wheatley mud pump for sale factory

Power Zone is a leading global supplier of new, used and reconditioned pumps for sale. Our inventory of pumps includes multi-stage centrifugal pumps, positive displacement pumps, reciprocating pumps, single stage centrifugal pumps and screw pumps in a variety of design standards including API 610 Centrifugal Pumps, API 674 Reciprocating Pumps and API 676 Rotary Pumps. We have an assortment of pumps that are used in various applications including water treatment, pipelines, frac water supply, salt water disposal and flood control in industries like municipal, manufacturing, oil & gas, mining and agriculture. We supply pumps of all major suppliers such as Sulzer, Flowserve, ITT Goulds, Aurora and National.

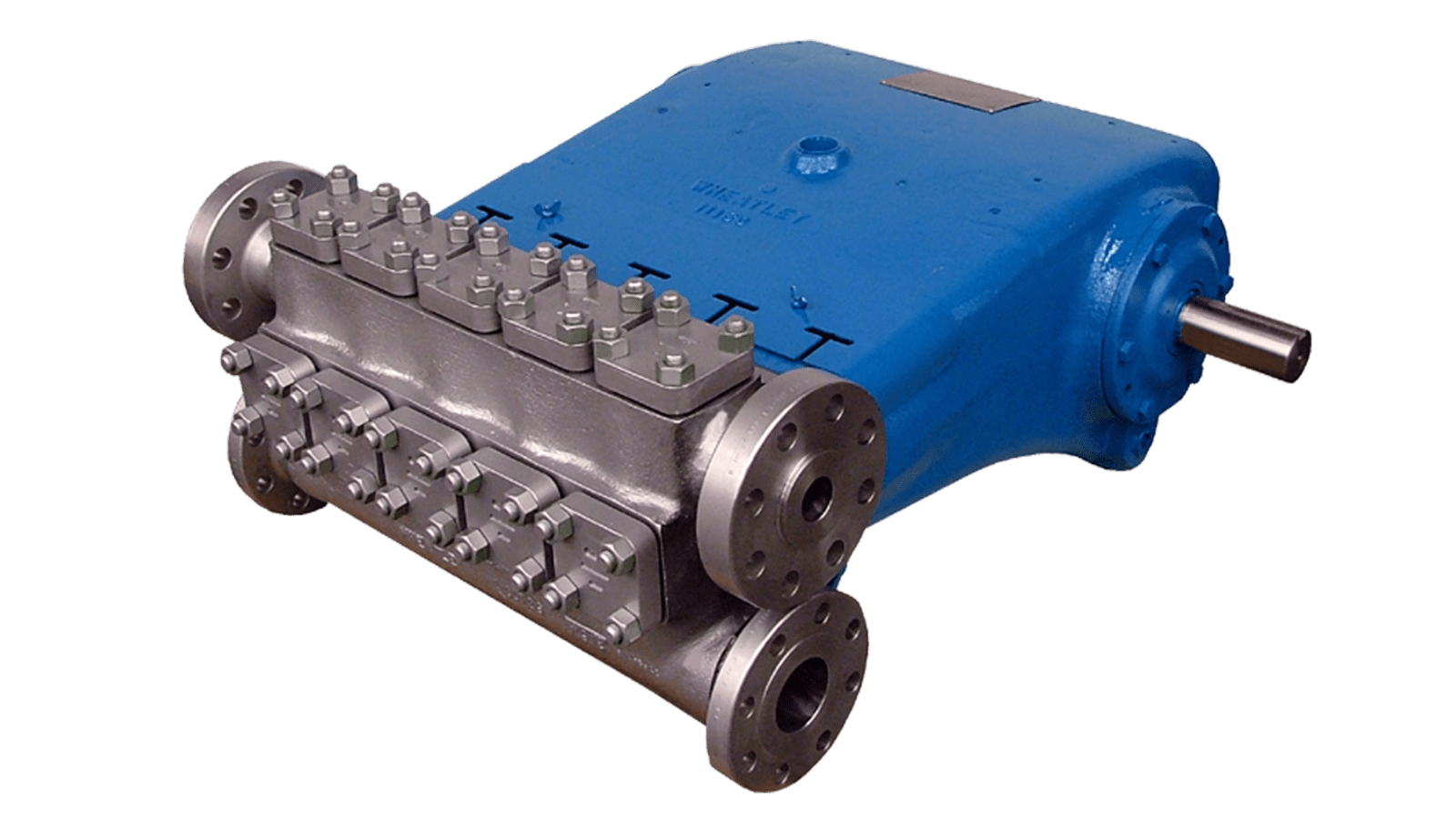

Wheatley engineering is supported by exact manufacturing processes. It is this commitment to quality that has made Wheatley plunger and piston pumps the most sought-after solutions for flow control problems. When you need a highly efficient reciprocating pump from 6 to 1800 horsepower, Our team delivers. Day after day… year after year.

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pumps - Misc. - New 1 5/8" ceramic plunger for pump models: P-323, 59T-3, (T-365, T-385), 5P-323, & HP-125M ( 103Q-3, 110Q-3, Q3115) Price listed is for 1. More Info

Pumps - Misc. - 1 5/8" 838 plunger packing for Wheatley/National models: 110Q-3M, HP-125M, P-50A, P-100A, P-175, P-200, P-200A, P-300, 5P-300A, 5Q-300A, P-323, 5P-323, P-200B, 5P-200A, T... More Info

Pump Parts - Wheatley 5P-200A Quintuplex Injection Pump, Pumps & Parts, Used Wheatley 5P-200A Quintuplex Injection Pump, 1.75" metal plungers x 2.25" stroke, steel fluid end, on skid ... More Info

Pump Parts - Wheatley 5P-200A Quintuplex Injection Pump, Pumps & Parts, Used Wheatley 5P-200A quintuplex pump, 1.75" metal plungers x 2.25" stroke, steel fluid end, on skid with belt ... More Info

Pump Parts - Wheatley 5P-200A Quintuplex Injection Pump, Pumps & Parts, Used Wheatley 5P-200A Quintuplex Injection Pump, steel fluid end, 1.75" metal plungers x 2.25" stroke, disc val... More Info

Quintuplex Pumps - Used Wheatly 5p-323 quintuplex, aluminum bronze head, 2.5"" steel plungers, power end in excellent condition, mounted on skid, bull wheel and 40 hp electric motor. More Info

Pump Parts - Wheatley HP-160M Triplex Pump, Pumps & Parts, Used Wheatley HP-160M Triplex Pump, 3" Metal Plungers x 6 1/8" Stroke, 400 RPM, Steel Block Fluid End, Bolt on Suction Manif... More Info

Quintuplex Pumps - Used Wheatley HP-375L quintuplex plunger pump, steel billet fluid end, with 4" plungers, 500 gpm max, 995 psi max, 300 rpm max. More Info

Quintuplex Pumps - Used Wheatley HP-600M Quintuplex pump only. 7 1/8" Stroke, 600 HP, Forged Carbon Steel Fluid End, 2 5/8" Plungers, 300 gpm max, 3085 psi max, 360 rpm max. More Info

Pump Parts - Wheatley P-200 Triplex Plunger Pump, Pumps & Parts, Used Wheatley P-200 Triplex Pump, 0.75" metal plungers x 2.125" stroke, stainless steel high pressure block fluid end,... More Info

Pump Parts - Wheatley P-530A Triplex Plunger Pump, Pumps & Parts, Used Wheatley P530A Triplex Plunger Pump, steel fluid end, size 1.75-2.75" x 5.125" stroke, max HP 130, max RPM 360, ... More Info

Pump Parts - Wheatley Q-4240AM Quintuplex Saltwater Disposal / Injection Pump, Pumps & Parts, Used aluminum bronze fluid end for Wheatley Q4240AM Quintuplex Saltwater Disposal/Injecti... More Info

Adjust or replace these bearings at first sign of wear. The bearings in the crank end are babbitt lined steel shells, adjustable for wear by removing shims and easily replaced when completely worn. These bearings should be watched closely and adjusted at first signs of looseness.. You will note on series 3400, 3800, 3500, and 3900 pumps, that the shims do not completely fill the outer gap between rod and cap casting, although the connecting rod bolts are tight. This is because the faces of the shell bearings project slightly beyond the faces of the rod and cap castings, and the shims are gripped only between the faces of the bearing halves. Do not try to close this outer gap by tightening the connecting rod bolt as it will put an excessive strain on the bolts.

To check for wear, place a wrench on the top connecting rod bolt and shake the rod parallel to the crankshaft. (The pressure must be relieved from the liquid end of the pump, so that the pump"s mechanism is free to move.) If the rod bearing moves without resistance, the bearing may be too loose and need adjusting. If the bearing does need adjusting, remove shims until you cannot shake the rod, then add .005" shims one at a time until there is little side movement. Be sure to torque rod bolt nuts to proper value for each adjustment. Oil clearance should be checked with Plastigage (available in most parts stores). Wipe crankshaft journal clean of any oil, place a strip of Plastigage on the crankshaft journal and tighten rod cap to the proper torque value. Once tightened, remove rod cap and measure oil clearance with scale on Plastigage package. See oil clearance chart. (NOTE: If you are making this adjustment after having had the crossheads out, be sure that the oil holes in the rod are pointing up. The "up" side is indicated by matching numbers stamped on the cap and rod at the split between them. These numbers should be the same on each rod and should be on the top side of the crankshaft.) Rotate the shaft by hand and if there is any hard drag or tight spots in the bearing, add another 0.005" shim. After this bearing is properly adjusted, loosen bolts a few turns and repeat the above operation on the other bearings. After all bearings have been adjusted.

Torque all connecting rod bolt nuts back to proper value. Again rotate the pump by hand to check for excessive drag and tight spots. If none, the pump should be ready for operation.

If the pump cannot be rotated by hand due to the drive being enclosed, care must-be taken: not to over-tighten the bearings, since they cannot be checked by rotating the pump. When bearings are adjusted by this method, watch carefully for overheating when the pump is put into operation.

It is usually better to have a bearing a little too loose than too tight. A slightly loose bearing will cause very little trouble because of the slow operating speeds of the pump, but a tight bearing will overheat and the babbitt may melt or pull. Normal precautions must be taken to insure cleanliness of parts upon their assembly.

Inspect connecting rod bearings and adjust as necessary every six months or when crankcase lubricant is changed. The bearings in the crank end are babbitt lined steel shells, adjustable for wear by removing shims and easily replaced when completely worn. These bearings should be watched closely and adjusted to compensate for wear. You will note that shims do not completely fill the outer gap between rod and cap casting although the connecting rod bolts are tight. This is because the faces of the shell bearings project slightly beyond the faces of the rod and cap castings and the shims are gripped only between the faces of the bearing halves. Do not try to close this outer gap by tightening the connecting rod bolt as it will put an excessive strain on them.

To check for wear, place a wrench on the top connecting rod bolt and shake the rod parallel to the crankshaft. (The pressure must be relieved from the liquid end of the pump so that the pump"s mechanism is free to move.) If the rod bearing moves without resistance, the bearing may be too loose and need adjusting. If the bearing does need adjusting, remove shims until you cannot shake the rod, then add .005" shims one at a time until there is a little side movement. Be sure to torque rod bolt nuts to proper value for each adjustment. (NOTE: If you are making this adjustment after having had the crossheads out, be sure that the oil holes in the rod are pointing up. The "up" side is indicated by matching numbers stamped on the cap and rod at the split between them. These numbers should be the same on each rod and should be on the top side of the crankshaft.) Turn the shaft by hand and if there is any hard drag or tight spots in the bearing, add another .005"" shim. After this bearing is properly adjusted, loosen bolts a few turns and repeat the above operation on the other bearings. After all bearings have been adjusted, torque all connecting rod bolt nuts back to proper amount. Again turn the pump by hand to check for excessive drag and tight spots. If none, the pump should then be ready for operation.

If the pump cannot be rotated by hand due to the drive being enclosed, the bearings may be completely adjusted by shaking the bearing on the shaft as stated above. Care must be taken not to over-tighten the bearings since they cannot be checked by rotating the pump by hand. When bearings are adjusted by this method, they must be watched carefully for overheating when the pump is put into operation.

Alternatively, plastic gauge strips, found in most parts stores may be used to adjust these bearings. It is usually better to have a bearing a little too loose than too tight. A slightly loose bearing will cause very little trouble because of the slow operating speeds of the pump, but a tight bearing will overheat and the babbitt may melt or pull. with experience, an operator can tell by feel when the bearings are properly adjusted. Normal precautions must be taken to insure cleanliness of parts upon their assembly. All wrenches used in adjusting these bearings are standard wrenches.

IEQ is an OEM supplier of the Wheatley 535/545 Pump. Let the friendly customer service staff at IEQ Industries help you find the Wheatley Pump you need.

RPM shown is Crankshaft speed. For Pinion Shaft speed, multiply RPM by Gear Ratio. Volumetric Rate is based on 100% Volumetric Efficiency. Brake Horsepower/Kilowatts Required is based on 85% Mechanical Efficiency.

Preferred Pump offers the best rewards program in the water well equipment industry. Check out our social media pictures to see what you"ve been missing!

*Note: "Danco Pump & Supply Co. is not a licensee or in any way affiliated with National Oilwell L.P. or it"s parent Company National Oilwell, Inc. and that neither National Oilwell L.P. or it"s parent company National Oilwell Inc. endorses any of the products or services offered by Danco. "National Oilwell", "Gaso", "Wheatley", and "Emsco" are trademarks belonging to National-Oilwell L.P."

"Danco Pump & Supply Co. is not a licensee or in any way affiliated with Gardner-Denver® and Gardner-Denver® does not endorse any of the products or services offered by Danco. "Gardner-Denver®" and all of its pumps and parts are registered to Gardner-Denver®."

Three cylinder single acting reciprocating mud pump has a long stroke and can run at a lower stroke, which effectively improves the water supply performance and greatly extends the service life of the vulnerable parts of the hydraulic end. Three cylinder single acting...

Small mud pumps can withstand heavy loads and are specially designed for conveying highly abrasive or corrosive slurries and high-density slurries, and are widely used in metallurgy, mining, coal, power stations, seawater river dredging, building materials and other...

Centrifugal drilling mud pump is a mud pump with centrifugal function. The main features are high pressure, large head, low energy consumption and convenient operation. It is used for geophysical prospecting to provide flushing fluid to the borehole and to provide flushing...

The drilling rig three cylinder mud pump is firm and compact in structure, small in size and outstanding in operation performance, and is suitable for the requirements of high pump pressure in oil fields and large displacement technology for drilling.

Oilfield hydraulic piston mud pump is a hot-selling mud pump product of our company. All its wearing parts can be interchanged with other spare parts produced according to API standards, so it is easy to repair and maintain. In the common positive circulation drilling, the...

Industrial horizontal centrifugal mud pump adopts a double-layer metal structure inside and outside, and the pump casing is a vertical open type. It has outstanding features such as high efficiency, energy saving, long service life, light weight, reasonable structure,...

Double piston drilling mud pump is a light grouting machine, which is a horizontal double-cylinder double-acting reciprocating piston pump. It is mainly used to inject flushing fluid into the hole during geological drilling.

Geothermal water well drilling mud pump is a mud pump used for geothermal steam and geothermal water drilling. It is an important equipment required for exploration and exploitation of geothermal fluid. The geothermal water well drilling mud pump is equipped with a gearbox or...

The diesel engine drilling mud pump has compact structure, light weight, small volume and beautiful appearance, and is driven by hydraulic motor, electricity or diesel engine. It has high stability and high pressure.

High pressure drilling mud pump is a mud pump developed by our company that can be used under high pressure. The high pressure drilling mud pump has a longer stroke and can run at a lower stroke, thereby effectively improving the water supply performance and greatly extending...

IEQ is an OEM supplier of the Wheatley T225 (32T-2) Pump. Let the friendly customer service staff at IEQ Industries help you find the GASO Pump and Parts you need.

IEQ is an OEM supplier of the Wheatley T365 (59T-3) Pump. Let the friendly customer service staff at IEQ Industries help you find the GASO Pump and Parts you need.

With our experience vast pool of resources and dedication to excellent customer service, we will go to the extra mile to confidently fulfill all of your pumping and equipment needs. One of our most important goals is to set the standard for great customer service. No matter if you need a seal, a gasket, or a complete new pump. We"ll treat you the same, with professional courtesy, throughout the sales process. Here"s a couple of testimonials from our customers.

I want to thank you for all of your efforts in tracking all of this down and providing the different options in such a timely manner. This type of service is why you will get all of our business. Thanks again!

United StatesAfghanistan, Islamic State ofAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaidjanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia-HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCambodia, Kingdom ofCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, The Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupe (French)Guam (USA)GuatemalaGuineaGuinea BissauGuyanaHaitiHeard and McDonald IslandsHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsraelItalyIvory Coast (Cote D"Ivoire)JamaicaJapanJordanKazakhstanKenyaKiribatiKuwaitKyrgyz RepublicLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartinique (French)MauritaniaMauritiusMayotteMexicoMicronesiaMoldaviaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNetherlands AntillesNew Caledonia (French)New ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth KoreaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestinian AuthorityPanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandPolandPolynesia (French)PortugalQatarReunion (French)RomaniaRussiaRwandaS. Georgia & S. Sandwich Isls.Saint BarthélemySaint HelenaSaint Kitts & Nevis AnguillaSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Tome (Sao Tome) and PrincipeSaint Vincent & GrenadinesSamoaSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovak RepublicSloveniaSolomon IslandsSomaliaSouth AfricaSouth KoreaSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan Mayen IslandsSwazilandSwedenSwitzerlandSyriaTadjikistanTaiwanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamVirgin Islands (British)Virgin Islands (USA)Wallis and Futuna IslandsWestern SaharaYemenZambiaZimbabwe

The Information provided in this website is for reference only. The reference of Gould’s, Griswold, Peerless, Flygt or any other OEM manufacturer is for reference only. Replicate Pump is not an authorized distributor of the parts or services for above OEMs products. Replicatepump.com offers aftermarket parts to replace above OEMs pumps and parts. Replicatepump.com also disclaims the information on this website is accurate for construction purpose. The dimension or specification shown in this website is for reference only.

8613371530291

8613371530291