wirth mud pump manual in stock

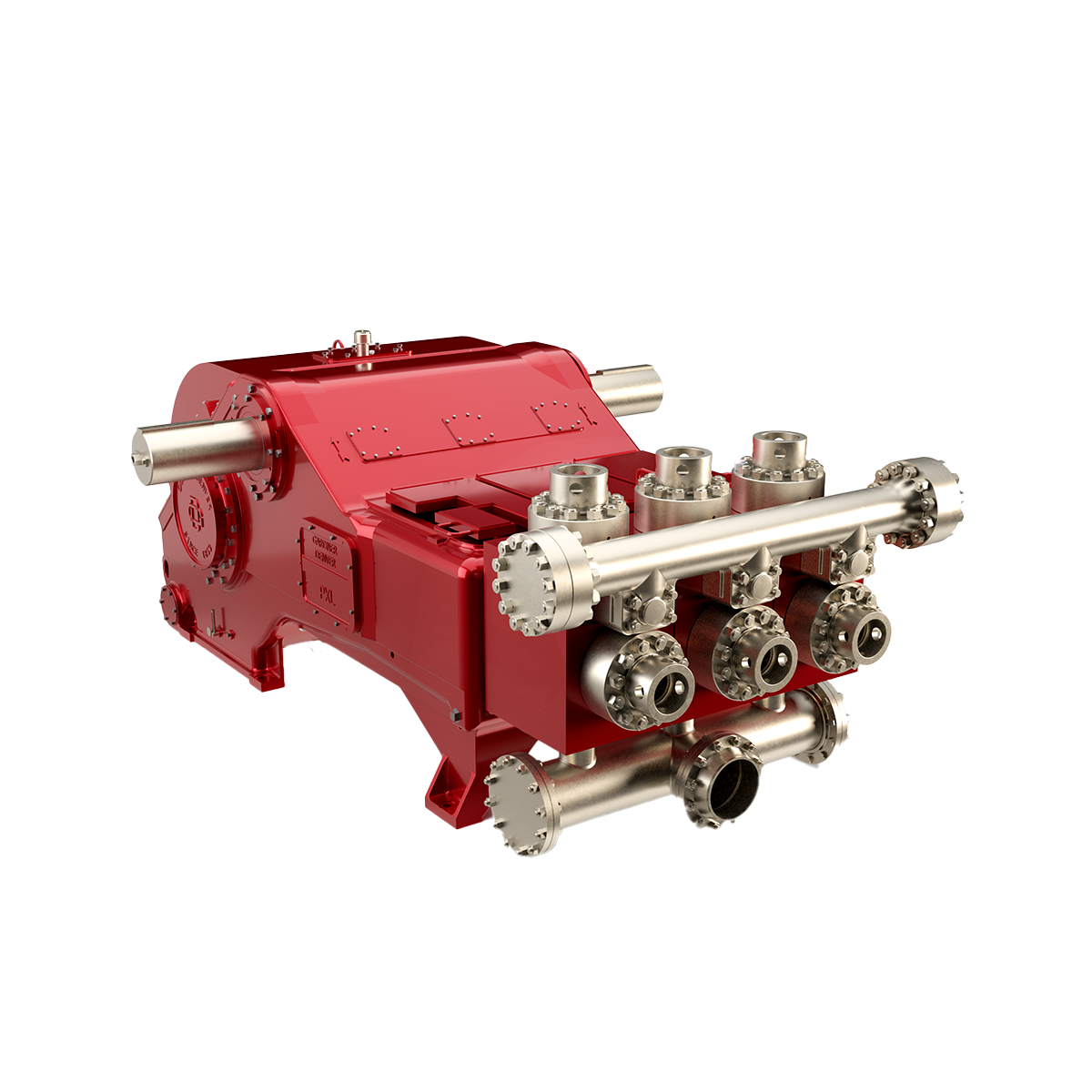

The NOV 12-P-160 Mud Pumps includes (3) Three New National 12-P-160 Triplex Mud Pumps 1600 HP, 7-1/4″ bore x 12″ stroke, single acting. 5000 PSI fluid ends. 1600 HP Bare Mud Pumps are currently configured for Offshore Service. The NOV 12-P-160 Mud Pumps are located in Houston and ready to be unitized for service.

Forged Steel crankshaft, Individual forged steel two piece interchangeable standard modules, 6-1/2” mission fluid king liners, Standard polyurethane valves and seats, Two piece fast change piston rods, Supreme pistons, Metal to metal liner retention, Clamp type liner and piston rod connections, Fast change valve covers standard, Piston liner lubricant spray system, Liner spray pump, Power end lube system with filter. Mounted on Integral two runner skid, Suction Manifold with vertical suction stabilizer, Suction line pressure relief valve, set for 70 PSI

Includes: motor supports, motor frame, tensioning screws, 2 V-belt guards, 2 pump Sheaves, 2 motor sheaves, banded V-belts, Holes to be drilled to accept EDM D79 Or GE-752 Traction Motors

National Oilwell Varco (NOV) is an American multinational corporation based in Houston, Texas. It is a leading worldwide provider of equipment and components used in oil and gas drilling and production operations, oilfield services, and supply chain integration services to the upstream oil and gas industry. The company conducts operations in more than 600 locations across six continents, operating through three reporting segments: Rig Technologies, Wellbore Technologies, and Completion & Production Solutions. National Oilwell’s two main predecessors, Oilwell Supply and National Supply, were founded in 1862 and 1893, respectively. These two companies manufactured and distributed pumps and derricks.

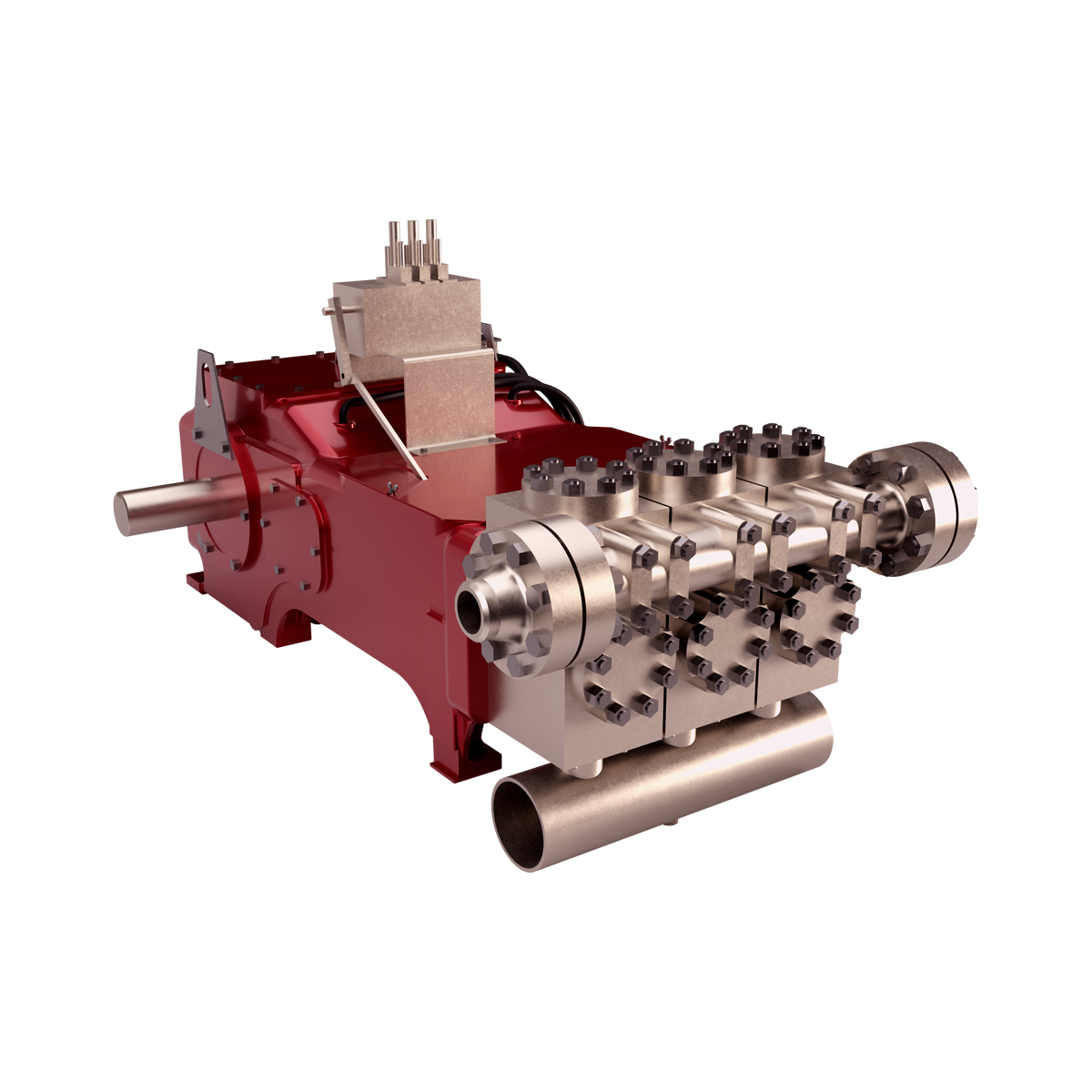

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

We carry mud pumps, connecting rods, and more than 2,000 drawings and blueprints of oilfield equipment and supplies. We can fill your orders with one-of-a-kind designs for:

Our vast inventory of fluid-end and gear-end parts for duplex pumps includes more than 500 duplex liners, as well as cages and stuffing boxes. If you can’t find the model you are looking for below, let us find it for you.

We carry more than 1,500 duplex piston rods and 200 duplex pony rods in our inventory. Though we keep in stock connecting rods primarily for GA550 and GA750 models, other options are available, including custom connecting rods for most duplex and triplex mud pumps.

We now offer crossheads and guides for both EMSCO D-375 and DB-550 duplex pumps. We also have slides and shoes for certain models. If you don’t see a part you need, let us find it for you.

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Mud-Pump Gear Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

Drilling consumables such as mud pump systems and their components can drastically increase your uptime while reducing costs and health/safety/environmental (HSE) risks. To support your drilling needs, Forum’s patented P-Quip® mud pump system offers a single-source solution that integrates high-quality fluid end components for maximum longevity and performance.

With more than 20 years of successful operation in severe environments, P-Quip offers a proven track record for the lowest cost of ownership in the industry. As part of our commitment to quality, our mud pump parts use patented Banded Bore™ technology that significantly reduces stress concentrations and leads to longer module life.

One of Forum’s most committed core values is that “no one gets hurt,” and the P-Quip system is designed to support that principle. Streamlined and easy to use, it reduces or eliminates the need for manual force during maintenance, shrinking the time needed to replace high-use components and minimizing safety risks.

You are viewing three (3) fully reconditioned National Oilwell 12P160 Triplex Mud Pumps for sale by Pickett Oilfield, LLC. These National 12-P-160 Mud Pumps are Rebuilt and Ready to go to work.

Some refurbishments include: Fully reconditioned mud pump assembly. Pinion shaft assembly complete with new SKF bearings and new seals. Pump internals painted with Oil Resistant 2 Part epoxy Jotun Tank guard. MPI inspection of all critical areas of pump frame. MPI of all load path components of Crankshaft and Pinion shaft assemblies, and all new Southwest Premium “L” Shape 6,000 psi Fluid End Modules. A full Data Pack with all dimensional control & MPI reports will be furnished.

Warranty on National 12-P-160 Triplex Mud Pumps: All new parts fitted come with a 12 month warranty or such as offered by the part manufacturer; The refurbished GE-752 traction motors come with an 18 month warranty.

Pickett Oilfield, LLC offers prospective buyers an extensive selection of quality new, used, and refurbished Oilfield Drilling Equipment at competitive prices, including Triplex Mud pumps.

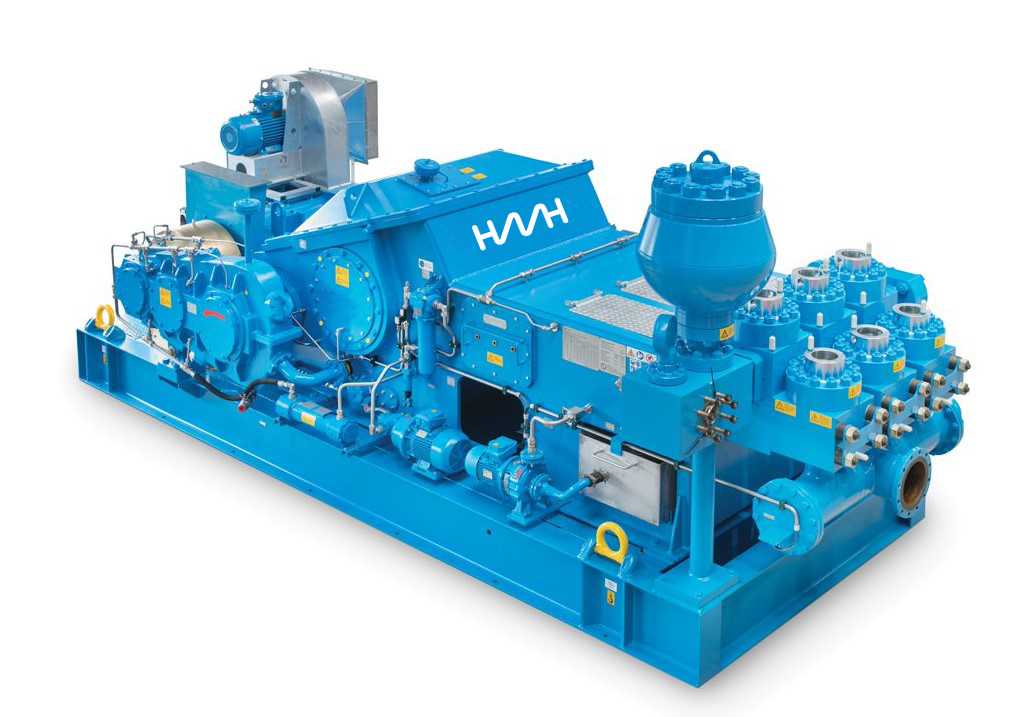

MHWirth provides global drilling lifecycle services (DLS) to all drilling equip-ment and systems customers around the world. Uninterrupted installation,commissioning and operation are essential benefits for our customers due tofinancial gains. Besides training, personnel for installation and commission-ing, and providing support throughout the operational phase, the supply ofspare parts is a vital part of our service.

We are a professional provider of OEM (Original Equip- With DLS offices and warehouses situated in local hubs,ment Manufacturer) parts with a vision to be the pre- we are always close to your project. Our experiencedferred partner for the supply of spare parts. We guaran- Service Account Managers are ready and available totee our customers the constant availability of all critical support you in resolving any difficulties that may occurreplacement parts and delivery within 24 hours – and of – if need be within a matter of hours – anywhere in thecourse all our delivered components come with a com- world.prehensive performance guarantee. Mud pump consumables

Fluid ends manufactured both from carbon steel and The valve chambers have been designed to complystainless steel as alternative material have a very posi- with the requirements for valve installation according totive impact on the lifecycle costs for triplex pumps API specification 7K.operating under difficult conditions. The stainless steelmodules have a lifespan that exceeds the general two- Inlet and outlet valve bonnets, and all of the componentyear lifespan associated with carbon steel modules. parts therein, are identical and can be easily inter-Consequently, they are economically viable, but are changed. Valve bonnets incorporate a hydraulically-op-depending on various parameters out of the operating erated bolt-tensioning system, which permits the rapidconditions. and safe removal of internal elements.

1 Only suitable for TPK 800 – 1000 to serial no. 46 | 2 Only suitable for TPK 1300-1600 from serial no. 47 to serial no. 57Mud pump consumables

We offer fluid end parts and consumables suitable for various types of mudpumps for each individual application. The hydraulic quick release systemguarantees low downtimes when replacing fluid end parts, and ensures thehighest possible degree of safety (HSE).

We offer two types of mud pump liners. They are de- gally-cast high-chrome sleeves for a greater hardness.signed to be highly durable for operating pressures of A retaining lip at the rear of the liner helps to maintainup to 7 500 psi. the internal chrome/iron wear sleeve and protects against the high pressures encountered in today’sPremium chrome liners market applications. Production with computer-con-We offer high chrome-plated liners for the triplex mud trolled machining ensures tighter tolerances and con-pumps. All liners have forged-steel external hulls, sistent durability and value. The liner is set to matchwhich provide resistance to hoop stress, and centrifu- the pressure rating of the pump for each liner size.

Premium chrome liners Zirconia liners Mud pump consumables

Zirconia liners The improved wear properties directly results in anZirconia liners are commonly used with MHWirth TPK extended service life for the sleeve, while the improvedseries mud pumps. These liners do not produce ID impact strength leads to a reduction in the significantridges which are common in high-chrome liners. ID costs for the replacement of broken liners in the field.ridges are a cause of piston failure. Zirconia sleeves As a consequence of the finer surface finish, there isare much harder than chrome sleeves and are also less friction with the elastomer-metal pump pistons,more durable, resulting in reduced rig downtimes and which in turn ensures an extended piston life andlower ownership costs. The liners are available in sizes reduced pump-cooling requirements.ranging from 4 ½’’ to 7’’. With a zirconia liner, less maintenance at the pumpRegarding its properties, zirconia has three important is required, due to the extended service life achievedadvantages compared other premium liners: for both pistons and liners, consequently leading to a Better impact strength¡ safer environment. Harder¡ Finer surface¡ Zirconia ceramic liners have been proven to be the most cost-effective liners in use in the industry today. These liners offer the consistent quality needed for reliable pump performance, improved safety, and cost savings.

Premium chrome liners Zirconia liners Mud pump consumables

Our different types of mud pump pistons are suitable Seal designfor various applications. Our pistons are designed to This piston uses a guide belt to help direct the pistondeliver maximum performance under almost all drilling into the liner while reducing the wear on the piston rub-conditions. The pistons have sizes ranging from 4 ½” to ber. With the guide belt, small degrees of misalignment7 ½” and are used with all MHWirth mud pump types. can be compensated for and a proper fit in the liner isThey are fully interchangeable with other API-compatible ensured.pistons. The most common piston types recommendedby us are described below; additional alternatives areavailable upon request. Stingray piston These pistons are designed to resist wear and abrasionStandard black piston with guide belt in service applications involving high pressures and non-These pistons are designed to resist wear and abrasion aqueous mud systems.in medium service applications involving water-basedmud environments. Applications All drilling applications featuring any type of synthetic ¡ Applications and oil-based drilling mud (OBM) All drilling applications featuring water-based drilling¡ Can withstand temperatures of up to 212 ° F (100 ° C) ¡ muds Operating pressure ranges from 1 000 psi to 7 500 psi ¡ Can withstand temperatures of up to 225 ° F (107 ° C)¡ One piston per open hole drilling section ¡ Operating pressure ranges from 1 000 psi to 7 500 psi¡ Stingray compoundBlack compound An improved ‘bull-nose’ lip design and urethane of ¡ The piston rubber is made from specially formulated the highest quality enable the stingray to significantlycompounds which are resistant to the effects of outperform the leading competition.heat, oil and water. A fabric-reinforced backing of Two different urethanes bonded together for superior ¡ the piston rubbers creates a wear-resistant seal. performance. All urethane pistons require adequateThe hub is formed from a high-grade steel to ensure cooling for optimum operation.high tensile strength and a long service life. 30 % more urethane compared to cup lip piston ¡ Bonded to hub for increased strength ¡ Cut-back hub protects liner ¡

Standard black piston Stingray piston Stingray HT extreme piston with guide belt Mud pump consumables

Seal design Stingray HT extreme compound Designed especially for triplex pumps to maximise¡ Superior design and high-temperature urethane of the ¡ performance highest quality enable the stingray HT to significantly Constant seal prevents any fluids being squirted by¡ outperform the leading competition piston Bonded dual hardness with 45 % more urethane com- ¡ Solid lip aids piston alignment in liner¡ pared to other pistons Superior abrasion resistance¡ Special additive to reduce friction between piston and ¡ liner. All urethane pistons require adequate cooling forStingray HT extreme piston optimum operation.These pistons are designed to resist wear and abrasion Enhanced chemical degradation resistance ¡ in service applications involving high temperatures and Premium urethane compounds with higher tensile ¡ non-aqueous mud systems. strength

Applications Seal design All drilling applications featuring any type of synthetic¡ Designed especially for triplex pumps to maximise ¡ & oil-based drilling mud (OBM) performance Can withstand temperatures of up to 300° F (148° C)¡ Constant seal prevents any fluids being squirted by ¡ Operating pressure ranges from 1 000 psi to 7 500 psi¡ piston One piston per open hole drilling section¡ Higher seal area moves piston hub away from liner ¡ Seal allows piston to run more concentrically in liner ¡

MHWirth offers a full range of valves and seats for triplex Cross web (CW) valvespumps. There are two different designs for valves and The cross web valve is made from carburised premiumseats which can be selected according to the specific alloy steel to resist wear, to provide an accurate seal,drilling conditions. and to protect against washout or damage to the pump. The original 3-web design allows a maximum flow areaFull open (FO) valves through the seat while providing a maximum seatingFull open valves enable uniform fluid end loading, lead- area for the valve. The body consists of a one-piece de-ing to a longer fluid end life. Virtually no warpage due to sign that contains the insert to the fullest extent with theheat treatment has been encountered because of very minimum use of the material. A patented polyurethanesmall insert extrusion gaps. The axisymmetric shape insert is equipped with a double angle (55 °) seal contactresults in nearly-uniform seat warpage. Serrations in the surface, which allows cylinder priming to be maintainedvalve insert groove lock insert in place, thereby reducing during pump shutdown.swelling of the insert in all environments. The valves are intended for all drilling operations withThe proven design minimises metal-to-metal bearing pressures of up to 7500 psi and a maximum operatingarea between valve and web seat with larger flows temperature of 300°F (149 ° C) for the cross web valveinvolved, increasing valve and seat lives. HT and 170°F (77 ° C) for the cross web valve. The large bearing area on the valve seat promotes a long serviceThe newly-developed insert compound has a tempera- life.ture rating of 300 °F (149 ° C) for the full open HT and160 ° F (71° C) for the full open valve. All are designed inaccordance with API 7K (styles # 6 and # 8).

Full open (FO) valve Cross web (CW) valve Mud pump consumables

Before any maintenance work is carried out, read the pump safety guidelines thoroughly and ¡ apply whenever applicable. Periodically review the information in the safety section with all persons who operate or work ¡ on the pumps.

WARNING! Wear safety harnesses, and ensure safe access is provided to all mud pump items which ¡ cannot be reached from floor/deck level.

Work on the mud pump may only be performed by physically, mentally and technically ¡ competent, duly authorised and certified personnel. Use the permit to work system (PTWS)! ¡ The work area must be adequately lit to assure sufficient all round vision. ¡ Hydraulic hand pump pressure gauges must be calibrated periodically. ¡ Maintain a good housekeeping regime during any service/repair on the mud pumps. ¡ Spare parts should always meet the technical requirements specified by the manufacturer. ¡ This is ensured when using MHWirth original spare parts. Ensure that adequate and suitable tools and equipment are available to perform all mainte- ¡ nance work. Mud pump consumables

CAUTION! Pump, motors, lubrication oil, pipe work and gearboxes may reach temperatures approach- ¡ ing 60°C during normal operation. Maintenance personnel shall be made aware of this and sufficient cooling off time shall be allowed before commencing work on hot parts.

WARNING! Stop and isolate the mud pump from all sources of hydraulic energy and the electrical power ¡ supply as per the operator’s lock out procedure. The pump must be completely depressurised before attempting any work on the fluid end or ¡ piston and liner assemblies. Bursting bladder of pre-charged suction and discharge dampener may cause serious injury ¡ to personnel and damage to equipment. Jets and leaks from high pressure oil may be fatal. Ensure the system is switched off, ¡ depressurised and locked out before any work is performed on the mud pump.

Use only adaptors and reduction pieces which have been approved by RK Kutting. ¡ The lines must be inspected at regular intervals. ¡ Before each installation, the hoses must be inspected for damage, kinks, wear, corrosion, ¡ cracks and other kinds of damage. It is absolutely essential to replace damaged hoses immediately. ¡ Use only hoses with a known working pressure. ¡ To extend the service life of the hose, use only clean media. ¡ If a malfunction is suspected, immediately shut down the product or machine in which the- ¡ hose is installed andreplace the hose. The maximum permitted operating pressure is determined by the weakest element in the ¡ installation.Mud pump consumables

Picture Description Part no All tools in our standard tool package are supplied in an aluminium box, except the piston assembly tool Fig 10 1 Liner puller 11002584 which is mounted to the pump frame local to the fluid end. 1 Fig 11 1 Valve cover puller 11012412 The size of the aluminium box is: L x W x H 1 200 mm x 800 mm x 500 mm Fig 12 1 High pressure hydraulic pump 10234283

Used for pulling the cylinder liners clear of the Used for removing the valve covers on the discharge fluid end. valve housing and the suction valve housings. Mud pump consumables

Fig 12: hydraulic pump Fig 13: hydraulic tool for suction valve Part no: 10234283 housing Part no: 11002814 The hand pump is used to pressurise the various stud tensioning devices used during regular maintenance Four hydraulic tensioning nuts and one hydraulic and for expelling the valve seat. It is also used to break manifold is used to tension the studs that fasten the taper lock on some bearings. the suction valve housing to the discharge valve housing.

This is used to turn the jacking screw as part of the This is used in conjunction with the socket wrench hydraulic bolt tensioning procedure, used for installation for valve closure drawing (part no: 10234304), and and removal of the discharge and suction valve closures. used in conjunction with driveshaft turning in order The torque bar (part no: 11002706) from the standard to turn the driveshaft by hand during maintenance tools set is used in conjunction with this tool. procedures.Mud pump consumables

The pressure intensifier is used in conjunction with the Fig 23: Piston assembly tool hydraulic pump. It increases the pressure output of the Part no: 11019861 pump threefold to 3 000 bar (43 500 psi). It is used to expel the valve seats in the discharge valve housings The piston assembly tool is used to install and the suction valve housings. and de-install the piston on the piston rod. Mud pump consumables

Fig 24 1 Special wear ring pulling device 11004321 The special tools will reduce human work-load during regular standard maintenance activities and can be ordered upon request.Fig 25 1 Manual valve seat puller ”cross web“ 11023700

Fig 25: manual valve seat Fig 26: manual valve seat puller for “cross web” seats puller for “full open” seats Part no: 11023700 Part no: 11051795Mud pump consumables

Details concerning your spare parts order at a glance We want to make the process of ordering spare parts as simple as possible for you. Simply choose the type and size of your MHWirth mud pump from the table below and order the corresponding spare parts (using the part numbers) at www.myDrilling.com. If you need additional information or have further questions, please contact your local Service Account Manager.

Operating pressure: max. 5 bar Flow rate: 25 l/min Power supply: Compressed air 6 – max. 8,4 bar Weight approximately: 170 kg Mud pump consumables

Mechanical valve seat puller – – Wear ring puller 11004321 11031722 –API style # 6Hydraulic valve seat puller 210325413 – Liner puller 11041842 – Suitable from serial no. 17 upwardsAPI style # 6 3 Only for pumps which are equipped with hydraulic quick release systemMud pump consumables

3 Only for pumps which are equipped with hydraulic quick release system Mud pump consumables

3 Only for pumps which are equipped with hydraulic quick release system | 4 Only for “modification kit”Mud pump consumables

Amplifier for hydraulic puller 10234285 10234285 Liner puller 11002584 – TPK 1600 suitable from serial no. 58 upwards TPK 2000 suitable from serial no. 58 upwards 5 Only for p umps which are equipped with hydraulic quick release system Mud pump consumables

Mechanical valve seat puller 11051795 11023700 Wear ring puller 11004321 11004045 –API style # 8Hydraulic valve seat puller 10234283 3 10234283 3 Liner puller 10234300 – –API style # 8Amplifier for hydraulic puller 10234285 10234285 3 Only for pumps which are equipped with hydraulic quick release systemContact

Lokbatan District,Salyan Highway - 15th km Australia Contact InformationAZ1063 Baku 96 Raubers Road, Northgate spare.parts@mhwirth.comAzerbaijan 4013 Queensland marketing@mhwirth.com+994 12 5650 965 Australia mhwirth.com +61 7 3164 900

Global Operational Support Center Middle East 24/7 technical support for critical Level 20, Platinum Tower issues on operational rigs Jumeirah Lakes Towers +47 3805 7911 Dubai +47 9911 2000 United Arab Emirates 911support@mhwirth.com +971 4 550 6200

mhwirth.com © 2020 MHWirth 51000721.4-0920

8613371530291

8613371530291