schlumberger mud pump free sample

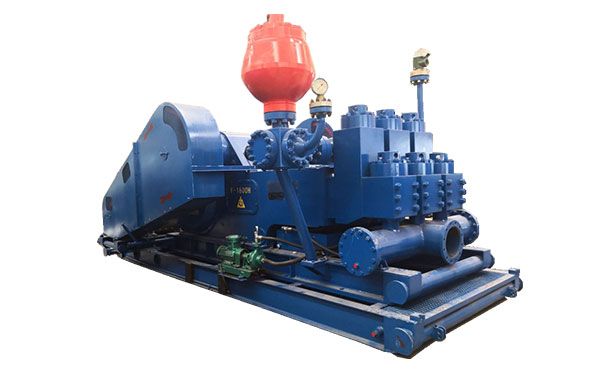

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

A comprehensive range of mud pumping, mixing, and processing equipment is designed to streamline many essential but time-consuming operational and maintenance procedures, improve operator safety and productivity, and reduce costly system downtime.

Timely, accurate information about well status and drilling performance help drill better wells more efficiently. Schlumberger provides formation evaluation and drilling support through Geoservices.

Cameron mud pumps provide superior performance for your onshore or offshore applications. Built on more than 40 years of experience and the successful WH-Series mud pump design, these improved pumps are constructed with premium components to ensure low total cost of ownership and increased reliability.

From simplifying installation to meeting temperature and viscosity demands, Schlumberger has the right ESP for conventional, unconventional, high-temperature, intervention-constrained, and offshore requirements. Maximize production, increase run life, and ultimately reduce system life cycle costs with a selection of fit-for-purpose ESP systems.

Access to Schlumberger engineering expertise further optimizes ESP well performance. Conveniently located assembly, repair, and test (ART) centers provide quick delivery and assistance in all major basins. Artificial Lift Surveillance Centers (ALSCs) monitor alarms 24/7/365 for rapid diagnostics, recommendations, and troubleshooting.

M-I SWACO became a Schlumberger company in 2010. Innovative drilling fluid engineers are at the company"s core, helping oil and gas operators increase efficiency and lower costs. We do this by developing drilling fluid systems and additives that accommodate a wide range of drilling environments and demanding applications—including HPHT, deep water and ultradeep water, shale gas, heavy oil, depleted wells, and more.

Cameron AC electric motors improve the performance of your mud pumps, drawworks, and rotary tables. Custom configuration is available, and ATEX, ABS, and DNV certification can be provided for new motors. Our flexible design offers you a choice between a tapered shaft or BullShaft to meet specific application requirements.

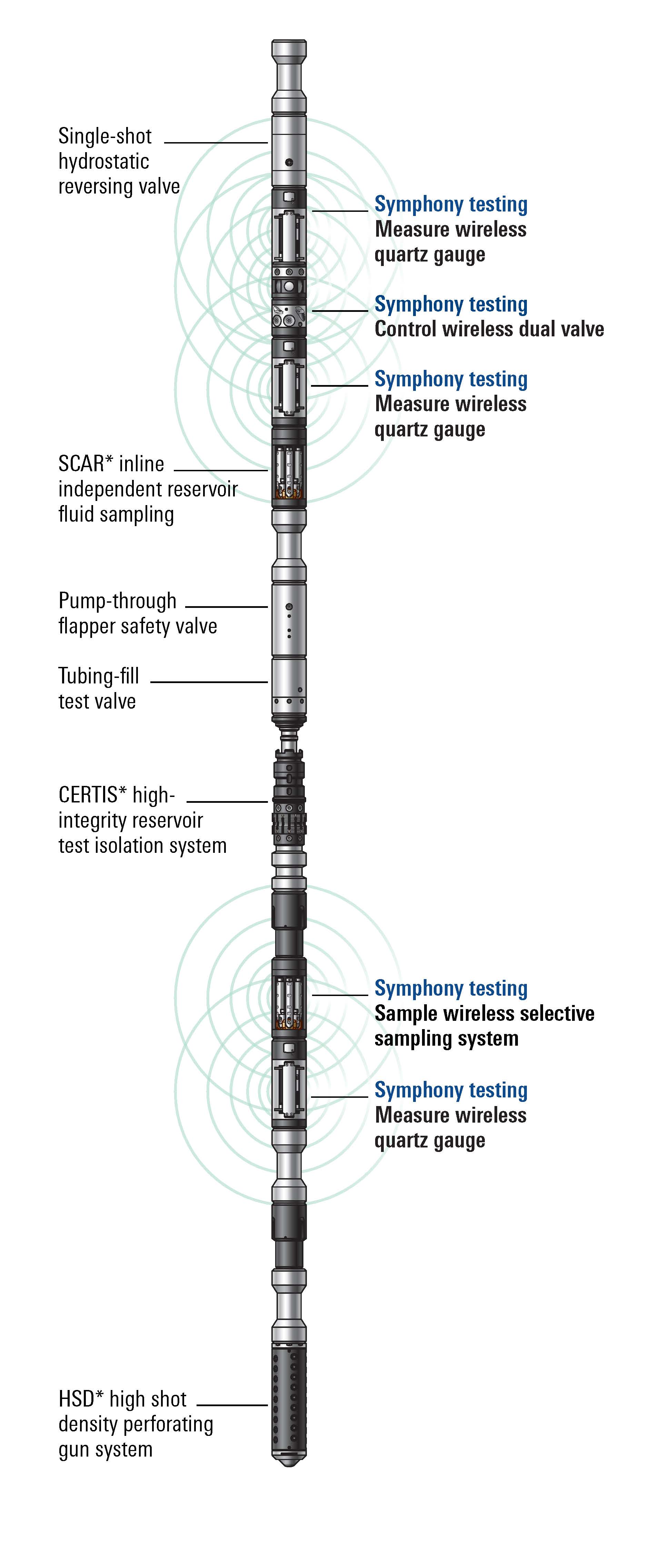

DTT on wireline was conceptualized and developed as a joint project between Schlumberger and Equinor (then Statoil) to bridge the gap between transient wireline formation testing and DST. From its inception, the project"s objective was to enable a more sustainable and economical solution for evaluating exploration and appraisal wells at a global scale.

The Ora platform includes DTT capability by design: The platform’s dual-inlet dual packer, highest flow-rate pump in the industry, and patented fluid-handling technology enable DTT on wireline with minimal or no flaring required. The pump’s capacity of up to 108 bbl/d lets you to pump higher volumes, while unique fluid-handling technology enables active hydrocarbon circulation to surface for well control, so you can test longer. And with advanced sensor technology, you can see deeper into your reservoir.

8613371530291

8613371530291