safety release valve mud pump brands

The Premium Oilfield Technologies Caliber® RV7500 Relief Valve was designed for today"s higher-pressure drilling conditions. The valve utilizes a pin buckling system to determine the relief pressure. Each pin is designed to deform when the pressure reaches a predetermined load. All pins go through a stringent quality control process and batch testing to ensure performance at the correct pressure rating.

Relief valve mud pump is also called the centrifugal pump, a compressor, and a compressor. It has a series of pistons, this is done in the form of a centrifugal pump, with a compressor. It is usually used by hydraulic maintenance. The rotating pumps have different cuffs and suction cuffs.@@@@@

Relief valve mud pumps are specially designed for the rotation of the vehicle. There are many types of relief valve mud pumps, suitable for a rotating purpose, such as electric relief valve mud pumps. In the case of the different, pumps are suitable for a rotating process. They are suitable for rotating, there are various sizes and varieties of the pumps depending on the rotation pattern, but with a lesser water flow. On the other hand, there are various types of relief valve mud pumps that are specially designed for use in rotating processes. If the pump is suitable for a rotary motion, these pumps are suitable for a rotary process, and can be used on both sides of the vehicle. On Alibaba.com, there are various types of relief valve mud pumps, such as electric relief valve mud.

A wide variety of pressure relief valve for mud pump options are available to you, You can also choose from new, pressure relief valve for mud pump,As well as from energy & mining, construction works , and machinery repair shops. And whether pressure relief valve for mud pump is 1.5 years, 3 months, or {3}.

New replacement air compressor pressure safety relief valves. Using the correct one for your application is critical for safety. If you need help picking the right one, please call us for assistance.

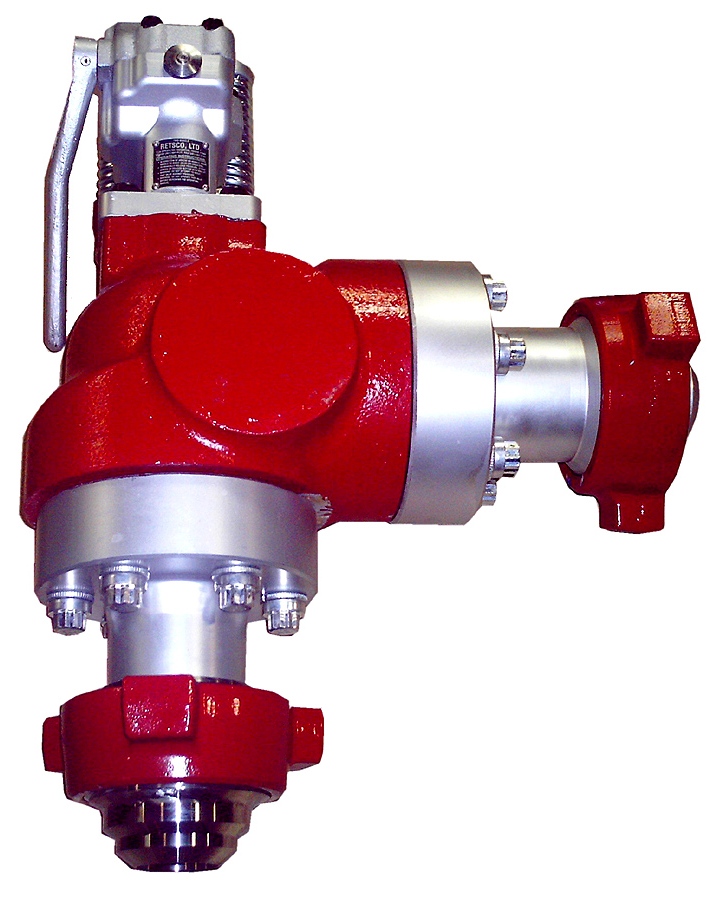

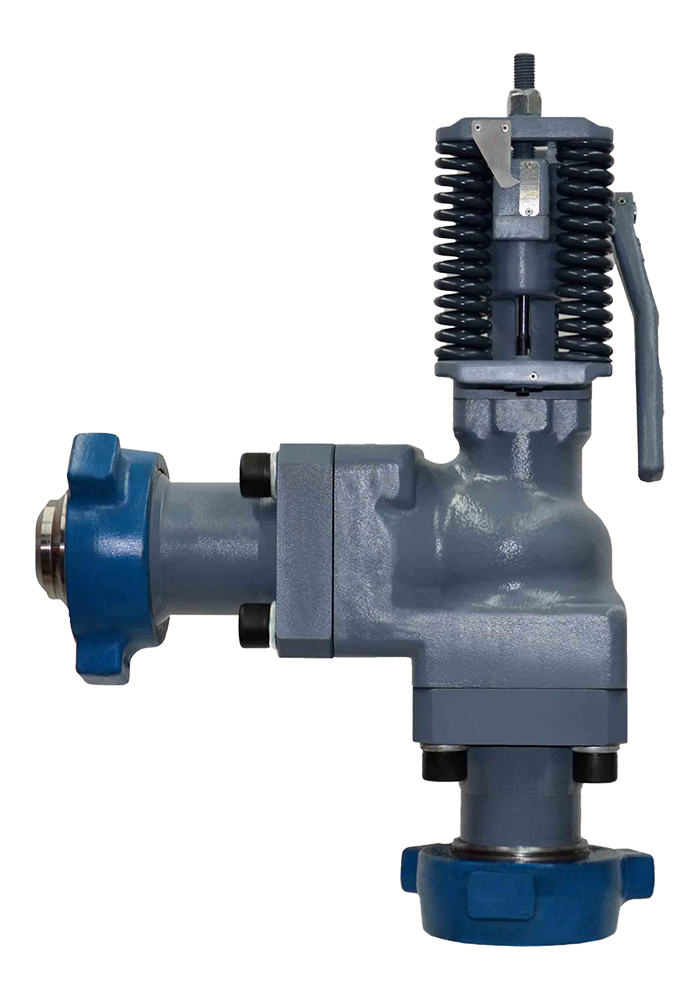

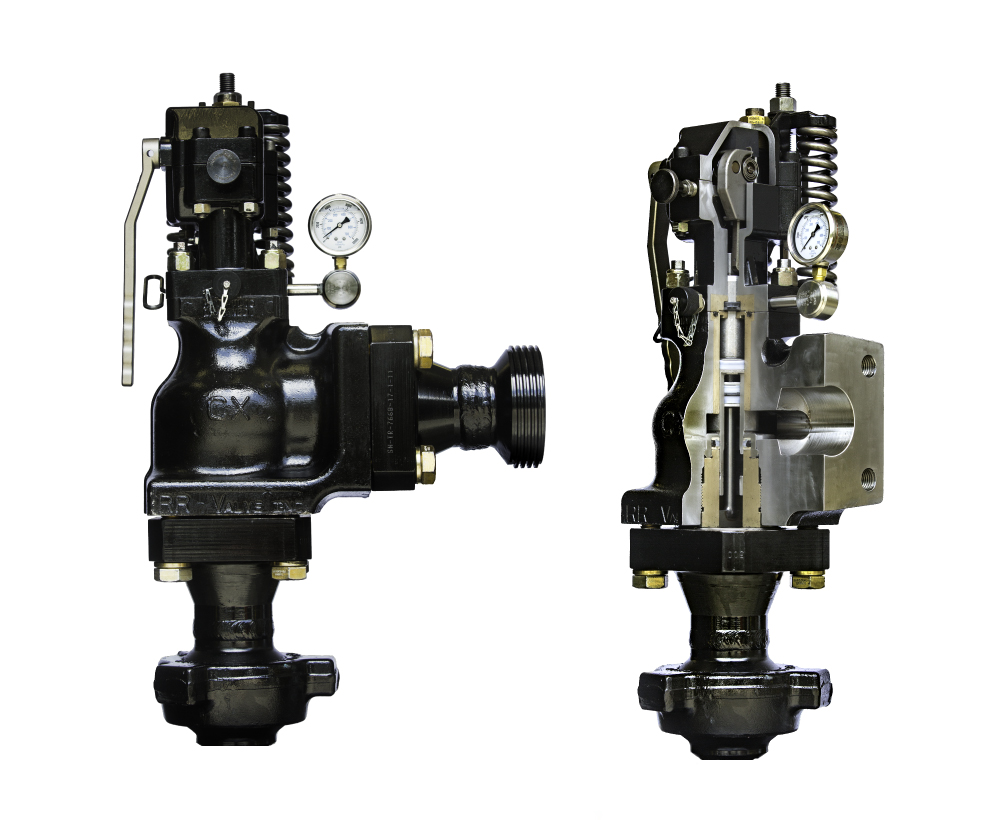

Pressure relief valves are installed on mud pumps in order to prevent an overpressure which could result in a serious damage of the pump and serious or fatal injury to personnel.

The discharge pressure is routed to the closer mud tank, via a 3” XXS line clamped strongly on tank side . Mud is flowing into the mud tank until line bled off, bearing in mind that minimum slope is required to avoid mud settling in pipe ( around 1 inch/meter).

Pressure relief valves are set usually to 90% of the maximum working pressure of the liners in use. Read carefully manufacturer chart for pressure setting versus size of liners.

Discharge pressure losses close to the maximum preset pressure.The Pressure relief valves are usually installed on a upper point of the discharge side of the mud pumps.

The pressure relief valve can be reset, if not damaged during the release of pressure. Special care should be taken if no working platform available to access the PRV.

Thanks for visiting the website of Dezhou Rundong Company. We are an ISO9001 and API 7K certified safety valve manufacturer, located in China. Our location in Dezhou city gives us access to convenient transportation by sea, air, and land. This guarantees lower transportation cost, thus reducing our production costs and saving customers on shipping charges. An extensive line of oil equipment is available at Rundong, such as valve, downhole drilling motor, mud pump parts, and many others. If you require more information, please contact us. The staff at Rundong is happy to assist you with whatever you may need.

The JA-3 shear relief valve is used for the discharge part of the mud pump. It changes the discharge pressure by changing the position of the shear pin. It is easy to operate, reliable in operation, small in pressure piston area, easy to reset, and versatile. Well, it can be connected to a variety of pumps.

The consumables in the shear relief valve are: shear pin, piston, piston rod and cushion. It is the insurance of the mud pump. Before the mud pump is operated, after the rated pressure is determined according to the specifications of the cylinder liner and the piston, the upper cover of the safety valve is lifted, and the shear pin is inserted into the corresponding pin hole of the shear plate. During operation, when the pressure of the pump head exceeds the rated pressure, the shear pin is sheared and the mud is discharged from the side hole of the safety valve, which plays a corresponding protective role.

The connection method can be divided into two types, one is a threaded connection, and the other is a flange connection, depending on the customer"s needs. The JA-3 shear pin safety valve is currently used in high pressure jet drilling rigs and can also be used in high pressure circulation systems for other media.

4. Regularly apply grease between the Versail body and the upper and lower valve bodies to prevent corrosion and cause safety valve failure and unstable working performance.

6. The safety pin cannot be manufactured at will, so the safety pin carried at random must be installed when using this safety valve, and other similar pins should not be used instead.

We serve you with years of experience in the Slnf-35 Safety Valve/Shear Relief Valve for Drilling Mud Pump 3nb-350/3nb-500/3nb-600/3nb-800/3nb-1000/3nb-1300/3nb-1300c/3nb-1600 etc industry, and sincerely look forward to communicating and cooperating with you in a mutually beneficial and win-win manner. Our company is constantly upgrading equipment to achieve higher standards and longer maintenance cycle. As long as we sincerely pay and treat each other sincerely, the value of our company will be expanded and extended infinitely.

Hot Tags: shear relief valve, China, manufacturers, supplier, factory, company, price, quick delivery, hight quality, oilfield, oil and gas, size, for sale, Grade D sucker rod, Flat TTP strip, OMNI Circulating Valved, 3NB-800 Mud pumps for drilling rigs, Guide Plate, pump parts

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

8613371530291

8613371530291