colonial overshot supplier

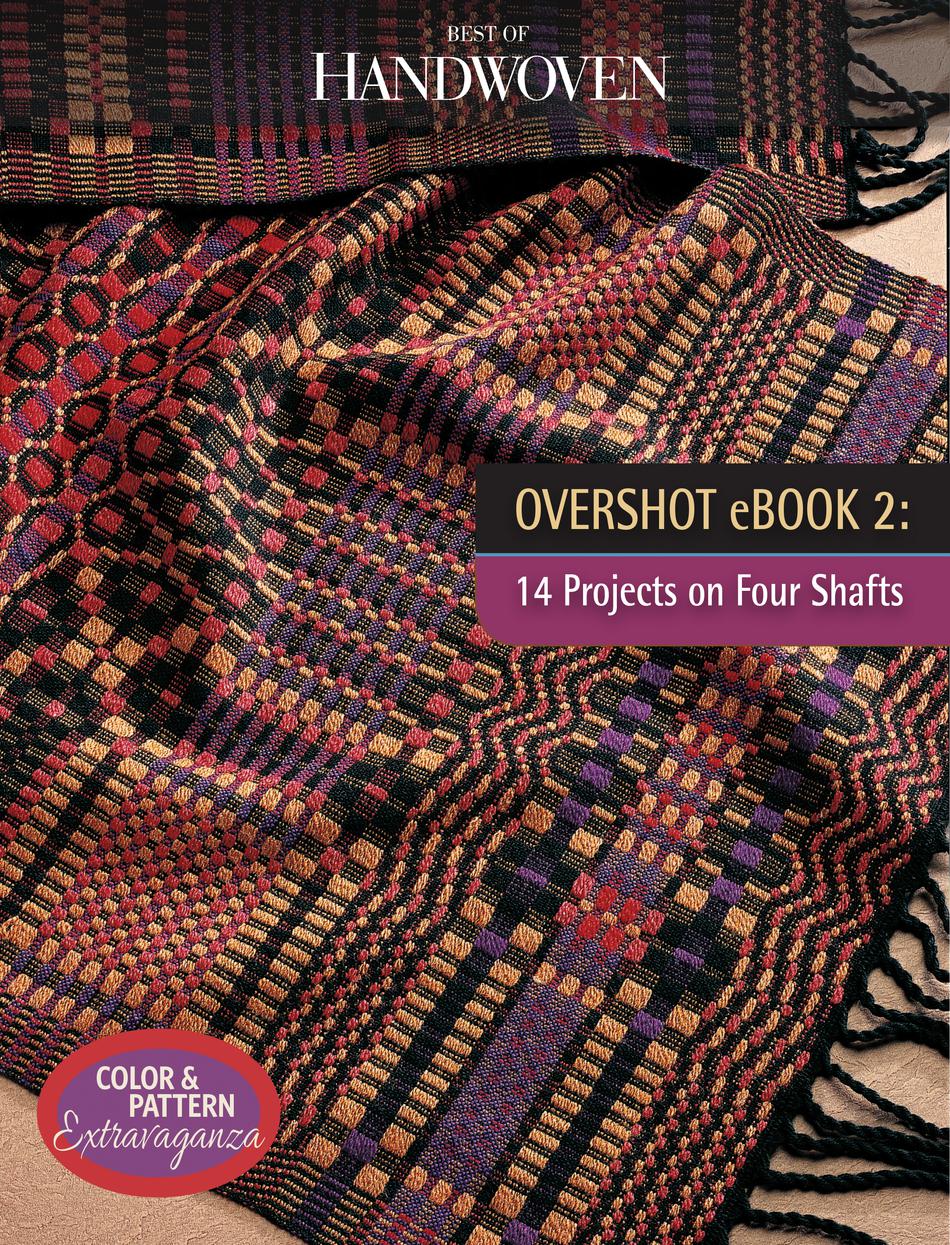

Overshot: The earliest coverlets were woven using an overshot weave. There is a ground cloth of plain weave linen or cotton with a supplementary pattern weft, usually of dyed wool, added to create a geometric pattern based on simple combinations of blocks. The weaver creates the pattern by raising and lowering the pattern weft with treadles to create vibrant, reversible geometric patterns. Overshot coverlets could be woven domestically by men or women on simple four-shaft looms, and the craft persists to this day.

Summer-and-Winter: This structure is a type of overshot with strict rules about supplementary pattern weft float distances. The weft yarns float over no more than two warp yarns. This creates a denser fabric with a tighter weave. Summer-and-Winter is so named because one side of the coverlet features more wool than the other, thus giving the coverlet a summer side and a winter side. This structure may be an American invention. Its origins are somewhat mysterious, but it seems to have evolved out of a British weaving tradition.

Multi-harness/Star and Diamond: This group of coverlets is characterized not by the structure but by the intricacy of patterning. Usually executed in overshot, Beiderwand, or geometric double cloth, these coverlets were made almost all made in Eastern Pennsylvania by professional weavers on looms with between twelve and twenty-six shafts.

America’s earliest coverlets were woven in New England, usually in overshot patterns and by women working collectively to produce textiles for their own homes and for sale locally. Laurel Thatcher Ulrich’s book, Age of Homespun examines this pre-Revolutionary economy in which women shared labor, raw materials, and textile equipment to supplement family incomes. As the nineteenth century approached and textile mills emerged first in New England, new groups of European immigrant weavers would arrive in New England before moving westward to cheaper available land and spread industrialization to America’s rural interior.

Southern coverlets almost always tended to be woven in overshot patterns. Traditional hand-weaving also survived longest in the South. Southern Appalachian women were still weaving overshot coverlets at the turn of the twentieth century. These women and their coverlets helped in inspire a wave of Settlement Schools and mail-order cottage industries throughout the Southern Appalachian region, inspiring and contributing to Colonial Revival design and the Handicraft Revival. Before the Civil War, enslaved labor was often used in the production of Southern coverlets, both to grow and process the raw materials, and to transform those materials into a finished product.

It is a popular and well know weave structure with well known motif designs such as Honeysuckle, Snails trails, Cat’s Paw, Young lover’s knot and Maple leaf. Overshot means the weft shoots either over or under the warp.

The Treadling for Overshot is a 2/2 Twill. That is 1-2, 2-3, 3-4, 4-1. Overshot is woven with a thick pattern thread alternating with a thinner tabby thread. The pattern block may be repeated as many times as you like to build up a pleasing block. So it will be pattern thread, tabby a, pattern thread, tabby b. Lift 1 and 3 for tabby a and 2 and 4 for tabby b.

Monks belt, so called because a monks’ status in the monastery was indicated by the pattern woven on the belt is different from the other Overshots motifs as it is woven in 2 blocks on opposites. A block will be either 1 and 2, or 3 and 4. The pattern is created by the varying size of the blocks.

It is not difficult to design your own overshot pattern. A name draft is just one of the ways to do so. The above tablecloth was made by a group of weavers, each wove a square and many of them designed their own name drafts.

While pursuing the Guild of Canadian Weavers certificate program in 1985, she found the requirement to hand-draw large overshot drafts too traditional. Bob was inspired to create a simple drafting program that became PCW, the foundation for later versions of Fiberworks PCW. Ingrid was always…

Advanced weavers with 8-, 12- or 16-harness looms will find a lot of useful information here. The purpose of this book is to present a number of weaves from which a wide range of designing is possible. Charts have been developed to assist in tying up, pegging or feeding the information to the computer so that precious time may be saved to apply to the designing aspect. Concepts are given in a terse but clear and to the point format eliminating the need for in-depth study. Once you understand the concepts you"ll understand many different multiple harness weave systems. After a short section explaining the Charts and Terminology used in the book, the author provides chapters that cover: Beiderwand, Crackle, Damask, Diaper Twill, Dimai, Double Two-Tie, Double Weave, Lace Weaves, Overshot, The Profile Draft, Summer & Winter, Tie-ups and Twills. There is a large bibliography for those who wish to do further study and a complete index at the end.

William Rittenhouse (born 1644 in Broich, Duchy of Berg; died February 18, 1708 in Germantown, PA) became the first paper maker in British North America when he established the Rittenhouse paper mill outside of Germantown, Pennsylvania, in 1690. He also created a paper-making dynasty that held a virtual monopoly on papermaking in the British colonies for almost forty years and produced paper for 150 years. He may thus be credited with transferring this important technology from Germany and Holland to America and building the foundation for the blossoming of a domestic, independent print culture in the colonies in the eighteenth century. His success can largely be attributed to his early migration to Holland and business experience among Dutch papermakers and subsequently his effective negotiation of the diverse transnational environment of early colonial Pennsylvania. Rittenhouse was a transnational and translingual personality who crossed borders and negotiated socially and ethnically diverse communities. Though his wealth at the time of his death is difficult to measure exactly, he left his son Claus Rittenhouse (already responsible for day-to-day operations at the time) a fully established paper mill with customers in various colonies, twenty acres of land well-suited for the operation of water-powered paper mills, and a widely recognized and respected company name.

Very little is known about the construction of the mill. In a 1690 letter to London Quakers, Bradford mentioned that “Samuel Carpenter and I are Building a Paper-Mill about a Mile from thy Mills at Skulkill, and hope we shall have Paper within less than four months.”[18] Bradford perhaps mentioned only himself and Carpenter because they were best known to the London Quakers or because they contributed the most capital, but certainly not because they were physically or personally building the mill. Rittenhouse was the one who contributed all expertise in building and operating a paper mill. Frame’s poem, printed on paper with a Rittenhouse watermark, is the earliest evidence of the mill’s operation by 1692. No description of the first paper mill exists, but circumstantial evidence allows the assumption that it was an undershot mill, with the wheel suspended above the water of the creek and driven by the flow of water.[19] This construction was relatively inefficient, because it did not make use of gravity — as did an overshot wheel which was powered by water falling onto the blades of the wheel from above — and was exposed to natural fluctuations in the water level.[20] Also, the building was apparently constructed relatively quickly and cheaply from logs, as timber was still abundant in the wooded areas around Germantown.[21] Although the direct source of key paper-making technology and hardware for the first mill is unknown, it is safe to assume that Rittenhouse received most of it from the German states and the Netherlands. For example, a receipt dated 1698 from the paper makers Johannes and Adolf Vorster in Rozendaal shows that Rittenhouse received paper molds from them.

Probably due to declining health, shortly after February 1706 William “leased” three of his four shares to his son Claus for the nominal rent of “one peppercorn yearly.”[33] He died from an unknown cause on February 18, 1708.[34] He left no will and all four shares of the mill went to his son Claus, who became the sole owner. Historian George Allen in particular underscored Claus’s key role in running the business even before his father’s death: “While it has been the custom to call William Rittenhouse the first manufacturer of paper in this country, this is unquestionably a partial injustice to his son, Nicholas. For it is a question, how much the elder Rittenhouse could have done without the aid of his eldest son, who seems to have been an excellent carpenter, as well as papermaker.”[35] If William’s reputation has overshadowed his son’s, we must probably fault the historiographic obsession with firsts or founding fathers. There is no evidence that the elder Rittenhouse attempted to diminish his son’s significance or business involvement. If anything, William Rittenhouse did everything in his power to leave a successful and well-established business to his son, situating him for a period of notable business expansion following his death. Claus, himself a first-generation immigrant, continued his father’s practice of rearing up family members in the craft of papermaking. In addition to his son, William (1691-1744), who inherited the mill in 1734, Claus also taught the trade to his brother-in-law William De Wees (brother of Claus’s wife Wilhelmina) and assisted him in setting up a second paper mill in the Chestnut Hill district nearby in 1710. Until Thomas Wilcox built a paper mill in Chester County, southwest of Philadelphia, in 1729, all paper production in Pennsylvania and the British colonies at large was in the hands of the extended Rittenhouse family.[36] The Rittenhouse family thus initiated the primacy of Pennsylvania, especially the Philadelphia area, as a colonial center of the paper-making industry. Historian John Bidwell further explains factors for the Rittenhouse mill’s success in this location: “Paper mills naturally clustered where the printing trade was strongest, in the Philadelphia area, where papermakers could count on a promising market, a rapidly developing transportation network, excellent commercial facilities, and optimum manufacturing conditions at mill sites in the surrounding countryside.” As a result — none the least due to Rittenhouse’s pioneering work — “Pennsylvania mills greatly outnumbered those of the other colonies until the 1770s and… even then, the paper trade was still growing faster in Pennsylvania than in any other American colony.”[37]

Unfortunately, very little information about the mills built by William and Claus Rittenhouse exists, and none of the mill buildings has survived. The only remaining structures dating back to William Rittenhouse’s life are the Rittenhouse homestead built in 1707 and a smaller building (presumed to have been built as a residence) built in 1690. The homestead includes a metal plate reading “W C R 1707,” for William and Claus Rittenhouse, 1707. A 1764 survey made by Christian Lehman shows two paper mills, an upper and a lower mill. It is unclear which of the two mills was the one reconstructed after the flood that destroyed the original 1690s mill.[38] Either way, the mill built by William and Claus Rittenhouse to replace the original one was serviced by a mill race, which is seen in the survey. Mill races were man-made runs that diverted water from the natural stream to the mill wheel, which helped provide a steady water supply and allowed water to fall onto the overshot wheel and thus operate the mill more efficiently.[39] Burgeoning business necessitated the construction of a second mill (the third Rittenhouse mill building counting the original 1690 mill), which was built some time after Claus’s death in 1734 but before Lehman’s survey in 1764.[40]

Yet hard work and entrepreneurial success did not carry the same meaning for William Rittenhouse as they carry for us today. His worldly accomplishments likely mattered little to the devout Mennonite minister, who shunned any public office and until right before his death demurred attempts by Germantown and even Hamburg Mennonites to make him the first bishop or “elder” of their faith in the New World. Though not raised as a Mennonite, Rittenhouse spent many years in Amsterdam, one of the centers of Anabaptist religion in seventeenth-century Europe. Although the exact circumstances of his conversion are unknown, it is reasonable to imagine that a man so intimately connected to books and print culture would have admired one of the most monumental books published in seventeenth-century Europe (and the largest book ever printed in colonial America): Thieleman J. van Braght’s Martyrs’ Mirror, a collection of martyr stories from Christ to the last Anabaptist executions in his own century, printed in Amsterdam in 1685.[46] Van Braght’s collection was richly illustrated with Jan Luyken’s copper-plate prints, which contributed additional pathos to the story of the so-called “blood witnesses” who died as victims of religious intolerance and in defense of their fundamental principles — pacifism, rejection of loyalty oaths, adult baptism, the community of believers, a separation from the world, and hard work as a sign of acceptance of the yoke to be carried by anyone following Christ.[47] The “Fac et Spera” (“Arbeite und Hoffe” / “Work and Hope”) emblem on the title page of the Martyrs’ Mirror encapsulated the meaning of hard work for the Mennonites and other Anabaptists: an obedient acceptance of suffering as the result of mankind’s fall and human sinfulness, paired with a hope for salvation. One can easily transfer the image of the humble and hard-working “Anabaptist Adam” (as the man in the emblem came to be known) onto the Mennonite printer William Rittenhouse — continually building and rebuilding his business as an expression of faith and acceptance. Unlike New England Puritans and other Calvinists, however, Mennonites like Rittenhouse did not interpret work and worldly success as a sign or result of election. For Anabaptists, the rewards of salvation would be reaped in the afterlife. Thus, William Rittenhouse would not have considered himself a self-made man but rather a fallible being serving God to the best of his abilities.

Scholarship on the formation of immigrant identity — including the development of German-American identity — usually distinguishes between the opposite poles of integration and ethnicization, with the former denoting Americanization and thus the assimilation of the immigrant into the mainstream culture, and the latter referring to the formation of a uniquely ethnic culture with characteristics distinguishable both from the homeland and the larger American society. Intriguingly, neither of these theories applies neatly to William Rittenhouse and the development of his business. Thus, understanding his success in a very inchoate American community rather contributes to a fundamentally different approach to the concept of immigrant identity in colonial America.

[14] Green, Rittenhouse Mill,8. Also see Alexander J. Wall, Jr., “William Bradford, Colonial Printer: A Tercentenary Review,” Proceedings of the American Antiquarian Society 73.2 (1963), 361-384. All currency conversions in the article are based on the Retail Price Index, which offers a conservative estimate of currency inflation using the relative value of goods and services available to consumers at given time periods. Lawrence H. Officer and Samuel H. Williamson, “Six Ways to Compute the Relative Value of a U.K. Dollar Amount, 1270 to present,” MeasuringWorth, March 2011 (accessed 26 June 2012).

[22] Qtd. in John Smolenski, Friends and Strangers: The Making of a Creole Culture in Colonial Pennsylvania (Philadelphia: University of Pennsylvania Press, 2010), 162. For a broader account of the Keithian schism and Bradford’s role in it, see Smolenski, Friends and Strangers,149-177.

[37] John Bidwell, “Printers’ Supplies and Capitalization,” in The Colonial Book in the Atlantic World, vol. I, A History of the Book in America, eds. Hugh Amory and David D. Hall (Chapel Hill: University of North Carolina Press, 2007), 163-183, here 176.

Colonial Mills brings innovation to braid. Through quality, American craftsmanship and adaptable design, we are creating the next generation of braided home fashions. We see braid as a method of construction, not a style. It is this thinking that allows us to combine the traditional and contemporary. Our approach reflects people"s eclectic sense of personal style. From the boldly modern to the classically rustic, we"re proudly made to order here in the USA.

8613371530291

8613371530291