wheatley mud pump for sale quotation

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pumps - Misc. - New 1 5/8" ceramic plunger for pump models: P-323, 59T-3, (T-365, T-385), 5P-323, & HP-125M ( 103Q-3, 110Q-3, Q3115) Price listed is for 1. More Info

Pumps - Misc. - 1 5/8" 838 plunger packing for Wheatley/National models: 110Q-3M, HP-125M, P-50A, P-100A, P-175, P-200, P-200A, P-300, 5P-300A, 5Q-300A, P-323, 5P-323, P-200B, 5P-200A, T... More Info

Pump Parts - Wheatley 5P-200A Quintuplex Injection Pump, Pumps & Parts, Used Wheatley 5P-200A Quintuplex Injection Pump, 1.75" metal plungers x 2.25" stroke, steel fluid end, on skid ... More Info

Pump Parts - Wheatley 5P-200A Quintuplex Injection Pump, Pumps & Parts, Used Wheatley 5P-200A quintuplex pump, 1.75" metal plungers x 2.25" stroke, steel fluid end, on skid with belt ... More Info

Pump Parts - Wheatley 5P-200A Quintuplex Injection Pump, Pumps & Parts, Used Wheatley 5P-200A Quintuplex Injection Pump, steel fluid end, 1.75" metal plungers x 2.25" stroke, disc val... More Info

Quintuplex Pumps - Used Wheatly 5p-323 quintuplex, aluminum bronze head, 2.5"" steel plungers, power end in excellent condition, mounted on skid, bull wheel and 40 hp electric motor. More Info

Pump Parts - Wheatley HP-160M Triplex Pump, Pumps & Parts, Used Wheatley HP-160M Triplex Pump, 3" Metal Plungers x 6 1/8" Stroke, 400 RPM, Steel Block Fluid End, Bolt on Suction Manif... More Info

Quintuplex Pumps - Used Wheatley HP-375L quintuplex plunger pump, steel billet fluid end, with 4" plungers, 500 gpm max, 995 psi max, 300 rpm max. More Info

Quintuplex Pumps - Used Wheatley HP-600M Quintuplex pump only. 7 1/8" Stroke, 600 HP, Forged Carbon Steel Fluid End, 2 5/8" Plungers, 300 gpm max, 3085 psi max, 360 rpm max. More Info

Pump Parts - Wheatley P-200 Triplex Plunger Pump, Pumps & Parts, Used Wheatley P-200 Triplex Pump, 0.75" metal plungers x 2.125" stroke, stainless steel high pressure block fluid end,... More Info

Pump Parts - Wheatley P-530A Triplex Plunger Pump, Pumps & Parts, Used Wheatley P530A Triplex Plunger Pump, steel fluid end, size 1.75-2.75" x 5.125" stroke, max HP 130, max RPM 360, ... More Info

Pump Parts - Wheatley Q-4240AM Quintuplex Saltwater Disposal / Injection Pump, Pumps & Parts, Used aluminum bronze fluid end for Wheatley Q4240AM Quintuplex Saltwater Disposal/Injecti... More Info

Power Zone is a leading global supplier of new, used and reconditioned pumps for sale. Our inventory of pumps includes multi-stage centrifugal pumps, positive displacement pumps, reciprocating pumps, single stage centrifugal pumps and screw pumps in a variety of design standards including API 610 Centrifugal Pumps, API 674 Reciprocating Pumps and API 676 Rotary Pumps. We have an assortment of pumps that are used in various applications including water treatment, pipelines, frac water supply, salt water disposal and flood control in industries like municipal, manufacturing, oil & gas, mining and agriculture. We supply pumps of all major suppliers such as Sulzer, Flowserve, ITT Goulds, Aurora and National.

We are here to serve you with fast customer service and quick turn around time for your plunger and piston pumps, pump parts, and technical information needs. We will always answer your inquiries with a quick and courteous response.

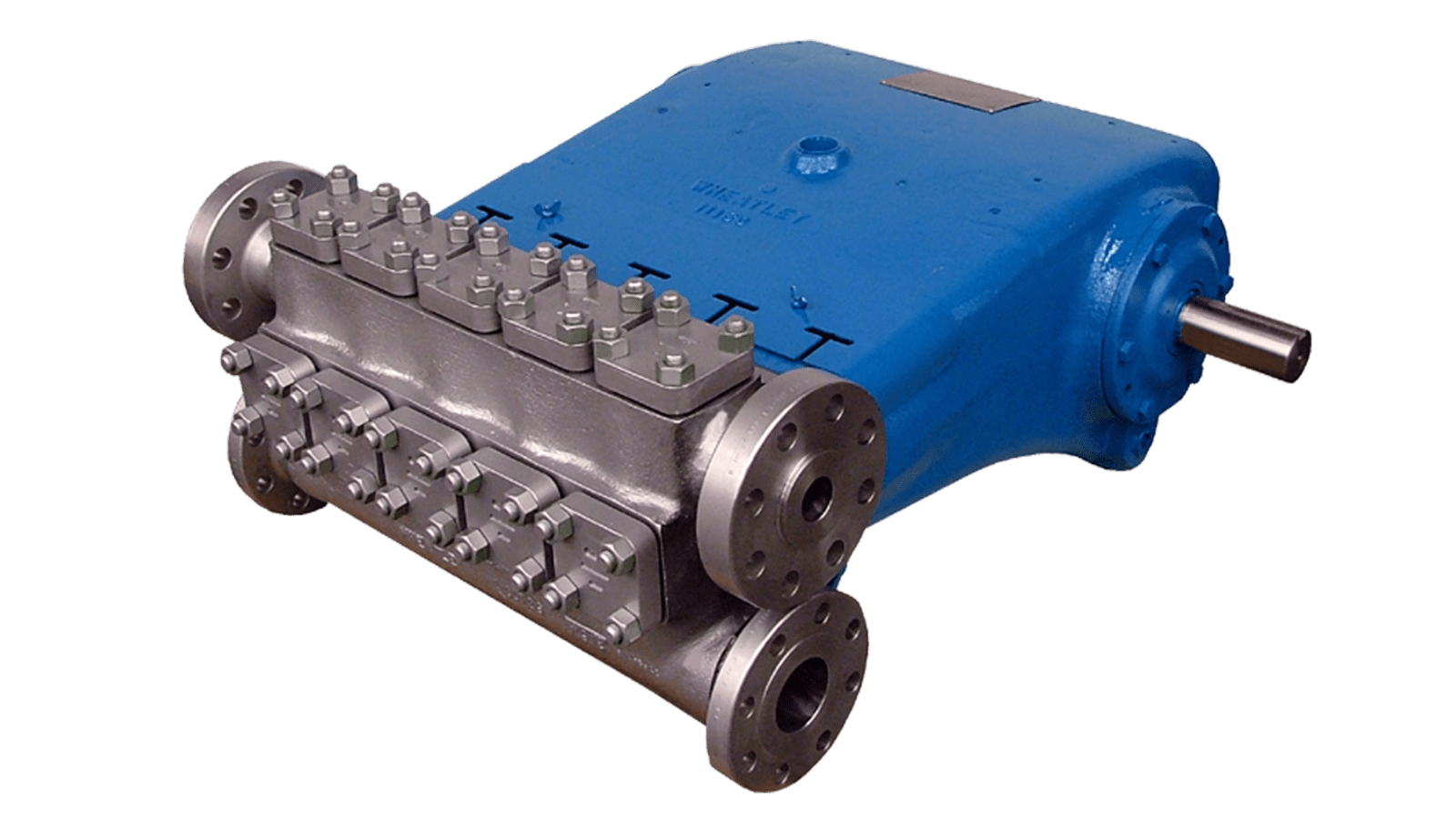

By offsetting the crankshaft Wheatley engineers have reduced vertical thurst loads by more than 40 percent. Crankshaft vibration is virtually eliminated. Friction, heat and wear are significantly reduced.

Wheatley pumps feature a low profile power end making them particularly suitable for close-quarter applications. Wheatley power frames are manufactured from close-grained, one-piece castings. They are precision-bored to provide dimensional stability and matched alignment of the stuffing box, wiper box, crosshead, pony rod and plunger.

We have simplified the alignment of the high-capacity tapered roller bearing to allow for easy adjustment from outside the pump. Bearing housings are precision-machined and interchangeable.

To provide maximum versatility, plungers are available in several high quality materials. For the ultimate in plunger surface hardness, the exclusive Weataloy™ plunger is made from a stainless steel body coated with a special nickel alloy. Other available materials are chrome oxide, and, for maximum corrosion resistance, solid ceramic plungers.

At Wheatley.com, we supply our customers with the hard-to-find plungers, pistons, packing, valves, connecting rods and bearings they can"t track down on their own. We serve national and international customers alike, and our business can be counted on for fast shipping and friendly assistance.

IEQ is an OEM supplier of the Wheatley 535/545 Pump. Let the friendly customer service staff at IEQ Industries help you find the Wheatley Pump you need.

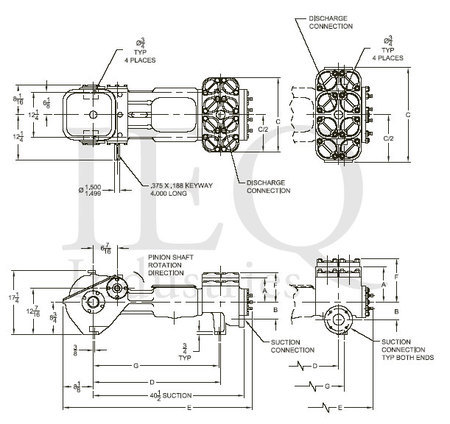

RPM shown is Crankshaft speed. For Pinion Shaft speed, multiply RPM by Gear Ratio. Volumetric Rate is based on 100% Volumetric Efficiency. Brake Horsepower/Kilowatts Required is based on 85% Mechanical Efficiency.

Adjust or replace these bearings at first sign of wear. The bearings in the crank end are babbitt lined steel shells, adjustable for wear by removing shims and easily replaced when completely worn. These bearings should be watched closely and adjusted at first signs of looseness.. You will note on series 3400, 3800, 3500, and 3900 pumps, that the shims do not completely fill the outer gap between rod and cap casting, although the connecting rod bolts are tight. This is because the faces of the shell bearings project slightly beyond the faces of the rod and cap castings, and the shims are gripped only between the faces of the bearing halves. Do not try to close this outer gap by tightening the connecting rod bolt as it will put an excessive strain on the bolts.

To check for wear, place a wrench on the top connecting rod bolt and shake the rod parallel to the crankshaft. (The pressure must be relieved from the liquid end of the pump, so that the pump"s mechanism is free to move.) If the rod bearing moves without resistance, the bearing may be too loose and need adjusting. If the bearing does need adjusting, remove shims until you cannot shake the rod, then add .005" shims one at a time until there is little side movement. Be sure to torque rod bolt nuts to proper value for each adjustment. Oil clearance should be checked with Plastigage (available in most parts stores). Wipe crankshaft journal clean of any oil, place a strip of Plastigage on the crankshaft journal and tighten rod cap to the proper torque value. Once tightened, remove rod cap and measure oil clearance with scale on Plastigage package. See oil clearance chart. (NOTE: If you are making this adjustment after having had the crossheads out, be sure that the oil holes in the rod are pointing up. The "up" side is indicated by matching numbers stamped on the cap and rod at the split between them. These numbers should be the same on each rod and should be on the top side of the crankshaft.) Rotate the shaft by hand and if there is any hard drag or tight spots in the bearing, add another 0.005" shim. After this bearing is properly adjusted, loosen bolts a few turns and repeat the above operation on the other bearings. After all bearings have been adjusted.

Torque all connecting rod bolt nuts back to proper value. Again rotate the pump by hand to check for excessive drag and tight spots. If none, the pump should be ready for operation.

If the pump cannot be rotated by hand due to the drive being enclosed, care must-be taken: not to over-tighten the bearings, since they cannot be checked by rotating the pump. When bearings are adjusted by this method, watch carefully for overheating when the pump is put into operation.

It is usually better to have a bearing a little too loose than too tight. A slightly loose bearing will cause very little trouble because of the slow operating speeds of the pump, but a tight bearing will overheat and the babbitt may melt or pull. Normal precautions must be taken to insure cleanliness of parts upon their assembly.

Inspect connecting rod bearings and adjust as necessary every six months or when crankcase lubricant is changed. The bearings in the crank end are babbitt lined steel shells, adjustable for wear by removing shims and easily replaced when completely worn. These bearings should be watched closely and adjusted to compensate for wear. You will note that shims do not completely fill the outer gap between rod and cap casting although the connecting rod bolts are tight. This is because the faces of the shell bearings project slightly beyond the faces of the rod and cap castings and the shims are gripped only between the faces of the bearing halves. Do not try to close this outer gap by tightening the connecting rod bolt as it will put an excessive strain on them.

To check for wear, place a wrench on the top connecting rod bolt and shake the rod parallel to the crankshaft. (The pressure must be relieved from the liquid end of the pump so that the pump"s mechanism is free to move.) If the rod bearing moves without resistance, the bearing may be too loose and need adjusting. If the bearing does need adjusting, remove shims until you cannot shake the rod, then add .005" shims one at a time until there is a little side movement. Be sure to torque rod bolt nuts to proper value for each adjustment. (NOTE: If you are making this adjustment after having had the crossheads out, be sure that the oil holes in the rod are pointing up. The "up" side is indicated by matching numbers stamped on the cap and rod at the split between them. These numbers should be the same on each rod and should be on the top side of the crankshaft.) Turn the shaft by hand and if there is any hard drag or tight spots in the bearing, add another .005"" shim. After this bearing is properly adjusted, loosen bolts a few turns and repeat the above operation on the other bearings. After all bearings have been adjusted, torque all connecting rod bolt nuts back to proper amount. Again turn the pump by hand to check for excessive drag and tight spots. If none, the pump should then be ready for operation.

If the pump cannot be rotated by hand due to the drive being enclosed, the bearings may be completely adjusted by shaking the bearing on the shaft as stated above. Care must be taken not to over-tighten the bearings since they cannot be checked by rotating the pump by hand. When bearings are adjusted by this method, they must be watched carefully for overheating when the pump is put into operation.

Alternatively, plastic gauge strips, found in most parts stores may be used to adjust these bearings. It is usually better to have a bearing a little too loose than too tight. A slightly loose bearing will cause very little trouble because of the slow operating speeds of the pump, but a tight bearing will overheat and the babbitt may melt or pull. with experience, an operator can tell by feel when the bearings are properly adjusted. Normal precautions must be taken to insure cleanliness of parts upon their assembly. All wrenches used in adjusting these bearings are standard wrenches.

IEQ is an OEM supplier of the Wheatley T365 (59T-3) Pump. Let the friendly customer service staff at IEQ Industries help you find the GASO Pump and Parts you need.

It"s imperative that you select the right pump for your business needs. Asking yourself the right questions is key to proper pump selection, as there are many different Wheatley and GASO pumps available. Choosing a pump that lacks the proper operating capabilities will prove a waste of your company"s time and money.

Before you purchase a Wheatley or GASO pump, there are a few technical questions that should be answered. For instance, you"ll need to determine how much horsepower you"ll need in a pump. Use this simple equation--gallons per minute multiplied by operating pressure, divided by 1500--to help you narrow down the number of Wheatley and GASO pumps that should be considered for purchase.

Call our customer service department at 1.800.544.9053 to speak with a friendly and efficient representative of WheatleyPump.com. Once we know a little more about your business, we can use our expert guidance to help you select the right Wheatley or GASO pump.

If you"ve already browsed our selection of Wheatley and GASO pumps and you know which pump you want, you can fill out our contact form to obtain a quote. You"ll find our prices are affordable, and our reputation for quality customer service is second to none. Quick turnaround times and fast shipping can also be expected, and you can even find replacement parts for discontinued Wheatley and GASO pumps in our inventory.

***DISCLAIMER*** Permian Pump & Power, LLC is not an authorized distributor, nor is affiliated in any way with National Oilwell L.P. ®, its parent company National Oilwell, Inc.®, Gardner Denver®, FMC®, Union®, Aplex®, Myers®, Kerr®, North American Electric, Inc.®, CoorsTek®, Status Flow, Inc.®, Weatherford®, Accelerated®, Dover®, Apergy®, or Mud King®. These trademarks are registered trademarks belonging to them or to their respective affiliates.

*Note: "Danco Pump & Supply Co. is not a licensee or in any way affiliated with National Oilwell L.P. or it"s parent Company National Oilwell, Inc. and that neither National Oilwell L.P. or it"s parent company National Oilwell Inc. endorses any of the products or services offered by Danco. "National Oilwell", "Gaso", "Wheatley", and "Emsco" are trademarks belonging to National-Oilwell L.P."

"Danco Pump & Supply Co. is not a licensee or in any way affiliated with Gardner-Denver® and Gardner-Denver® does not endorse any of the products or services offered by Danco. "Gardner-Denver®" and all of its pumps and parts are registered to Gardner-Denver®."

The Information provided in this website is for reference only. The reference of Gould’s, Griswold, Peerless, Flygt or any other OEM manufacturer is for reference only. Replicate Pump is not an authorized distributor of the parts or services for above OEMs products. Replicatepump.com offers aftermarket parts to replace above OEMs pumps and parts. Replicatepump.com also disclaims the information on this website is accurate for construction purpose. The dimension or specification shown in this website is for reference only.

Preferred Pump offers the best rewards program in the water well equipment industry. Check out our social media pictures to see what you"ve been missing!

We specialize in complete Wheatley restoration of internal wear parts Offering thermal spray coatings and specialty welding processes OD & IS Grinding & Machining To OEM Size.

Periodically we"ll inspect for wear, cracks and damage to critical components such as bearings, bull gear and pinion, conrods and crossheads. We"ll check the condition of your seals and other rubber goods and look for oil contamination. We"ll inspect your frame and ensure your pump is set up as per the manufacturer"s recommended tolerances, providing feedback and detailed reporting.

We keep your Wheatley mud pumps running in first class condition - providing onsite inspections, repairs and complete overhaul as well as all associated

Wheatley parts including the fluid end, power end, stuffing boxes, plungers, seals, bearings, diesel engines, and natural gas engines. We also have blasting and painting facilities as well as a machine shop. We have many years of experience rebuilding mud pumps

Where Wheatley overhaul is required we"ll take care of complete disassembly, cleaning and NDT. Repairs will be made to machined components as necessary. Bearings, seals and other components will be replaced in line with our inspections. Motors will be overhauled, lube systems serviced and pulsation dampeners recertified. We"ll also check your fluid ends are in spec and can repair or replace. Your pump is then fully reassembled and commissioned.

This website uses cookies to improve your experience while you navigate through the website. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are as essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may have an effect on your browsing experience.

8613371530291

8613371530291