schlumberger mud pump pricelist

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

A comprehensive range of mud pumping, mixing, and processing equipment is designed to streamline many essential but time-consuming operational and maintenance procedures, improve operator safety and productivity, and reduce costly system downtime.

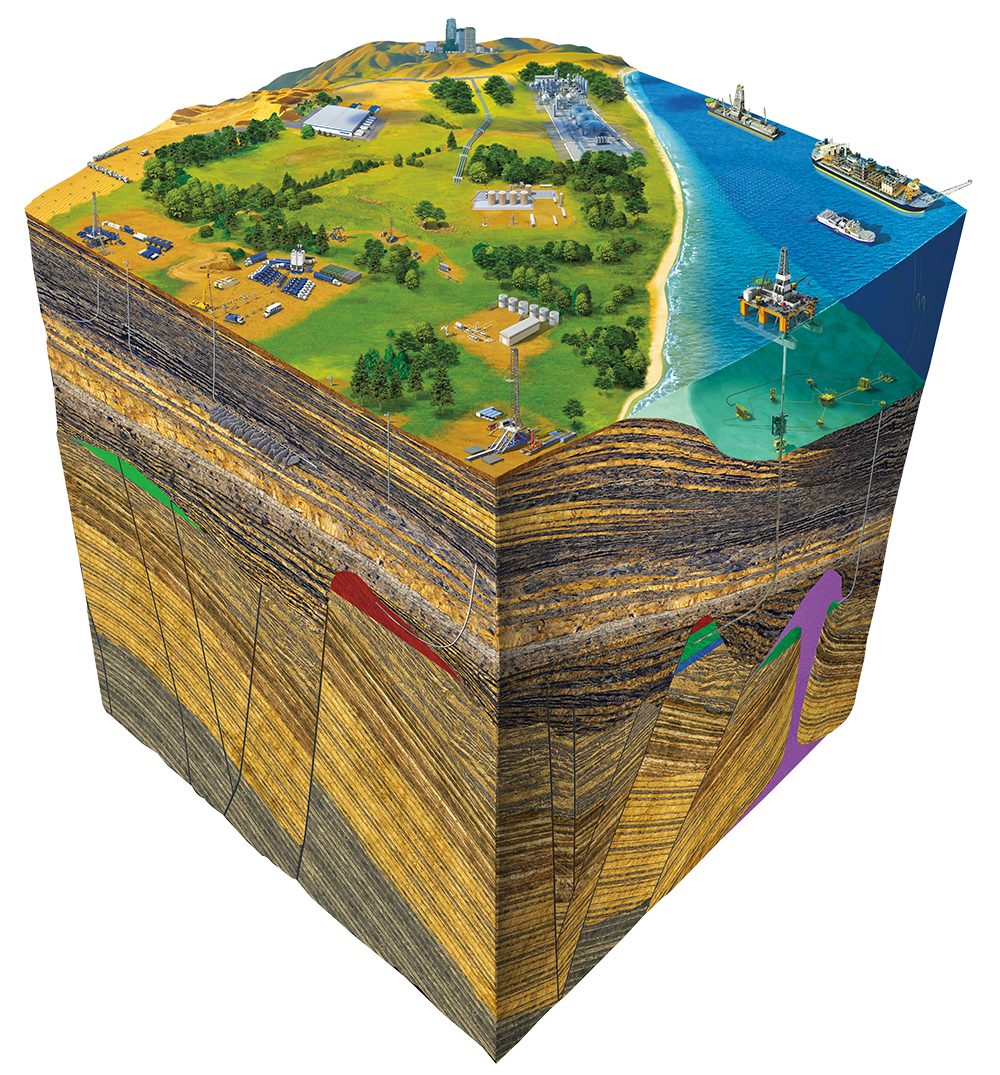

Cameron provides a range of integrated pump packages, including top- or rear-mount AC- or DC-electric drives, controls, manifolds, piping, and accessories for onshore and offshore applications.

From simplifying installation to meeting temperature and viscosity demands, Schlumberger has the right ESP for conventional, unconventional, high-temperature, intervention-constrained, and offshore requirements. Maximize production, increase run life, and ultimately reduce system life cycle costs with a selection of fit-for-purpose ESP systems.

Access to Schlumberger engineering expertise further optimizes ESP well performance. Conveniently located assembly, repair, and test (ART) centers provide quick delivery and assistance in all major basins. Artificial Lift Surveillance Centers (ALSCs) monitor alarms 24/7/365 for rapid diagnostics, recommendations, and troubleshooting.

Cameron AC electric motors improve the performance of your mud pumps, drawworks, and rotary tables. Custom configuration is available, and ATEX, ABS, and DNV certification can be provided for new motors. Our flexible design offers you a choice between a tapered shaft or BullShaft to meet specific application requirements.

Cameron mud pumps provide superior performance for your onshore or offshore applications. Built on more than 40 years of experience and the successful WH-Series mud pump design, these improved pumps are constructed with premium components to ensure low total cost of ownership and increased reliability.

Working with some of the world"s leading suppliers of low-pressure equipment, we offer low-pressure pump packages and agitating units to suit every operation.

To maintain optimal performance in corrosive or abrasive wells, our standard Ni-Resist stage material improves abrasion resistance, increasing pump life. MONEL high-strength shafts enable greater horsepower delivery to the pump, improving lift performance.

REDA HPS horizontal multistage surface pumping systems—commonly referred to as “hps pumps” or “h pumps”—are centrifugal pumps horizontally mounted on a rigid skid, which is often called a weldment.

A reliable, field‐proven, and cost‐effective alternative to conventional API Std 610 pumps, they increase pumping efficiency and reduce operating costs. Designed using ARZ abrasion‐resistant zirconium for high‐wear‐resistance bearings, the pumping system effectively handles harsh fluids and challenging installation environments.

Horizontal REDA pumps require no daily maintenance. The modular housing and flexible plug‐and‐play design enable simple, quick reconfiguration of pumps and motors and fast thrust chamber changeouts, minimizing downtime. All major components can be exchanged within 2 to 3 hours, compared with days or weeks for a split-case pump.

Generation 3 REDA HPS pumps feature product enhancements that increase reliability, and they are flexible enough to enable updates in the field. This multistage centrifugal pump has a modular design that provides a cost-effective solution for a wide variety of applications, from simple water injection to more

When necessary, major components can be replaced or resized within 2–3 hours to track changes in applications. Because of the modular design and factory alignment, restarting the pump is a simple procedure.

Designed for years of trouble‐free service, the third-generation REDA HPS surface pump requires no daily maintenance. There are no V‐belts or packing to service, and a typical routine maintenance schedule simply consists of a quarterly lubricant change for the thrust chamber and component

Our portfolio encompasses specialized expertise and complete equipment packages for every flow rate, including rod lift pumps, progressing cavity pumps (PCPs), hydraulic stroking units, ESPs, electric submersible PCPs (ESPCPs), horizontal surface pumps, and gas lift systems.

Improve pumping performance with API-monogrammed and third-party certified equipment, including pump jack units, downhole API insert pumps, and other equipment.

Sensia is a joint venture that combines the process automation, real-time control, and IoT technologies of Rockwell Automation with the measurement, instrumentation, analysis, software, and analytics capabilities of Schlumberger. In doing so, and with the use of digital technologies, Sensia is creating solutions to solve specific oil and gas industry challenges.

Our comprehensive suite of electric submersible pump (ESP) systems optimizes production through unparalleled technology and global expertise. We offer fit-for-purpose ESP solutions that meet conventional, unconventional, high-temperature, and deepwater conditions.

The TPS-Line electric submersible pump system is a Russia-compliant ESP system that uses selected technologies from the REDA Maximus ESP system to maximize production in conventional reservoirs while adhering to Russian production standards.

M-I SWACO became a Schlumberger company in 2010. Innovative drilling fluid engineers are at the company"s core, helping oil and gas operators increase efficiency and lower costs. We do this by developing drilling fluid systems and additives that accommodate a wide range of drilling environments and demanding applications—including HPHT, deep water and ultradeep water, shale gas, heavy oil, depleted wells, and more.

For ROP enhancement, 1% to 2% by volume of the DRILZONE L surfactant should be introduced directly to the mud system at or near the pump suction over one circulation period—ideally, before drilling out the casing shoe. Alternatively, treatment can take place after a trip before entering the hole while the bit and BHA are clean. After the initial treatment, the product should be continually added or injected into the mud stream at the pump suction while drilling. The injection rate varies according to hole size, pump rate, dilution rates, and ROP.

Typically, addition rates range from 15 to 30 galUS [57 to 114 L] per hour of drilling. An injection pump attached to the low-pressure side of the mud pump helps to precisely control addition rates. DRILZONE L surfactant concentrations of up to 5% to 7% by volume do not affect drilling fluid properties or environmental toxicity.

8613371530291

8613371530291