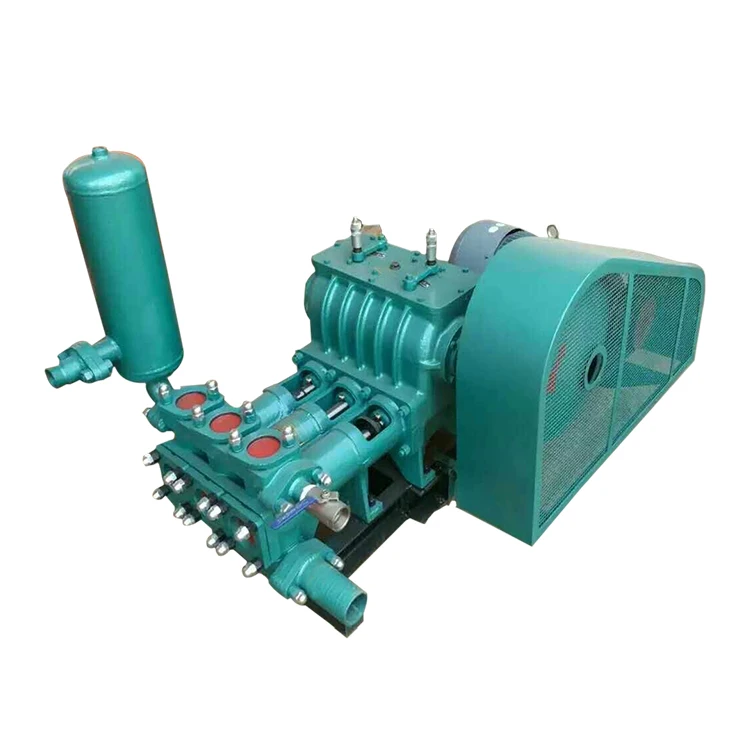

wear plate mud pump for sale

A wide variety of mud pump wear plate options are available to you, such as 1 year, not available.You can also choose from new, mud pump wear plate,As well as from energy & mining, construction works , and machinery repair shops. and whether mud pump wear plate is 1.5 years, 6 months, or unavailable.

A wide variety of wear plate for mud pump options are available to you, such as 1 year, not available.You can also choose from new, wear plate for mud pump,As well as from energy & mining, construction works , and machinery repair shops. and whether wear plate for mud pump is 1.5 years, 6 months, or unavailable.

Mud pump wear plate is the main component in the drilling pump fluid end system. It is installed on the inner side of the cylinder and plays the locating role for mud pump cylinder.

It is forged from 35CrMo. The wear-resistant discs manufactured by our company have high hardness and nickel-plated surface, which has good wear resistance and corrosion resistance.

The driving device realizes the valve opening and closing by rotating the valve disc by a certain angle through the valve stem and the rocker arm. The sealing surface of the valve disc is closely fitted to the valve seat by means of a spring. The valve disc is displaced in the vertical direction of the sealing surface. This helps to compensate the deformation of the valve parts caused by thermal expansion and contraction and the slight wear and tear caused by multiple opening and closing, overcomes the impact of any back pressure changes on the seal and prevents particulate media from entering between the sealing surfaces; During the closing process, the difference in friction between the valve seat seal and the valve disc in the tangential direction causes the valve disc to rotate during an opening and closing cycle and can continuously cut and clean. It may accumulate in the valve cavity during the process These characteristics of the medium are not found in other valves.

The sealing surface of the valve seat adopts an open structure. The valve disc will agitate and remove the medium during each action process, avoiding the accumulation of internal materials that often occur in other forms of wear-resistant valves; the changing circulation pipe space makes the flowing materials vortex Generates self-cleaning effect, avoids the corrosion and damage caused by the accumulation of materials inside the valve body, and maintains the valve in a good seal. Compact structure and easy installation

The valve disc and the valve disc are metal-to-metal hard seals. The sealing surface is made of nickel-based and cobalt-based hard alloys as a whole, with high hardness, corrosion resistance, oxidation resistance, high temperature resistance, suitable for corrosion and wear resistance at high temperature Wide temperature range.

The wear plate for mud pump has high hardness and nickel plating on the surface, which has good wear resistance and corrosion resistance. The wear plate is used on the F1300/1600 mud pump and is installed on the inner side of the liquid cylinder to function as a cylinder liner.

The blank of the mud pump wear plate is made of 35CrMo forging, and the quenching and tempering treatment is 241-285HB. The metric system of the wear plate differs in that the screw holes are different, and the remaining dimensions are identical.

Wear plate is the main component of hydraulic power end in drilling mud pump. It is forged of 35CrMo alloy steel.The wear-resistant disc produced by our company has high hardness and nickel plating, which has good wear resistance and corrosion resistance.

Premium Oilfield Technologies takes the responsibility of listening to our clients’ concerns very seriously. Acting on those needs enables Premium to offer robust solutions to customer issues at the rig. The Caliber® DS-7500 Fluid Ends bring together our years of field experience and unmatched client interface to represent the NEW standard for your Gardner Denver pumps.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

The NOV 12-P-160 Mud Pumps includes (3) Three New National 12-P-160 Triplex Mud Pumps 1600 HP, 7-1/4″ bore x 12″ stroke, single acting. 5000 PSI fluid ends. 1600 HP Bare Mud Pumps are currently configured for Offshore Service. The NOV 12-P-160 Mud Pumps are located in Houston and ready to be unitized for service.

Forged Steel crankshaft, Individual forged steel two piece interchangeable standard modules, 6-1/2” mission fluid king liners, Standard polyurethane valves and seats, Two piece fast change piston rods, Supreme pistons, Metal to metal liner retention, Clamp type liner and piston rod connections, Fast change valve covers standard, Piston liner lubricant spray system, Liner spray pump, Power end lube system with filter. Mounted on Integral two runner skid, Suction Manifold with vertical suction stabilizer, Suction line pressure relief valve, set for 70 PSI

Includes: motor supports, motor frame, tensioning screws, 2 V-belt guards, 2 pump Sheaves, 2 motor sheaves, banded V-belts, Holes to be drilled to accept EDM D79 Or GE-752 Traction Motors

National Oilwell Varco (NOV) is an American multinational corporation based in Houston, Texas. It is a leading worldwide provider of equipment and components used in oil and gas drilling and production operations, oilfield services, and supply chain integration services to the upstream oil and gas industry. The company conducts operations in more than 600 locations across six continents, operating through three reporting segments: Rig Technologies, Wellbore Technologies, and Completion & Production Solutions. National Oilwell’s two main predecessors, Oilwell Supply and National Supply, were founded in 1862 and 1893, respectively. These two companies manufactured and distributed pumps and derricks.

8613371530291

8613371530291