stroke counter for mud pump brands

Our pump stroke counter systems (CPS101 Series) measure the stroke rate and number of strokes on mud pumps. The oilfield pump stroke system is user-friendly and reliable and is configurable to measure up to three mud pumps at once. Our digital pump stroke counter systems are manufactured here in the U.S. by Crown Oilfield Instrumentation, and Crown’s Pump Stroke Counter provides easy monitoring of strokes per minute on multiple mud pumps. Each mud pumps’s stroke rate can be selected individually and the display is updated regularly for accurate monitoring. LCD displays indicate both pumps strokes per minute and the total number of strokes. Located at the bottom of the panel, push buttons provide easy operation and reseting of each pump. When you need to accurately monitor and maintain the amount of mud being pumped, you can trust Crown’s oilfield stroke counters.

Crown"s CPS101-3 Three Pump Stroke Counter Rate Meter displays the total strokes and strokes per minute for three pumps, giving the operator the ability to monitor the flow rate of three mud or water pumps at once. Built with the toughest material on the market, Crown CPS101-3 three pump stroke counter/rate meter will stand up to anything that the oilfield can throw at it. The Three Pump Stroke Counter System is ready to use out of the box with everything you"ll need to measure the flow rate of three mud pumps. In this system, you will get the following:

Crown CPS101-3 three pump rate meter is built in a rugged, all stainless steel case, with easy-to-read LCD screens that are powered by a long-life lithium battery. The system is a self-powered, low-voltage, and self-contained, making it intrinsically safe. Being water-proof, vibration resistant, and extreme weather resistant, the CPS101-3 three pump stroke counter system will provide up to 5 years of use, under normal operating conditions. The front panel control is easy-to-use with power and reset buttons to reset each pump and will monitor three pumps all at the same time. Each pump has a LCD screen that monitors total accumulated strokes up to 9,999 and strokes per minute from 8 to 240 strokes.

Each limit switch assembly comes with a c-clamp, limit switch counter and stainless steel rod. The sturdy c-clamp can be mounted anywhere near the piston, and the bendable stainless steel rod can be position as needed.

Need more information about our three pump stroke counter systems? Check out our Stroke Counter Page or our Blog. And if you only need one of the components of this system, give us a call, We"re more than happy to get you exactly what you need.

This product contains lithium batteries and is classed UN3091, lithium batteries contained in equipment. It can only be shipped via ground in the US. If you would like to purchase a system outside the US, please contact us directly to arrange transport. For international customers, if you"d like to ship this product without a lithium battery to save on shipping costs, we can provide you with the information needed to purchase the required battery and detailed instructions on how to install the battery. Just give us a call at 1-877-908-3790 or email sales@drillinginstruments.com, and we"ll set that up for you.

The HDI 2100 Pump Stroke Counter is an intrinsically safe, certified, solid-state electronic stroke counter primarily used for monitoring mud pumps. Found most commonly within the HDI 9000 Choke Console System, the HDI 2100 monitors and displays the total accumulated mud pump strokes and the stroke rate of up to 4 individual mud pumps simultaneously. The stroke rate for each mud pump can be individually selected for display and is updated every second. Once installed, there is virtually no maintenance or calibration required. The quartz crystal oscillator provides high precision counts with no drift. The stainless steel case is completely sealed and features stainless steel piezo switches for long life. The entire package is constructed to operate in harsh environments and high vibration conditions encountered in land and offshore drilling. All HDI Gauges provide safety, accuracy, reliability, and low maintenance for the user.

The Two-pump Digital Stroke Rate Meter monitors and displays the Rate and Total Strokes of up to two individual pumps simultaneously. The unit continually displays, on large easy to read, low power LCD displays, RPM, TOTAL ACCUMULATED STROKES (0-9999 total strokes) and STROKE RATE (8-350 strokes per minute) for each pump. The unit is internally powered by a battery source having an operational life of 3 years.

At Matherne Instrumentation, we"re proud to provide both our two-pump and three-pump stroke counters to companies and oilfield operators across the states of Texas, Louisiana, North Dakota, and Pennsylvania. While our offices are based in Odessa, TX; Lafayette, LA; and Houma, LA, we"re proud to serve those across the cities of Midland, TX; Houston, TX; Williston, ND; and Pittsburgh, PA. To learn more or for a quote, please feel free to give us a call today!

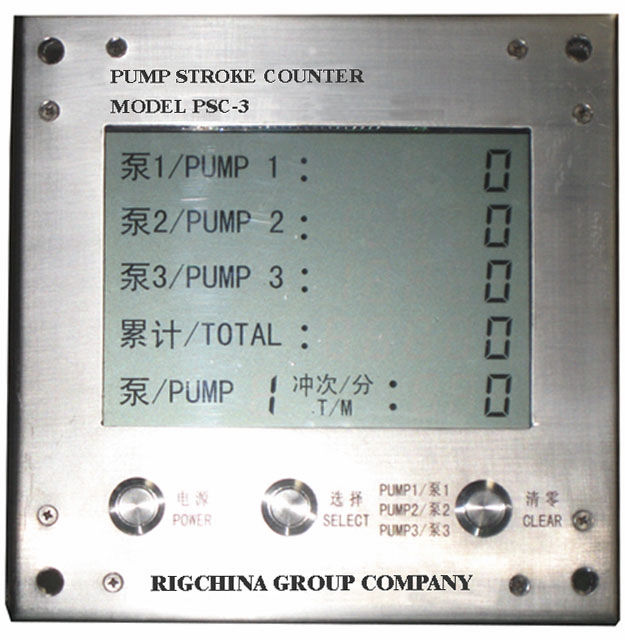

The RIGCHINA Pump Stroke Counter/Rate Meter displays both the total number of strokes and the strokes per minute for 3 mud pumps up to 1,024 strokes per minute for each pump. Push buttons conveniently located on the front of the instrument make it easy for the operator to reset each pump count

Sales and services for weight indicators, electronic weight indicators, cement recorders, six inch gauges, cylinders, torque assemblies, line pull assemblies, 1502 assemblies, wireline gauges and cylinders, depthometers, electronic depth systems, counters, diaphragms, auto drilling systems, rotary torque systems, and pump stroke counters.

Sales and services for weight indicators, electronic weight indicators, cement recorders, six inch gauges, cylinders, torque assemblies, line pull assemblies, 1502 assemblies, wireline gauges and cylinders, depthometers, electronic depth systems, counters, diaphragms, auto drilling systems, rotary torque systems, and pump stroke counters.

EFC’s Pump Stroke Counter (PSC) can be provided as a stand-alone unit or incorporated into a Choke Control or Drilling Instrumentation system. The PSC display enclosure can be customised to suit existing cut outs, or standard EFC enclosure can be supplied.

The RIGCHINA Pump Stroke Counter/Rate Meter displays both the total number of strokes and the strokes per minute for 3 mud pumps up to 1,024 strokes per minute for each pump. Push buttons conveniently located on the front of the instrument make it easy for the operator to reset each pump count

Monitors and displays number of strokes and stroke rate for Three mud pumps The Pump Stroke Counter/Rate Meter displays both the total number of strokes and the strokes per minute for 3 mud pumps up to 1,024 strokes per minute for each pump. Push buttons conveniently located on the front of the instrument make it easy for the operator to reset each pump count

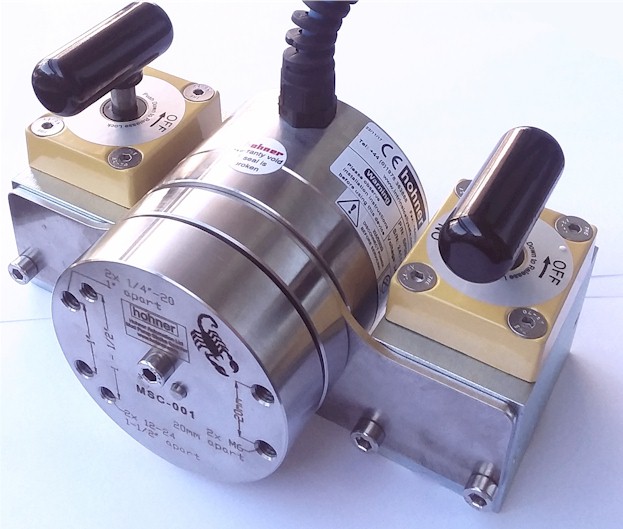

The Magneto® Pump Stroke Sensor is the latest new product from ASD Holdings (Advanced Sensor Design). ASD has successfully introduced unique products for the Oil & Gas Industry for over a decade. In this newest creation we find that the Magneto® Pump Stroke Sensor has been patented by Advanced Sensor Design. It is the world’s first pump stroke sensor that is mounted to the outside housing of the rig pump. It is mounted and stays in place by the use of a heavy duty magnet. The Magneto PSS is completely capable of detecting and counting Oil Rig “mud pump piston strokes” without having to make or be in contact with the pistons.

It is no longer a requirement to open the covers of the Oil Rig mud pumps to install a C-clamp style micro switch with a metal whisker. (Note picture below labeled C-clamp style micro switch) No longer is it necessary to bore a hole through the pump housing in order to get a proximity switch close enough to a piston to count actual strokes. (Note picture below labeled Cable going through pump housing) The Magneto® Pump Stroke Sensor is simple to install and easy to monitor!

The magnetic base of the Magneto® PSS makes it totally different than anything available in the marketplace today relative to its form and fit. However, that is not its only outstanding feature. Advanced Sensor Design is using “State of the Art” electronic circuitry that has the ability to give the end user (Oil Rig Mud Pump Operator) an On/Off switch type electrical output. Just like what the conventional mud pump sensors emit today. The obvious benefit to the oil rig is that No Special accommodations to their Data Acquisition Systems are required.

Monitors and displays the total accumulated mud pump strokes and the stroke rate of up to 4 individual mud pumps simultaneously. Constructed to operate in harsh environments and high vibration, conditions encountered in land and offshore drilling.

Monitors and displays the total accumulated mud pump strokes and the stroke rate of up to 4 individual mud pumps simultaneously. Constructed to operate ...

IRIS RMS is an on-board integrated riser instrumentation system for drilling risers. IRIS RMS integrates sensors with finite element software as well as providing measured data used to predict ...

Monitors and displays the total accumulated mud pump strokes and the stroke rate of up to 4 individual mud pumps simultaneously. Constructed to operate ...

responsible for all electrical and instrument maintenance and engineering activities on the jack up installation with accountability for the health and safety of all persons under their authority

The ideal candidate for this position will have experience in the maintenance and control of field instrumentation; control valves and control systems

Underwater WeldingQuick Guide: What is underwater welding and how to get underwater welding jobs! What is Underwater Welding? Underwater welding, a term for methods adapted for subsea welding, for the purpose of repairing damage to ships…

ROVOTICSRovotics is based in the United Arab Emirates , Rovotics was formed in 2011 when a group of experienced ROV technical experts felt the market was lacking advanced systems that harnessed the latest technology, provided…

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291