wheatley mud pump parts manufacturer

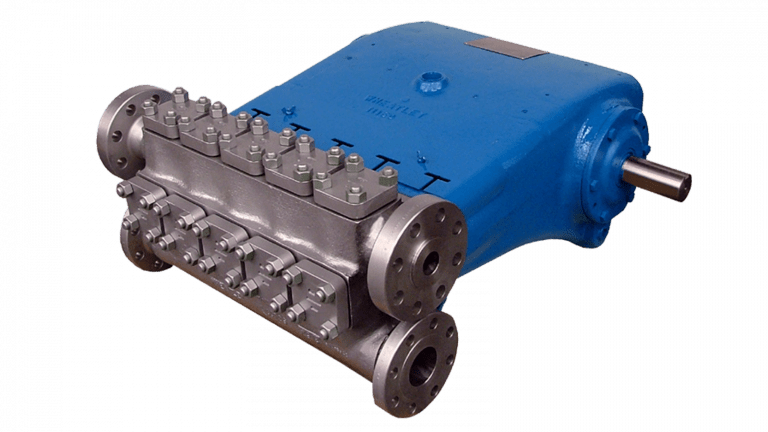

Wheatley Pump.com - Services all Duplex, Triplex and Quintuplex Plunger and Piston Pumps by Wheatley Pump and Frank Wheatley Inc. (FWI). We are your "one stop" source for all Wheatley pump needs - parts and service. We have all of the power end and fluid end parts for all Wheatley reciprocating plunger and piston pumps, both current and obsolete. We specialize in Wheatley Pumps; new, used and reconditioned pumps and remanufactured.

We hope that this web-site is helpful to you in keeping your Wheatley pump in good working order by giving you the technical tools you need to have. A list of parts and services is provided below for your convenience.

Adjust or replace these bearings at first sign of wear. The bearings in the crank end are babbitt lined steel shells, adjustable for wear by removing shims and easily replaced when completely worn. These bearings should be watched closely and adjusted at first signs of looseness.. You will note on series 3400, 3800, 3500, and 3900 pumps, that the shims do not completely fill the outer gap between rod and cap casting, although the connecting rod bolts are tight. This is because the faces of the shell bearings project slightly beyond the faces of the rod and cap castings, and the shims are gripped only between the faces of the bearing halves. Do not try to close this outer gap by tightening the connecting rod bolt as it will put an excessive strain on the bolts.

To check for wear, place a wrench on the top connecting rod bolt and shake the rod parallel to the crankshaft. (The pressure must be relieved from the liquid end of the pump, so that the pump"s mechanism is free to move.) If the rod bearing moves without resistance, the bearing may be too loose and need adjusting. If the bearing does need adjusting, remove shims until you cannot shake the rod, then add .005" shims one at a time until there is little side movement. Be sure to torque rod bolt nuts to proper value for each adjustment. Oil clearance should be checked with Plastigage (available in most parts stores). Wipe crankshaft journal clean of any oil, place a strip of Plastigage on the crankshaft journal and tighten rod cap to the proper torque value. Once tightened, remove rod cap and measure oil clearance with scale on Plastigage package. See oil clearance chart. (NOTE: If you are making this adjustment after having had the crossheads out, be sure that the oil holes in the rod are pointing up. The "up" side is indicated by matching numbers stamped on the cap and rod at the split between them. These numbers should be the same on each rod and should be on the top side of the crankshaft.) Rotate the shaft by hand and if there is any hard drag or tight spots in the bearing, add another 0.005" shim. After this bearing is properly adjusted, loosen bolts a few turns and repeat the above operation on the other bearings. After all bearings have been adjusted.

Torque all connecting rod bolt nuts back to proper value. Again rotate the pump by hand to check for excessive drag and tight spots. If none, the pump should be ready for operation.

If the pump cannot be rotated by hand due to the drive being enclosed, care must-be taken: not to over-tighten the bearings, since they cannot be checked by rotating the pump. When bearings are adjusted by this method, watch carefully for overheating when the pump is put into operation.

It is usually better to have a bearing a little too loose than too tight. A slightly loose bearing will cause very little trouble because of the slow operating speeds of the pump, but a tight bearing will overheat and the babbitt may melt or pull. Normal precautions must be taken to insure cleanliness of parts upon their assembly.

To check for wear, place a wrench on the top connecting rod bolt and shake the rod parallel to the crankshaft. (The pressure must be relieved from the liquid end of the pump so that the pump"s mechanism is free to move.) If the rod bearing moves without resistance, the bearing may be too loose and need adjusting. If the bearing does need adjusting, remove shims until you cannot shake the rod, then add .005" shims one at a time until there is a little side movement. Be sure to torque rod bolt nuts to proper value for each adjustment. (NOTE: If you are making this adjustment after having had the crossheads out, be sure that the oil holes in the rod are pointing up. The "up" side is indicated by matching numbers stamped on the cap and rod at the split between them. These numbers should be the same on each rod and should be on the top side of the crankshaft.) Turn the shaft by hand and if there is any hard drag or tight spots in the bearing, add another .005"" shim. After this bearing is properly adjusted, loosen bolts a few turns and repeat the above operation on the other bearings. After all bearings have been adjusted, torque all connecting rod bolt nuts back to proper amount. Again turn the pump by hand to check for excessive drag and tight spots. If none, the pump should then be ready for operation.

If the pump cannot be rotated by hand due to the drive being enclosed, the bearings may be completely adjusted by shaking the bearing on the shaft as stated above. Care must be taken not to over-tighten the bearings since they cannot be checked by rotating the pump by hand. When bearings are adjusted by this method, they must be watched carefully for overheating when the pump is put into operation.

Alternatively, plastic gauge strips, found in most parts stores may be used to adjust these bearings. It is usually better to have a bearing a little too loose than too tight. A slightly loose bearing will cause very little trouble because of the slow operating speeds of the pump, but a tight bearing will overheat and the babbitt may melt or pull. with experience, an operator can tell by feel when the bearings are properly adjusted. Normal precautions must be taken to insure cleanliness of parts upon their assembly. All wrenches used in adjusting these bearings are standard wrenches.

Wheatley engineering is supported by exact manufacturing processes. It is this commitment to quality that has made Wheatley plunger and piston pumps the most sought-after solutions for flow control problems. When you need a highly efficient reciprocating pump from 6 to 1800 horsepower, Our team delivers. Day after day… year after year.

Are you trying to navigate your way through the hundreds of different Wheatley pump parts on the market? Thanks to the variety of current and discontinued items, it can difficult to pinpoint exactly which parts you need to repair your pump. Don"t worry, IEQ Industries can help. Our online company offers parts and services for new, remanufactured and used Wheatley pumps. We also stock parts and pieces for Wheatley pumps that have been discontinued. Whatever it is you need, IEQ Industries is your number-one resource.

If you"re not sure which parts your Wheatley pump requires, our friendly customer service representatives will be happy to assist you. We work with customers all over the world, walking them through the process of reviewing their pumps to ensure the correct replacement parts are ordered. We understand that replacing a non-working pump is never ideal. Replacing a few of its parts is usually all it takes.

Should you already know which Wheatley pump parts you need, navigating our website to order plungers, valves or connecting rods is a cinch. If you want a price quote, simply head over to the "Get a Quote" option. Fill out the contact form to get more information or simply contact our customer service department at 1.800.544.9053.

At IEQ Industries, we"re not happy until you"re happy. More accurately put, we"re not happy until you have the parts you need to get your used or discontinued pump back into working order. Work with the company that cares--work with WheatleyPump.com.

*Note: "Danco Pump & Supply Co. is not a licensee or in any way affiliated with National Oilwell L.P. or it"s parent Company National Oilwell, Inc. and that neither National Oilwell L.P. or it"s parent company National Oilwell Inc. endorses any of the products or services offered by Danco. "National Oilwell", "Gaso", "Wheatley", and "Emsco" are trademarks belonging to National-Oilwell L.P."

"Danco Pump & Supply Co. is not a licensee or in any way affiliated with Gardner-Denver® and Gardner-Denver® does not endorse any of the products or services offered by Danco. "Gardner-Denver®" and all of its pumps and parts are registered to Gardner-Denver®."

We specialize in complete Wheatley restoration of internal wear parts Offering thermal spray coatings and specialty welding processes OD & IS Grinding & Machining To OEM Size.

Periodically we"ll inspect for wear, cracks and damage to critical components such as bearings, bull gear and pinion, conrods and crossheads. We"ll check the condition of your seals and other rubber goods and look for oil contamination. We"ll inspect your frame and ensure your pump is set up as per the manufacturer"s recommended tolerances, providing feedback and detailed reporting.

We keep your Wheatley mud pumps running in first class condition - providing onsite inspections, repairs and complete overhaul as well as all associated

Wheatley parts including the fluid end, power end, stuffing boxes, plungers, seals, bearings, diesel engines, and natural gas engines. We also have blasting and painting facilities as well as a machine shop. We have many years of experience rebuilding mud pumps

Where Wheatley overhaul is required we"ll take care of complete disassembly, cleaning and NDT. Repairs will be made to machined components as necessary. Bearings, seals and other components will be replaced in line with our inspections. Motors will be overhauled, lube systems serviced and pulsation dampeners recertified. We"ll also check your fluid ends are in spec and can repair or replace. Your pump is then fully reassembled and commissioned.

IEQ is an OEM supplier of the Wheatley T225 (32T-2) Pump. Let the friendly customer service staff at IEQ Industries help you find the GASO Pump and Parts you need.

We specialize in complete Wheatley restoration of internal wear parts Offering thermal spray coatings and specialty welding processes OD & IS Grinding & Machining To OEM Size.

Periodically we"ll inspect for wear, cracks and damage to critical components such as bearings, bull gear and pinion, conrods and crossheads. We"ll check the condition of your seals and other rubber goods and look for oil contamination. We"ll inspect your frame and ensure your pump is set up as per the manufacturer"s recommended tolerances, providing feedback and detailed reporting.

We keep your Wheatley mud pumps running in first class condition - providing onsite inspections, repairs and complete overhaul as well as all associated

Wheatley parts including the fluid end, power end, stuffing boxes, plungers, seals, bearings, diesel engines, and natural gas engines. We also have blasting and painting facilities as well as a machine shop. We have many years of experience rebuilding mud pumps

Where Wheatley overhaul is required we"ll take care of complete disassembly, cleaning and NDT. Repairs will be made to machined components as necessary. Bearings, seals and other components will be replaced in line with our inspections. Motors will be overhauled, lube systems serviced and pulsation dampeners recertified. We"ll also check your fluid ends are in spec and can repair or replace. Your pump is then fully reassembled and commissioned.

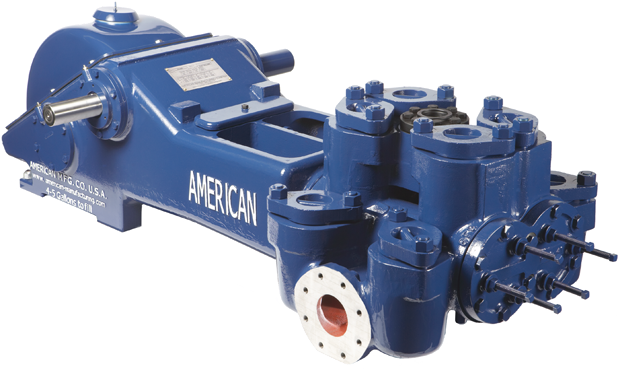

American Mfg Company is a quality manufacturer of replacement parts for the wide variety of mud pumps, centrifugal pumps, rig parts, and swivel parts found on the World market today.

American Mfg Company Pumps And Parts carry over $5,000,000 of interchangeable mud pumps parts, centrifugal pump parts, rig parts and swivel parts in stock for all major manufacturers such as Gardner Denver, Failing, Wheatley, National, Emsco, Ideco and Opi, as well as OE AM pumps.

Lubrication. All power and parts including gears, cross heads, connecting rod bearings, crankshaft bearings and pinion crank shaft bearings, are lubricated

Power Frame. Alloys stocked are Molybdenum’s cast iron and cast steel. Fluid ounce can be trimmed out for pumping various liquids. Ductile iron can be

Liners. All pumps are available with interchangeable pipe liners. Standard materials available are Molybdenums alloyed iron, file hard steel and special

Stuffing Box Lubrication. Furnished by use of regulated flow of oil from a force-feed lubricate or mounted on the pump, with a separate oil line to each

WheatleyGaso.com is your resource for Gaso pumps, Gaso pump parts and a supplier of ORIGINAL GASO PARTS and equipment, new used and remanufactured Wheatley, GASO and

Since 1987, FSI Canton, LLC, has been a distributor / representative for pump and filtration equipment serving the industrial, Oil & Gas, Mining, Pulp & Paper, Municipal, and Power markets in Ohio.

Ideal for applications where high discharge pressures are required, Wheatley Gaso plunger pumps are ideal. These positive displacement plunger pumps can be supplied in simplex (single plunger) up to quintuplex (5 plungers) to cover a wide range of applications needs, including fluid injection, crude oil disposal, and any other applications where high discharge pressures are required. The proven design of the Wheatley Gaso pump is known world wide and used in many critical applications.

Process Pumps has been selecting, designing, and servicing Wheatley Gaso pumps for decades, supplied into refinery applications such as gas scrubbers, glycol injection systems and numerous other applications, we have a wealth of experience in selecting the right pump for your requirements. Our fabrication facilities allow us to complete the entire pump assembly to your specificiations.

Many Wheatley Gaso pumps comply to API674 (with exceptions) for refinery use, and their simple design and ease of servicability ensure that many years of trouble free running are certain, ideal for remote facilities where reliability is desired. Process Pumps is also able to supply all your spare parts needs and can even arrange on site service visits if preferred.

8613371530291

8613371530291