triplex mud pump video pricelist

Welcome to Pickett Oilfield’s mud pumps web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used mud pumps and mud pump parts to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including mud pumps and parts to choose from at competitive prices. Browse our inventory of mud pumps and mud pump parts for sale at competitive rates.For more information or to request a quote, please Contact Us at 936-336-5154 or email to Sales@PickettOilfield.com.

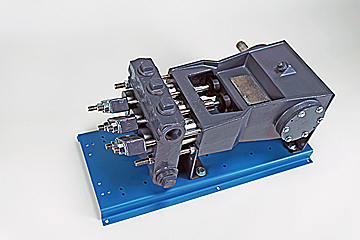

You are viewing three (3) fully reconditioned National Oilwell 12P160 Triplex Mud Pumps for sale by Pickett Oilfield, LLC. These National 12-P-160 Mud Pumps are Rebuilt and Ready to go to work.

Some refurbishments include: Fully reconditioned mud pump assembly. Pinion shaft assembly complete with new SKF bearings and new seals. Pump internals painted with Oil Resistant 2 Part epoxy Jotun Tank guard. MPI inspection of all critical areas of pump frame. MPI of all load path components of Crankshaft and Pinion shaft assemblies, and all new Southwest Premium “L” Shape 6,000 psi Fluid End Modules. A full Data Pack with all dimensional control & MPI reports will be furnished.

Warranty on National 12-P-160 Triplex Mud Pumps: All new parts fitted come with a 12 month warranty or such as offered by the part manufacturer; The refurbished GE-752 traction motors come with an 18 month warranty.

Pickett Oilfield, LLC offers prospective buyers an extensive selection of quality new, used, and refurbished Oilfield Drilling Equipment at competitive prices, including Triplex Mud pumps.

United StatesAfghanistan, Islamic State ofAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaidjanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia-HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCambodia, Kingdom ofCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, The Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupe (French)Guam (USA)GuatemalaGuineaGuinea BissauGuyanaHaitiHeard and McDonald IslandsHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsraelItalyIvory Coast (Cote D"Ivoire)JamaicaJapanJordanKazakhstanKenyaKiribatiKuwaitKyrgyz RepublicLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartinique (French)MauritaniaMauritiusMayotteMexicoMicronesiaMoldaviaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNetherlands AntillesNew Caledonia (French)New ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth KoreaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestinian AuthorityPanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandPolandPolynesia (French)PortugalQatarReunion (French)RomaniaRussiaRwandaS. Georgia & S. Sandwich Isls.Saint BarthélemySaint HelenaSaint Kitts & Nevis AnguillaSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Tome (Sao Tome) and PrincipeSaint Vincent & GrenadinesSamoaSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovak RepublicSloveniaSolomon IslandsSomaliaSouth AfricaSouth KoreaSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan Mayen IslandsSwazilandSwedenSwitzerlandSyriaTadjikistanTaiwanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamVirgin Islands (British)Virgin Islands (USA)Wallis and Futuna IslandsWestern SaharaYemenZambiaZimbabwe

We specialize in drilling. We provide drilling and workover RIGS, three-cylinder mud pumps (F&3NB series), solid control systems and their components. High quality drilling and workover engineering services

Business. We provide high quality EMSCO F-series mud pump, including F-500, F-800, F-1000, F-1300, F-1600, RLF-2200 and China 3NB series mud pump, including 3NB350, 3NB500, 3NB-600, 3NB800, 3NB1000A/D, 3NB1300A/D, 3NB1600. A full range of products can fully meet any needs

Black gold is truly the best description to sum up the value of oil. One of the most important contributors to change and industrialization, it drives the wheels of progress. ShalePumps is headquartered in Houston, the global oil capital. Headed by experts, it has a vision to support the industry with superior completion equipment. Frac operators, drilling contractors and well service companies source rely on ShalePumps for superior quality.

The key personnel of ShalePumps have a combined experience of more than a hundred years. This experience is reflected in the quality of our equipment. The fracking pumps, components and all services are much sought after for reliability and long life. This is because of the processes we follow. The design, materials, precision engineering and expertise contribute to an advanced assembly line.

After many years of thought and conscientious engineering, the team at ShalePumps is proud to add the Q5K™ 5000 HP Frac Pump to their list of many product offerings. Perfectly capable and suited for the next generation of hydraulic fracking market demands and technology. The Q5K is the only frac pump that has been designed and developed from the ground up to be capable of accepting true 5000 HP in a continuous duty frac application.

ShalePumps has consistently delivered high quality completion equipment to all stakeholders. The mission is to develop faster, rugged and efficient equipment to help the Oil and Exploration Industry. The vision is to continue leading the race with the best quality in completion equipment.

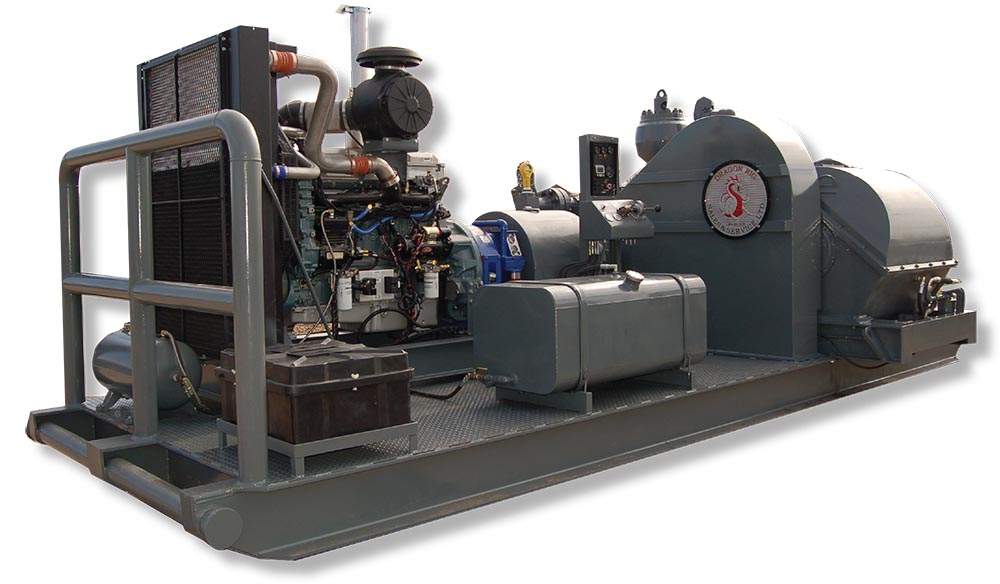

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

There are a lot of people who use the terms piston and plunger pump interchangeably. Granted, they are both positive displacement pumps and there are similarities, but their subtle differences are kind of a big deal when it comes to an operator’s desired performance, price, and pump longevity.

Plunger pumps have a reciprocating plunger (a type of rod). When it moves back and forth, it sucks liquid in through an inlet valve and forces it out the outlet valve. Plunger pumps have a stationary, high-pressure seal that is attached to the cylinder housing of the pump.

Piston pumps also have a reciprocating rod called a piston that moves back and forth to force liquid through a set of valves. Unlike a plunger pump, however, a piston pump’s seal is connected to the piston, meaning it moves in unison with the piston inside the cylinder housing.

From an engineering standpoint, it’s easy to understand that the main difference between piston and plunger pumps is the placement of the seals or O-rings. Again, the plunger pump’s seal is stationary while the piston pump’s seal moves with the piston.

When a reciprocating rod goes back and forth within either a piston or plunger pump, you have to seal it against the cavity wall so that it doesn’t lose compression. Because the seals of a plunger pump are not attached to a rod, it allows for less friction and higher pressure output. When the seal is connected to the moving part, as with a piston pump, the dynamic sliding action occurs along the walls of the housing, resulting in less pressure.

Here’s why. When a piston pump pushes a rod with an attached seal forward, you get friction that pushes back against the seal. Friction makes the seal want to react in the opposite direction of the motion, making the pump have to work harder to achieve more pressure.

A plunger pump has a smoother sliding action. Translation: less friction. In a plunger pump where the reciprocating rod doesn’t have an attached seal, the friction is in the same direction as the movement of the plunger. But the pressure is in the opposite direction, meaning they help to cancel each other out to some degree. Reduced friction means the motor doesn’t need to work as hard to achieve higher pressures.

Design for Manufacturability (DfM) comes into play when determining the durability of a pump’s design, especially in regards to which materials can be used where.

The material makeup of a pump’s housing and the reciprocating plunger or piston will have the greatest impact. In general, you want the component that has the greatest potential for wear to be as hard as possible to avoid scratches and a broken seal.

Common materials used in the pump industry include anodized aluminum, stainless steel, and brass. But the hardest available material used in some pump designs is ceramic. It doesn’t wear out over time like most metals, plus it has great chemical compatibility. It can be polished to a very consistent and smooth surface finish which is perfect for creating a tight seal.

Why does this matter? In a plunger pump, it’s the plunger that needs to seal against the cavity wall, meaning it should be the hardest material possible. In a piston pump, it’s the cavity walls that need to seal against the rod with the O-ring, meaning the cavity wall needs to be as strong as possible.

However, engineering and fabricating a thin, tube-like cavity wall out of ceramic or other material and making the inside of it perfectly smooth and consistent is a much greater challenge than fabricating the exterior of a perfectly smooth plunger out of those same materials. Even if it were possible to make the internal housing walls out of ceramic, its poor tensile strength would quickly lead to cracking and pump failure.

In other words, it’s much easier to make the plunger out of hard materials than it is to make the housing out of those same materials. As a result, plunger pumps can be engineered to be much more durable than piston pumps.

Many piston pumps require an oil bath. Some versions also have a second oil reservoir or oil pan with a wick to lubricate the backside of the piston seal. These reservoirs need to be refilled and maintained if you want to keep the pump operating as it should.

Many plunger pumps, like those manufactured by Pumptec, have oil that is contained in a sealed chamber and do not require draining or refilling of any oil reservoirs.

The more parts you have, the more maintenance is required. Plunger pumps have a relatively simple design, fewer parts, and require much less maintenance than piston pumps. Simply put, there’s less that can go wrong with a plunger pump.

What else results from fewer parts and a simpler design? Lower cost. Plunger pumps, in general, can have considerably lower up-front costs than piston pumps when comparing similar performance. Their total cost of ownership is typically less, too, especially when you factor in maintenance, repairs, or replacement over time.

If you haven’t guessed by now, we’re a bit biased toward plunger pumps. Many of the reasons stated here are why our company ventured into the industry in the first place: we saw the need for better durability and performance at a fair price point.

If you’re in the market for high-performance, high-pressure electric commercial pumps for your industry application, get in touch with our team of pump experts. We’re happy to talk through your needs and challenges to determine a solution.

Curious about some of the terms used in this article? We developed a helpful Pump Terms Glossary with common terms and relevant information. Click below to download your copy today.

8613371530291

8613371530291