strokes per minute mud pump manufacturer

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The RIGCHINA Pump Stroke Counter/Rate Meter displays both the total number of strokes and the strokes per minute for 3 mud pumps up to 1,024 strokes per minute for each pump. Push buttons conveniently located on the front of the instrument make it easy for the operator to reset each pump count

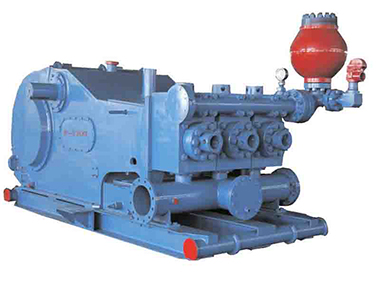

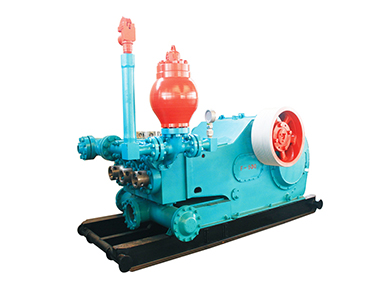

F 500 mud pump for oil drilling have features of solid and compact structure, small volume, good and reliable performance. It can meet the drilling requirements such as high pressure and big displacements whether in land drilling or off-shore drilling.

F 500 mud pumps have a longer stroke and can be operated at a lower stroke, thus improved the water supplying performance effectively and extended the lifetime of mud pump fluid end parts greatly.

Monitors and displays number of strokes and stroke rate for Three mud pumps The Pump Stroke Counter/Rate Meter displays both the total number of strokes and the strokes per minute for 3 mud pumps up to 1,024 strokes per minute for each pump. Push buttons conveniently located on the front of the instrument make it easy for the operator to reset each pump count

Acadiana Pump Stroke Counter or Rate Meter Displaying both the total number of strokes and the strokes per minute for two or three mud pumps (up to 1,024 strokes per min per pump), the Acadiana Oilfield Instruments’ pump stroke counter has easy to use push buttons for resetting the pump count. Built-in a stainless steel design, this indicator will last in any environment.

Acadiana Oilfield Instruments strives to design, develop and manufacture safe, cost-effective, and superior products in the industry without sacrificing quality. Through a team approach of continually improving our processes, traceability, design, and procurement, executing an aggressive commitment to meet and exceed industry standards while always conforming to our customers’ needs.

Our team knows all aspects of instrumentation, and we work side by side with our customers to deliver the right solution to suit their needs, regardless of the circumstances or obstacles to overcome. Our product lines range from hydraulic, pneumatic, electronic, and digital instruments catering to all sectors of industry, from drilling, drilling contractors, operators, tong manufacturers, wireline services, fracking, and workover services.

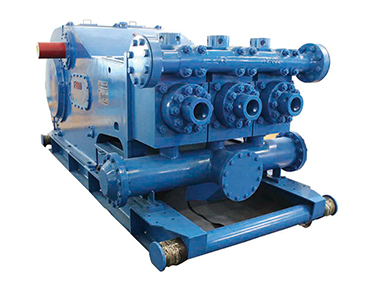

The 12-P-160 is rated @ 1,600 input horsepower (1,193 kW) at 120 strokes per minute with a 12 inch (304 mm) stroke. Multiple liner sizes allow pressure and volume to handle circulation in deep drilling applications.

Bentec completely redeveloped the concept of Mud Pumps. Being equipped with a direct-driven gearbox, an own developed motor, and a state-of-the-art pump housing, there is no need for an internal gear coming with many disadvantages and no more belt tensioning.

Bentec Mud Pumps are light weight and have a small footprint. The AC-powered motor is top or rear mounted – suitable for any drilling rig arrangement. The pump is available with 5 000 or 7 500 psi fluid ends, and all its parts that are subject to wear and tear meet API standards and are available worldwide.

A handling crane makes it easy to handle the fluid end components. Furthermore, Bentec uses a patented liner and valve clamping technology to reduce the maintenance time significantly. A quick-change liner and piston system serves for easy maintenance. A special feature of the Bentec MUD PUMP is the side-mounted gear drive.

This design eliminates the need for chain or belt tensioning systems. The two-stage helical gear feeds directly into a forged/welded crankshaft, which is balanced and provides quiet and vibration-reduced operation.

Liner cooling and gear oiler systems are included; a supercharge pump and a noise reduction package can be installed upon request. The Bentec MUD PUMP is the right choice especially when it comes to noise-sensitive environments such offshore or densely populated environments.

Beyond the supply of Mud Pumps, Bentec acts as system supplier. The pumps can be delivered together with a Bentec Power Control System and a Bentec Soft Pump System.

Our RL3NB series triplex single-action reciprocating mud pump is designed with longer stroke allowing the pump to work at a lower stroke rate. The optimized design helps to improve the suction performance of our products and extend the service life of the expendable parts. Triplex mud pumps of the RL3NB series are produced and tested strictly in accordance with the SY5138 standard formulated by Ministry of Petroleum Industry of China.

These slurry pumps can be used for well drilling, well repair, long-distance liquid transportation, polymer filling and water injection in oil fields or other industrial and mining enterprises.

RL3NB series triplex mud pump is mainly composed of the power end and the fluid end. The power end contains components like the base, the housing, main driving shaft, crank shaft, gear pair and connection rod crosshead. The fluid end is made up of parts including high pressure valve box, discharge manifold assembly and suction manifold assembly.

Diesel Mud pumps (temporally not available due to lack of engines 12/1/22) features 2-stage, 44 to 1 gear reduction with a large diameter output gear and heavy duty ball bearing construction. Often referred to as Mud pumps or Sludge pumps, diaphragm trash pumps are designed to pump mud, slurry, sewage, and thick liquids that have the ability to flow. Hatz Diesel engine 1B20.

Built-in molded polyurethane flapper/check valve assures self-priming to 20 feet after initial prime. Heavy duty gear box is designed to operate pumps at 40 strokes per minute for electric motor. Each unit includes a 3" NPT steel suction strainer, two 3" NPT nipples, and wheel kit with 10" semi-pneumatic transport wheels for portability. Pumps are designed for use with non-flammable liquids which are compatible with pump component materials. Suction and discharge port size cannot be reduced.

Suction and discharge port size cannot be reduced. Due to positive pumping action of diaphragm pumps, by all mfr"s, the discharge is recommended to only be 25FT long unless oversized. Discharge can not be restricted. There is no relief valve.

Our pump stroke counter systems (CPS101 Series) measure the stroke rate and number of strokes on mud pumps. The oilfield pump stroke system is user-friendly and reliable and is configurable to measure up to three mud pumps at once. Our digital pump stroke counter systems are manufactured here in the U.S. by Crown Oilfield Instrumentation, and Crown’s Pump Stroke Counter provides easy monitoring of strokes per minute on multiple mud pumps. Each mud pumps’s stroke rate can be selected individually and the display is updated regularly for accurate monitoring. LCD displays indicate both pumps strokes per minute and the total number of strokes. Located at the bottom of the panel, push buttons provide easy operation and reseting of each pump. When you need to accurately monitor and maintain the amount of mud being pumped, you can trust Crown’s oilfield stroke counters.

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

NOV 12-P-160 Mud Pump is rated at 1600 input horsepower (1193 kw) at 120 strokes per minute, with a 12-inch (304.8 mm) stroke. Multiple liner sizes allow pressures and volumes to handle circulation requirements in deep drilling applications.

Flexibility: Compact engineering provides higher efficiency in less space. The NOV 12-P-160 Triplex Mud Pump light weight and flexible design make it easily adaptable to a variety of rig configurations. This provides flexibility as drilling requirements and conditions change.

Fluid End Modules: NOV offers a choice of fluid end modules and valve covers for every P Series pump model to select the fluid end module that exactly matches drilling requirements. All pump models can be equipped with either the standard or premium forged, two-piece interchangeable fluid modules

8613371530291

8613371530291