

In response to many customer requests, we have designed our own version of the legacy Ross Hill Controls AutoSync AC generator control module; the new module has been completely re-designed and incorporates all new digital circuitry as well as optional expansion capability to future proof the module.

The use of modern digital circuitry and components has resulted in much improved parameter control over the previous legacy module without compromising operational reliability, and the ultra-stable frequency control system ensures safe and accurate control of generation systems.

The new front panel includes the familiar controls, but has been enhanced with the inclusion of an LCD display for module set-up and parameter display purposes; front panel controls include the manual circuit breaker and engine controls, with the addition of digital menu navigation buttons for module set-up and display options.

An important feature of the new modules is that they have exactly the same footprint and connection geometry as the old style legacy modules, making installation and upgrading of the new modules simple and quick.

Wire loom connections and attachment points are identical, meaning that no extra wiring or hardware is required in order to facilitate installation, and the new digital circuitry uses the latest available components and techniques, yielding enhanced reliability and performance over older legacy modules.

Our Research & Development department is currently working on new versions of the traditional AC and DC modules which will be available soon to add to the already released DDC and the Digital AutoSync.

These new modules will provide existing system users with a quick and cost effective upgrade path, maintaining the continuity and availability of well established installations.

Zeefax is an established global supplier of high-quality and reliable electrical and mechanical engineering services. As part of the complete service we provide to the industry, we carry out repair and maintenance of all GE752 Motors, including:

Advancements in technology mean that many of the power semiconductors which were built into SCR systems 30 or more years ago have been superseded by new devices, often with improved specifications.

Our engineers are able to ensure that, when the original component is not available, a suitable replacement can be found. If the replacement is not an exact fit, we can engineer an adaptation to ensure continued serviceability of legacy equipment.Hill Graham Controls (HGC)

Following our acquisition of Hill Graham Controls (HGC), Zeefaxis in a unique position to offer total support for all legacy Hill Graham and Ross Hill Controls (RHC) systems both in the UK and throughout the world.

Zeefax’s unique experience and expertise has allowed the company to design, manufacture, supply, repair and calibrate many of the control modules used within older Hill Graham installations, as well as other manufacturer’s systems, including Ross Hill Controls (RHC) type systems.

In recent times,Zeefax has developed and brought to market a new digital AutoSync module, with an improved contemporary design and operation. This advanced module occupies the exact same footprint and has pin-for-pin connection compatibility with the now obsolete Ross Hill module, thereby providing a simple and cost effective upgrade path for existing users of the AutoSync module.

These services mean that equipment manufactured up to 30 years ago, is still fully supported by Zeefax, and can continue to provide return on investment far beyond the normal life expectancy.Troubleshooting & Maintenance

Zeefax has the experience to assist and provide engineers to troubleshoot issues, help during downtime, and establish a program of scheduled maintenance, targeted and customised for your individual requirements.

As part of our maintenance and service offerings for SCR systems, Zeefax is able to mobilise support and engineers to provide technical assistance during emergency shutdowns and downtime periods.

It is well established that a program of planned maintenance and support can and will ease pressure on people and systems, and can result in increased reliability, uptime and ultimately profitability of the system.

By predicting issues, and by scheduling maintenance, spare parts and manpower can be correctly scheduled, minimising downtime, keeping spare part inventory under control and avoiding unwanted breakdowns.

At Zeefax, we recognise that high-quality and experienced technical resources are required during major works, such as emergency breakdown repairs or un-scheduled downtime.

Given our years of experience and unique position to offer total support for all legacy Hill Graham Controls (HGC), and other manufacturer’s systems including Ross Hill Controls (RHC), IPS, and GE Micro Drill SCR systems, Zeefax can provide a full range of technical services for installation, commissioning, and ongoing operational support.SCR System Health Checks

The time to find out if your system is reliable is when operations are quiet – not during critical well operations – so the Zeefax SCR System Health Check is designed to identify potential weaknesses and either repair or replace immediately, or mitigate against these until a repair or replacement can be effected – usually at a quite time.

Zeefax can help you to perform a comprehensive health check, and propose a detailed scope of work designed to compliment and conform to your operation schedule; this means that any potential disruption is absolutely minimised.

Zeefax understands that each rig or vessel has different circumstances and different requirements. Our engineers are able to tailor a maintenance schedule to suit any installation or operational constraints. Where special equipment is required, such as secondary injection test equipment for testing circuit breakers, Zeefax will arrange to have the equipment on site, and our technician will be competent in its use.

For reliable operation, the contact between the SCR devices and the heatsinks must be as good as possible but over time, and especially in offshore installations, corrosion may attack the interface between the SCR device plating and the aluminium heatsink. If corrosion is present it takes an expert to decide if refurbishment is required because as long as the damage is minimal and the two elements remain undisturbed, the mutual corrosion may still maintain a good contact.

As part of the health check our engineer will do a sample inspection of the heatsinks and recommend a course of action based on experience and knowledge.Repair & Calibration

Since our acquisition of Hill Graham Controls (HGC), our module repair facility and engineers, have been able to test and calibrate modules sent to us for repair within a quick turnaround period. In an important development, Zeefax has designed and built a new AC and DC Module simulator, to provide an improved testing platform for Hill Graham and Ross Hill type AC and DC modules. In particular, the AC module simulator is much improved over the older unit, and provides a greatly enhanced engine control and start-up simulation.

These improvements have been made based on our experience with testing and repairing the modules over many years, and our customers can be confident that any module returned to us for repair will receive the most comprehensive bench test possible.

In addition, we are able to repair and re-calibrate most Hill Graham and Ross Hill type printed circuit boards (PCBs), including Power Limit, Field Supply Regulator, Sprocket Slip, Drillers Console, DC Auxiliary, SCR Auxiliary and Generator Exciter PCBs. Furthermore if following evaluation, repair is not possible, in many cases we can supply new manufactured boards using the original designs, but enhanced by us using modern components and manufacturing techniques. In this way, we can help to ensure that legacy systems remain operational and continue to provide reliable and trouble free service beyond their expected life.Motors & Generators

Even given the relatively controlled working environment of typical SCR pods, the conditions can often cause deterioration to both electrical and mechanical performance, requiring removal of the unit from the system, followed by refurbishment and renovation.

During refurbishment, the pods are disassembled, checked and thoroughly cleaned; resistors and capacitors are replaced, and fuses, actuators and switches are checked and tested for operation, and replaced where necessary, and the pod is fully re-wired.

The heat sinks are inspected and if required, will be re-machined to ensure excellent electrical contact is maintained. Importantly, the SCR Thyristor ‘puck’ is replaced, and very special attention is given to the clamping torque and orientation.

When complete, a full quality inspection and electrical test is performed to ensure that the refurbished cell is in perfect working order prior to dispatch back to the owner.

The severe environment on rigs often leads to a deterioration of both electrical and mechanical performance of Foot Throttles, requiring removal of the unit followed by factory refurbishment and renovation.

Typically, units arrive in poor condition – totally seized and unusable; they are then completely disassembled, thoroughly cleaned and de-scaled, and are fitted with new bearings, bearing blocks, hardware and seals, prior to re-wiring and calibration.

Zeefax is able to provide both factory refurbishment of existing Foot Throttles and in cases where the deterioration is too severe for refurbishment, we can supply a brand new replacement to meet specific requirements.

If you would like to know more about the range of available Driller’s Foot Throttles, please call or email us, and we will be pleased to assist.SCR Blower Assemblies

An important part of every system is the forced air cooling, which is vital to ensure continuity and reliability of operation of the SCR stacks. It is essential that the heat generated during operation is reliably carried away, and Zeefax now produce a series of SCR Blower Assemblies which are compatible with the those used in legacy Hill Graham and Ross Hill type systems.

The Zeefax SCR Blowers are designed to operate with voltages up to 600 V @ 50 or 60 Hz; the operating voltage needs to be specified at the time of purchase (see the details and specification form below) and the blower may be configured with either Single or Duplex impellers and with or without base frames.

In order to aid potential users with the selection of replacement blowers, we have created a simple form which can be used to provide the few technical details we require. In this way, we can ensure that any SCR Blower supplied by us is fully compatible with existing assemblies, and will then install directly into the available location with minimal re-work required. You can download this form from this site; please fill it in and return it to us to receive a quotation.

If you would like to know more about the range of available blowers, please call or email us, and we will be pleased to assist.Printed Circuit Boards (PCBs)

Through our in-house R&D, we are developing improved specification products as replacements for legacy Hill Graham Controls or Ross Hill Controls boards; we can provide original replacements for many of the PCBs used on these systems, and by using modern techniques and components, we can even improve on some of the design features of the original products to enhance reliability and functionality.

This means that equipment manufactured up to 30 years ago is still fully supported by Zeefax, and can continue to provide a return on investment well beyond the normal life expectancy.PLC Training Course Program

During the course, we aim to provide students with an advanced training experience, enhancing the already popular series of PLC training courses provided by Zeefax.

This training course includes modules for both novice and advanced users of PLCs, and includes information and techniques for manufacturers including AB, GE Fanuc, Mitsubishi and Siemens. Courses are intended for both technicians and engineers who wish to expand their skills and knowledge of PLC programming, fault finding and maintenance.

Course programs and content may be tailored for specific requirements and needs, but will typically focus on the more practical aspects of Programmable Logic Controller applications.

At the end of the course, engineers and technicians will be familiar with the program modules and functions, and will be able to fault-find on PLC controlled plants.

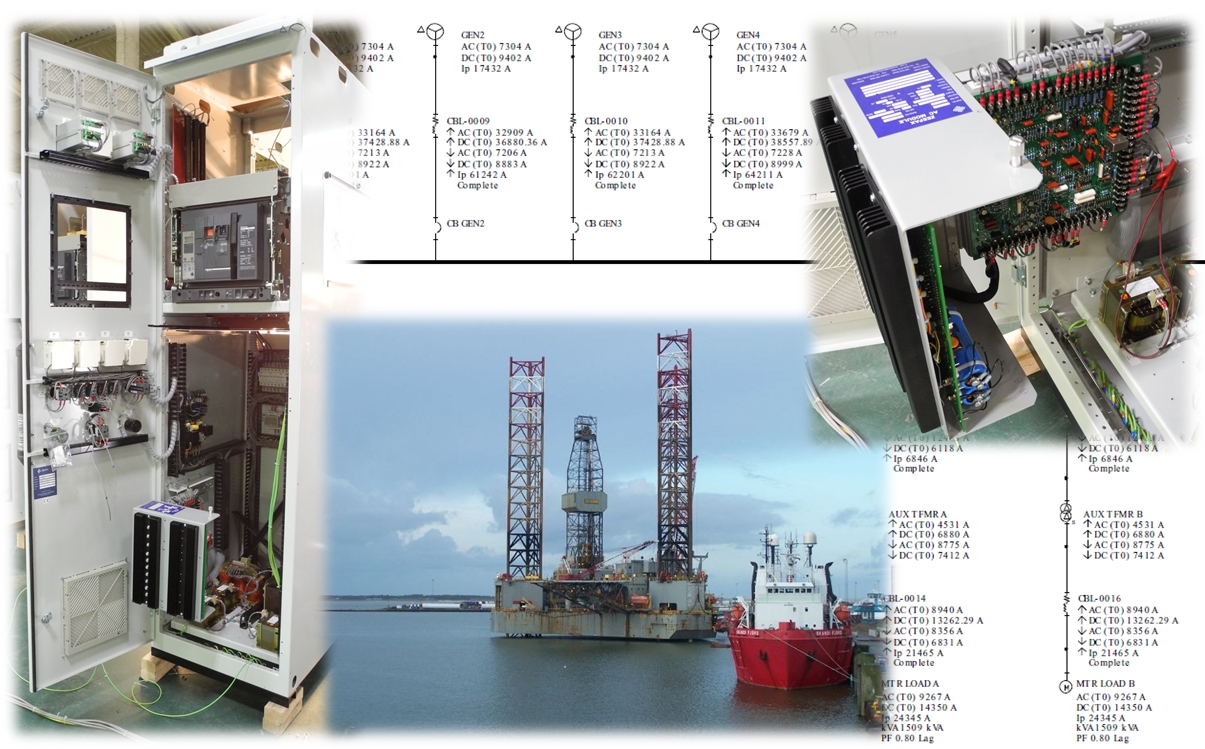

ENSCO 71 is a Jack-Up drilling rig which was originally constructed at the Hitachi Zosen shipyard in 1982. The original GE motor controls comprised five 1163 KVA generators and four 1800 ADC SCR units with associated auxiliary transformer feeders and jacking units. The SCRs were assignable to two 1600 HP twin-motor Mud Pumps, a twin motor 2000 HP Drawworks and a 1000 HP Rotary Table. A separate feeder drives a 1110 HP Top Drive. A fifth SCR was added by Hill Graham Controls in 1985 to power a third 1600 HP Mud Pump, which was cabled to the main busbars.

In early 2012, a decision was made to add a fifth 2500 KVA generator and an additional auxiliary transformer, to close-couple these to the main switchboard via a bus tie circuit breaker, and to include a dedicated feeder for the fifth SCR. A sixth SCR was also included in the switchboard extension to provide an alternative drive source for the third Mud Pump, effectively removing this load from the main switchboard. The switchboard extension, including full integration with the existing GE and Hill Graham equipment, was engineered and built by Zeefax.

As well as providing an extension to the main 600 V switchboard, Zeefax also designed, built and commissioned an accompanying 480 V switchboard comprising of an incoming circuit breaker and a number of small moulded case distribution circuit breakers.

The design and engineering process involved completing a detailed Power Studyto examine the consequences, in terms of fault rating, of adding the new equipment. Various scenarios were considered, and the financial impact was assessed to determine the most cost effective interconnection configuration. As a result of the study the amount of upgrade work required on the existing equipment was minimised.

The Power System Study was completed by gathering data about the existing switchboard arrangement and comparing this to the original, hand written, fault level calculations. The new calculations were performed using software modelling and verified to IEC 61363. The IEC 61363 Short Circuit study represents conditions that may affect typical marine or offshore installations more significantly than land-based systems, including more emphasis on generator and motor decay. This confirmed the original calculations were accurate.

As well as considering the effects of fault currents, Zeefax also completed a complete protective device co-ordination study to confirm and ensure that proper co-ordination was established for all operating scenarios. This included the existing equipment as well as the components in the switchboard extension, and the new 480 V switchboard and transformer.

Finally, the study also included calculating the strength and current-carrying capacity of the busbars under normal and fault conditions to establish the correct busbar sizes and bracing.

Modern drilling techniques require additional equipment not found on older drilling rigs. Existing power systems can be modified by Advanced Control Systems in the field to accommodate the addition of Top Drives, Generators, Mud Pumps, and Independent Rotary Tables.

Obsolete SCR / Engine-Generator Control Systems can be economically retrofitted, refurbished or replaced altogether to increase dependability and decrease downtime.

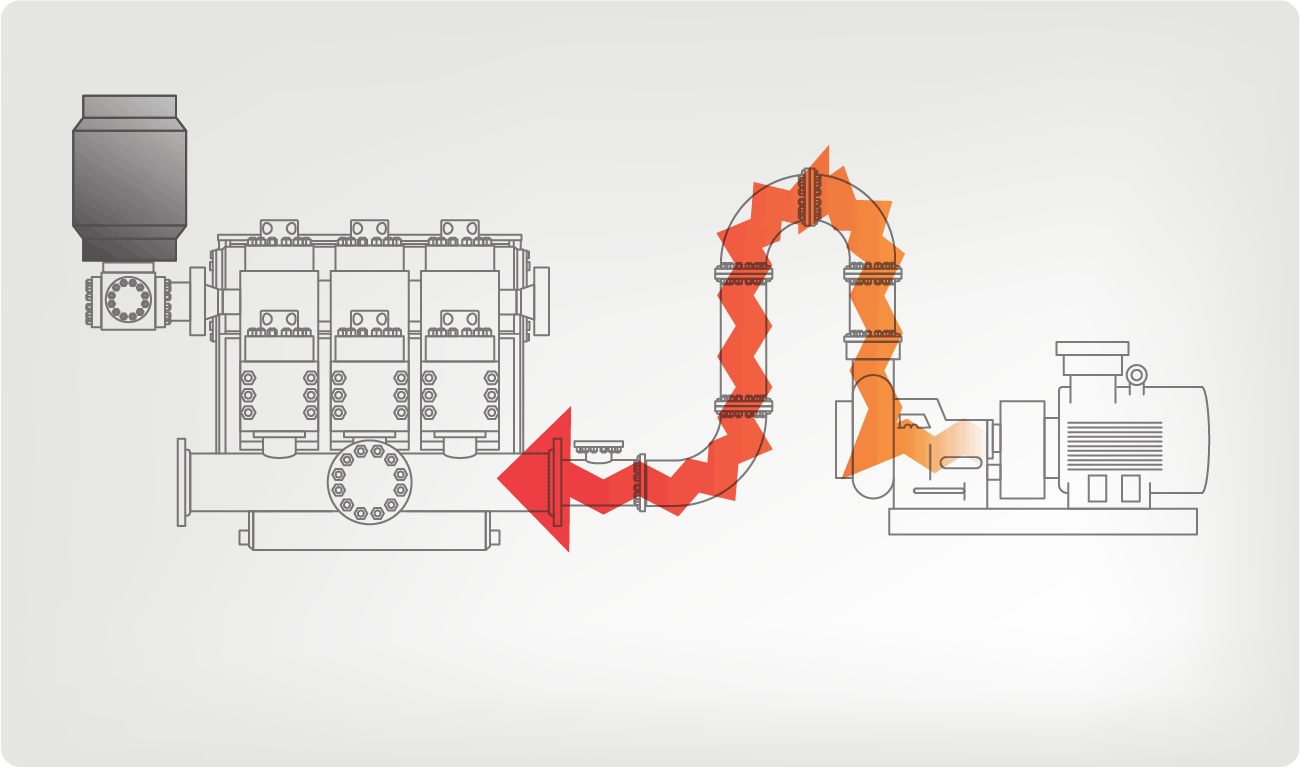

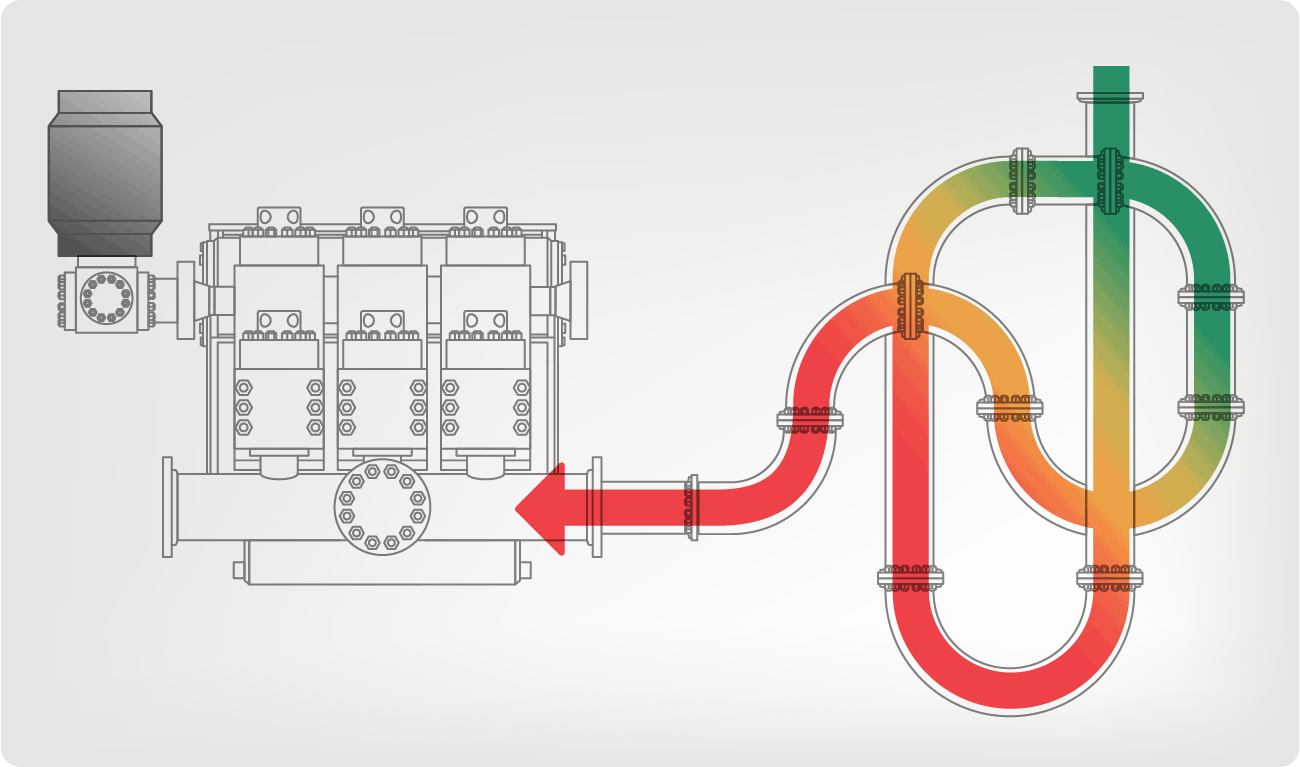

I’ve run into several instances of insufficient suction stabilization on rigs where a “standpipe” is installed off the suction manifold. The thought behind this design was to create a gas-over-fluid column for the reciprocating pump and eliminate cavitation.

When the standpipe is installed on the suction manifold’s deadhead side, there’s little opportunity to get fluid into all the cylinders to prevent cavitation. Also, the reciprocating pump and charge pump are not isolated.

The gas over fluid internal systems has limitations too. The standpipe loses compression due to gas being consumed by the drilling fluid. In the absence of gas, the standpipe becomes virtually defunct because gravity (14.7 psi) is the only force driving the cylinders’ fluid. Also, gas is rarely replenished or charged in the standpipe.

Installing a suction stabilizer from the suction manifold port supports the manifold’s capacity to pull adequate fluid and eliminates the chance of manifold fluid deficiency, which ultimately prevents cavitation.

Another benefit of installing a suction stabilizer is eliminating the negative energies in fluids caused by the water hammer effect from valves quickly closing and opening.

The suction stabilizer’s compressible feature is designed to absorb the negative energies and promote smooth fluid flow. As a result, pump isolation is achieved between the charge pump and the reciprocating pump.

The isolation eliminates pump chatter, and because the reciprocating pump’s negative energies never reach the charge pump, the pump’s expendable life is extended.

Investing in suction stabilizers will ensure your pumps operate consistently and efficiently. They can also prevent most challenges related to pressure surges or pulsations in the most difficult piping environments.

Planned power outages from utilities are becoming more common for multiple reasons. As a result many people have no water because the well and submersible water pump that supply water to their property rely on utility power. This lack of water causes many homeowners to purchase and install generators to ensure electricity is available during these power outages. In this blog we are going to explore the primary factors you’ll need to consider before purchasing a generator. Make sure to read to the end, because we’ll also explore a few proven ways to supply water without the hassle, expense and maintenance of a generator.

If you have bigger needs that involve running your electric heater, AC unit, well pump or electric stove, don’t make assumptions! If you have a 1 HP pump (746 watts if you remember your high school physics) a 1000 watt generator is NOT large enough to run your pump.

Electric motors require a large amount of power to start and get to full speed. Once they have come up to speed their power demands drop to those listed on the label. In the case of a 1 HP standard submersible well pump; a 3-4 KW generator is required for the well pump to be able to start, even though 1 KW is the amount of power the pump uses when it is running. In the rest of this blog we’ll give some tips on generator sizing and even some suggestions at the end that may help you avoid purchasing a generator at all if your primary need is for some water during power outages.

Your pump equipment should have a labels on the control box. The control box has the power cables that go to the submersible well pump. Above ground pumps will have a label on the motor that has a label. The label should indicate the voltage, most likely 220 or 230 volts and the horsepower or current draw (in amps) of the pumping equipment. These are the most critical bits of information you’ll need to start with. If you don’t know what size pump you have or can’t find the labels, check out this recent blog to help you get that information.

Pump manufacturers have provided information available to help you select the correct size generator for your well pump. Franklin Water has what the AIM Manual, which has become the defacto industry bible for many that install, service and design pumping system equipment. The AIM Manual contains this reference chart for sizing a generator to your well pump. If you have a new type control system that uses a variable frequency drive or constant pressure controller, check out this Franklin Subdrive reference chart as a guideline for sizing a generator. If your pump controller is of a different manufacturer, please verify the manufacturer specific requirements for operation using a generator. If you can’t find that manufacturer’s data, then the Franklin information could be used to approximate the needs.

So, for that 1 HP example we briefly visited earlier, a Honda 4500 watt Generator would work well with power remaining to run other parts of your home. If you don’t like yanking a starter cord or lifting/dragging the generator around, check out this 4500 watt Honda Generator that has an electric start.

Keep in mind that many water systems may have more than one pump that are used to provide water. Well pumps are frequently used to pump water into a storage tank and then a booster pump is used to pump water from the storage tank and pressurize it for irrigation and household needs. Some people choose only to use generator power for the booster pump that supplies water from the storage tank, but in some cases with large water demands, it is necessary to size the generator to run both the well and booster pumps at the same time. If you plan to irrigate normally during an extended power outage you need a generator that can run the submersible well pump and the booster pump at the same time. You’ll also need a large enough fuel supply to last through the irrigation cycle.

In addition to the demands of your well pump, there are the demands for lighting and appliances you want to run during power outages. While these electrical loads may seem insignificant, they can add up, especially if you use electric heating or an electric stove. Make sure to include these demands as you calculate what size generator is adequate for your needs or consult with a qualified electrician.

As mentioned earlier, it is important to consider the type of power your well pump equipment requires. Most residential pumping equipment is single phase 230 volts, however, some small pumps in the USA may use 120 volts single phase. Larger pumping installations may require 208, 230 volt or 480 volt 3-phase power. In general, small generators in the USA under ~2000 watts usually only provide single phase 120 volt power while most medium size generators will provide 120/230 volt single phase power. The Honda generators I have linked above all offer 120 and 240 volt single phase outputs so that you can run your well equipment and household equipment at the same time!

Our friends at Franklin Water have created this video about the use of generators for well pumps, check it out when you have time to ensure you are connecting and operating your well pump properly with a generator!

There’s nothing like trying to run a customer’s pump with a generator that won’t start or that doesn’t have enough power for the job. Because we rely on these units, many of our trucks are equipped with Honda 6500 watt portable Generators. These units provide both 120 & 240 volt single phase power and have enough power to start and run a 3 HP single phase submersible well pump. If you’re after a reliable, easy starting, minimal maintenance generator to run your house and well pump, this unit is a great option. Not all houses will need a generator this large! Keep reading for more details on specifics about, electrical connection strategies and safety precautions you should consider when operating a generator.

Generators can be loud, emit toxic gases and pose fire hazards. Generators should be placed so that: a) noise is minimized for both you AND your neighbors b) it is never located inside of a room connected to your house c) it is located with proper ventilation for both cooling and provision for dangerous exhaust fumes d) it is not close to any combustable surfaces.

If you plan to install a generator outside; wood, brush, plastic and any fuel containers should be cleared to a safe distance from the generator site. Bare, clean dirt or cement are are great options. The generator should have a properly installed spark arrestor on the exhaust and care should be taken that the generator won’t tip over or vibrate in one direction or another (or get stolen). A fire extinguisher should be kept close at hand and fuel stored a safe distance from the generator. Portable generators should not be left running unsupervised. Keep in mind that if a generator belonging to you starts a fire, you may be held liable for the damages!

This aspect is of serious concern as it is a matter of safety, not just for you, but for others referenced in the video above. Improperly connected generators can back feed the power grid, electrocuting utility workers and causing other issues that you may be held responsible for. Properly connected generators come in two forms:

1) Installation of a transfer switch compliant with local/national electrical codes. A transfer switch allows the electrical load to be connected either to the generator or to the utility power source and, if installed properly, will never allow the generator to be connected to the utility grid. Some people try to install their generator using a separate circuit breaker in their electrical panel. With this setup they turn the utility circuit breaker off and then turn the generator circuit breaker on. This is considered unsafe practice as it is possible, through human error, to have both the generator and utility circuit breaker on at the same time. Some areas allow for installation of a breaker interlock in your breaker panel, but this needs to be confirmed with your local building code and needs to be carefully selected to fit your specific electrical panel. Utility workers will frequently check sites that have generators running to see if the generator is safely connected before starting their repair work or turning the utility power back on. If they see a potential hazard, they will “pull” your electrical meter and your system will need to be inspected, often by the county building inspector, before the utility will reinstall the meter and restore utility power.

2)Plug items that need power directly into outlets provided on the generator. On the upside, this method is quite simple and much less expensive than installing a transfer switch. There are, however, several drawbacks with this method. It means running extension cords and only being able to power a few key items that are plugged into the generator. This method means putting all the extension cords away and plugging everything back into the house when you are done. Some people will have an electrician install 220 volt plugs/receptacle on the well pump equipment that can be unplugged from the utility power and plugged into the generator to ensure that water is available during a power outage. If you are going the extension cord route, make sure you are using high quality, grounded extension cords that have wire size large enough (we only recommend using extension cords with #12 or #10 wire) for the electrical loads and that all safety precautions and building/electrical codes are followed. Using a cheap electrical cord with small wire will ensure you don’t have enough power to run your appliances from your generator. Make sure that the extension cords are not going to be a trip or safety hazard and that they are in good condition without cuts, scrapes or damage or loose cord ends. Limit the use of power strips/splitters by using extension cords that have integrated splitters, and don’t try to run everything in your house, just the essentials. Power splitters plugged into power splitters are a “no-no” and a fire hazard.

If your generator is too small to run everything you want to, it is time to prioritize! If you have an electric stove or use electricity for heating, then you are simply out of luck for those appliances unless you can run them on the lowest settings. Other techniques to make the most of a generator that just can’t run everything include plugging in the fridge 8 hours and then unplugging the fridge and plugging in the deep freezer for a 8 hours on a rotating basis. You’ll also want to ensure that you turn off lights when you aren’t using them and switch out those old light bulbs for some good quality LED lights bulbs. Unplug any electronics or appliances you are not using, even though you aren’t using them, they often still consume some amount of power and it can add up! The good news is that computers, chargers for phones and laptops as well as your internet router typically consume very small amounts of power and you should be able to keep them online.

Found a cheap generator from the big box store or the local hardware store? One generator is like another? That may be your initial impression, but we’ve found that these cheap units let you down when you need them most, and then you’ll toss it in the trash and replace it in frustration because trying to find somebody that will repair it will cost more than the unit is worth. Stop the waste of your money, halt the frustration with junk, quite buying disposable plastic CRAP that lets you down and ends up in landfills. That’s why we stick with Honda. Honda has a good network of service providers, the parts are readily available and they make a quality product that just plain work and last for a long time. Honda’s are also the better option for the environment-not just because they last and you aren’t having to constantly replace them, but because they are fuel efficient! We don’t sell generators, but check out our blog about shopping for a generatorbefore you buy!

Unless you are willing to spend a large amount installing an automatic backup generator with an automatic transfer switch, you should expect some hassle when using a portable generator. When the power goes out you get to drag the generator out, make the connections and fiddle around with starting it. It may have been a year or more since the generator was last used and the battery for the starter is dead or the gas is old and has fouled the carburetor or fuel system. When you get the generator running you get to check the fuel and oil every few hours. If it’s time to run and pick the kids up from school, don’t forget to shut the generator off before you leave and fill the empty gas container! When the power comes back on, don’t forget switch everything back over and put the generator away and extension cords away!

“Isn’t there a better way?” you may be asking. In some cases, yes, there are other, potentially better ways to ensure water without resorting to the purchase of a generator. The potential solution really depends on your situation, budget and the amount of water needed during power outages.

1) Check with your neighbors to find out who has water that is not affected by utility outages. It may be possible, with their permission, to run a garden hose from one of their hose bibs to one of yours and connect it using a double hose connector from your local hardware store. Keep your water usage down and offer your neighbor a few bucks, some cookies, or a invitation to dinner to show your appreciation!

2) One of my favorite solutions is to install an additional pressure tank or a larger pressure tank into the water system. This will increase the amount of pressurized water available during a power outage. Many standard systems have small pressure tanks that hold only a few gallons. This means after washing hands and a few toilet flushes, the stored reservoir of pressurized water is gone and the pump must run again to re-pressurize the system! A single 119 gallon Well X Trol WX350pressure tank will give you 37 gallons of usable, pressurized water, ready to use even if the power is off. This is enough for several short showers, dishes from several meals, and a half dozen toilet flushes! As I’m certain you’ve already noticed, pressure tank size and drawdown capacity are different. An 80 gallon pressure tank may displace a physical volume of 80 gallons, but may only have a water storage capacity of 25-30 gallons when the air charge needed to provide pressure is accounted for. While a large pressure tank can be expensive, there is virtually no maintenance and installation is usually not difficult! If you have any water leaks, this type of solution won’t be of any help until those leaks are identified and repaired. Give our team a call if you’d like to discuss this option!

3) Some people choose to install a small storage tank near the house. To ensure the water stays clean use a small quantity of chlorine bleach or purchase a commercial water preservative. This small storage tank serves as a point you can go to fill buckets to use for toilet flushing, washing dishes and watering plants if needed. Make sure you refill your tank when the power is back on! If you want your tank to fill automatically when the water is on you can install a float valvein the tank and connect the float valve to a faucet with a garden hose. You may need the correct hose adaptor to connect the hose to the float valve.

1)If you have elevation on your property in the form of a hill or a sturdy elevated platform, gravity will be your friend! It may be time to install a storage tank that can fill when the electricity is on and then water can flow by gravity to your house when needed.

2) If you have already installed solar panels on your house and have solar power available, you can upgrade this system with a battery bank to ensure power in the event of power outages. This can be quite expensive and may also require more than just installing a battery bank. Some systems may require changing the type and location of the inverter(s) and the installation of charge controllers. Please contact your solar installer for more information on converting your grid tied solar system to a grid tied solar with battery backup.

Oakville Pump Service has been helping our customers ensure reliable and available water for our clients for over 35 years! Please call us at (707)944-2471 if we can help you ensure your water needs are met. Check out more of our blogs that discuss generators and other options to supply water in the event of an emergency! If your after very simple simple solutions for water during power outages, check out this recent blog on simple solar power and hand pumps that some of our clients use!

Please note that Amazon links have been provided to show illustrations of products mentioned in this blog. These links are not intended to show the exact product for your specific application, rather a generic example of the product referenced. While purchasing these items is possible, please do so after having done your own due diligence and understand that these links may generate Amazon commissions.

The Montclair High School girls and boys swim teams pulled off a sweep on Monday night in the North 1 Group A state semifinals at Montclair State University.

Diesel Exhaust Fluid (DEF) is a blended aqueous urea solution of 32.5% high purity urea and 67.5% deionized water used to reduce pollution in newer Tier 4 Final diesel engines. As DEF is injected directly into your SCR system, quality control is critical for peak operation of your equipment.

Poor quality DEF can cause significant component damage, equipment failure and void the manufacturer’s warranty leading to expensive repair costs. When diesel exhaust fluid quality deteriorates, you may experience increased DEF consumption or reduced DEF effectiveness, equipment failure, SCR system malfunctions or component damage.

Crystallization: Crystallization can occur in a couple of ways – over-dosing and hard water top ups. Over-dosing occurs when too much DEF is added to the system – the DEF may not fully hydrolyze which can lead to crystalized deposits in the exhaust or injector nozzle. Over-dosing can result from a partially open DEF injector nozzle, plugged DEF lines or DEF pump issues. Topping up your DEF system with hard water can also result in scale or deposits forming.

UREA Concentration (Dilution): Diluted DEF (too much water) reduces its NOx neutralization effectiveness. Most DEF is sold pre-mixed but topping up with water will affect concentrations (and could also lead to crystallization as noted above).

Cold Weather: DEF may gel or freeze in colder climates (12ºF (-11ºC)) preventing engine operation. Additives should not be used to thaw DEF as additives can throw off the concentration of the fluid and damage the SCR system.

Other Fluids: Contamination of the DEF tank from other fluids such as diesel fuel, coolant, or engine oil being added can cause damage to the SCR system and engine shutdown.

Crystallization builds up over time. Testing DEF currently in the tank may or may not indicate issues which can cause future crystallization. Common field and lab testing include:

Confirming DEF quality during delivery or in bulk storage by requesting the Certificate of Analysis from your DEF supplier or submitting a sample for testing according to the ISO 22241-1 standard.

DEF is naturally clear – if it appears cloudy or colored, you may have an issue with age or contamination. You can also visually inspect the DEF filter and storage containers for dirt or metal debris.

DEF should meet the ISO 22241-1 standard for cleanliness and is measured using the Insoluble Matter test (<20 ppm max). For many OEMs, DEF cleanliness is measured using ISO Particle Count and should have a result of 18/16/13 or lower.

The percentage of Urea should be between 31.8% – 33.2% (target is 32.5%). You can use a handheld DEF refractometer to measure the concentration specifications of the fluid and also submit samples for analysis using the Urea Content (Refractive Index Method) or (from Nitrogen) tests.

As DEF is often contaminated with diesel fuel. A simple smell test should indicate if fuel has contaminated your DEF. For DEF contaminated with antifreeze, the % Urea concentration may change, and testing should be done as noted above. Engine oil or hydraulic oil contamination can be tested by collecting a sample at the top layer of the DEF tank. If engine or hydraulic oil is present, it will form a separate layer in the sample taken.

IDM system with 3 SCR cubicles to operate DC traction motors, 3 generator control cubicles, motor control center complete with (one) 150 kva lighting transformer and (one) 750 kva 600/480 volt transformer. Rated at 1600 amps

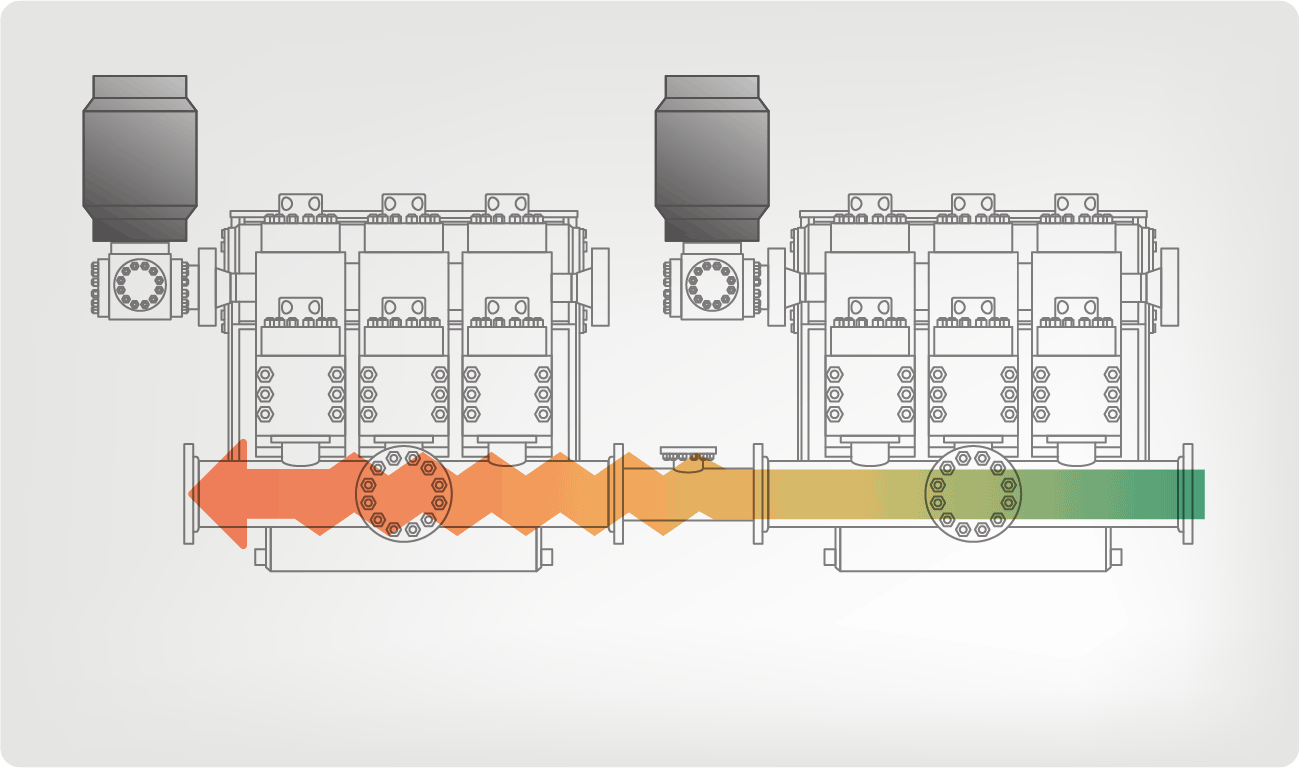

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

When looking at what this unit can run, and what can be run simultaneously, you must look at each of those things you want to power to determine their power draw and insure that it does not exceed the generator"s capacity. The EU2200i provides 1,800W sustained and up to 2,200W surge. This equates to 15A (1,800W/120v) & 18.3A (2,200W/120v) respectively. Look in the User"s Guide or on the data plate for each appliance to get their power requirements. As an example, my refrigerator data plate states that it draws 7A of power. If I plug it in to the generator, 7A of the 15A total is now being used, so I have 8A remaining that can be used for other things that would be run simultaneously. If you also wanted to run a heater that draws 1,500W, convert that to amps (1,500W/120v=12.5A), the power draw would be too high to run that at the same time as the refrigerator (7A + 12.5A=19.5A which is greater than the sustained 15A the generator can supply. So take all of your items you want/need to run and see if the generator can supply the necessary power for that load. If the demand exceeds what the generator can supply, then you may have to swap things in and out as you need them. Plug in the fridge and let it get cold, then if needed, unplug to use others items; things will stay cold if you don"t open the door a lot. Just some thoughts, as all of the questions about the combination of what can be run can best be answered by "it all depends". Good luck all!! Have an awesome day!!

8613371530291

8613371530291