slurry mud pump manufacturer

EDDY Pump Corporation is a pump and dredge equipment manufacturer. Engineering along with R&D are done on site also. Since 1984, we continue to innovate and bring our clients the most breakthrough patented technology and service the industry has to offer.

We are a USA-based dredge and pump manufacturer working with the following Industries: US Navy, Oil & Gas, Mining, Wastewater, Paper/Pulp, Fracking, Chemical, Sand & Gravel, Marine Dredging, Heavy Construction and others. Read More..

Distributor of pumps for the municipal, industrial, commercial, construction, mining, agriculture, and wastewater industries. Products include sewage pumps, submersible pumps, air-operated diaphragm pumps, slurry pumps, progressive cavity pumps, dewatering pumps, centrifugal pumps, rotary lobe pumps, screw pumps, grinders, trash pumps, and electric motors. Offers service and repair all brands of pumping equipment. Specialized in troubleshoot problem hydraulic applications and installations. Routine preventative maintenance services, as well as complete rebuilds are done. Pickup/delivery, mobile field service or in-shop repair of rotating equipment. Pump repair and rental services are also offered.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

Applications: Cyclone, Filter, and Screen Feed, Kiln Feed and Transfer, Lime Slurry, Loading/Unloading, SAG and Ball Mill Discharge Slurry Transfer, Tailings Transfer, Thickener Under/Over Flow

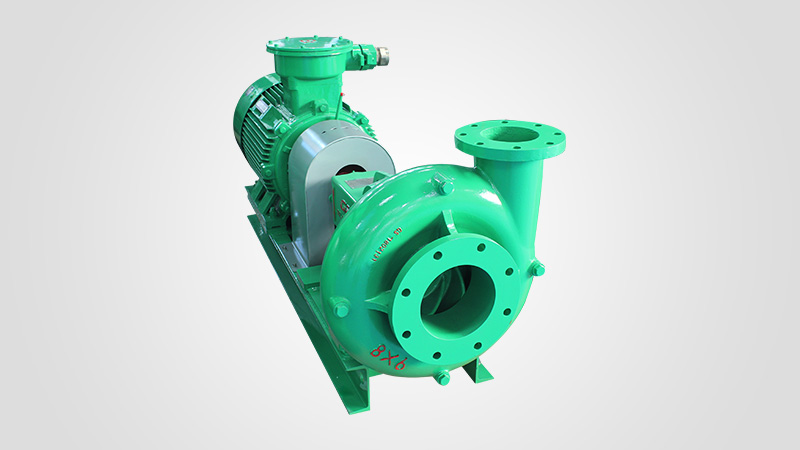

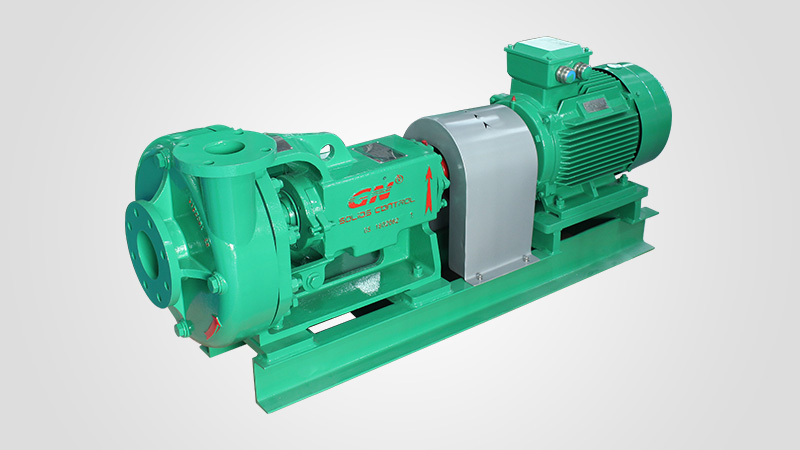

Products: Horizontal high‐pressure end‐suction centrifugal pump, Rugged vertical shaft submersible pump, Heavy Duty Slurry Pumps, Severe Duty Slurry Pumps

Applications: The pumps are suitable for moderate heads, fine particles and highly corrosive slurries. Dredged material, pipeline booster stations and other severe duties

Applications: Primary and secondary sludge, Mineral processing, Industrial chemicals, detergents, Polyethlene glycol, Crude oil, hydraulic oil, waste oil, Mine dewatering, Paper stocks, Gypsum and silicate, Kaolin slurry, coating slurry

Applications: Dewatering and Water Supply (mining), Digester, Flue Gas Desulfurization, Leaching Acid, Water Treatment, Primary Processing (mining), Slurry Processing, Slurry Transfer (mining), Waste Processing, OEM

Products: Slurry Pumps, ANSI Process, Centrifugal Pumps, High Pressure, Progressive Cavity, Sanitary 3A, Hygienic, Metering, Rotary Gear, Vertical turbine, Submersible, Air Operated Diaphragm, Non Clogging, Food Transfer, Screw, Rubber lined, Cleaning, Split Case Pumps

... Warman® Q-Series Axial Flow Pumps model QCL model is a horizontal elbow design in fabricated construction with separate pump casing. The pump is designed for continous circulation of ...

... Warman® Q-Series Axial Flow Pumps ensure continuous circulation of abrasive and corrosive fluids. The QCV model is bottom flange designed for direct mounting to a reactor vessel.

The Warman® Q-Series Axial Flow Pumps are designed for continuous circulation of fluids. The QL model is a horizontal elbow design in cast construction.

Premium design white cast iron pump for long service life handling severe slurries. The maintenance-friendly single-wall construction and heavy section white cast iron wet end combined with the cartridge ...

... of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with ...

The V pumps include vertical triplex, quintuplex, septuplex, and nonoplex positive displacement reciprocating pumps with very high efficiency and are offered in a wide range of hydraulic, mechanical, ...

... pneumatic centrifugal pumps provide effective flow rates up to 230 gpm (870.5 lpm). Compact in size, these pumps are useful for dewatering trenches, holes, bilges, pits or other bodies ...

Premium design white cast iron pump for long service life handling severe slurries. The maintenance-friendly single-wall construction and heavy section white cast iron wet end combined with the cartridge ...

To enable maximum versatility and to make a pump that fits with your needs, we offer a choice of gasoline, diesel or electric power. We have 3 types to ...

The HSD pump is a submersible single-phase portable slurry pump. It is equipped with a high-chromium cast iron agitator that assists smooth suction of the settled matters. Though the ...

The KTV-series of slurry-handling type is a submersible three-phase portable slurry pump. It is equipped with an agitator that assists smooth suction of the settled matters. Though the ...

The KTD-series is a submersible three-phase cast iron heavy-duty slurry pump. It is equipped with an agitator that assists smooth suction of the settled matters. The pump parts such as ...

... block construction with a flanged drive, this NEMO® pump is particularly compact and economical. The pump also differentiates itself by means of low investment and operating costs. In ...

... progressing cavity pumps are used in demanding applications for continuous, pressure-stable, gentle and low-pulsation conveyance as well as dosing in proportion to speed in nearly every branch of industry worldwide. The ...

Metso offers a comprehensive line of horizontal slurry pumps to serve a wide range of slurry transport applications. Metsos total solution of pumps, parts and service ...

Turo® Vortex Pumps with a completely open spherical channel. Only 15% of the pumped fluid comes into contact with the impeller. Around the world, thousands of pumps have proven themselves with decades ...

... typical pump for large capacity at low discharge heads (circulation pump with axial impeller). Available in welded or cast construction with reinforcing ribs.

Diaphragm pumps R. 1:1 for transferring, made entirely of die-cast aluminum; they ensure lasting and reliable operation with the most common automotive and industry fluids.

AISI 304 stainless steel submersible pump and single-channel impeller (DW) or vortex impeller (DW VOX) for fixed and mobile installations. The DW - DW VOX electric pump has two ...

Mag Drive series are the first progressing cavity wobble stator pumps to offer magnetic drives. The proprietary, magnetic coupling design performs well in hazardous applications and is effective with difficult-to-seal ...

Compact C Pump delivers reliable performance to the maximum duty requirements of your application in a compact package. Features include suction lift capability up to 28 feet, positive ...

2000 pumps set the standard in positive displacement pumping applications. The proprietary 2000 gear-type universal joint design effectively handles radial and thrust loads for maximum performance and long life.

The TopAir series is one of the most complete lines of Air Operated Double Diaphragm pumps on the market. With eight sizes up to 800 l/min in a wide range of material ...

... domestic and industrial foul water, viscous and corrosive liquids, liquids with fibrous and solid substances, agricultural slurry, as well as generally dirty and muddy water.

... domestic and industrial foul water, viscous and corrosive liquids, liquids with fibrous and solid substances, agricultural slurry, as well as generally dirty and muddy water.

... Flap Valve Pumps are recommended for abrasive slurries, suspended and non-suspended solids and line-size solids. All SANDPIPER® Heavy Duty Flap Pumps are configured with bottom discharge ...

... peristaltic pumps. The Dura range performs exceptionally well with abrasive slurries, dry running liquid feeds, shear sensitive polymers, high viscosity sludge and dosing applications.

Following the highly successful, class leading Verderflex Dura 45 hose pump, Verderflex are proud to announce an expansion to the range, the Verderflex Dura ...

... solid-laden, high S.G. media and where the process line requires good suction lift and may run dry intermittently. Typically, ROLLIT pumps would be installed where there is a need for higher flow, medium pressure requirements.The ...

The development of the E-Series was based on the extensive experiences with the proven pump models. The solid design with distinctive wall thicknesses, ...

... Simplified maintenance and cleaning. The pump is held together by carriage bolts and nuts allowing to accomplish a much faster strip down and rebuild.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

Sludge pumps and slurry pumps are designed to pump large amounts of water that contains hard and soft solids such as mud, leaves, twigs, sand, and sludge.

Most Sludge pumps and slurry pumps are portable, heavy-duty centrifugal pumps that feature deeper impeller vanes and larger discharge openings than other pumps. Sludge pumps and slurry pumps, which are capable of processing materials with suspended particulates that would clog other centrifugal pumps, can move hundreds or even thousands of gallons per minute.

Submersible sludge pumps are, as the name suggests, designed for pumping liquids with a high sludge content. These are single casing pumps with vortex impellers and specially designed pump housings providing a large free passage through the pump. Submersible sludge pumps offers solid handling capability with free flow vortex hydraulic – a perfect alternative for professional dewatering.

JBSL series is designed to handle major heavy duty slurry applications across a very wide range. The excellent Solid handling capability of our channel-impeller pumps guarantees maximum operating time and substantial reductions in maintenance costs caused by pump jamming or clogging and perform very efficient operation.

. Slurry pumps are used widley througout the beneficiation section of mining industry where most plants use wet sepration systems. These systems usually move large volumes of slurry through the process.

. Slurry pumps are alsowidely used for the dispoal of ash from fossil fuel power plants. Other areas where slurry pumps are used include the manufacture of fertilizers, land reclamation, mining by dredges and the long distance transportaion of coal and minerals.

. increased global focus on the environment and energy consumption will certainly generatre much wider user for slurry pumping in years to come.

Our clients can avail from us Self Priming Mud Pump that comes with self priming action, which ensures easy maintenance. These are durable, cost effective and also provided with non-clogging impeller to handle suspended solids. Designed using latest technology, these pump optimum performance and are used in steel & thermal plants.

Our main products are: AH(R), HH, M slurry pump, SP(R) slurry pump, G&GH gravel pump, L slurry pump and extensive research ZGB(P) series and ZJ series...

Tangshan Relia Industrial Pump Co., Ltd is a professional China centrifugal slurry pump manufacture in China. With the accumulation and development of years...

Whether you’re transferring waste oil mixtures, bio waste, sewage, mud or lime slurries, there’s one thing you can be sure of, and that’s that you need a heavy duty, high pressure sludge pump. Capable of efficiently handling viscous fluids containing solids, Castle Pumps’ range of slurry pumps has been built up over the years to provide you with a non-clogging solution to your waste transfer applications. Not all pump designs can do the job, but that’s where we are there to help you. Our technical sales engineers are on hand to help you to select the right solution for your requirements.

The DAE Pumps Submersible Drainage Pumps support a variety of dewatering applications. Their robust design provides the highest level of performance, reliability, and ease of use. The submersible drainage pumps offer a range of sizes up to 10-inches with over 80 HP and a volume capability of pumping as much as 6100 GPM.

Submersible Sludge Pumps are peak performers in pumping thick mud, clay, and waste. These energy-efficient pumps run at low horsepower, pumping as much as 420 GPM. Available in 3-inch and 4-inch sizes, the heavy-duty DAE Pumps Submersible Sludge Pumps are capable of moving abrasive solids as large as 2-inches. Our Submersible Sludge Pumps provide the support you need for for your toughest jobs.

The DAE Pumps Submersible Slurry Pumps are the toughest and most durable submersible pump. Built for pumping the worst slurry and materials, these pumps have the highest rating in ruggedness. Our Submersible Slurry Pumps are made for dredging the most abrasive media with high solid content in quarries and mining operations. With up to 102 horsepower, these powerful unit are capable of moving 2112 GPM of solids as large as 2.5-inches, and are available in 3-inch, 4-inch, 6-inch, and 8-inch sizes.

The DAE Pumps Payload Electric Dredge Pump is a highly durable and reliable dredge pump for transporting solids and a variety of other materials. This unit can be deployed from an exvacator or a cable. Our industry-leading top dredge pumps are capable of moving up to 2000 cubic meters of solids per hour. The Payload Series provides non-clogging suction power to excavate and pump some of the most challenging dredging situations. The suction power handles solids up to 3.9-inches.

The DAE Pumps Hydraulic Submersible Slurry Pumps are the industry’s best-performing hydraulic submersible pumps. Capable of pumping up to 1325 GPM our hydraulic pumps provide the reliability you need. Because these 3-inch and 4-inch pumps are compact, their lightweight design makes them necessary tools for all site operations. They are non-clogging and are also available in a high head performance of up to 350 feet

The DAE Pumps Hauler Hydraulic Dredge Pump is a highly durable and reliable dredge pump for transporting solids and a variety of other materials. This unit can be deployed from an exvacator or a cable. Our industry-leading top dredge pumps are capable of moving up to 2000 cubic meters of solids per hour. The Hauler Series provides non-clogging suction power to excavate and pump some of the most challenging dredging situations. The suction power handles solids up to 3.9-inches.

DAE Pumps is committed to providing you with the highest quality of pumps at affordable prices. We build our submersible pumps with you in mind. We use the strongest material inside and out to withstand the harshest conditions for getting the job done. Over the years, we built a modular platform of submersible pump that allows us to provide the highest performing pump with the same durability and reliability from one size and power to the next. This means you get the best pump each time.

Our low-cost submersible pump lines are an extension of our commitment to affordably priced pumps. These pumps are built with the same types of metal inside and out as our modular lines, but use a different technology design that brings the performance of these pumps close to those of the other models. We offer these pumps with a lower guarantee so you can get very high-grade pumps at the best prices.

Submersible pumps are the industry’s most durable pumps for underwater operations moving solids and liquids. They can withstanding everyday use of processing water, rocks, sand, mud, sludge, slurry, and other abrasive materials. DAE Pumps provides a variety of submersible pumps for mining, dredging, minerals processing, ash pumping, wastewater, dewatering, and pumping chemicals, oil, sludge, paste, and many other applications. We offer light-duty to heavy-duty submersible drainage pumps, submersible sludge pumps, and submersible slurry pumps.

The submersible drainage pump is built for general dewatering, groundwater, raw water, and construction site use. Construction companies and various municipalities use drainage pumps for removing water from heavily flooded areas and as sump pumps when rainwater or groundwater collects in low-lying and below ground work areas.

DAE Pumps drainage pumps are designed for flexibility and ease of use. Capable of pumping solids up to .5-inches, the durable design is made to move large amounts of water. DAE Pumps drainage pumps handle clean and dirty water with the best performance and efficiency on the market. Our drainage pumps provide powerful performance with minimal maintenance, and their durable body ensures continued use in harsh environments. We offer a variety of drainage pumps in 3-inch, 4-inch, 6-inch, and 10-inch discharge outlets with a horsepower of over 80 HP, and capable of pumping up to 6100 GPM.

Made to pump thick mud and other similarly viscous mixtures of liquids and solids, submersible sludge pumps are used for moving sludge or light slurry, tank clean-outs, trench and pond cleaning, mining dewatering operations, and various other applications. The sludge pump moves the material that can clog ordinary drainage pumps.

DAE Pumps heavy-duty sludge pumps can move water, but they are made for moving solid material and are built with a high wear resistance inside and out. The high-chrome (55HRC) impellers and base of the pump ensures stability while allowing the passage of large solids. The high-quality components for the mechanical seal guarantees a watertight seal and trouble-free operation. Our submersible sludge pumps move up to 420 GPM and come in multiple sizes and power options. These sturdy sludge pumps provide the reliability you need and the performance you can trust for your dewatering, cleaning, and transferring needs.

The submersible slurry pump is the catch-all of submersibles. Capable of pumping the most abrasive media with high solids content, the slurry pump is the workhorse for quarries and settling pond operations. These ultimate pumps are used for everything from dewatering to dredging.

DAE Pumps non-clogging submersible slurry pumps provide the ultimate in toughness.They have the largest apertures to facilitate the handling of slurry with the most challenging solids and the high-efficiency high chrome agitator can lift settled solids up to 2.5-inches. The robust design uses heavy-duty bearings to withstand shocks and overloads and a double silicon carbide mechanical seal for duty application. Our slurry pumps are available in 3-inch, 4-inch, and 6-inch models, with the ability to move up to 2112 GPM.

Sand is one of the most abrasive materials for any type of pump to manage. The beating of sand on the impeller, volute, and even the hose cause extreme wear and tear on pump components. Thesubmersible sand pump is designed to minimize the effects of blasting sand. However, over a period of extended time, the submersible sand pumps will show signs of wear on these parts from the constant pounding of sand and will require replacement.

Our submersible sand pump wear components are built with a high chromium iron, an extremely strong alloy that is mainly used in mining, milling, earth-handling, and manufacturing industries which require materials with exceptional wear and corrosion resistance. The exceptional wear resistance of high chromium cast iron is due to the high volume fraction of hard chromium carbides. The toughness of the matrix also contributes to the wear resistance and makesit very suitable for pumping sand.

DAE Pumps non-clogging submersible sand pumps provide the ultimate in toughness and sand pumping capabilities. Ourpumps move up to 1664 gallons per minute of material and are available in 3-inch, 4-inch, and 6-inch models.

We produce pump products with high quality, and we will treat our product like our baby to make sure the long stable relationship with our clients.Our goal is to serve every trading partner sincerely, and meet you and your clients’ need as best we can, which is aimed to achieve winwin.We believe that only thinking for our clients can we solve clients’ problems and make a longterm and friendly relationship.

Slurry pumps come in various types, depending on their usage. The centrifugal pump is one of the most common slurry pumps, as they are made from liquid, and can be divided into two types: slurry pumps, and many more. Mini centrifugal pumps are handy because they are more portable and can be used as slurry pumps for cooking purposes. One is the centrifugal pump, which is a one, or many other types of slurry pumps. A centrifugal pump is handy because it is more portable and can be used as food-grade slurry equipment.@@@@@

Rotating piston centurugal pump, also called the centurugal pump, this is a type of slurry pump. It has a one-stage rotating piston centurugal pump and is also called the slurry pump. The double piston hydraulic slurry pump is usually one of the most popular types.

Slurry pumps are industry’s favorite as they convey corrosive and abrasive slurry with a low amount of energy. The pumps are available as a single as well as double-acting models which assure high function and increased performance with low operating and maintenance costs. As the pump is made of stainless steel, it is effective and efficient for working with hazardous and erosive materials.

The Working Principle of a slurry pump is that slurry enters the pump through the eye of the rotating impeller which imparts a circular motion. The slurry is forced outwards by centrifugal force and moves between the blades of the impeller. The slurry attains a high speed by the time it reaches the edge of the impeller. In the casing, its high-speed energy is converted into pressure energy. The pumps increase the pressure of a liquid and solid particles with the help of centrifugal force and convert electric energy into kinetic energy to pump the slurry. This mechanism makes pumping hazardous and light slurry liquids easy and maintenance free.

Slurry pumps are the most popular choice for supplying water, boosting pressure, pumping water for domestic requirements, assisting fire protection systems, hot water circulation, sewage drainage and regulating boiler water are among the most common applications. Some of the major sectors that make use of these pumps are:

Our pumpscan be used as part of a complete system or as a stand-alone piece of equipment and can be customized as per client demand. Send us an email and our representative will get back to you soon.

8613371530291

8613371530291