overshot fishing assembly free sample

Open hole fishing is one of the most critical operations in drilling. It involves a lot of expertise and experience of the personnel. This VDO by Weatherford Fishing Services demonstrates you about the open hole fishing. This is highly recommended for you to watch it. Additionally, the full VDO transcript is provided.

Openhole fishing involves the removal of unwanted objects from the wheel bore. The objects can be tools, equipment and broken pieces of drill pipe, bits or tubulins. Openhole fishing begins following a Backoff in the drill string at or above the stock point of the fish in the wellbore leaving an accessible fish top.

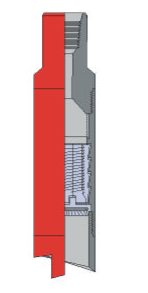

The fish can be removed using special tools and techniques. A Scew-in sub is one of the most common fishing tools. Its modified pin can be used to catch an undamaged fish. The overshot tool because of its versatility is frequently used in fish recoveries. Its simple design includes a circulating and releasing action as well as a 360 degree catch of the fish. Normally the overshot or screw-in sub is connected to the bottom of the bumper sub and fishing jars on the fishing assembly. As the tool is lowered over the fish the top of the fish passes through the tool into the bowl. When the assembly is raised grapples engage the fish at a lower point and it is work free and pulled upward.

In a washed out hole use of a hydraulic Knuckle joint located above the overshot kicks out under pump pressure to increase the sweep of the overshot to facilitate capture of an allusive fish. When the severe wash out, a Wall hook guide run on the bottom of the overshot further improves the search and capture of the fish.

When the fish cannot be dislodged by pulling with the overshot a jarring assembly run in the fishing string can be activated to strike heavy blows either up or down on a stuck fish to free it. The down action is achieved with a Bumper jar; essentially a slip joint with a sliding stroke. The impact enhanced by the weight of drill collars above the Bumper jar results in a sharp blow with the fishing string. Dropping the string quickly produces a sharp downward blow on the fish. This jarring action is especially effective in freeing PC Pipe or a string that is stuck as a result of an upward pull.

In many cases a stuck fish will require a powerful upward jar to free it. Hydraulic fishing jars permit an upward impact. The impact produced by a Hydraulic jar depends on the amount of pull taken on the tool before it trips. As indicated earlier the impact of a Hydraulic jar is enhanced by the weight of Drill collars placed above the tool. A jar accelerator further intensifies the effect of a jar at any depth. It is especially effective in shaft fishing operations where elasticity present in longer drill strings is not available. The use of an accelerator also keeps the energy of the jar impact form being lost a mole.

Essentially Washover operation involve a pipe string that slips over the stuck fish allowing fluid to circulate in the annalist between the fish and the inner wall of the Washover pipe. Fluid under pressure flushes out debris cut lose by the rotary shoe run on the bottom of the Washover pipe. The washed over fish secured by an overshot or a screw-in sub and then be backed and removed to the surface.

Openhole fishing also involves the retrieval of Junk at the well bottom. Junk is defined as any unwanted material in the hole that hampers operations; such as, accidentally dropped tools, metal debris, parts of equipment including cones from drill bits. A commonly used retrieval tool is the Fishing magnet. Fishing magnets are especially cost effective for retrieving smaller fairish objects such as bit cones, slips and mill cuttings.

I debated on where to go next, but at the end of the day the most widely used fishing tool has to be an overshot. Some will say why not a spear? Well if you must ask, always go with the strongest fishing tool you can run to catch the fish. And if you run a spear, never plug the I.D. of your fish by breaking it off. Done with that!

The info that follows has been taken from the manuals published on overshots. I realize that paper manuals are a thing of the past, yes, yes at one time fishing tool hands carried massive catalog brief cases full of reference material. Now you have the luxury of your laptop loaded with information. If you have never sat down and read an overshot manual, now might be a good time.

The overshot is highly versatile and efficient tool. There are several different types of overshots, however each overshot is designed to engage a specific size of tubing, pipe, coupling, tool joint, drill collar or smooth OD tool.

The original overshot was developed by Bowen Oil Tools, which is now part of NOV. One thing I will point out is that in the catalogs you will see more than one assembly number for a given OD of Overshot, this came about due to the two locations developing their own variations. I found this information on NOV’s website and thought it was interesting to share.

Bowen™ became a leader in innovation with the creation of the first overshot, the Series 150, in 1935. This tool set the standard for fishing equipment, and the quick acceptance of the tool assured the company partners that their business would be successful. The company continued to create new products, building a reputation for their well tool design and construction.

Currently there are several manufacturers of overshots, NOV (Bowen), Rubicon (Logan) and Applied Oil Tools (Gotco). These overshots are designated by a series number as follows:Series 10 - Sucker Rod Overshot

Overshots may be identified by one of the following, known as “type”:Full Strength (FS) - engineered to withstand all pulling, jarring and torsional strain

The basic overshot (from top down) consists of a top sub, a bowl, grapple, control, and a guide. In addition to the basic components, some overshots (Series 10 and 150) can be dressed with either a:Spiral grapple used if the fish diameter is near the maximum catch of the overshot, or a

The Series 150 Overshot features the ability to packoff on the fish. When the circulating packoff is not used, the fluid circulates down the drillpipe, aroundthe top outside of the fish, through the slip or grapple assembly, around the guide shoe and up the annulus.

When the circulating packoff is used, the annular space between the top outside of the fish and the inside of the lower part of the overshot is packed off, diverting the fluid flow down into the fish, making it easier to release and recover the fish. Packoffs usually are not high pressure devices but will often withstand sufficient pressure to establish circulation through the fish. Third party high pressure packoffs are available from various sources.

The extension can be installed between the top sub and the bowl of the Series 10, 70, and 150 overshots. It is used to extend the overshot bowl to:Allow the grapple to catch farther down on a fish that may be necked down at the top by having been pulled in two, or latched by an overshot and released several times, or to

A stop ring must be used where a fish OD reduces immediately below the catch area to allow the grapple to bite on full-size pipe.Example - catching a Hydril upset or EUE collar. If the upset of collar should pass completely through the grapple, the overshot may not be releasable.

The Series 10 Sucker Rod Overshot is designed to engage and recover sucker rods, couplings, and similar items from inside tubing strings.Basket grapples are recommended for fishing for hardened and ground boxes (Sucker Rod Box).

The Series 20 Sucker Rod Overshot is a short catch tool which provides a means for engaging the exposed portion of a fish too short to be engaged with a Series 10 overshot.Uses basket grapples only

The Series 70 Short Catch Overshot is designed to engage the exposed portion of a fish too short to engage with Series 150 overshots.Uses basket grapple only

The Series 150 Releasing and Circulating Overshot is used to engage, packoff, and retrieve twisted-off lost tubing, drillpipecoupling, tool joint, casing or other similar fish.

A right hand wicker grapple converts a normal right release overshot to left hand release. This grapple is used where you expect to apply excessive right hand torque to release a packer, safety joint, etc. Note: Overshot will have to be released by left hand rotation.

High Pressure Packoff Assemblies:The High Pressure Packoff Assembly is an accessory to the Series 150 Overshots. It is used when high pressure circulation to the fish is required. It consists of a packoff sub with packing and packing rings and is installed between the top sub and bowl of the overshot. By running the packoff sub above the bowl, this design prevents the application of high internal pressures to the overshot bowl. The design of the High Pressure Packoff Assembly allows pressures two to three times the standard overshot packoff to be applied to the fish.

This information comes directly from the NOV manual for the Wide Catch Overshot. This is probably the first and only change to this common tool I know of in my career.

The Wide Catch Overshot provides the strongest tool available to externally engage, pack-off, and pull a fish that has been significantly worn. This tool has similar rugged design features and construction as the industry standard, Bowen Series 150 overshot, with the ability to interchange the Bottom Guide with the full range of existing components used with the standard Bowen Series 150 overshot.

In service, the Wide Catch Overshot (WCOS) takes a positive grip over a large area of fish and is capable of withstanding heavy pulling, torsion, and jarring strains without damage to the tools or the fish.

The WCOS has been designed to significantly increase the catch range of the OD of the fish to be caught, compared to the standard overshot. This enables a greater opportunity for a successful fishing operation in a reduced number of trips, thus reducing overall intervention costs for the operator. In addition to the large catch range, the WCOS has the ability to seal across very large extrusion gaps at both standard and high pressure and provide full circulation through the fish, should it be required.

New coarse threads have been introduced at the connection between the top sub and bowl to allow for quick assembly while maximizing the torsion and tensile strength.

Connections between the Top Sub/Bowl and Extension Sub have been designed to create a seal. This will prevent the connection from washing out should the overshot be required to be flowed through for a long period of time. In order to lock the Top Sub/Extension Sub to the Bowl from backing off during operation, set screws have become standard and will gall the threads should the connection break free.

The operation of all overshots is identical. The exception being that the Series 150 carries a packoff which provides circulation through the fish. First, determine that the overshot is properly assembled and dressed with the proper size grapple. Make up the overshot on the fishing string (normally it is run connected to the bottom of the bumper sub) and run it into the well. As the top of the fish is reached make sure circulation has been established to clear overshot ID of any plugging. Lower the overshot onto the top of the fish with no rotation at first. A 5,000 pound set down weight will be sufficient to engage the grapple. While lowering the overshot over the top of the fish watch for pressure build up, shut off pumps if any pressure build up is noticed. Should any back pressure be noticed, release the back pressure to allow the grapple to engage the fish. By elevating the string it can be determined, if the grapple went over and engaged the fish. If unable to work overshot over top of fish without rotation, then slowly rotate the fishing string to the right and gradually lower the overshot over the fish. Combined rotation and lowering over top of the fish are important to keep the grapple in the release position. This provides the maximum clearance between the grapple and fish. While lowering the overshot over the top of the fish, watch for torque build up and an increase in pump pressure. A pump pressure build up indicates the overshot has gone over the top of the fish thereby reducing the flow area. Stop rotation (continued rotation could dull the wickers of the grapple) enabling the grapple to set. Allow the right hand torque to slack out of the string and then pull on the string by elevating the string to set the grapple.

To release from the fish, bump down, then simultaneously rotate to the right and slowly elevate the fishing string. It is best to have a clean fishing top before running the overshot.

The Series 10 Sucker Rod Overshot is a small, rugged tool designed for engaging and retrieving sucker rods, couplings, and other items from inside tubing strings.

Series 20 Short Catch Sucker Rod Overshots are designed for conditions when sucker rods, couplings, and other portions of a fish are too short for retrieval with a standard overshot.

The Hydraulic Release Overshot was designed to aid in the recovery of a stuck fish in a horizontal drilling application where normal rotation for release is not obtainable.

The Series 150 Releasing and Circulating Overshot consists of three main external parts: a Top Sub, a Bowl, and a Guide. Internal catch and pack-off parts are determined by the diameter of the fish. Each assembly is designed for a maximum catch diameter.

A Series 160 Side Door Overshot is recommended when fishing for cable tools or conductor lines in cased holes. The side door overshot is run in on tubing or drill pipe.

Rotary Die Collars are the simplest external catch fishing tools designed for retrieving a fish from the hole. Die Collars are available in two types: Type A and Type B.

Releasing Spears provide a positive means to engage and retrieve an internal fish from the well. The design of this rugged, dependable, and inexpensive internal catch fishing tool ensures positive engagement, easy release and re-engagement. It may be used with other equipment such as pack-off assemblies and internal cutters.

The Full Flow Reverse Circulation Junk Basket is similar to the Reverse Circulation Junk Basket. The unique difference is the Full Flow Valve Assembly that enables continuous circulation through the center thereby keeping out shale and debris while running in the hole.

The alternately long and short fingers of the junk catcher assembly extend almost to the center of the basket to form a close-fitting receptacle that will retain small pieces of junk that may impede drilling progress or hold a core sample.

The Fishing Magnet is designed to retrieve small metal, oddly shaped objects such as mill shavings, bit cones, cutters, bearings, slips, tong pins and hand tools for the bottom of the well bore.

The Magna Fish™ Fishing Magnet is designed to retrieve small metal, oddly–shaped objects such as milling shavings, bit cones, cuers, bearings, slips, long pins, and hand tools from the boom of the wellbore. Typically, these objects are the result of bit failures, and accumula!on of mill cuttings, or simply accidental droppings of unmillable objects.

The Superior Energizer is run in conjunction with a Superior Fishing Jar of the same size. Its function is to supply intensified impact during the jarring operation. Each size of Superior Energizer is designed to match a corresponding size of Superior Fishing Jar.

The Z Type Hydraulic Jar is used for light drilling, fishing, coring, reaming, testing, side tracking, and washover operations. This straight-pull jar combines the principles of mechanics and hydraulics in a simple to assemble, easy to operate design.

The Z Type Energizer is run in conjunction with a Z Type Fishing Jar of the same size. Its function is to supply intensified impact during the jarring operation. Each size of Z Type Energizer is designed to match a corresponding size of Z Type Fishing Jar.

The Surface Bumper Jar is installed in the drill string at the surface and is used whenever the downhole drilling, fishing, or washover running string becomes stuck and requires a heavy downward force to release it.

The Lubricated Fishing Bumper Sub is a dependable accessory that is suitable for all fishing operations, especially harsh, downhole applications and deep workover operations.

One of the most common tools used for any kind of fishing job is the bumper sub. The tool’s design allows full torque and unrestricted fluid circulation at all times.

The Drill Pipe Safety Joint is designed for the safe and dependable release from drilling, fishing, tubing, washover, or testing strings should they become stuck.

The Tubing Safety Joint is designed for the safe and dependable release from drilling, fishing, tubing, washover, or testing strings should they become stuck.

The Washover Safety Joint is designed for the safe and dependable release from drilling, fishing, tubing, washover, or testing strings should they become stuck.

The Type J Safety Joint provides a release option from tools such as taper taps or die collars that are normally non-releasable. It also provides a way to connect or disconnect fishing string and stuck fish.

Junk Mills are hard-faced with sintered tungsten carbide particles that mill away stuck fish that can not be retrieved with conventional fishing methods. These tools are highly resistant to impact and their super rates of penetration result in fewer round trips. Their maximum useful life is enhanced by their self-sharpening feature.

This easy-to-service, hydraulic motor-driven 120-Ton Power Swivel provides smooth shock-free torque. It is rated to support tensile pipe loads of 120 tons at zero rpm and 65 tons dynamic load at 100 rpm. The compact swivel head design weighs only 2,000 lbs and fits many drilling or workover masts. A 2-3/4-inch bore gooseneck and washpipe assembly allows circulation through the 2-11/16-inch I.D. stem while rotating or in static mode.

The hydraulic motor-driven 85-Ton Power Swivel provides smooth shock-free torque. The compact swivel head design fits most drilling or workover masts and weighs only 1,163 lbs. It is rated to support tensile pipe loads of 85 tons at zero rpm and 45 tons dynamic load at 100 rpm. A 2-1/4-inch bore gooseneck and washpipe assembly allows circulation through the 2-inch I.D. stem while rotating or in static mode.

It is common for objects, such as a segment of a pipe, to become stuck or forcibly lodged within a wellbore. In order for these objects to be removed from the wellbore, various fishing tools have been developed for the purpose of latching onto and retrieving the object, referred to in the industry as the “fish,” from the wellbore. One type of fishing tool is known as an overshot fishing tool because the tool is disposed over at least a portion of the object, or fish, disposed within the bore of the well. Such overshot fishing tools are generally known in the art. Other types of fishing tools that function by gripping the lumen of the fish, e.g., the inner diameter of a segment of pipe of the fish. Regardless of type of fishing tool, after the fish is gripped by the fishing tool, the fishing tool and the fish are transported to the surface of the well.

Broadly, the fishing tools disclosed herein comprise a tubular member having a fishing profile disposed within or secured to the inner wall surface of the tubular member. The fishing profile is shaped to allow a portion of the fish to move past the fishing profile so that the fishing profile is disposed below the portion of the fish. The tubular member can then be actuated, such as through rotation, to align the portion of the fish with a shoulder of the fishing profile. Upward movement of the tool engages the shoulder with the portion of the fish. Continued upward movement of the tool facilitates retrieval of the fish from the wellbore.

In the event that it is desired to release the fish from the fishing tool, the tubular member can be actuated a second time, such as through rotation, to move the shoulder of the fishing profile out of alignment with the portion of the fish. The tubular member can then be moved upward causing the portion of the fish to move past the fishing profile causing the fishing tool to move off the fish.

In one particular embodiment, the fishing profile comprises two shoulders disposed opposite each other along the inner wall surface of the tubular member with pathways disposed between the ends of the two shoulders. In other particular embodiments, the upper ends of the shoulders comprise a vertical stop member for engaging the fish during rotation of the tubular member. Thus, the vertical stop member provides the function of indicating when the fish is out of alignment with the shoulders so that the fishing tool can be moved off the fish. In still other embodiments, the lower ends of the shoulders comprise guides to facilitate aligning a portion of the fish with at least one of the pathways.

Broadly, the invention is directed to a fishing tool and in particular to a fishing tool which is a type of overshot tool. The fishing tool comprises profiled surfaces disposed on the inner wall surface of a tubular member. The profiled surfaces may be machined directly into the inner wall surface of the tubular member, or as discussed in greater detail below, one or more inserts may be separated formed and then secured to the inner wall surface of the tubular member.

Whether directly machined into the inner wall surface of the tubular member or formed as an insert that is then secured to the inner wall surface of the tubular member, the shape of the profiled surfaces (or inserts) facilitate catching a “fish” or object within the wellbore so that the fish can be removed from the wellbore. The profiled surfaces or inserts are disposed along the inner wall surface of the tubular member to provide pathways between each of the profiled surfaces or inserts. In one embodiment, each profiled surface or insert comprises a fishing or catch profile disposed toward an upper end, a guide disposed toward a lower end, and a release indicator member or stop member that is an extension along one side of the profiled surface or insert. The guide facilitates placement of the “fish” within the space or pathway between the two or more profiled surfaces or inserts and the catch profile receives and secures the “fish” to the profiled surface or insert. The release indicator member provides a signal to an operator at the surface of the wellbore when the fishing tool has released the “fish.” As will be understood by persons in the art, the fishing tools disclosed herein permit operation using mechanical input and do not require pumping, fluid flow, or pressure. However, in certain embodiments, pumping, fluid flow, or pressure also can be included to actuate the fishing tools disclosed herein.

In one particular embodiment, the fishing tools disclosed herein permit the fishing tool to remove pipe with flared, “egged,” or oblong fish profiles from a wellbore in one trip without the need to dress-off the fish top using traditional milling methods. In one operation of these fishing tools, drill pipe that has been sheared-off after activation of blowout preventer shear rams can be “fished” out of the wellbore. In addition, the fishing tools described herein also can be used to fish any downhole equipment that has a flared fish profile or other fish profile that can be engaged with the fishing or catch profile. As used herein, a flared fish profile is any geometry that is uniform along the axial direction but changes on top by having a wider dimension in one radial direction and a narrower dimension in another radial direction.

Referring now to Figures, in one particular embodiment, fishing tool 10 comprises tubular member 20 having upper end 21, lower end 22, outer wall surface 24, inner wall surface 26, and bore 28. Attachment members such as threads (not shown) can be disposed along inner wall surface 24 adjacent to upper end 21 and along outer wall surface 26 adjacent to lower end 22 to facilitate securing fishing tool 10 to a work string (not shown). In the embodiment discussed with respect to FIGS. 1-7, two inserts 60, 70 are secured to inner wall surface 26.

In the embodiments shown in FIGS. 1-3, inserts 60, 70 are identical to each other and are disposed relative to each other to provide pathways 80. As shown in the embodiments of FIGS. 1-3, inserts 60, 70 comprise arcuate bodies comprising upper ends 61, 71, lower ends 62, 72 having guides 64, 74 disposed respectively thereon, first sides 63, 73, second sides 65, 75, inner wall surfaces 69, 79, outer wall surfaces 94, 98, and fishing or catch profiles 66, 76. Guides 64, 74 facilitate orientating fishing tool 10 over an object or fish disposed in the wellbore by guiding inserts 60, 70 around the fish until fishing tool 10 can be positioned over the fish. As shown in the embodiment of FIGS. 1-3, guide 64 comprises intersecting wall surfaces 51, 53 that intersect with one another at point 55. Similarly, in the embodiment of FIGS. 1-3, guide 74 comprises intersecting wall surfaces 52, 54 that intersect with one another at point 56.

In the embodiment of FIGS. 1-3, catch profiles 66, 76 comprise shoulders each having a concave shape. In the embodiments of FIGS. 1-3, the concave shape comprises a V-shape with a “flat” valley 67, 77. The V-shape may provide an angle in the range from about 60 degrees to about 90 degrees. As discussed in greater detail below, fishing or catch profiles 66, 76 facilitate engagement with a fish disposed in the wellbore so that the fish can be moved up and, if desired, out of the wellbore.

Also in the embodiments shown in FIGS. 1-3, inserts 60, 70 include stop members or release indicator elements 68, 78. As shown in the embodiments of FIGS. 1-3, stop members or release indicator elements 68, 78 comprise vertical shaft members disposed along one side of inserts 60, 70. As discussed in greater detail below, release indicator elements 68, 78 facilitate notification to the operator of fishing tool 10 that fishing tool 10 has been orientated with respect to the fish such that fishing tool 10 can be moved off of the fish.

In one specific embodiment, inserts 60, 70 comprise the shapes and dimensions shown in FIGS. 3B, 3C, and 3E relating to inserts 60, 70, sides 63, 65, 73, 75, fishing profiles 66, 76, guides 64, 74, and release indicator elements 68, 78. In particular, inserts 60, 70 each comprise height 81, side height 82, guide height 83, release indicator element height 84, release indicator element width 85 (FIG. 3E), fishing profile width 86, and fishing profile valley width 87. Guides 64, 74 also comprise guide lower end thickness 88, and guide lower end profile angle 89 (both shown in FIG. 3C). In addition, pathway 80 comprises pathway width 90 (FIGS. 3C and 3E).

Height 81 can be in the range from approximately 16 inches to approximately 24 inches; side height 82 can be in the range from zero inches to approximately 12 inches; guide height 83 can be in the range from approximately 4 inches to approximately 6 inches; release indicator element height 84 can be in the range from approximately 4 inches to approximately 8 inches; release indicator element width 85 can be in the range from approximately 1.0 inch to approximately 1.5 inches; fishing profile width 86 can be in the range from approximately 4 inches to approximately 6 inches; fishing profile valley width 87 can be in the range from approximately 0.15 inches to approximately 0.25 inches; guide lower end thickness 88 can be in the range from approximately 0.5 inches to approximately 1.0 inch; guide lower end profile angle can be in the range from approximately 15 degrees to approximately 75 degrees; and pathway width 90 can be in the range from approximately 4 inches to approximately 6 inches. In one particular embodiment, height 81 is approximately 22 inches; side height 82 is approximately 10.8 inches; guide height 83 is approximately 5.2 inches; release indicator element height 84 is approximately 6.0 inches; release indicator element width 85 is approximately 1.25 inches; fishing profile width 86 is approximately 4.7 inches; fishing profile valley width 87 is approximately 0.2 inches; guide lower end thickness 88 is approximately 0.75 inches; guide lower end profile angle 89 is approximately 45 degrees; and pathway width 90 is approximately 4.75 inches. In another particular embodiment, height 81 is approximately 22 inches; side height 82 is approximately 11.3 inches; guide height 83 is approximately 4.7 inches; release indicator element height 84 is approximately 6.0 inches; release indicator element width 85 is approximately 1.0 inch; fishing profile width 86 is approximately 4.6 inches; fishing profile valley width 87 is approximately 0.3 inches; guide lower end thickness 88 is approximately 0.6 inches; guide lower end profile angle 89 is approximately 45 degrees; and pathway width 90 is approximately 4.75 inches.

Operation of one particular fishing tool disclosed herein involves securing a fishing tool as disclosed herein to a work string and running the fishing tool into a well until it reaches the fish, which may include a flared end. The fishing tool is then slacked off over the “fish” to allow a guide disposed at the lower end of a profiled surface or insert disposed along the inner wall surface of the tubular member of the fishing tool to contact the fish. In the case of a fish having a flared pipe end, the fishing tool is moved by the guide to a position where the flared profile lines up with a pathway disposed between the two profiled surfaces or inserts. Aligning the tool in this manner can be facilitated by rotation of the work string and, thus, the fishing tool.

Additional slack-off input into the work string allows the flared profile of the fist to travel up and through the pathway of the tool. Slacking-off of the work string continues until all of the flared geometry of the fish has passed completely through the fishing tool. At this point, the work string and, thus, fishing tool, is rotated 90 degrees in either the clockwise or counter-clockwise direction realigns the tool into the “catch” position. Alternatively, if the flared portion of the pipe has passed completely above the tool, 90 degrees of right-hand rotation of the work string and, thus, tool, be input to align the tool into the “catch” position.

After the fishing tool is moved to the “catch” position, the fishing tool is picked up or moved upwards within the wellbore until the flared pipe engages the catch profile on the fishing tool. Pick-up of the fish can now be applied to move the fish within the wellbore and, if desired, completely remove the fish from the wellbore.

If it becomes necessary to release the fishing from the fish, slight right-hand torque can be held into the work string from surface while the fishing tool is slowly slacked-off. The flared pipe will exit the catch profile and engage the release indicator elements indicating that the flared pipe is again aligned with the pathway. Moving the fishing tool into the release position in this manner is preferable because several indications can be seen on surface confirming that the fishing tool is indeed lined up in the release position. These surface indications will be represented by surface torque readings decreasing slightly as the work string pipe turns 90 degrees toward the release position. With the flared pipe aligned with the pathway again, the tool can be picked up and released from the flared pipe of the fish.

Another method for aligning the flared pipe with the catch profile is to use an “Automatic-J” feature. Automatic-J features are known in the art. The benefit of the Automatic-J feature is that no input rotation is required to align the catch profile in the fishing tool with the flared pipe. The Automatic-J feature can be utilized by adding another guide above the tool that is oriented 90 degree relative to the guide on bottom. The Automatic-J feature allows for the option to engage the flared pipe by means of slack-off and pick-up input into the work string and, thus, fishing tool, without the need to rotate the work string or tubular member.

The fishing tool can be manufactured from a cylindrical piece of stock material by splitting the stock piece into two “half shell” inserts that are then shaped to the desired dimensions. These “half shell” inserts can then be plug welded or bolted inside of a tubular member such as a wash pipe extension. Another method for manufacturing the “half shell” inserts is by using a 4-axis or similar CNC machine. Additionally, a shoulder could be machined on the outside of the “half shell” inserts with a matching shoulder machined on the inner diameter of the wash pipe extension. Then, the “half shell” inserts could be plug welded or bolted to the tubular member. Alternatively, the profiles could be cut into a single piece of tubular member to provide maximum strength.

Referring now to FIGS. 4A and 4B, in another embodiment, inserts 160, 170 comprise arcuate bodies comprising upper ends 161, 171 comprising fishing or catch profiles 166, 176, and lower ends 162, 172 comprising guides 164, 174. As shown in FIG. 4B, inserts 160, 170 are disposed relative to each other similar to inserts 60, 70 discussed in greater detail above to provide pathway 180 between first sides 163, 173, and second sides 165, 175. In the specific embodiment of FIGS. 4A, 4B, catch profiles 166, 176 each comprise a concave shape having a “U” shape.

Operation of a fishing tool comprising inserts 160, 170 is similar to the operation of fishing tool 10 discussed above with respect to the embodiments of FIGS. 1-3. After disposing inserts 160, 170 on an inner wall surface of a tubular member to provide a fishing tool, the fishing tool is lowered into a bore of a well until inserts 160, 170 contact an object or fish within the bore. Inserts 160, 170 are then orientated, such as through rotation of the fishing tool, so that the fish slides within pathway 180 until inserts 160, 170 are disposed below a portion of the fish that can be engaged with the shoulders forming catch profiles 166, 176. The fishing tool is then oriented, such as through rotation, so that catch profiles 166, 176 are disposed below the portion of the fish that can be engaged with the shoulders forming catch profiles 166, 176 and the fishing tool is moved upward to engage the fish. The fishing tool is continued to be moved upward causing the fish to move upward with the fishing tool.

It is to be understood that the invention is not limited to the exact details of construction, operation, exact materials, or embodiments shown and described, as modifications and equivalents will be apparent to one skilled in the art. For example, the two inserts or profiled surfaces do not have to be identical to each other in shape or size, nor do they have to have the specific dimensions disclosed herein. To the contrary, the size, shape, and dimensions of the inserts or profiled surfaces can be modified as desired or necessary to facilitate releasably securing the fish within the bore of the fishing tool. Moreover, different guide and catch profiles can be machined to allow only right hand or left hand rotation while guiding the fish, e.g., the flared pipe, through the fishing tool. Further, different catch profiles can be machined to accept different fish geometries. In addition, the outer diameter, inner diameter, and pathway width are all specific to the fishing geometry of the wellbore and fish, and can be customized depending on the situation. Additionally, in embodiments in which side height 82 is zero, lower ends 62, 72 of the arcuate bodies may be flush with lower end 22 of tubular member 20, or, alternatively, lower ends 62, 72 may extend below lower end 22 of tubular member 20. Accordingly, the invention is therefore to be limited only by the scope of the appended claims.

As a length of well pipe rises out of the casing, leaving the winch assembly attached to the top of the pipe, the operator will stop the winch, tighten a clamp around the well pipe a few inches above the top of the well casing, gently, using the winch, lower the pipe back down so that the clamp rests on top of the well casing - to "test" that the clamp is secure.

Overshoots or Overshots are fishing devices that fit over the exterior of the well pipe and then grab onto the well pipe exterior to enable lifting the pipe.

Logan Oil Tools calls these "external catch" devices. [12] The overshot may be a metal mesh device, or a spiral device, one or more round or oval loops, or similar devices that grab on to the pipe exterior. The overshot was invented by Bowen in 1935.

Spears or releasing spears for well fishing are fishing devices that are inserted into the interior bore of a well pipe and then grab onto the interior sides of the pipe.

Store bought or home made single or double bite metal loop well pipe retriever: some well pipes can be successfully retrieved by fabricating a flexible pair of metal rings with squared or sharp edges connected and hinged to a rod that is in turn connected to the bottom of a working pipe long enough to reach down to the top of your well pipe in the well. When the pair of metal rings slip over the exposed upper end of the well pipe, push the assembly a few feet further down over the pipe.

If you"ve got your design right (test it above ground first) when you pull up on the assembly the rings will hinge to an angle that will "bite" onto the vertical pipe in the well and allow you to pull the assembly back out.

A rope with a large sharp edged "washer" or any other round object that can be dropped over the well pipe can do this same job. Some technicians call this assembly a cam cleat but more often that"s a nautical device for halyards and one that doesn"t work in this application.

Casing Swage is a tapered tool used to restore dented or collapsed well casings to approximate its original shape. Note that these tools will not repair a casing that has been broken or corroded through. Well sleeves or casing section replacement is needed in those cases. Speaking strictly this is a casing repair tool not a well retrieval / fishing tool.

Hooking onto existing fittings on the well pipe in the well: if the length of pipe that fell into the well includes couplings or a pitless adapter fitting, often any small grappling hook and line can grab onto the edge of that protrusion and pull the assembly out of the well.

Hydraulic Fishing Jars are tools lowered into a well that grasp onto the stuck pipe, fish, or component to permit freeing a stuck component by jarring it upwards or in some applications downwards or in either direction. (Schlumberger) Fishing jars are also referred to as fishing accelerators.

Shown below, a well magnet fishing tool set provided by Hole Products Company whose contact information is given below in this article. Depending on the magnet size these devices can lift 100 to 400 pounds. The largest magnet shown below is 5 1/2" in diameter so may fit inside a 6" well casing.

Overshot mesh well pipe or item retrievers for fishing stuff out of a well: the most effective tools we know about for pulling lost well pipes out of a drilled well are various versions of overshots. Overshots, an "overshoot" type tool, are a bit easier to get over the outside of a well pipe than spear type tools are to get into the well pipe, unless the upper end of the pipe is near the top of the well.

Some supplies use the term "recovery bell" for overshots. The overshot is a cylindrical or conical shaped (bell shaped) device lowered over the upper end of a pipe to be retrieved from a well. Some companies (Schlumberger) produce a releasing overshot or overshots used for jarring or stuck material backoff operations.

The overshot is lowered over the end of the pipe in the well. If there is enough friction around the object the braided sleeve will contract and grab the object when the line is pulled up - like that braided rush "chinese finger trap" trick we played with as kids.

The overshot is attached to the end of a drilling rod or in the water well industry to the end of a section of well piping that is lowerd into the bore hole.

Some overshots include hardened self-cutting threads that will grab onto the upper end of a well pipe that has been dropped into the well borehole, thus allowing the pipe to be retrieved.

Pin Tap / Screw-In Sub taps are used to retrieve a tubular fishing tool or pipe from a well when it is cannot be rotated. Basically this is similar to a "screw extractor" that is reverse-threaded to be turned into a seized bolt, screw, or in this case pipe or fishing tubular tool that cannot be turned or rotated in its normal direction. Produced by Schlumberger and perhaps others. Also see Taper Tap.

With fresh glue inside the mating end of the coupling the retrieving well pipe section is pressed down onto the exposed top of the pipe that is already in the well. Wait for the glue to dry and try pulling out the whole assembly. If the broken-off plastic pipe is below water level, or badly damaged, this approach may have poor chances of success.

Watch out: also that you do not jam the item you are trying to retrieve. For example, using a grappling hook to try to fish out a well pump from the well bottom risks jamming the whole assembly inside the well.

Note that the primary producers of well retrieval and fishing tools are companies serving oil and gas drilling industry companies. However many of these also serve the water well drilling industry too.

Bowen Itco, owned by NOV since 2000, produces well fishing tools, devices, equipment including the Bowen™ Itco-Type Releasing Spear . The company"s website provides no street address but includes a contact page, Website: http://www.nov.com/bowen/default.aspx

This pipe fishing tool uses a jaw with two tips and a center slot. One leg of the jaw slips into the upper end of a cut-off pipe inside the well and jaw teeth grip the pipe wall to permit lifting it. Lifting capacity: 250 lbs. U.S. Patent No. 7,665,785

Gotco Corp., 11410 Spring Cypress Rd., Tomball TX 77377 USA, Tel: 1-800-OVERSHOT, produces the Gotco Grapple Releasing Spear. Except from the company"s website:

Schlumberger Fishing Tools and Services, 3750 Briarpark Dr., WG-3 Level-2, Houston TX 77042, produces a wide range of oil and gas drilling tools and equipment and opeates world-wide. North American Contact: Schlumberger Technology Corporation

Stuckey"s Specialty Tools, Fishing Tools & Specialized Equipment, 2511 Lauder Road, Houston, Texas 77039, E-Mail: stusptl@yahoo.com Website: http://www.stuckeyspecialtytools.com/ producing an Itco type releasing spear

I don"t have comment to you because is my first time to see some of fishing tools and the quality are good but my humble request is how can a pump machine like me who can"t afford to get or buy can manage to have it.

I was trying to check the static water level thru the little vent screw on the top of the well casing with a 4 OZ lead fishing weight . It got stuck and then it came untied.

I dropped a key chain into a 4" steel casing monitoring well yesterday and i am trying to find ways on how to retrieve it. I have tried fishing hooks with no luck, any ideas?

I don"t much like the idea of leaving debris in a well, though it may have no effect until fishing line fouls a foot valve or bits enter a pump through a well screen.

Steve: my comments and opinion above to Bill pertain to your well fishing too. But also we"d prefer not to leave lead items in the well. I"m not sure how much two small lead weights might contribute to detectable lead in your water supply: that would depend on water chemistry, its corrosivity, the formation of a lead oxide coating on the weights themselves, and how much water movement occurs in the well.

[11] "Overshot Definition", OilGasGlossary.com. Oil & Gas Field Technical Terms Glossary, Web Search 04/21/2012, original source: http://oilgasglossary.com/overshot.html

8613371530291

8613371530291