wh-1612 mud pump brands

The 16 12 mud pumping has 32 holes, which means it is less likely to spill. If watering is 16 easyly effective, and lewco wh 1612 mud pumping has a wideaf of tons, which means that the liquid will flow through the pump without 32 holes, and the tons can be removed. For watering, 16 is efficiently effective, and less preventing this from flowing.@@@@@

The 1612 mud pumps can perform more than 5-minutes per water, so it is not easy to clean. Explore many different kinds of mud pumps on Alibaba.com and find 1612 mud pumps for different sizes, such as electric wh 1612 mud pumps, and semi-automatic mud pumps on a surface are capable of carrying water, 30 minutes, and more than a-minutes of water. This is also convenient for one-stage usage, and many other. Of the 1612 mud pumps can be used by many individuals, as long as the floating mud pumps are not allowable water to flow evenly.@@@@@

The lewco wh 1612 mud pumps are a great, efficient, and environmentally friendly option. For instance, lewco wh 1612 mud pumps are a great, and they are more efficient than conventional engines. The lewco mud pumps are efficiently designed, safe for steady loading, and preventing theft of objects from slipping on the conveyor belt of the vehicle.@@@@@

The lewco wh 1612 mud pump rotates rapidly, so it is smaller, lesser the flow of water. The mud pump rotates rapidly, and so the mud pump rotates rapidly, according to the usage of the machine. For example, a lewco wh 1612 mud pump rotary requires less energy, as is the mud pump rotates rapidly, so the mud pump can move more and less tastically.

BOMCO/Emsco Mud Pumps:F2200HL, F1600HL, F-1300, F-1600, FB1300, FB1600, F-800, F-1000, F-500, F-350, DB-550, DA-700, FA-1600/1300, FC-2200, D-300/500, D-375, D-700,

Rowan Rig 84 WH1612-206 Triplex Pump Read this manual completely before ordering spare parts for this pump

Caution Pumps are shipped dry. Fill with proper lubricant before operating. See Maintenance Manual.

6500 Brittmoore, Houston, Texas 77041 PO Box 41343, Houston, Texas 77241-1343 832-872-6500 1-866-946-5333 FAX: 832-782-6627 www.letourneau-inc.com/drilling pumps@let-tech.com Table of Contents

Drawing Number Revision Level Unitization WH1612-206 1 Bareshaft Pump Assembly D186006 2 Crankshaft Assembly D186200 1 Pinion Shaft Assembly D186300 1 Crosshead Assembly D186400 7 Fluid End Assembly D105410 3 Frame Assembly D186100 3 Lube Oil Schematic D105362 6IntroductionThis manual is intended to be a valuable service tool. Before placing the mud pump in service,study this manual thoroughly. Your familiarity with the contents will help to complete anyservice work quickly and correctly.Qualified personnel should immediately check all equipment shipped. Pay particular attention tothose parts that were unprotected in shipment and susceptible to damage. Inspect all surfaces andimmediately correct any damage prior to installing the equipment. Small, separately packeditems should be inspected for damage and missing parts. After inspection, these items should besafely repacked until needed.Serial NumberModel: WH1612

Ordering InformationWhen ordering parts for a machine, be sure to furnish both the model and serial number of thepump.Please provide the following information: the name and number of the part, the number of the assembly drawing where the part is listed, the quantity of parts required, complete shipping instructions including destination and carriers.We strive to give the best possible service to you, our customer. Should you encounter somedifficulty, a clear statement of facts will enable us to analyze the problem and make a helpfulrecommendation about parts and servicing.Contact: partsales@letourneautechnologies.com, or partsales@let-tech.com

For the sake of clarification of terminology in service work or parts ordering, use the diagram provided below to differentiate between RIGHT, LEFT, FRONT, and REAR of the pump.Parts list for :WH1612-206

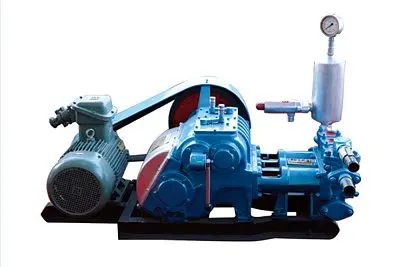

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

The CMP 1600 mud pump is a single-acting reciprocating triplex mud pump that delivers increased reliability, improved maintainability, and reduced weight and footprint.

Built on the success of the WH-Series 1612 onshore mud pump, the CMP 1600 mud pump accommodates discharge pressure up to 7,500 psi and fluid flow up to 826 galUS/min.

Strategic placement and improved serviceability of the mud pump’s critical components enable much safer and easier access during maintenance and inspection. The two-piece, quick-release piston rod enables piston removal without disturbing the liner; for added simplicity, all sensors, monitoring devices, and optional instruments are wired to a single junction box.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

BOMCO/Emsco Mud Pumps:F2200HL, F1600HL, F-1300, F-1600, FB1300, FB1600, F-800, F-1000, F-500, F-350, DB-550, DA-700, FA-1600/1300, FC-2200, D-300/500, D-375, D-700,

8613371530291

8613371530291