4 shaft overshot manufacturer

This project was really popular when I posted it on Instagram, so I thought I would share it here also. It is a simple overshot pattern - with a twist. Also a great way to show off some special yarn. The yarn I used for my pattern was a skein of hand spun camel/silk blend. I wove the fabric on my Jack loom but you could also use your four or eight shaft loom.

Overshot is a weave structure where the weft threads jump over several warp threads at once, a supplementary weft creating patterns over a plain weave base. Overshot gained popularity in the turn of the 19th century (although its origins are a few hundred years earlier than that!). Coverlets (bed covers) were woven in Overshot with a cotton (or linen) plain weave base and a wool supplementary weft for the pattern. The plain weave base gave structure and durability and the woollen pattern thread gave warmth and colour/design. Designs were basic geometric designs that were handed down in families and as it was woven on a four shaft loom the Overshot patterns were accessible to many. In theory if you removed all the pattern threads form your Overshot you would have a structurally sound piece of plain weave fabric.

I was first drawn to Overshot many years ago when I saw what looked to me like "fragments" of Overshot in Sharon Aldermans "Mastering Weave Structures".

I wanted to use my handspun - but I only had a 100gms skein, I wanted to maximise the amount of fabric I could get using the 100gms. I thought about all the drafts I could use that would show off the weft and settled on overshot because this showcases the pattern yarn very nicely. I decided to weave it “fragmented” so I could make my handspun yarn go further. I chose a honeysuckle draft.

When doing the treadle tie-up I used 3 and 8 for my plain weave and started weaving from the left, treadle 3 - so you always know which treadle you are up to - shuttle on the left - treadle 3, shuttle on the right treadle 8. I then tied up the pattern on treadles 4,5,6 and 7. You can work in that order by repeating the sequence or you can mix it up and go from 4 to 7 and back to 4 again etc. You will easily see what the pattern is doing.

One interesting piece of information I learned is that overshot is a fairly modern term. Originally this type of weaving would have been referred to as floats or floatwork. It seems that many people are returning to this original terminology, though the weaving world has thus far shown little interest in making the change back. Personally, I like it. Floatwork sounds a bit less frenetic than overshot – as though I’m peacefully hitting my mark rather than missing it in a wild fashion.

Floatwork, formerly known as overshot which was originally known as floatwork, is a block design traditionally woven on four shafts where a heavier pattern yarn floats above a plain weave ground cloth and creates a raised pattern. Your plain weave background cloth is woven using a finer yarn in your warp and in every other weft pick (these weft picks being the ‘use tabby’ part of your pattern.)

This finer yarn is hidden in places by the thicker yarn floats, blended in places with the thicker yarn (as plain weave) creating areas that are shaded (referred to as halftone), and woven across itself to create delicate areas of plain weave. Most of us think of antique coverlets when we hear ‘overshot.’

Here is the thing about floatwork that really helped it to make sense for me. It is basically a twill weave. As Mary Black puts it, “An examination of an overshot draft shows it to be made up of a repetitive sequence of the 1 and 2, 2 and 3, 3 and 4, and 4 and 1 twill blocks”.

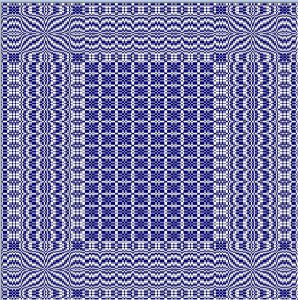

Let’s look at the pattern picks only. When weaving, your pattern blocks should overlap by one thread. This creates a pattern that flows from unit to unit instead of making a sharp step. It also means that the last thread of a given block is the first thread of the next block, and as you are initially threading your loom, your threads will move from odd shaft to even shaft.

Probably the trickier part of treadling is keeping track of where you are in the sequence. Like many traditional floatwork patterns, the pattern I used is meant to be woven tromp as writ or as drawn in. This means that your treadling is the same as your threading. So if your threading is 1-2-1-2-3-2-3-4, then your pattern picks are treadled 1-2-1-2-3-2-3-4. You will be throwing tabby picks after each pattern pick, so your actual treadling looks like (inthis example let’s consider your tabby picks to be ‘a’ and ‘b’) 1-a-2-b-1-a-2-b-3-a-2-b-3-a-4-b. If this looks a bit intimidating, don’t fret. At first it might feel that way, but the pattern really does start to make sense after you get going.

In the case of my draft, the threading sequence is 134 threads long. This is a lot to remember, but I used an index card to write out the sequence. I marked my place by sliding a second card down the pattern as I progressed, keeping it in place with a paperclip.

You can find it listed in the chapter or sub-chapter entitled ‘Notes on the Overshot Drafts.’ As someone who generally cheers on the underdog, I was drawn to this pattern without a name.

Atwater’s patterns are written for a sinking shed loom. For a rising shed loom, like the Baby Wolf I used, simply tie up the shafts left blank in the draft instead of the shafts she tells you to tie up. For all of her traditional floatwork patterns, including the pattern I used, this tie-up would be 3-4, 1-4, 1-2, 2-3. Your tabby tie up should be 1-3 and 2-4.

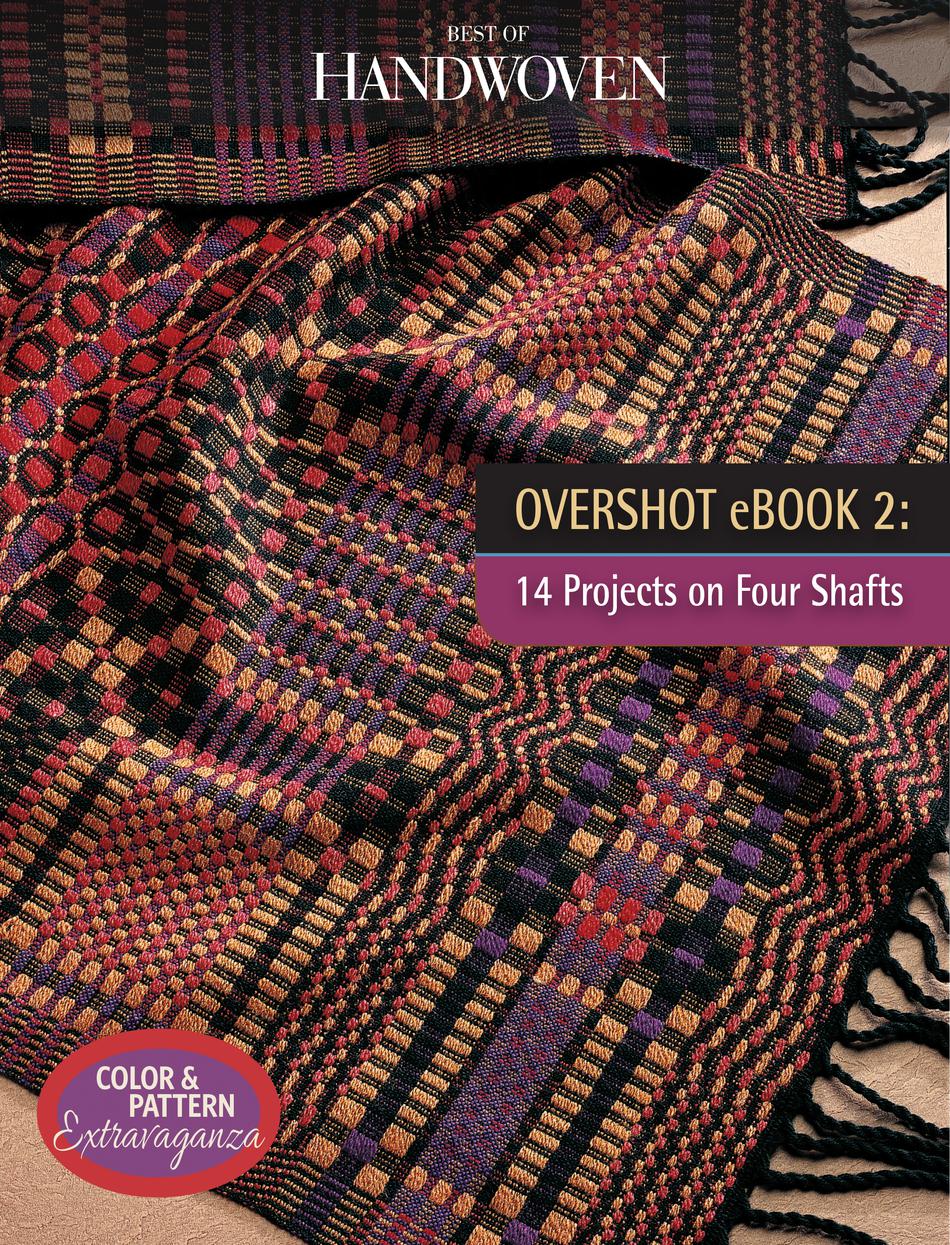

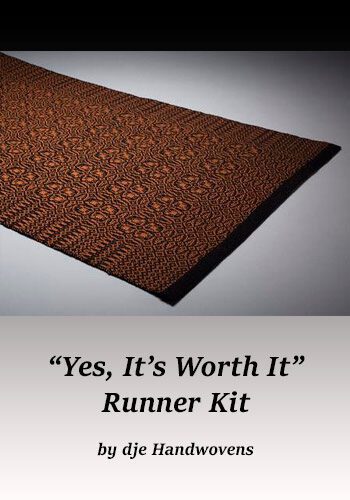

Here is a list of books and magazines that might be of interest if you’d like to learn more about floatwork/overshot. Many of these references include patterns in addition to thorough instructions.

The term overshot recalls coverlets woven on Early American barn frame looms dating back to the 1700’s. It is believed Europeans brought the weave structure to North America and fortunately weaving materials such as wool and cotton were readily available.

Susan invites you to spend two insightful days exploring one of her favorite weave structures. Her workshop creates multiple overshot samples serving as a ‘snapshot’ of overshot treadling sequences. Her goal is for each participant to enjoy learning the process of weaving “per block order” and understanding the benefits of doing so. This teaching method provides the groundwork for wider (on the loom) weaving projects once concepts are mastered.

Utilizing apre-wound8/2 cotton warp and tabby weft along with Borgs Fårö 6/1 for pattern weft, looms will be dressed prior to the workshop with an 8 1/2″ wide warp. Overshot treadlings such as Star and Rose will be explored in addition to Echo, On-Opposites, Petit Point, Lace Weave, Spetsväv, and Honeycomb.

As a bonus, at the end of the workshop, students will receive a 4-Shaft Overshot Pillows Draft which could include up to ten pillow tops. Sampling first, as we will do in the workshop, will enable you to enjoy your new-found knowledge for such a project.

4-Shaft Floor or table loom with 10-dent Imperial or 45/10 Metric reed; a minimum weaving width of 10”, in good working orderWooden Temple for 8-1/2” weaving width (a binder-clip temple is acceptable but not recommended.)

The Mills Machine Overshot is a rugged, external catch, fishing tool that is economical and simple to use. Overshots are manufactured like taper taps except they go over the O.D. of the fish. Like taper taps, overshots are stocked in a variety of sizes and standard connections so we are able to get something to you rapidly. To build an overshot from scratch takes four to six days due to the heat treat process necessary to harden the teeth. It is speedier to build a sub to fit a stocked overshot and match your needs than to build the entire product. We can build the overshot with oversize guides to more easily catch the fish or with a wall hook to snag behind a fish leaning against the drill hole wall. Your Mills sales representative will work with you to get the fastest solution to your problem at the lowest cost. The carbonized threads on overshots are extremely hard and brittle. Be extra careful to avoid impact. In use, slowly lower the tool down the hole until the fish is engaged. Then slowly rotate the tool while applying some down pressure. Mark the drill rod to tell how far into the fish you have penetrated. Overshots can be reworked by annealing, re-threading the overshot and then re-heat treating the re-threaded area. We will quote you pricing as necessary.

Pattern is designed to use our Organic cottolin (Cotolin) to weave 4 placemats- finished size 14"X20", 4 napkins 14"X14" and a runner with a finished size 14"X38". Requires an 8 shaft loom, 24 epi, 15" wide. 1 tube each of our 4 Ruby Anniversary colors Vendor item: HYPattern

Related items:15 3/4" 8 shaft loom, 12 dent reed double sleyed, shuttles, 4 bobbins. Pattern gauge: 12 dpi Yarn weight: Lace Yardage needed:1 tube each of 4 colors. We used 2 reds 5096 & 5116, and 2 purples 8264 & 5153.

Pattern is designed to use our Organic cottolin (Cotolin) to weave 4 placemats- finished size 14"X20", 4 napkins 14"X14" and a runner with a finished size 14"X38". Requires an 8 shaft loom, 24 epi, 15" wide, and 1 (half pound) tube each of 4 red/purple colors. Vendor item: HYPattern

Related items:15 3/4" 8 shaft loom, 12 dent reed double sleyed, shuttles, 4 bobbins. Pattern gauge: 12 dpi Yarn weight: Lace Yardage needed:1 tube each of 4 colors. We used 2 reds 5096 & 5116, and 2 purples 8264 & 5153.

The versatile four-shaft loom is popular with beginners and experienced craftspeople. Here award-winning weaver and teacher, Anne Field has written a comprehensive text specifically for this loom. It covers planning a warp, pattern drafting, weaving techniques and fourteen innovative projects. Projects in this book include: Two scarves, six tablemats, two cushions, upholstery fabric, surface-weave fabric, cotton jacket, stole, cocoon jacket, crossover shawl, overshot runner, weft-face hanging, tapestry hanging, warp-face hanging and double-width knee rug.

Overshot: The earliest coverlets were woven using an overshot weave. There is a ground cloth of plain weave linen or cotton with a supplementary pattern weft, usually of dyed wool, added to create a geometric pattern based on simple combinations of blocks. The weaver creates the pattern by raising and lowering the pattern weft with treadles to create vibrant, reversible geometric patterns. Overshot coverlets could be woven domestically by men or women on simple four-shaft looms, and the craft persists to this day.

Summer-and-Winter: This structure is a type of overshot with strict rules about supplementary pattern weft float distances. The weft yarns float over no more than two warp yarns. This creates a denser fabric with a tighter weave. Summer-and-Winter is so named because one side of the coverlet features more wool than the other, thus giving the coverlet a summer side and a winter side. This structure may be an American invention. Its origins are somewhat mysterious, but it seems to have evolved out of a British weaving tradition.

Twill:Twill along with plain and satin weave is one of the three simple weave structures. Twill is created by repetition of a regular ratio of warp and weft floats, usually 1:2, 1:3, or 2:4. Twill weave is identifiable by the diagonal orientation of the weave structure. This diagonal can be reversed and combined to create herringbone and diamond effects in the weave.

Multi-harness/Star and Diamond: This group of coverlets is characterized not by the structure but by the intricacy of patterning. Usually executed in overshot, Beiderwand, or geometric double cloth, these coverlets were made almost all made in Eastern Pennsylvania by professional weavers on looms with between twelve and twenty-six shafts.

America’s earliest coverlets were woven in New England, usually in overshot patterns and by women working collectively to produce textiles for their own homes and for sale locally. Laurel Thatcher Ulrich’s book, Age of Homespun examines this pre-Revolutionary economy in which women shared labor, raw materials, and textile equipment to supplement family incomes. As the nineteenth century approached and textile mills emerged first in New England, new groups of European immigrant weavers would arrive in New England before moving westward to cheaper available land and spread industrialization to America’s rural interior.

Southern coverlets almost always tended to be woven in overshot patterns. Traditional hand-weaving also survived longest in the South. Southern Appalachian women were still weaving overshot coverlets at the turn of the twentieth century. These women and their coverlets helped in inspire a wave of Settlement Schools and mail-order cottage industries throughout the Southern Appalachian region, inspiring and contributing to Colonial Revival design and the Handicraft Revival. Before the Civil War, enslaved labor was often used in the production of Southern coverlets, both to grow and process the raw materials, and to transform those materials into a finished product.

Overshot: The earliest coverlets were woven using an overshot weave. There is a ground cloth of plain weave linen or cotton with a supplementary pattern weft, usually of dyed wool, added to create a geometric pattern based on simple combinations of blocks. The weaver creates the pattern by raising and lowering the pattern weft with treadles to create vibrant, reversible geometric patterns. Overshot coverlets could be woven domestically by men or women on simple four-shaft looms, and the craft persists to this day.

Summer-and-Winter: This structure is a type of overshot with strict rules about supplementary pattern weft float distances. The weft yarns float over no more than two warp yarns. This creates a denser fabric with a tighter weave. Summer-and-Winter is so named because one side of the coverlet features more wool than the other, thus giving the coverlet a summer side and a winter side. This structure may be an American invention. Its origins are somewhat mysterious, but it seems to have evolved out of a British weaving tradition.

Twill:Twill along with plain and satin weave is one of the three simple weave structures. Twill is created by repetition of a regular ratio of warp and weft floats, usually 1:2, 1:3, or 2:4. Twill weave is identifiable by the diagonal orientation of the weave structure. This diagonal can be reversed and combined to create herringbone and diamond effects in the weave.

Multi-harness/Star and Diamond: This group of coverlets is characterized not by the structure but by the intricacy of patterning. Usually executed in overshot, Beiderwand, or geometric double cloth, these coverlets were made almost all made in Eastern Pennsylvania by professional weavers on looms with between twelve and twenty-six shafts.

America’s earliest coverlets were woven in New England, usually in overshot patterns and by women working collectively to produce textiles for their own homes and for sale locally. Laurel Thatcher Ulrich’s book, Age of Homespun examines this pre-Revolutionary economy in which women shared labor, raw materials, and textile equipment to supplement family incomes. As the nineteenth century approached and textile mills emerged first in New England, new groups of European immigrant weavers would arrive in New England before moving westward to cheaper available land and spread industrialization to America’s rural interior.

Southern coverlets almost always tended to be woven in overshot patterns. Traditional hand-weaving also survived longest in the South. Southern Appalachian women were still weaving overshot coverlets at the turn of the twentieth century. These women and their coverlets helped in inspire a wave of Settlement Schools and mail-order cottage industries throughout the Southern Appalachian region, inspiring and contributing to Colonial Revival design and the Handicraft Revival. Before the Civil War, enslaved labor was often used in the production of Southern coverlets, both to grow and process the raw materials, and to transform those materials into a finished product.

The overshot weaving project shown is woven on a 16″ Ashford Table Loom 8 shaft, The yarns used are Ashford 100% mercerised cotton in 10/2 and 5/2. (We don’t have this yarn currently listed on our site, but we’re able to order it in for you. Send us an email at: info@sweetgeorgiayarns.com!) The pattern is Overshot Sampler from the book Next Steps in Weaving by Pattie Graver

I debated on where to go next, but at the end of the day the most widely used fishing tool has to be an overshot. Some will say why not a spear? Well if you must ask, always go with the strongest fishing tool you can run to catch the fish. And if you run a spear, never plug the I.D. of your fish by breaking it off. Done with that!

The info that follows has been taken from the manuals published on overshots. I realize that paper manuals are a thing of the past, yes, yes at one time fishing tool hands carried massive catalog brief cases full of reference material. Now you have the luxury of your laptop loaded with information. If you have never sat down and read an overshot manual, now might be a good time.

The overshot is highly versatile and efficient tool. There are several different types of overshots, however each overshot is designed to engage a specific size of tubing, pipe, coupling, tool joint, drill collar or smooth OD tool.

The original overshot was developed by Bowen Oil Tools, which is now part of NOV. One thing I will point out is that in the catalogs you will see more than one assembly number for a given OD of Overshot, this came about due to the two locations developing their own variations. I found this information on NOV’s website and thought it was interesting to share.

In the early 1930s, the consequences of the stock market crash prompted S.R. Bowen to consider starting a company in Houston, where oil exploration and drilling was accelerating. In the early spring of 1934, his son Walter and a friend formed Bowen Company of Texas.

Bowen™ became a leader in innovation with the creation of the first overshot, the Series 150, in 1935. This tool set the standard for fishing equipment, and the quick acceptance of the tool assured the company partners that their business would be successful. The company continued to create new products, building a reputation for their well tool design and construction.

Currently there are several manufacturers of overshots, NOV (Bowen), Rubicon (Logan) and Applied Oil Tools (Gotco). These overshots are designated by a series number as follows:Series 10 - Sucker Rod Overshot

Overshots may be identified by one of the following, known as “type”:Full Strength (FS) - engineered to withstand all pulling, jarring and torsional strain

The basic overshot (from top down) consists of a top sub, a bowl, grapple, control, and a guide. In addition to the basic components, some overshots (Series 10 and 150) can be dressed with either a:Spiral grapple used if the fish diameter is near the maximum catch of the overshot, or a

The Series 150 Overshot features the ability to packoff on the fish. When the circulating packoff is not used, the fluid circulates down the drillpipe, aroundthe top outside of the fish, through the slip or grapple assembly, around the guide shoe and up the annulus.

When the circulating packoff is used, the annular space between the top outside of the fish and the inside of the lower part of the overshot is packed off, diverting the fluid flow down into the fish, making it easier to release and recover the fish. Packoffs usually are not high pressure devices but will often withstand sufficient pressure to establish circulation through the fish. Third party high pressure packoffs are available from various sources.

The extension can be installed between the top sub and the bowl of the Series 10, 70, and 150 overshots. It is used to extend the overshot bowl to:Allow the grapple to catch farther down on a fish that may be necked down at the top by having been pulled in two, or latched by an overshot and released several times, or to

A stop ring must be used where a fish OD reduces immediately below the catch area to allow the grapple to bite on full-size pipe.Example - catching a Hydril upset or EUE collar. If the upset of collar should pass completely through the grapple, the overshot may not be releasable.

The Series 10 Sucker Rod Overshot is designed to engage and recover sucker rods, couplings, and similar items from inside tubing strings.Basket grapples are recommended for fishing for hardened and ground boxes (Sucker Rod Box).

The Series 20 Sucker Rod Overshot is a short catch tool which provides a means for engaging the exposed portion of a fish too short to be engaged with a Series 10 overshot.Uses basket grapples only

The Series 70 Short Catch Overshot is designed to engage the exposed portion of a fish too short to engage with Series 150 overshots.Uses basket grapple only

The Series 150 Releasing and Circulating Overshot is used to engage, packoff, and retrieve twisted-off lost tubing, drillpipecoupling, tool joint, casing or other similar fish.

A right hand wicker grapple converts a normal right release overshot to left hand release. This grapple is used where you expect to apply excessive right hand torque to release a packer, safety joint, etc. Note: Overshot will have to be released by left hand rotation.

High Pressure Packoff Assemblies:The High Pressure Packoff Assembly is an accessory to the Series 150 Overshots. It is used when high pressure circulation to the fish is required. It consists of a packoff sub with packing and packing rings and is installed between the top sub and bowl of the overshot. By running the packoff sub above the bowl, this design prevents the application of high internal pressures to the overshot bowl. The design of the High Pressure Packoff Assembly allows pressures two to three times the standard overshot packoff to be applied to the fish.

This information comes directly from the NOV manual for the Wide Catch Overshot. This is probably the first and only change to this common tool I know of in my career.

The Wide Catch Overshot provides the strongest tool available to externally engage, pack-off, and pull a fish that has been significantly worn. This tool has similar rugged design features and construction as the industry standard, Bowen Series 150 overshot, with the ability to interchange the Bottom Guide with the full range of existing components used with the standard Bowen Series 150 overshot.

In service, the Wide Catch Overshot (WCOS) takes a positive grip over a large area of fish and is capable of withstanding heavy pulling, torsion, and jarring strains without damage to the tools or the fish.

The WCOS has been designed to significantly increase the catch range of the OD of the fish to be caught, compared to the standard overshot. This enables a greater opportunity for a successful fishing operation in a reduced number of trips, thus reducing overall intervention costs for the operator. In addition to the large catch range, the WCOS has the ability to seal across very large extrusion gaps at both standard and high pressure and provide full circulation through the fish, should it be required.

Connections between the Top Sub/Bowl and Extension Sub have been designed to create a seal. This will prevent the connection from washing out should the overshot be required to be flowed through for a long period of time. In order to lock the Top Sub/Extension Sub to the Bowl from backing off during operation, set screws have become standard and will gall the threads should the connection break free.

The operation of all overshots is identical. The exception being that the Series 150 carries a packoff which provides circulation through the fish. First, determine that the overshot is properly assembled and dressed with the proper size grapple. Make up the overshot on the fishing string (normally it is run connected to the bottom of the bumper sub) and run it into the well. As the top of the fish is reached make sure circulation has been established to clear overshot ID of any plugging. Lower the overshot onto the top of the fish with no rotation at first. A 5,000 pound set down weight will be sufficient to engage the grapple. While lowering the overshot over the top of the fish watch for pressure build up, shut off pumps if any pressure build up is noticed. Should any back pressure be noticed, release the back pressure to allow the grapple to engage the fish. By elevating the string it can be determined, if the grapple went over and engaged the fish. If unable to work overshot over top of fish without rotation, then slowly rotate the fishing string to the right and gradually lower the overshot over the fish. Combined rotation and lowering over top of the fish are important to keep the grapple in the release position. This provides the maximum clearance between the grapple and fish. While lowering the overshot over the top of the fish, watch for torque build up and an increase in pump pressure. A pump pressure build up indicates the overshot has gone over the top of the fish thereby reducing the flow area. Stop rotation (continued rotation could dull the wickers of the grapple) enabling the grapple to set. Allow the right hand torque to slack out of the string and then pull on the string by elevating the string to set the grapple.

To release from the fish, bump down, then simultaneously rotate to the right and slowly elevate the fishing string. It is best to have a clean fishing top before running the overshot.

8613371530291

8613371530291