overshot drilling free sample

An OVERSHOT is attached to the end of a wireline and lowered into the outer tube. The Overshot then locks on to the Latch Head Assembly at the top of the core barrel.

The inner tube is then pulled to the surface with the core sample inside. Givens International offers an overshot for a spear point or quad latch head.

Open hole fishing is one of the most critical operations in drilling. It involves a lot of expertise and experience of the personnel. This VDO by Weatherford Fishing Services demonstrates you about the open hole fishing. This is highly recommended for you to watch it. Additionally, the full VDO transcript is provided.

The fish can be removed using special tools and techniques. A Scew-in sub is one of the most common fishing tools. Its modified pin can be used to catch an undamaged fish. The overshot tool because of its versatility is frequently used in fish recoveries. Its simple design includes a circulating and releasing action as well as a 360 degree catch of the fish. Normally the overshot or screw-in sub is connected to the bottom of the bumper sub and fishing jars on the fishing assembly. As the tool is lowered over the fish the top of the fish passes through the tool into the bowl. When the assembly is raised grapples engage the fish at a lower point and it is work free and pulled upward.

In a washed out hole use of a hydraulic Knuckle joint located above the overshot kicks out under pump pressure to increase the sweep of the overshot to facilitate capture of an allusive fish. When the severe wash out, a Wall hook guide run on the bottom of the overshot further improves the search and capture of the fish.

When the fish cannot be dislodged by pulling with the overshot a jarring assembly run in the fishing string can be activated to strike heavy blows either up or down on a stuck fish to free it. The down action is achieved with a Bumper jar; essentially a slip joint with a sliding stroke. The impact enhanced by the weight of drill collars above the Bumper jar results in a sharp blow with the fishing string. Dropping the string quickly produces a sharp downward blow on the fish. This jarring action is especially effective in freeing PC Pipe or a string that is stuck as a result of an upward pull.

Essentially Washover operation involve a pipe string that slips over the stuck fish allowing fluid to circulate in the annalist between the fish and the inner wall of the Washover pipe. Fluid under pressure flushes out debris cut lose by the rotary shoe run on the bottom of the Washover pipe. The washed over fish secured by an overshot or a screw-in sub and then be backed and removed to the surface.

When the fish is stuck off bottom a Washpipe spear may be run in conjunction with the Washpipe and screwed into the fish prior to the Washover procedure. This prevents a fish freed by the Washover operation from dropping to the well bottom and damaging the wellbore, drilling string or drilling bit.

A screw-in sub is one of the most common fishing tools. Its modified pin can be used to catch an undamaged fish. The overshot tool because of its versatility is frequently used in fish recoveries. Its simple design included circulating and releasing action as well as a 360 degree catch of the fish.

Normally, the overshot or screw in sub is connected to the bottom of the bumper sub and fishing jars on the fishing assembly. As the tool is lowered over the fish, the top of the fish passes through the tool into the ball. When the assembly is raised, grapples engage the fish at a lower point and it is worked free and pulled upward. If the top of the fish is bad, twisted or broken, it should be dressed off to provided clean top so grapple can insecurity firmly. Dressing off is achieved with a skirted or hollow food mill. Several types of mills are available for this purpose and other jobs.

In a washed-out hole, use of a hydraulic knuckle joint located above the overshot kicks out under pump pressure to increase the sweep of the overshot to facilitate capture of an elusive fish. With a severe washout, a wall hook guide run on the bottom of the overshot, further improves the search and capture of the fish. When the fish cannot be dislodged by pulling with the overshot, a jarring assembly run in the fishing strain can be activated to strike heavy blows either up or down on a stock fish to freak. The down action is achieved with a bumper jar, essentially a slip joint with a sliding stroke. The impact, enhanced by the weight of drill collars above the bumper jar results in a sharp blow with the fishing string. Dropping the string quickly produces a sharp downward blow on the fish. This jarring action is especially effective in free e-seated pipe or a string that is stuck as a result of an upward blow.

Essentially, washover operations involve a pipe string that slips over a stuck fish allowing fluid to circulate in the annulus between the fish in the inner wall of washover pipe. Fluid under pressure flushes out debris cut loos by the rotary shoe run on the bottom of the washover pipe. The washed over fish secured by an overshot or screw in sub and then he backed off and removed to the surface. The washover pipe selected requires an inside diameter large enough to accommodate the fish and an outside diameter they can rotate without sticking in the open hole and still allow circulation.

Various types of weatherford rotary shoes are available. Each shoe is custom designed for a particular procedure. Tooth-type shoes for example, are recommended when the formation to be cut is relatively soft. When metals such as tool joints or stabilizer blades must be cut, the rotary shoe is dressed with tungsten carbide or diamonds internally, externally or both, tailored specifically. And improper choice could severely damage the fish, complicating the recovery operation. Occasionally with drill pipe maybe plug usually by mud. Cutting the free drill pipe with a mechanical outside cutter run on the washpipe will remove the obstruction and establish a clean, workable top. Following the washover, the washpipe is pulled up and the shoe removed and replaced by a mechanical outside cutter. Run into the well and over the freed fish, the cutter is engaged. With a slight upward string, cutter knives are fed through the wall of the drill piped fish and the fish is parted. Rotation has then stopped and the cut piece of fish is recovered and pulled to the surface. When the fish is stock off bottom, washpipe spear maybe run in conjunction with the wash wipe and screwed into the fish prior to the washover procedure. This prevents the fish freed by the washover operation from dropping to the well bottom and damaging the well board, drilling string or drilling bit.

Drilling tool fishing is probably every driller’s least favorite activity. But it happens. There are a huge number of tools available to fish almost anything out of the hole. For drill pipe and collars, there are overshots and spears — in many sizes for almost any job. But, when it comes to loose junk on the bottom of the hole, things get a little more interesting. It might be a loose bit, a wrench, a sledge hammer or tong dies. Anything that can fit in the hole will sooner or later end up on the bottom. I reckon it’s human nature, or Murphy’s law, but it happens.

I debated on where to go next, but at the end of the day the most widely used fishing tool has to be an overshot. Some will say why not a spear? Well if you must ask, always go with the strongest fishing tool you can run to catch the fish. And if you run a spear, never plug the I.D. of your fish by breaking it off. Done with that!

The info that follows has been taken from the manuals published on overshots. I realize that paper manuals are a thing of the past, yes, yes at one time fishing tool hands carried massive catalog brief cases full of reference material. Now you have the luxury of your laptop loaded with information. If you have never sat down and read an overshot manual, now might be a good time.

The overshot is highly versatile and efficient tool. There are several different types of overshots, however each overshot is designed to engage a specific size of tubing, pipe, coupling, tool joint, drill collar or smooth OD tool.

The original overshot was developed by Bowen Oil Tools, which is now part of NOV. One thing I will point out is that in the catalogs you will see more than one assembly number for a given OD of Overshot, this came about due to the two locations developing their own variations. I found this information on NOV’s website and thought it was interesting to share.

In the early 1930s, the consequences of the stock market crash prompted S.R. Bowen to consider starting a company in Houston, where oil exploration and drilling was accelerating. In the early spring of 1934, his son Walter and a friend formed Bowen Company of Texas.

Bowen™ became a leader in innovation with the creation of the first overshot, the Series 150, in 1935. This tool set the standard for fishing equipment, and the quick acceptance of the tool assured the company partners that their business would be successful. The company continued to create new products, building a reputation for their well tool design and construction.

Currently there are several manufacturers of overshots, NOV (Bowen), Rubicon (Logan) and Applied Oil Tools (Gotco). These overshots are designated by a series number as follows:Series 10 - Sucker Rod Overshot

Overshots may be identified by one of the following, known as “type”:Full Strength (FS) - engineered to withstand all pulling, jarring and torsional strain

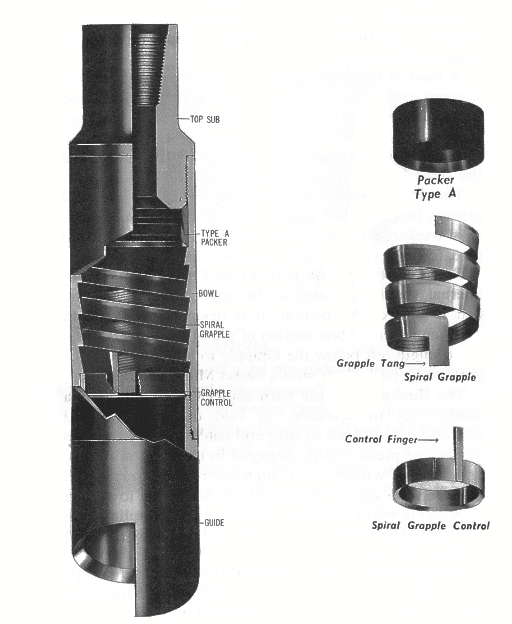

The basic overshot (from top down) consists of a top sub, a bowl, grapple, control, and a guide. In addition to the basic components, some overshots (Series 10 and 150) can be dressed with either a:Spiral grapple used if the fish diameter is near the maximum catch of the overshot, or a

The Series 150 Overshot features the ability to packoff on the fish. When the circulating packoff is not used, the fluid circulates down the drillpipe, aroundthe top outside of the fish, through the slip or grapple assembly, around the guide shoe and up the annulus.

When the circulating packoff is used, the annular space between the top outside of the fish and the inside of the lower part of the overshot is packed off, diverting the fluid flow down into the fish, making it easier to release and recover the fish. Packoffs usually are not high pressure devices but will often withstand sufficient pressure to establish circulation through the fish. Third party high pressure packoffs are available from various sources.

The extension can be installed between the top sub and the bowl of the Series 10, 70, and 150 overshots. It is used to extend the overshot bowl to:Allow the grapple to catch farther down on a fish that may be necked down at the top by having been pulled in two, or latched by an overshot and released several times, or to

A stop ring must be used where a fish OD reduces immediately below the catch area to allow the grapple to bite on full-size pipe.Example - catching a Hydril upset or EUE collar. If the upset of collar should pass completely through the grapple, the overshot may not be releasable.

The Series 10 Sucker Rod Overshot is designed to engage and recover sucker rods, couplings, and similar items from inside tubing strings.Basket grapples are recommended for fishing for hardened and ground boxes (Sucker Rod Box).

The Series 20 Sucker Rod Overshot is a short catch tool which provides a means for engaging the exposed portion of a fish too short to be engaged with a Series 10 overshot.Uses basket grapples only

The Series 70 Short Catch Overshot is designed to engage the exposed portion of a fish too short to engage with Series 150 overshots.Uses basket grapple only

The Series 150 Releasing and Circulating Overshot is used to engage, packoff, and retrieve twisted-off lost tubing, drillpipecoupling, tool joint, casing or other similar fish.

A right hand wicker grapple converts a normal right release overshot to left hand release. This grapple is used where you expect to apply excessive right hand torque to release a packer, safety joint, etc. Note: Overshot will have to be released by left hand rotation.

High Pressure Packoff Assemblies:The High Pressure Packoff Assembly is an accessory to the Series 150 Overshots. It is used when high pressure circulation to the fish is required. It consists of a packoff sub with packing and packing rings and is installed between the top sub and bowl of the overshot. By running the packoff sub above the bowl, this design prevents the application of high internal pressures to the overshot bowl. The design of the High Pressure Packoff Assembly allows pressures two to three times the standard overshot packoff to be applied to the fish.

This information comes directly from the NOV manual for the Wide Catch Overshot. This is probably the first and only change to this common tool I know of in my career.

The Wide Catch Overshot provides the strongest tool available to externally engage, pack-off, and pull a fish that has been significantly worn. This tool has similar rugged design features and construction as the industry standard, Bowen Series 150 overshot, with the ability to interchange the Bottom Guide with the full range of existing components used with the standard Bowen Series 150 overshot.

In service, the Wide Catch Overshot (WCOS) takes a positive grip over a large area of fish and is capable of withstanding heavy pulling, torsion, and jarring strains without damage to the tools or the fish.

The WCOS has been designed to significantly increase the catch range of the OD of the fish to be caught, compared to the standard overshot. This enables a greater opportunity for a successful fishing operation in a reduced number of trips, thus reducing overall intervention costs for the operator. In addition to the large catch range, the WCOS has the ability to seal across very large extrusion gaps at both standard and high pressure and provide full circulation through the fish, should it be required.

Connections between the Top Sub/Bowl and Extension Sub have been designed to create a seal. This will prevent the connection from washing out should the overshot be required to be flowed through for a long period of time. In order to lock the Top Sub/Extension Sub to the Bowl from backing off during operation, set screws have become standard and will gall the threads should the connection break free.

The operation of all overshots is identical. The exception being that the Series 150 carries a packoff which provides circulation through the fish. First, determine that the overshot is properly assembled and dressed with the proper size grapple. Make up the overshot on the fishing string (normally it is run connected to the bottom of the bumper sub) and run it into the well. As the top of the fish is reached make sure circulation has been established to clear overshot ID of any plugging. Lower the overshot onto the top of the fish with no rotation at first. A 5,000 pound set down weight will be sufficient to engage the grapple. While lowering the overshot over the top of the fish watch for pressure build up, shut off pumps if any pressure build up is noticed. Should any back pressure be noticed, release the back pressure to allow the grapple to engage the fish. By elevating the string it can be determined, if the grapple went over and engaged the fish. If unable to work overshot over top of fish without rotation, then slowly rotate the fishing string to the right and gradually lower the overshot over the fish. Combined rotation and lowering over top of the fish are important to keep the grapple in the release position. This provides the maximum clearance between the grapple and fish. While lowering the overshot over the top of the fish, watch for torque build up and an increase in pump pressure. A pump pressure build up indicates the overshot has gone over the top of the fish thereby reducing the flow area. Stop rotation (continued rotation could dull the wickers of the grapple) enabling the grapple to set. Allow the right hand torque to slack out of the string and then pull on the string by elevating the string to set the grapple.

To release from the fish, bump down, then simultaneously rotate to the right and slowly elevate the fishing string. It is best to have a clean fishing top before running the overshot.

The Series 10 Sucker Rod Overshot is a small, rugged tool designed for engaging and retrieving sucker rods, couplings, and other items from inside tubing strings.

Series 20 Short Catch Sucker Rod Overshots are designed for conditions when sucker rods, couplings, and other portions of a fish are too short for retrieval with a standard overshot.

The Hydraulic Release Overshot was designed to aid in the recovery of a stuck fish in a horizontal drilling application where normal rotation for release is not obtainable.

The Series 150 Releasing and Circulating Overshot consists of three main external parts: a Top Sub, a Bowl, and a Guide. Internal catch and pack-off parts are determined by the diameter of the fish. Each assembly is designed for a maximum catch diameter.

A Series 160 Side Door Overshot is recommended when fishing for cable tools or conductor lines in cased holes. The side door overshot is run in on tubing or drill pipe.

The alternately long and short fingers of the junk catcher assembly extend almost to the center of the basket to form a close-fitting receptacle that will retain small pieces of junk that may impede drilling progress or hold a core sample.

The EZ Clean™ Ditch Magnet with Rare Earth Elements is the most effective means available to trap and remove metal particles from drilling mud missed by the shale shaker. The ditch magnet will capture all magnezed metals. During milling operations, the magnet is parcularly valuable for the removal of mill cuttings and debris that cause wear on mud pumps and other equipment.

The Z Type Hydraulic Jar is used for light drilling, fishing, coring, reaming, testing, side tracking, and washover operations. This straight-pull jar combines the principles of mechanics and hydraulics in a simple to assemble, easy to operate design.

The Surface Bumper Jar is installed in the drill string at the surface and is used whenever the downhole drilling, fishing, or washover running string becomes stuck and requires a heavy downward force to release it.

The Drill Pipe Safety Joint is designed for the safe and dependable release from drilling, fishing, tubing, washover, or testing strings should they become stuck.

The Tubing Safety Joint is designed for the safe and dependable release from drilling, fishing, tubing, washover, or testing strings should they become stuck.

The Washover Safety Joint is designed for the safe and dependable release from drilling, fishing, tubing, washover, or testing strings should they become stuck.

The Bi-Directional Coiled Tubing Jar is designed to hit upward and downward blows. It can be dressed to only hit up or down. These tools’ small outside diameters and shorter lengths make them ideal for milling, drilling, workover, remedial, or completion operations, especially in vertical, deviated, and ultradeep wellbores.

The Welded Cup Junk Sub is an accessory tool that prevents cuttings from milling or drilling operations that are too heavy to be circulated from settling at the bottom of the hole.

The Threaded Cup Junk Sub is an accessory tool that prevents cuttings from milling or drilling operations that are too heavy to be circulated from settling at the bottom of the hole.

This easy-to-service, hydraulic motor-driven 120-Ton Power Swivel provides smooth shock-free torque. It is rated to support tensile pipe loads of 120 tons at zero rpm and 65 tons dynamic load at 100 rpm. The compact swivel head design weighs only 2,000 lbs and fits many drilling or workover masts. A 2-3/4-inch bore gooseneck and washpipe assembly allows circulation through the 2-11/16-inch I.D. stem while rotating or in static mode.

The hydraulic motor-driven 85-Ton Power Swivel provides smooth shock-free torque. The compact swivel head design fits most drilling or workover masts and weighs only 1,163 lbs. It is rated to support tensile pipe loads of 85 tons at zero rpm and 45 tons dynamic load at 100 rpm. A 2-1/4-inch bore gooseneck and washpipe assembly allows circulation through the 2-inch I.D. stem while rotating or in static mode.

8613371530291

8613371530291