weatherford mp 8 mud pump brands

The Weatherford MP Series F & FB style design compatibility means that parts are readily available and fully interchangeable. The MP series mud pumps are based on the industry-recognized, proven and trusted F & FB style mud pump. The MP10 & MP16 Models are always in stock and available for immediate shipment.

The MP Series F style design compatibility means that parts are readily available and fully interchangeable. The MP series mud pumps are based on the industry-recognized, proven and trusted F style mud pump. Any of these parts for the MP Series models below can be purchased from Rig Manufacturing, LLC.

Weatherford products and services are subject to the Company’s standard terms and conditions, available on request or at weatherford.com. For more information contact an authorized Weatherford representative. Unless noted

otherwise, trademarks and service marks herein are the property of Weatherford and may be registered in the United States and/or other countries. Weatherford products named herein may be protected by one or more U.S. and/or

foreign patents. For more information, contact patents@weatherford.com. Specifications are subject to change without notice. Weatherford sells its products and services in accordance with the terms and conditions set forth in the

ERUI has been deeply engaged in the field of oil and gas energy for many years, integrating a large number of high-quality supply channels. Our products are comprehensive and the price advantage is obvious.

Weatherford creates innovative pumps for the oil and gas industry. Focused on ethical and sustainable business practices, Weatherford provides W and T Series power pumps, along with products related to drilling and rigs.

From their W-60 Triplex Pump to their W-375 Quintuplex Pump, this brand offers high performance products which will suit any of your power pump needs. Weatherford’s power pumps are made of materials like bronze and steel, and they are created with harsh conditions and continuous use in mind.

Knighten Industries offers products from some of the most recognizable brands on the market, and this includes Weatherford. Whatever the application, we can help you find the right choice from a versatile range of pumps.

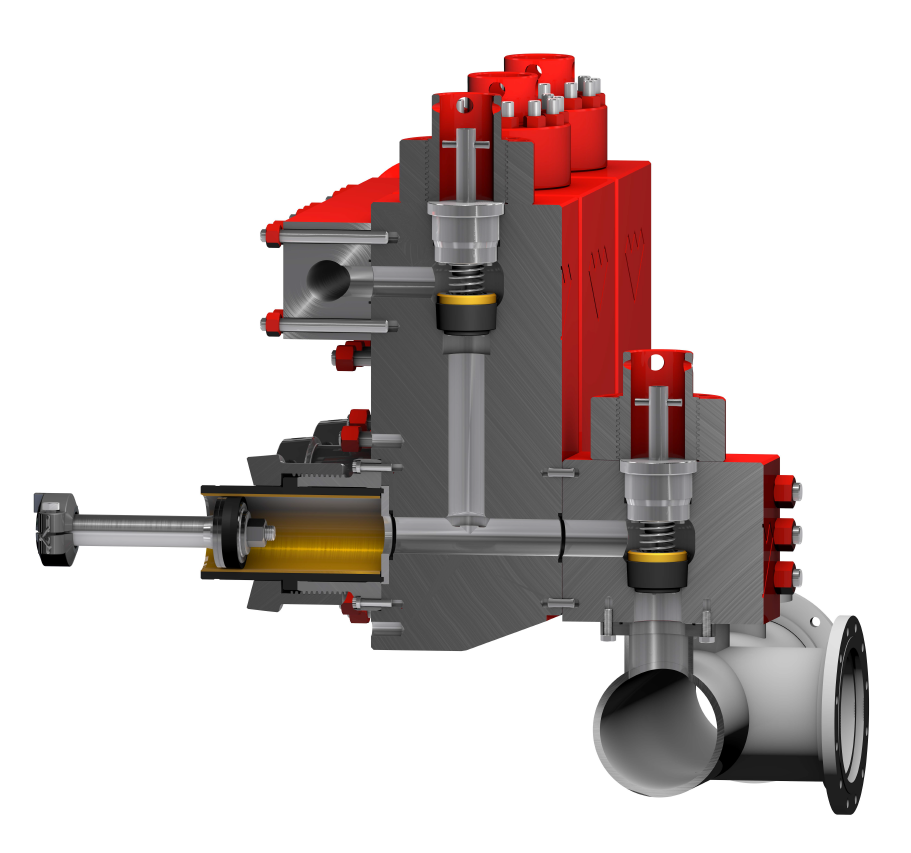

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

The fluid end includes cylinders (module), valve assembly, cylinder liners, piston assembly, suction manifold, discharge manifold, piston rod, pulsation dampener assembly, etc.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

For Fluid End: piston rod clamp, piston rod, piston assembly, cylinder cover, liner, liner flange, wear plate, cylinder, valve assembly, valve cover, valve guide, flashboard assy., cylinder cover flange, cylinder head, gaskets, studs, nuts, seal rings, pulsation dampener, bladder, discharge manifold, suction manifold, etc.

/is2.ecplaza.com/ecplaza1/offers/c/c7/c7e/1196221232/weatherford-mp5mp-8mp.jpg)

A wide variety of weatherford mud pump options are available to you, such as 1 year, not available.You can also choose from new, weatherford mud pump,As well as from energy & mining, construction works , and machinery repair shops. and whether weatherford mud pump is 1.5 years, 6 months, or unavailable.

Description PZ-7 mud pump PZ-8 mud pump PZ-9 mud pump PZ-10 and PZ-11 mud pump Liner of Crosshead Upper 200PZG309 2012509 PZ222 200PZL309 Liner of Crosshead Lower 200PZG309 2012509 PZ222 200PZL309 Pin of ... Read More

Weatherford offers a full line of premium-quality mud pumps based on proven and simple-to-maintain designs that are accepted around the world. Each pump comes with exceptional service and support that only a ... Read More

Weatherford is one of the world"s largest multinational oil and natural gas service companies. The company provides products and services for drilling, evaluation, completion, production and intervention of oil ... Read More

Website: www.premiumrigparts.com Weatherford is one of the world"s largest multinational oil and natural gas service companies. The company provides products and services for drilling, evaluation, completion, ... Read More

Weatherford is one of the world"s largest multinational oil and natural gas service companies. The company provides products and services for drilling, evaluation, completion, production and intervention of oil ... Read More

Spare parts for SPM TWS-2250 pumps with plunger 4.5" Item No. Name Code Part Number SPM 1 Fluid end IMZ-07.331.00 1P100646 2 Spacer IMZ-07.331.21 4P100649 3 Header ring IMZ-07.330.07 P100195HP 4 Pressure ring ... Read More

Description F500 F800 F1000 F1300/1600 F1600HL F2200HL Liner of Crosshead Upper AH0501010402 AH0801010402 AH1001010402 AH1301010402 AH1301010402 AH2202010402 Liner of Crosshead Lower AH0801010408 AH1001010409 ... Read More

Weatherford is one of the world"s largest multinational oil and natural gas service companies. The company provides products and services for drilling, evaluation, completion, production and intervention of oil ... Read More

Weatherford offers a full line of premium-quality mud pumps based on proven and simple-to-maintain designs that are accepted around the world. Each pump comes with exceptional service and support that only a ... Read More

Website: www.premiumrigparts.com Weatherford is one of the world"s largest multinational oil and natural gas service companies. The company provides products and services for drilling, evaluation, completion, ... Read More

All CategoriesAir compressors (2)Air compressor (1)Screw air (1)Attachments (2)Bucket (1)Screen (1)Backhoes (1)Excavators (1)Compactors (2)Compactor (1)Roller (1)Drill Rigs (1)Drilling (18)Brakes (1)Cat walk (1)Drilling Rig (1)Equipment (5)Mud Pits (3)Pipe wrangler (1)Pumps (3)Solids separation (3)Electrical Equipment (4)Circuit Breaker (1)Cutler Hammer (1)Eaton (1)Switchgear (1)Engines (24)Cores (2)Diesel (7)Drilling (2)Drilling Rig (1)Engine (5)Equipment (2)Natural Gas (2)Oilfield (1)Pump drive (1)Pumps (1)Generators (18)Cat (3)Diesel (7)Generator (7)John Deere (1)Heaters (3)Air heater (1)Blower (1)Indirect fired heater (1)Iron (2)Pipe (1)Sucker Rod (1)Man Camps (3)Man Camp (2)Rig House (1)Mud Pumps (27)1000hp (4)Cat (1)Diesel (2)Drilling (1)Emsco (3)Engine (1)Equipment (1)Mud pump (7)Pump (7)Natural Gas Compression (10)Compressor Station (3)Engine (1)Frick (2)Natural Gas (3)Waukesha (1)Oil Field (5)Bathroom (1)Shipping container (1)Substructure (1)Support Equipment (1)Tanks (1)Production (3)Injection (1)Pump (1)Pumping Unit (1)Rigs (1)Swabbing Unit (1)Road Graders (3)Blade (1)Road Grader (1)Service Trucks (1)Service Truck (1)Silos (2)Sand silos (1)Tanks (1)Support Equipment (19)Accumulator (3)Cat walk (1)Closing Unit (2)Drilling Rig (2)HPU (1)Koomey (2)Kubota (1)Mud pump (1)Oilfield (1)Pipe handling (1)Pipe rack (1)Pipe wrangler (1)Power Swivel (1)Tanks (1)Telehandler (4)Cat (1)Forklift (1)Reachlift (1)Telehandler (1)Trailer (4)Flatbed (1)Gooseneck (1)Step deck (1)Trailer (1)Valves (82)

DESCRIPTIONLINER (REFER TO GUIDE TO ORDERING CHART FOR TYPE (Y) AND FOR SIZE (XX))LINER SEALWEARPLATEPISTON (REFER TO GUIDE TO ORDERING CHART FOR TYPE (Y) AND SIZE (XX))PISTON BUSHING (FROM 1 5/8 TO 1 STRAIGHT BORE)PISTON O-RINGPISTON ROD (WITH ELASTIC STOP NUT)PISTON ROD ELASTIC STOP NUT

6274CWY1200H301286CWYFP144020-291200G74SEE PAGESEE PAGESEE PAGESEE PAGESWTM17004490-514590-514690-51AJO495R4790-508000453080006900800006304020-73800093004790-1479080001500

ROD CLAMP (CONSIST OF 8A, 8B, 8C)HOSE (1/2 X 30 WITH MALE X 3/8 MALE CONNECTIONS)SPRAY PIPEROD CLAMP BOLT (5/8-8 GRADE 8 BOLT WITH LOCK NUT AND WASHER)PONY RODVALVEVALVE INSERT (IF REQUIRED)VALVE SPRINGVALVE SEAT

THREADED FLANGESCREW GLANDPLUG (COMPLETE WITH VALVE GUIDE, SCREWS, AND BUSHING)CYLINDER HEAD PLUG SEALLOWER VALVE GUIDE ALIGNMENT RINGLOWER VALVE GUIDELOWER VALVE GUIDE BUSHINGLOWER VALVE GUIDE LOCK BOLTCYLINDER HEAD STUD (WITH SW PART# HHN1500-8 1-1/2-8 HEAVY HEX NUT)VALVE COVERUPPER VALVE GUIDEUPPER VALVE GUIDE RETAINERUPPER VALVE GUIDE RETAINER CAP SCREW

DESCRIPTIONVALVE COVER GASKETPOWER END STUD (WITH SW PART# HHN1500-8 1-1/2-8 HEAVY HEX NUT)LINER RETAINER STUD (WITH SW PART# HHN1000-8 1-8 HEX NUT)LINER RETAINER FLANGELINER RETAINER NUTLINER LOCK RINGLINER LOCK O-RINGSUCTION MANIFOLD CAP SCREWSUCTION MANIFOLDSUCTION MANIFOLD GASKETMODULEDISCHARGE MANIFOLDDISCHARGE MANIFOLD GASKETDISCHARGE MANIFOLD STUD (WITH SW PART# HHN1250-8 1-1/4-8 HEAVY HEX NUT)

Production Process: The bi-metal cylinder Liner of our company combined with the advantages of abrasion hot-forging out liner and anticorrosion high chrome inner liner. The out liner is made of high quality carbon steel by hot pressing forming. Its tensile strength is over 900000psi. The inner liner is made of high-chromium alloy by centrifugal casting.

Bi-metal Liners combine the strength of a forged steel outer shell with the abrasion and corrosion resistance of a high chrome inner sleeve. These liners feature a centrifugally cast high chrome iron sleeve which is machined and heat treated to a minimum uniform bore hardness of 59-65HRC. Bi-metal Liners is the main expendable parts of the mud pump, it adapts double metal fix together.

Ceramic Liners combine the strength of a forged steel outer shell with the abrasion and corrosion resistance of a ceramic inner sleeve. Ceramic cylinder inner sleeve is used zirconia toughening alumina ceramics obtained the national patent, using zirconium oxide the characteristics of high fracture toughness and high hardness of alumina, the combination of these two can improve the fatigue strength of the product. Its coat uses 45 steel forging with good mechanical properties. After tempering heat treatment, hardness of HB235-265, the tensile strength is not less than 655 mpa.

8613371530291

8613371530291